PU foam is a versatile material with a wide range of uses. It's lightweight, yet incredibly durable, making it perfect for packaging fragile items.

PU foam is commonly used in the shipping and packaging industry to protect goods during transportation. This reduces the risk of damage and ensures products arrive at their destination in pristine condition.

One of the most significant benefits of PU foam is its ability to provide excellent insulation. It can be used to keep buildings warm in the winter and cool in the summer, reducing energy costs and carbon emissions.

In addition to its practical uses, PU foam is also used in the production of furniture and car seats. Its high density and resilience make it an ideal material for these applications.

Worth a look: Pu Foam Uses

What Is PU Foam?

PU foam is a versatile material made from the chemical reaction between polyol resins and isocyanate. It's popular for its superior thermal insulation properties, durability, and flexibility.

Polyurethane foam is a spray-applied material that expands on contact to create an air seal. This unique property makes it ideal for creating thermal barriers and sound insulation.

There are two main types of polyurethane foam: closed-cell polyurethane and open-cell polyurethane foam. Each type has its own unique characteristics, but both are widely used in construction.

The main constituents of PU foam are polyol resins and isocyanate. Polyol contributes to polyurethane foam's flexibility, rigidity, and foamy nature.

Isocyanate is the other major constituent that makes up polyurethane foam, but it's worth noting that inherently, isocyanates are poisonous and cause different types of irritation.

Related reading: Green Cell Foam

Properties and Performance

The properties of pu foam material can be measured and specified very precisely to allocate the right grade of foam to the right application.

Foam performance is a crucial aspect to consider, and it's discussed in more detail on our dedicated Foam Performance page.

Pu foam material can be specified very precisely, thanks to the test methods used under Industry Standards, which cover the test methods used to specify foam.

The precision of pu foam material makes it suitable for a wide range of applications, from furniture to packaging and insulation.

Uses and Applications

One of the most commercially important reformulations of foam is the processing of foam scrap into bonded carpet cushion.

Bonded carpet cushion is the most popular type of carpet cushion, with a market share of over 80 percent.

Scrap foam of various types can be shredded and placed into a processing unit with a chemical adhesive to create this material.

The mixture is then pressurized and injected with steam to form a large foam cylinder or block.

This process results in a large foam cylinder or block that can be "peeled" into the proper thicknesses for carpet cushion use.

Here's an interesting read: Pu Foam Block

Health and Safety

Polyurethane foam is generally not hazardous if you take the necessary precautions. However, it's essential to use it safely to avoid accidents and other potential hazards.

Always wear protective equipment when handling polyurethane foam, as it can cause eye and respiratory irritation, as well as skin irritation. This includes wearing gloves, safety glasses, and a mask to prevent inhaling volatile organic compounds (VOCs).

Proper ventilation is also crucial when using polyurethane foam. Installing it in a well-ventilated area can help prevent headaches, nausea, and dizziness caused by inhaling VOCs.

Some common short-term exposure effects of polyurethane foam include irritation, headaches, and dust-related issues. These can be prevented by wearing protective equipment, working in a well-ventilated area, and following the manufacturer's instructions.

Safe Usage Options

When working with materials that can be hazardous if not handled properly, it's essential to take necessary precautions. Always wear protective equipment when handling polyurethane foam, as it can be a delicate job.

Protective equipment can include gloves, safety glasses, and a mask to prevent exposure to potential hazards. I've seen many DIY projects go awry because people didn't take the time to properly gear up.

Installing polyurethane foam in a well-ventilated area is also crucial to avoid accidents and other potential hazards. This allows for better airflow and reduces the risk of inhaling fumes.

For your interest: Bulk Materials Handling Equipment

Store polyurethane foam away from direct sunlight to prevent degradation and ensure it remains effective. Direct sunlight can cause the foam to break down over time.

Follow the manufacturer's manual when using foam products, as it will provide specific instructions and guidelines for safe use. This is especially important for polyurethane foam insulation, which requires a bit more finesse.

If you're not comfortable handling polyurethane foam insulation, consider hiring a professional contractor. They have the experience and knowledge to do the job safely and efficiently.

Here are the 5 safe ways to use polyurethane foam:

- Always wear protective equipment when handling polyurethane foam.

- Install polyurethane foam in a well-ventilated area.

- Store polyurethane foam away from direct sunlight.

- Follow the manufacturer's manual when using foam products.

- Hire a professional contractor when using polyurethane foam insulation.

How Does Affect Health?

Polyurethane foam can have both short-term and long-term effects on human health, depending on how it's installed and manufactured.

Proper installation is key to preventing short-term exposure effects, such as irritation, headaches, and dust-related issues. Wearing Personal Protective Equipment, like masks and gloves, can help prevent these problems.

The absence of ventilation during installation can lead to headaches, nausea, and dizziness due to the inhalation of volatile organic compounds (VOCs). Trimming polyurethane foam after it hardens can also generate dust that releases toxic chemicals.

Improper installation can cause long-term exposure effects, including respiratory problems and environmental impact. Prolonged exposure to off-gassing chemical compounds can lead to respiratory issues like asthma and bronchitis.

It's essential to follow EPA regulations and allow polyurethane foam to cure for at least 24 hours to prevent off-gassing. Even then, there's a risk of off-gassing if the foam is not installed correctly.

Here are some short-term exposure effects to watch out for:

- Irritation: Polyurethane foam can cause eye and respiratory irritation, as well as skin irritation.

- Headaches: Inhaling VOCs can cause headaches, nausea, and dizziness.

- Dust: Trimming polyurethane foam can generate dust that releases toxic chemicals.

Regulations and Recycling

Pu foam material has a complex recycling process, but some manufacturers are working to improve it.

In the United States, the Environmental Protection Agency (EPA) regulates the disposal of expanded polystyrene (EPS), the main component of pu foam.

Pu foam can be recycled, but it's not widely accepted in curbside recycling programs.

Suggestion: Dart Container Foam Recycling Drop-off

Uses for Recycled Flexible Materials

Recycled flexible polyurethane foam is a valuable resource, and its uses are numerous. One of the most commercially important reformulations of foam is the processing of foam scrap into bonded carpet cushion, which has a market share of over 80 percent.

Bonded foam is the most popular type of carpet cushion, and it's made by shredding scrap foam, mixing it with a chemical adhesive, and then pressurizing it with steam to form a large foam cylinder or block. This process creates a material that's then "peeled" into the proper thicknesses for carpet cushion use.

Recycled polyurethane foam waste is also used in manufacturing insulating materials, mattresses, and insulation foam boards. This shows that even difficult-to-recycle materials can be given new life.

Latex foam is another eco-friendly alternative to polyurethane foam, made from biodegradable, renewable, and toxins-free materials that provide cushioning comfort.

For more insights, see: Egg Crate Foam Cushion

Regulations Governing Use

In the United States, the Environmental Protection Agency (EPA) regulates the use of polyurethane foam, production of polyurethane products, and its environmental impact. The EPA is concerned about the emissions of volatile organic compounds (VOCs) and other air pollutants.

The EPA's regulations aim to minimize the negative effects of polyurethane foam on the environment.

Manufacturing and Handling

Polyurethane foam is a delicate material that requires careful handling to avoid accidents and potential hazards.

Always wear protective equipment when handling polyurethane foam, as it's essential for your safety.

Store polyurethane foam away from direct sunlight, as this can affect its quality and performance.

Follow the manufacturer's manual when using foam products, as it provides specific instructions for safe and effective use.

To ensure smooth use of polyurethane foam, consider hiring a professional contractor when using polyurethane foam insulation, especially if you're not experienced in DIY projects.

Raw Materials

Polyurethane foams are produced by reacting polyols and diisocyanates, both products often derived from crude oil. This process is the foundation of polyurethane foam manufacturing.

The main diisocyanate used in the production of flexible polyurethane foam is TDI (Toluene diisocyanate).

Some foams, notably so-called visco-elastic or memory foams, can also be made with MDI (Methylene diphenyl diisocyanate). Moulded foams are more often made with MDI.

When mixed with polyols, these chemicals form the building blocks of polyurethane.

Fabrication

Fabrication is a crucial step in the manufacturing process of polyurethane foam. It involves shaping the foam into complex forms and structures.

Foam can be fabricated into various shapes using basic tools adapted from woodworking machinery, such as vertical bandsaws and horizontal slitters. These tools enable fabricators to create intricate designs and patterns.

Loop slitting is a technique used to cut foam into loops, which can be attached to a vertical wheel configured with cutting blades. This process is commonly used in the production of bonded carpet cushion.

Lasers, hot wires, water jets, and wave convolutes are also used in foam fabrication to create complex shapes and patterns. Foam can be compressed as it is cut to produce effects such as convoluted foam, often used in mattress toppers.

Bonding techniques, such as flame bonding, hot film bonding, hot melt adhesion, and powder laminating, are used to combine foam with other materials, like nonwoven substrates, netting, fabric, and fiber.

For another approach, see: Pu Foam Process

Instructions for Use

To ensure a successful project, it's essential to determine the required amount of PU foam and consider that an overdose of up to 100% may be necessary for narrow cavities.

The temperature of both component A and B must be kept constant at a minimum of 18°C.

Accurate measurement or weighing of both components is crucial before mixing.

Mix component A and add component B to it, following the instructions for the correct mixing speed and batch size.

A large mixer, such as a spiral mixer, should be used at a speed of 1,500 rpm for batches of 5-10 kg.

To prevent foam from overflowing in narrow cavities, it's recommended to mix at a speed of 1,500 rpm for batches of 5-10 kg.

Wet the surface of small cavities before applying the foam to ensure it adheres properly.

For long, narrow shapes, place them at an angle of 10-15° to fill them completely.

The temperature of the cavity should be maintained between 15-25°C for optimal results.

Frequently Asked Questions

What are the downsides of polyurethane foam?

Polyurethane foam insulation is expensive, unsustainable, and can harm the environment. Additionally, it may release toxic fumes during and after installation.

Is PU foam hard or soft?

PU foam can be either hard or soft, depending on its type and density. Understanding the difference is key to choosing the right type for your needs.

Is PU foam a plastic?

Yes, polyurethane (PU) foam is a type of plastic made from a combination of diisocyanates and polyols. Its unique properties, such as the use of carbon dioxide as a blowing agent, make it a versatile material used in various applications.

Is a PU foam mattress good?

A PU foam mattress can be a good option, but its durability and lifespan depend on its quality and maintenance. While good quality PU foam can last 2-5 years, it may not be the most durable choice for long-term use.

Sources

- https://www.pfa.org/what-is-polyurethane-foam/

- https://polyestershoppen.com/polyurethaanhars/polyurethaanschuim-306.html

- https://pipingtech.com/resources/technical-bulletins/polyurethane-foam-puf-technical-information/

- https://krakenbond.net/blogs/insulation/is-polyurethane-foam-toxic

- https://europur.org/flexible-pu-foam/raw-materials/

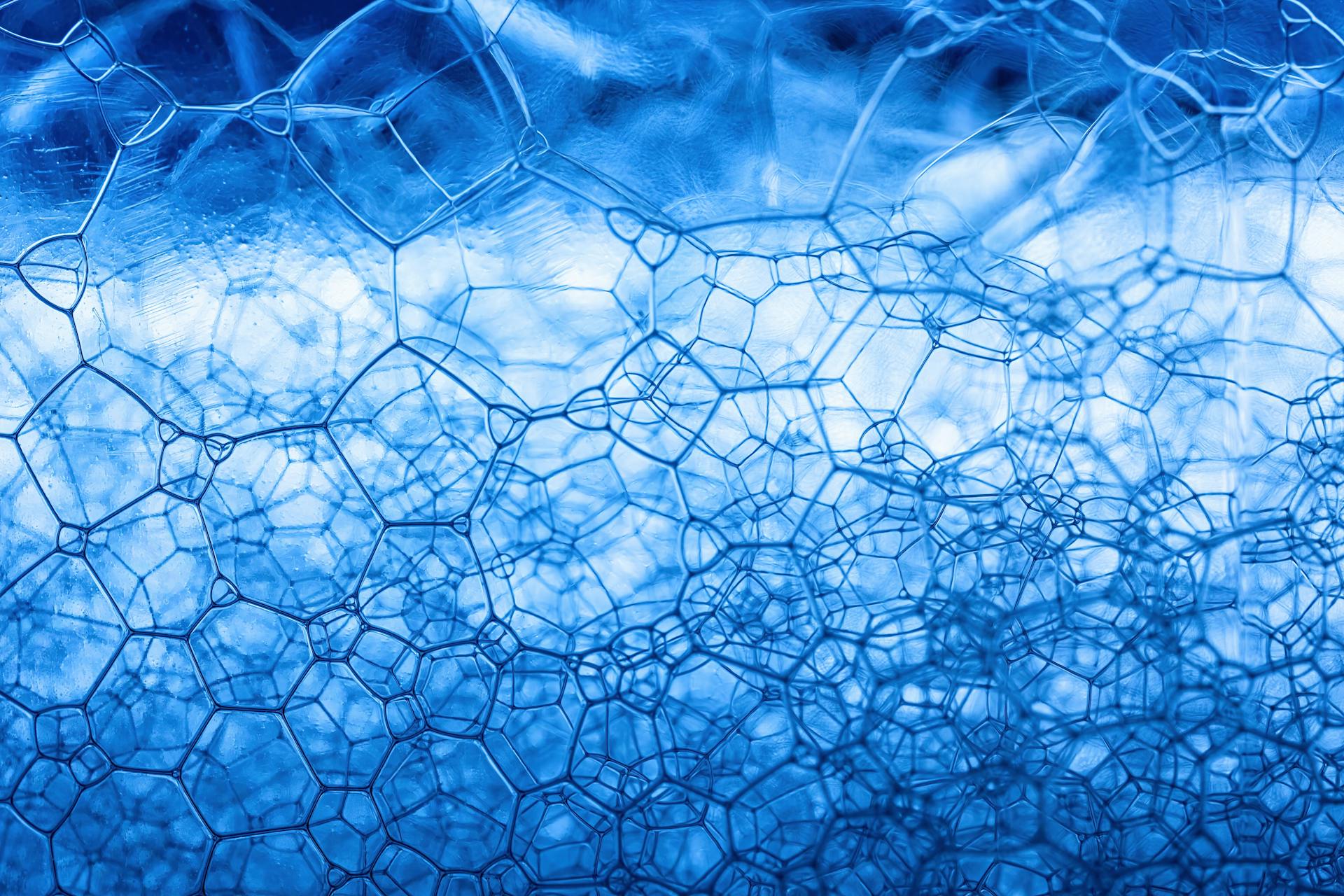

Featured Images: pexels.com