XPS foam sheet is a versatile material with numerous benefits and applications. It's a type of rigid foam insulation made from extruded polystyrene.

One of the key benefits of XPS foam sheet is its high thermal resistance, which can help reduce heat transfer and energy loss in buildings. This can lead to significant cost savings on heating and cooling bills.

XPS foam sheet is also water-resistant and can withstand exposure to moisture without breaking down. This makes it an ideal choice for exterior wall insulation and other applications where water may be present.

Its low weight and ease of handling make XPS foam sheet a popular choice for builders and contractors.

On a similar theme: Foam Xps

What Is Insulation?

Insulation is a crucial component in building and construction, providing a strong, yet lightweight and flexible solution. It's made from closed-cell materials that are resistant to water absorption.

XPS foam insulation is a type of insulation commonly used in remodeling and new construction applications. Brands of XPS rigid insulation are recognizable by the color of the insulation, such as blue made by Dow, pink made by Owens Corning, and green made by Kingspan.

Explore further: Egg Crate Foam Insulation

XPS foam insulation is available in standard dimension square or rectangular boards, making it a convenient option for builders and homeowners. This type of insulation is ideal for a range of building and commercial applications.

The manufacturing process of XPS insulation results in it being only available in standard size square or rectangular panels. This can be a limitation for some projects, but it's a trade-off for the insulation's many benefits.

XPS insulation is a closed-cell product that provides a water-resistant and highly compressive solution. This makes it a popular choice for retrofit and new construction applications.

Broaden your view: Xps Foam 10mm

Types of Insulation

Extruded Polystyrene (XPS) foam sheets are the most common type of 10mm foam sheet, made through an extrusion process that creates a closed-cell structure.

These sheets are dense and have a uniform thermal resistance, making them widely used for foundation insulation, roof insulation, and wall insulation. They're also available in different sizes and can be cut into different shapes.

Take a look at this: Spray Foam Insulation Shipping Container

10mm XPS foam sheets have interlocking edges that help reduce heat loss, and they're also waterproof, making them suitable for applications in areas with high moisture content.

Here are the common types of 10mm XPS foam sheets:

These types of foam sheets offer different benefits and are suited for various applications, such as insulation, packaging, and refrigeration.

What Is Rigid Insulation?

Rigid insulation is a type of insulation that's formed with polystyrene polymer, but manufactured using an extrusion process. This process gives it a distinctive color to identify the product brand.

One of the most common types of rigid insulation is Extruded Polystyrene (XPS) foam, which is made from a closed cell insulation product. XPS insulation is water-resistant and highly compressive, making it a popular choice for retrofit and new construction applications.

The R-Value of XPS foam insulation varies by thickness, with a nominal R-value of 5 per inch. This means that for every inch of XPS foam, you can expect a certain level of insulation performance.

Curious to learn more? Check out: Rigid Pu Foam Sheets

Here are the R-Value values for XPS foam insulation at different thicknesses:

As you can see, the R-Value increases with the thickness of the XPS foam insulation. This means that thicker XPS foam will provide better insulation performance.

Check this out: Spray Foam Insulation Truck

Types of 10mm Sheets

10mm XPS foam sheets are a popular choice for insulation due to their durability and excellent insulation properties. They are suitable for applications that don't require heavy insulation.

The most common type of 10mm foam sheet is Extruded Polystyrene (XPS). It's made through an extrusion process that creates a closed-cell structure, making it dense and uniform in thermal resistance. XPS foam sheets are widely used for foundation insulation, roof insulation, and wall insulation.

Expanded Polystyrene (EPS) sheets are another type of 10mm foam sheet. They are made from polystyrene beads that are expanded and fused together, making them lighter than XPS foam but still offering good insulation. EPS sheets are white and commonly used for applications like packaging and void filling.

Intriguing read: Expanded Polystyrene Sheets

Polyurethane (PUR) Foam is a type of 10mm foam sheet that's made through a chemical process, creating a foamed, closed-cell structure. It's highly insulating and lightweight, making it ideal for applications where high insulation is required. PUR foam sheets are yellow and commonly used in refrigerated trucks and containers.

Phenolic Foam is a type of 10mm foam sheet made from phenolic resin that's been foamed and formed into a closed cell. It offers good insulation, has low thermal conductivity, and is commonly used for fire-resistant insulation. Phenolic foam sheets are green or brown.

Here are the common types of 10mm XPS foam sheets:

- Extruded Polystyrene (XPS)

- Expanded Polystyrene (EPS)

- Polyurethane (PUR) Foam

- Phenolic Foam

Insulation Performance

XPS foam sheet is a closed-cell insulation product commonly used in retrofit and new construction applications. It's a great choice for humid environments because the tightly packed unit of XPS foam helps prevent air and water from entering.

The R-value of XPS foam sheet is 5 per inch, making it a great option for exterior wall sheathing. It's also very strong and rigid due to its tightly packed closed-cell structure.

XPS foam sheet has a few benefits, including saving on materials like concrete and epoxy floor coatings. It's also a rigid foam board, making it an ideal choice for structural panels.

For more insights, see: Green Cell Foam

Exceptional Long-Term Performance. Low Emissions

Exceptional long-term performance is a hallmark of Styrofoam Brand XPS Insulation, which has been innovating in the building industry since 1941.

This insulation material has a rich heritage and has created an entire insulation material category with its unique closed-cell structure and rigid foam board technology.

Styrofoam Brand XPS Insulation meets core thermal, moisture, air, and vapor performance requirements, making it a reliable choice for builders and homeowners alike.

Low-GWP Styrofoam Brand XPS Insulation has reduced embodied carbon by 94%, a significant step towards sustainability.

It also meets all HFC regulations and building codes, giving users peace of mind when choosing this insulation material.

Styrofoam Brand XPS Insulation continues to offer the same long-term value and R-value as before, making it a consistent choice for insulation needs.

The transition to low-GWP formulation was completed at the end of 2023, with all North American manufacturing sites now producing this version, signified by a new grey color.

Additional reading: Polystyrene Foam vs Styrofoam

Extruded Polystyrene Insulation Performance

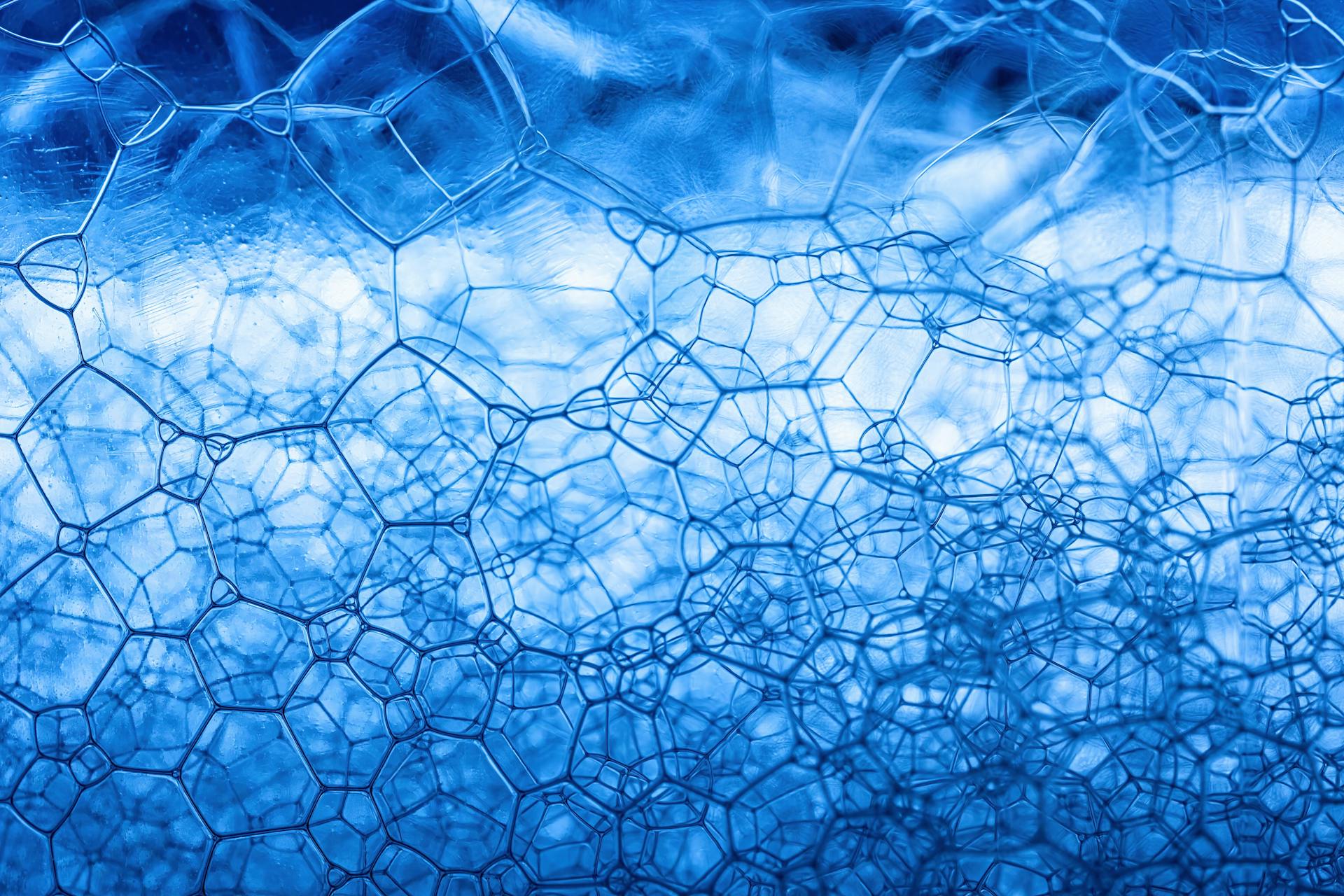

XPS foam has a unique closed-cell structure, where the cells are closely packed together and there are no voids or spaces between them, making it more suitable for humid environments.

This tightly packed unit helps prevent air and water from entering, which is especially important in areas with high humidity.

The closed-cell structure of XPS foam also makes it very strong and rigid, making it an ideal choice for structural panels.

In fact, XPS foam has a tightly packed closed-cell structure that's comparable to a tightly packed unit, which provides excellent strength and rigidity.

The low-GWP version of Styrofoam Brand XPS Insulation, introduced in 2019, offers a 94% reduction in embodied carbon and meets all HFC regulations and building codes.

This new formulation continues to offer the same long-term value (and R-value) as the original Styrofoam Brand XPS Insulation.

Here are some key benefits of using XPS foam insulation:

- Excellent performance in humid environments

- Very strong and rigid due to its closed-cell structure

- Low embodied carbon and meets HFC regulations

- Same long-term value (and R-value) as original Styrofoam Brand XPS Insulation

R-Value of Insulation

The R-Value of insulation is a measure of its ability to resist heat flow.

Extruded polystyrene foam, also known as XPS, has a nominal R-value of 5 per inch.

This type of insulation improves with colder temperatures.

Its R-value is generally consistent, but it can lose some insulation performance over time, especially in real-world applications.

This is especially true for XPS foam used below-grade, which can off-gas and lose some of its insulating properties.

SOPRA 60 Product Line

The SOPRA 60 product line is a series of xps foam sheets designed for various applications. There are two products in this line.

Each product has a specific diameter, color, and dimensions. For example, the SOPRA-XPS 60 with butt edges has a diameter, color, length of 8 ft, width of 2 ft, and thickness of 2 in.

The SOPRA-XPS 60 with butt edges has a weight of and a unit sales quantity of volume and piece. The gross area and net area of this product are also specified.

The granules size and coverage per pail of the SOPRA-XPS 60 with butt edges are also provided. The application temperature, R Value, and weight per surface of this product are also listed.

The board thickness, temperature grade, and fire resistant properties of the SOPRA-XPS 60 with butt edges are also detailed. Additionally, the thickness tapered, maximum thickness, and minimum thickness of this product are specified.

A comparison of the two products in the SOPRA 60 product line is as follows:

10mm Insulation Sheets

10mm insulation sheets are a popular choice for various applications due to their durability and excellent insulation properties. They are made from extruded polystyrene (XPS) foam and are available in different sizes and shapes.

The 10mm thickness of these sheets makes them suitable for applications that don't require heavy insulation. They are commonly used in commercial and residential construction projects, as well as in refrigeration and cold storage. Their lightweight and easy-to-handle properties make them convenient for installation.

Here are some common types of 10mm XPS foam sheets:

- Extruded Polystyrene (XPS)

- Expanded Polystyrene (EPS)

- Polyurethane (PUR) Foam

- Phenolic Foam

10mm Sheet Features

10mm sheet features make them suitable for construction and insulation applications. Their versatility allows them to be used in different projects, such as building and construction, packaging, and civil engineering.

10mm XPS foam sheets have a thermal insulation property that minimizes heat transfer between surfaces, reducing heat loss or gain in buildings. This leads to energy conservation and lower energy bills.

Their closed cell structure makes them resistant to water and moisture penetration. This means they can be used in applications where there is water, such as basements, without being damaged.

The sheets are also lightweight, making them easy to handle and transport. This reduces transportation costs and makes them convenient to fix on surfaces like walls.

10mm XPS foam sheets have a compressive strength of about 300 kPa, which is about 1.6 times greater than that of polyisocyanurate foam. This makes them stable and strong, able to support loads without being crushed or deformed.

Here are some key features of 10mm XPS foam sheets:

- Thermal Insulation

- Moisture Resistance

- Lightweight

- Structural Support

- Versatility

Choosing 10mm Sheet

The 10mm XPS foam sheet is a popular choice for insulation due to its durability and excellent insulation properties. Its thickness of 10mm or 1cm makes it suitable for applications that don't require heavy insulation.

When selecting a 10mm XPS foam sheet, consider the specific needs of your project. Determine the R-value required, as this will affect your choice of sheet. For example, if you're looking for insulation in a building project, a higher R-value is essential for energy efficiency.

The R-value of a 10mm XPS foam sheet is not affected by its thickness, but a thicker sheet will have a higher R-value. This is an important consideration when choosing a sheet for your project.

The 10mm XPS foam sheet is available in different sizes, making it easy to cut to fit your needs. Its lightweight property makes it easy to handle and transport.

Here are some key factors to consider when choosing a 10mm XPS foam sheet:

- Application Requirements: Determine the specific needs of your project.

- Thickness and Dimensions: Consider the thickness and dimensions of the sheet.

- Thermal Insulation Properties: Look for the sheet's R-value or thermal conductivity.

- Compressive Strength: Assess the sheet's compressive strength.

- Moisture Resistance: Consider the level of moisture resistance required.

- Environmental Impact: Choose a sheet with a low global warming potential (GWP).

- Cost: Compare prices and consider the long-term value of the sheet.

Insulation Specifications

XPS foam sheet is a popular choice for insulation due to its closed-cell structure, which prevents air and water from entering. This makes it suitable for humid environments.

The R-value of XPS foam insulation is 5 per inch, making it a good option for exterior wall sheathing. This is especially true in colder temperatures.

XPS foam sheets have a compressive strength of at least 150 kPa, which is a measure of their ability to withstand pressure. This is due to their tightly packed closed-cell structure.

Water absorption is also a concern with insulation materials. Fortunately, XPS foam sheets have a water absorption rate of no more than 1.0% (V/V) after 96 hours, according to GB/T 8810-1988.

Here are some key specifications for XPS foam sheets:

XPS foam sheets are available in various sizes, including lengths of 1800mm and 1200mm, widths of 600mm, 900mm, and 1200mm, and thicknesses ranging from 20mm to 100mm.

How Insulation Is Made

Insulation is a crucial component in building construction, and XPS foam sheets are a popular choice for many builders and homeowners. XPS foam sheets are made from a type of plastic called extruded polystyrene.

The manufacturing process of XPS foam sheets involves combining polystyrene resin with other materials, such as air and stabilizers. This mixture is then heated to a high temperature and blown into a mold to create the desired shape.

The XPS foam sheet production process can be divided into several stages, including raw material selection, mixing, and extrusion. Each stage requires careful attention to detail to ensure the final product meets the required standards.

The extrusion process involves forcing the polystyrene mixture through a die to create the desired shape and size. This process can be repeated multiple times to achieve the desired thickness and density of the XPS foam sheet.

XPS foam sheets have a unique cellular structure that provides excellent insulation properties. The cells are made up of a mixture of air and polystyrene, which helps to reduce heat transfer and prevent moisture from entering the building.

The manufacturing process of XPS foam sheets is designed to produce a consistent and high-quality product. The production line is equipped with advanced machinery and quality control measures to ensure that every XPS foam sheet meets the required standards.

For more insights, see: Pu Foam Process

Insulation Use Cases

10mm XPS foam sheets are used in building and construction to minimize heat transfer between surfaces, reducing heat loss or gain in buildings and leading to energy conservation.

They are also used in commercial construction applications to reduce the need to cool or heat buildings, resulting in lower energy bills and increased comfort.

These sheets are suitable for use in applications like load-bearing foundations due to their compressive strength of about 300 kPa, which is about 1.6 times greater than that of polyisocyanurate foam.

Their versatility makes them a popular choice among manufacturers and engineers, reducing the need for several other types of insulation materials.

Their closed cell structure makes them resistant to water and moisture penetration, making them ideal for use in applications where there is water, such as basements.

Rigid Board Insulation Applications

Rigid board insulation is a popular choice for various applications, and for good reason. It's incredibly versatile and can be used in a wide range of settings.

Domestic and commercial buildings can benefit from rigid board insulation, particularly in areas such as cavity walls, decks, underwalls, and over truss or between rafters. It's also a great option for suspended ceilings, inverted roofs, floors, and balconies.

One of the most common types of rigid board insulation is XPS foam, which is commonly used in retrofit and new construction applications. It's available in standard-sized square or rectangular boards and can be used in a variety of settings, including walls, ceilings, and floors.

10mm XPS foam sheets are a popular choice for construction and insulation applications, offering excellent thermal insulation and moisture resistance. They're lightweight, easy to handle, and can be cut into different shapes to fit specific needs.

Here are some common applications for 10mm XPS foam sheets:

- Construction and building: XPS foam sheets are used as thermal insulation for foundations, walls, and roofs.

- Packaging: XPS foam sheets are used to make custom packaging inserts and containers.

- Cold storage and refrigeration: XPS foam sheets are used in the construction of refrigerated trucks, containers, and storage facilities.

- Below grade walls: XPS foam sheets are used to insulate walls below grade in basements or foundation walls.

- Marine applications: XPS foam sheets are used to make insulated boxes, docks, and floating platforms.

- HVAC systems: XPS foam sheets are used to insulate ductwork and chiller cabinets.

- Agriculture: XPS foam sheets are used in the construction of root cellars and insulated storage for agricultural products.

- Arts and crafts: XPS foam sheets are used to create architectural models, crafts projects, and signs.

- Emergency shelters: XPS foam sheets are used to insulate temporary shelters and emergency housing.

- Geothermal applications: XPS foam sheets are used to insulate horizontal loop systems and foundation walls in geothermal heating systems.

- Sports and recreational facilities: XPS foam sheets are used to insulate outdoor rinks, pools, and sports facilities.

Overall, rigid board insulation is a reliable and efficient option for a wide range of applications, from construction and building to packaging and cold storage.

Scenarios of 10mm

10mm XPS foam sheets have a wide range of applications across various industries. Here are some of the most common scenarios:

In construction, 10mm XPS foam sheets are used as thermal insulation for foundations, walls, and roofs. They provide a stable insulation value over time and are a favorite among builders.

In packaging, XPS foam sheets are used to make custom inserts and containers that protect fragile items like electronics and medical devices during shipping and storage. Their lightweight property makes them suitable for reducing overall shipping costs.

Below grade walls are another application where 10mm XPS foam sheets excel. They provide continuous insulation and a moisture barrier, reducing the risk of mold and mildew growth.

In cold storage and refrigeration, XPS foam sheets are used to construct insulated trucks, containers, and storage facilities. They help reduce energy consumption and maintain optimal temperatures in perishable goods storage.

Here's a breakdown of some of the key applications:

In marine applications, XPS foam sheets are used to make insulated boxes, docks, and floating platforms. They're waterproof, providing buoyancy.

In HVAC systems, XPS foam sheets are used to insulate ductwork and chiller cabinets, reducing energy loss and improving efficiency.

In agriculture, 10mm XPS foam sheets are used in the construction of root cellars and insulated storage for agricultural products. They provide temperature stability and reduce spoilage.

In emergency shelters, XPS foam sheets are used to insulate temporary shelters and emergency housing due to their lightweight, easy assembly, and high insulation properties.

In geothermal applications, XPS foam sheets are used to insulate horizontal loop systems and foundation walls, minimizing heat loss and improving system efficiency.

In sports and recreational facilities, XPS foam sheets are used to insulate outdoor rinks, pools, and sports facilities, providing a thermal barrier and resisting moisture.

Use of Plates

XPS plates are suitable for various applications, including wall and ceiling insulation, cold rooms, refrigeration, under concrete slabs, and even architectural modeling or hobby modeling.

Their semi-permeable nature, with a permeability rating of approximately 1, makes them a great choice for many projects. Thicker XPS is stronger and has a lower perm rating.

A nominal R-value of 5 per inch means XPS plates are effective at insulating buildings. This is especially true for exterior sheathing, where they can help keep buildings warm in cold temperatures.

Both pink and blue XPS plates are rigid insulation boards made from extruded polystyrene, with the main difference being their manufacturers.

Other Attributes

XPS foam sheet board is a rigid material with very high compressive strength, reaching 100 psi or higher. This makes it an excellent choice for various applications.

The product has a homogeneous closed cell cross-section with no voids, giving it impressive strength. It's also chemically inert, resistant to most acids, alkalis, and aqueous solutions of salts and alkalis.

Its service life is up to 50 years, as it won't rot or decompose over time. This is due to its thermoplastic material properties, which also make it resistant to microorganisms in the soil.

XPS foam sheet board is not attractive to rats and other pests as a food source. This is a significant advantage in certain applications.

It's worth noting that while XPS foam sheet board is chemically inert, it can be attacked and dissolved by certain organic solvents.

Related reading: Pu Foam Material

Sources

Featured Images: pexels.com