End-of-line palletizing solutions can significantly boost productivity by automating the palletizing process, which is a manual and time-consuming task that often leads to errors and inefficiencies. According to industry estimates, manual palletizing can take up to 30 minutes per pallet.

Automated palletizing systems can handle high volumes of products quickly and accurately, reducing labor costs and increasing throughput. In one case, a company saw a 25% increase in production after implementing an automated palletizing system.

By streamlining the palletizing process, companies can free up resources for more value-added activities, such as quality control and packaging customization. This can lead to improved customer satisfaction and loyalty.

Readers also liked: B Pallets

Features

End-of-line palletizing solutions are designed to handle a variety of products, from beverages and foods to pharmaceuticals and more. These systems can achieve production rates of up to 150 packs per minute, making them ideal for high-volume applications.

The type of technology used can vary depending on the production rate and product type. Two common approaches include the use of multi-axis robots and layer palletizers.

Multi-axis robots, such as 4 or 6-axis robots coupled with a gripping tool, can handle products at either low or high levels. This flexibility is crucial for maintaining accurate alignment and stacking strength.

Layer palletizers with high-level infeed, on the other hand, do not require gripping the product, allowing for more controlled palletizing and precise alignment of boxes from one layer to the next.

The latest generation of robotic servo-driven layer palletizers, such as the 4.0 model, boasts impressive features like quiet operation, energy efficiency, and high reliability. These systems also offer fast recovery times, minimizing downtime and keeping operations running smoothly.

A high-quality palletizing solution should come with features that maintain consistent performance, including advanced precision to stack items securely and reduce the potential for product damage.

You might enjoy: High Cube Reefer Container

Benefits

The benefits of end-of-line palletizing are numerous and significant. High capacity is one of the major advantages, allowing for efficient and effective use of space.

End-of-line palletizing with the Compact robot palletizer offers excellent operator visibility and access, making it easier to program and maintain. This is especially important for operators who need to program new patterns regularly.

One of the key benefits of high-level palletizers is their ability to offer greater line efficiencies. This means that production lines can run more smoothly and efficiently, reducing downtime and increasing productivity.

A high-level palletizer can also handle imperfect product with greater tolerance, which is a significant advantage in many manufacturing environments. This means that products don't have to be perfect to be palletized, which can help reduce waste and increase overall efficiency.

Here are some of the key benefits of high-level palletizers:

- High capacity

- Excellent operator visibility and access

- Greater line efficiencies

- Greater tolerance of "imperfect product"

- Flexibility for operators to program new patterns

- Accuracy of locating layers of interlocking product

- High financial returns thanks to great flexibility (products and patterns), proven reliability and low cost of maintenance

- Customized for your application

- Robustness and reliability

- Flexible regarding the diversity of products to be palletized

- Minimal footprint whilst using “free” headroom

- Very satisfied, repeat customers

Overall, high-level palletizers offer a wide range of benefits that can help improve the efficiency and productivity of manufacturing operations.

Choosing the Right Equipment

Choosing the right equipment for your end-of-line palletizing needs is crucial for efficiency and productivity. Consider the throughput of the system, which can range from 20 p/min to 150 p/min, or even up to 10,000 p/h with the RA-C series.

The type of equipment you need will also depend on the size of your workspace. If you have limited floor space, a compact design like the PalletizUR might be the perfect fit.

For heavy-duty tasks, a system like the PalletizHD is a great choice, capable of handling products that require careful and supported placement. The RA-C series is also a flexible option, suitable for palletizing packs, boxes, or filled bottles at the end of the filling line.

Here's a quick rundown of the different equipment options:

Compact

If you're looking to streamline your packaging process, compact palletizers are definitely worth considering. These machines can handle a range of products efficiently and accurately, reducing labor and manual handling.

They come in various designs, including the Scott compact robot palletiser system, which offers flexibility and compactness. The compact design enables the system to fit into smaller spaces, making it perfect for businesses with limited floor space.

For your interest: 3pl Transportation Management System

Compact palletizers are capable of processing a high volume of products, with some models able to handle up to 30 products per minute. This makes them ideal for businesses that need to package large quantities of products quickly.

Some compact palletizers also feature automatic tray supply, which can save time and reduce labor costs. For example, the semi-automatic palletizer in trays mentioned in Example 4 comes with automatic tray supply, making it a great option for businesses that want to automate their packaging process.

Here are some key features of compact palletizers:

- Pallet over motorized elevator platform.

- Manual tray supply.

- Pallet height: Up to 1.5m (to confirm depending on the palletizer’s input conveyor).

- Automatic tray supply.

- Automatic tray former with hot glue application.

These features make compact palletizers a great option for businesses that want to improve their packaging efficiency and reduce labor costs.

Pallet Conveyors

If you're looking to automate palletizing, consider using pallet conveyors. They can handle high volumes of goods efficiently.

Pallet conveyors can be integrated with end-of-line systems, such as the one mentioned in the Pal 4.0 project. This integration enables streamlined processing and reduced labor costs.

Pallet conveyors come in various types, including belt, roller, and chain conveyors. Each type has its own advantages and is suited for specific applications.

A well-designed pallet conveyor system can increase productivity and reduce errors. It's essential to choose the right type of conveyor for your specific needs.

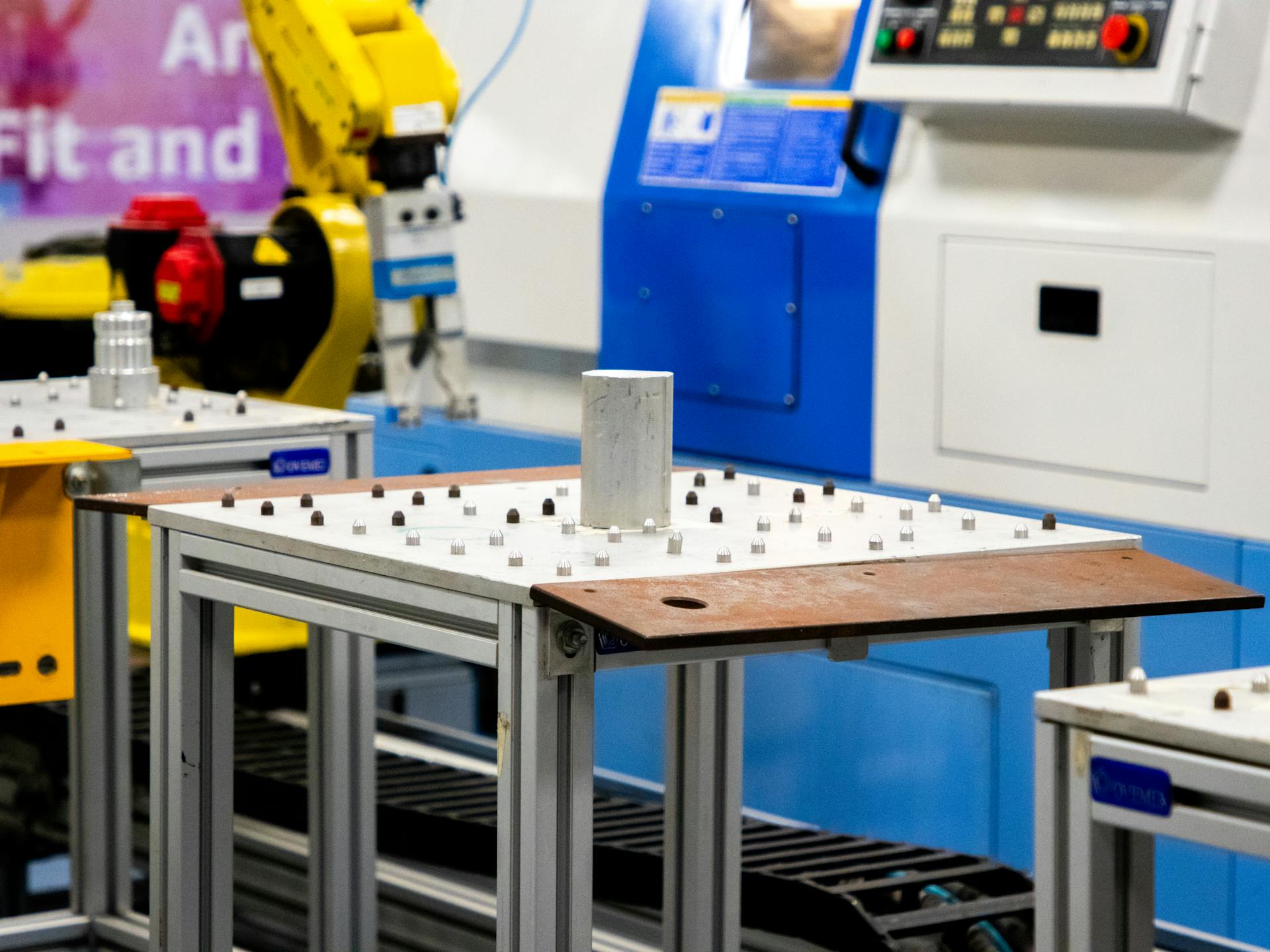

Palletizability with Universal Robots

Choosing the right equipment for your business can be a daunting task, but when it comes to palletizing, Universal Robots offers a versatile solution.

The PalletizUR, built with Universal Robots cobot technology, is a compact and flexible palletizer that's perfect for companies with limited space but high demands for automation.

Its powerful reputation and top-tier performance make it an excellent choice for manufacturers looking to automate end-of-line palletizing.

The PalletizUR offers payload variations of 10 kg, 20 kg, and 30 kg, making it adaptable to a wide range of products and pallet configurations.

Here are some key features of the PalletizUR:

This system's intuitive design and flexibility make it a great option for businesses new to robotic automation, and its innovative lightweight arm design enhances agility and efficiency.

PalletizHD: Doosan Built

The PalletizHD is a robust solution built with Doosan Robotics, specifically designed for high-payload applications. This makes it the ideal choice for facilities handling larger or heavier products.

One of the standout features of the PalletizHD is its high precision and speed, thanks to Doosan cobots being engineered for exceptional accuracy and fast operation. This ensures efficient and precise palletizing in various applications.

The PalletizHD also comes equipped with advanced safety features, including cutting-edge safety mechanisms that allow it to work alongside human operators safely and effectively.

You can choose from two payload options: 20 kg and 30 kg capacities, making the PalletizHD adaptable for handling a diverse range of products in your palletizing process.

Here are the key features of the PalletizHD:

- High Precision and Speed: Ensures efficient and precise palletizing

- Advanced Safety Features: Allows safe operation alongside human operators

- Flexible Payload Options: 20 kg and 30 kg capacities for diverse product handling

High Level Infeed

High Level Infeed is a great option for companies with low production needs. It's ideal for any kind of bags.

The products on infeed are distanced one from the other, orientated, grouped into layers, and stacked on a pallet. This process is efficient and accurate.

A high level infeed palletizer can achieve a throughput of 40 products per minute. This is a good option for small to medium-sized businesses that don't require high-speed production.

The pallet is in a stationary position during the palletizing process. This provides a stable and secure environment for the products to be stacked.

High level infeed palletizers are often used for low-volume production runs. They're a great choice for companies that need to palletize products sporadically.

With a high level infeed palletizer, you can achieve a maximum production speed of 300 layers per hour. This is slower than some other options, but it's still a reliable and efficient choice.

Sack

When choosing equipment for sack palletizing, consider throughput and pallet weight. The maximum pallet weight for sack palletizers is 1500.0 kg.

Sack palletizers can handle a range of throughputs, from 0 p/min to 6 p/min. This makes them suitable for various production lines.

Cartesian palletizers are a simple and robust solution, often used in end-of-line applications with low to intermediate throughputs.

If you're looking for a flexible model, consider an automatic bags palletizing robot. These robots can be installed at the end of the line and are designed for bags palletizing.

Expand your knowledge: U Haul Car Transport Trailer Weight

The RD series robots are specifically designed for bags palletizing, making them a good option for lines that require this type of equipment.

Here are some key features to consider when choosing a bags palletizing robot:

- Bags conveyor from the line to the pick-up area.

- Anthropomorphic robot, model selected depending on line specifications.

- Gripper designed depending on line requirements.

Highrunner HR8

The Highrunner HR8 Palletizer is a machine that can handle a high volume of work, with a throughput of 1,500 p/h.

It's designed to work with cartons containing IQF products, which can be a challenge to palletize.

The palletizer can create pallets that are 1,550 mm wide and 1,700 mm long.

This specific design makes it suitable for palletizing cartons with IQF products, mainly vegetables, fries, and fruits.

On a similar theme: Palletizer Machine

Equipment

Choosing the right equipment for your manufacturing site can be a daunting task, but let's break it down. The throughput of a palletizer can range from 4 p/min to 300 p/h, depending on the type of equipment.

For high production volumes, a dedicated palletizer for each line is often the optimal solution. These end-of-line palletizing solutions can achieve throughputs of 20 p/min to 150 p/min.

Intriguing read: What Is an In-line Palletizer

If you're looking for a more compact option, consider a robot palletizer. These systems can palletize a range of products efficiently and accurately, reducing labor and manual handling. Compact robot palletisers can achieve throughputs of 4 p/min to 30 p/min.

For high-capacity palletizing, look for systems with a strong construction, such as the Antares model. This machine can palletize cartons, packs, or trays and achieve great production capabilities, with a throughput of 300 p/h.

Some popular options include:

Keep in mind that the specific requirements of your manufacturing site will determine the best equipment choice. Be sure to consider factors such as product size, weight, and packaging needs when selecting the right equipment for your operation.

RMP

The RMP robotic palletizer is a game-changer for automating the packaging process. It can form pipe pallets in fully automatic mode.

One of the key advantages of the RMP is its ability to process pipe bundles that have been previously packed either by IRT or IST. This means you can easily integrate it into your existing workflow.

With the RMP, you can also process pipe packages fixed by saddles that have been previously packed by RMT. This flexibility makes it a versatile solution for various packaging needs.

The RMP is designed for quick and reliable packaging, which is essential for maintaining productivity and efficiency.

A unique perspective: End of Line Packaging Equipment

Tray Warehouse

Choosing the right equipment for your warehouse can be a daunting task, but understanding your specific needs can make all the difference.

A compact automatic palletizer with a tray warehouse is a great option for many businesses, capable of handling pallet heights of up to 3m.

This type of equipment can accommodate various types of packaging, including upside trays, inverted trays, cardboard sheets, and top frames.

The tray warehouse is a key component of this system, providing a efficient way to store and retrieve trays as needed.

The versatility of this equipment is one of its greatest benefits, allowing businesses to adapt to changing packaging needs without having to purchase new equipment.

Recommended read: Cross Docking Warehouse Systems

Desk and Tray Former

The desk and tray former is a crucial component in many packaging systems. It's a compact model that can handle various tray sizes, including 1200×800, 600×800, 1200×1000, and 600×1000 mm.

Automatic tray supply is a feature you'll find in some models, making it easier to keep the production line running smoothly. This is especially useful in high-volume packaging operations.

On a similar theme: Packaging Pallets

The desk and tray former can be configured to form trays using hot glue application, which is a reliable and efficient method. This is a key advantage over other tray forming methods.

Some models come with automatic tray former, which can fold and glue cardboard sheets to form trays. This saves time and labor, and ensures consistent tray quality.

The desk and tray former can be part of a larger system, including a palletizing robot, which provides flexibility and increased production capacity.

Bagger

Choosing a bagger for your operation can be a bit overwhelming, but let's break it down. A flexible model that combines a bagger and in-line palletizer can be a great option.

This type of system, like the CPZ compact palletizer, can handle in-line displacement and features a customized gripper with a frame to collect bags. It's a compact and efficient solution that can save you space and increase productivity.

Filled Containers

Filled containers are an essential part of any equipment setup. They come in various shapes, sizes, and materials to suit different needs.

For instance, plastic containers are lightweight and easy to clean, making them ideal for storing liquids or chemicals.

Metal containers, on the other hand, are more durable and can withstand extreme temperatures, making them perfect for storing hazardous materials.

A good rule of thumb is to choose a container that's at least 20% larger than the object being stored to allow for expansion and movement.

Some containers also have specialized features, such as airtight seals or ventilation systems, which can be beneficial in specific situations.

Display PEM Series

The Display PEM Series is a game-changer for manufacturers and distributors. It offers a range of benefits, including the ability to palletize display products quickly and efficiently.

These palletizers are designed to work with a variety of formats, and can be adjusted without the need for parts changes. This makes them a great option for companies that need to switch between different product lines.

Explore further: Display Pallets

The Display PEM Series can include a layer forming table, a bottles dispenser or a pusher, and a Pick&Place universal gripper. This combination of features allows for fast and accurate palletizing.

One of the key advantages of the Display PEM Series is its ability to insert filled bottles into carton trays, half trays or quarter trays. This level of precision is essential for companies that need to ensure their products are packaged correctly.

Here are some of the key benefits of the Display PEM Series:

- Great benefits to manufacturers, distributors, and final consumers

- Complementary with other equipment options

- Can include a layer forming table, bottles dispenser or pusher, and Pick&Place universal gripper

- Inserts filled bottles into carton trays, half trays or quarter trays

Automation and Integration

Automation and integration are crucial for efficient end-of-line palletizing. Seamless integration with your existing production line is essential for efficiency, and your chosen palletizing system should be compatible with other machinery, such as conveyors or stretch wrapping equipment.

Consider software integration—systems that connect with production management tools can offer real-time insights, helping you track performance and identify areas for improvement. This can be especially helpful in tracking production and making data-driven decisions.

A well-integrated system can also include automatic tray formers, such as the PFC, which folds and glues cardboard sheets to form trays using a hot melt system. This can be a game-changer for companies looking to streamline their packaging operations.

Here are some key components of a comprehensive end-of-line palletizing system:

- Automatic tray former with hot glue application

- Automatic plastic sheet supply between layers

- Output roller or chain conveyor for pallet accumulation or transportation

- Automatic wrapping machine integration

- Automatic strapping machine integration

- Mobile carriage for transporting pallets long-distance

Case Conveyors

Case conveyors are a crucial part of many manufacturing processes, especially in end-of-line palletizing projects.

In an end-of-line palletizing project with a robot, case conveyors play a vital role in efficiently moving cases to the palletizing area.

These conveyors can significantly reduce labor costs and improve production throughput by automating the transportation of cases.

A good example of this is the end-of-line palletizing project with a robot, where case conveyors help streamline the process.

The use of case conveyors in such projects can also lead to improved product quality and reduced damage during transportation.

Case conveyors can be designed to handle a wide range of case sizes and types, making them a versatile solution for many manufacturing applications.

In an end-of-line palletizing project with Pal 4.0, case conveyors were used to great effect, helping to increase productivity and efficiency.

Explore further: Case Palletizing

Sorter

The sorter is a crucial component in many modern manufacturing and processing facilities. It's designed for high capacity slaughterhouses, making it a valuable addition to any large-scale operation.

One notable example is a palletizer with sorter, which can work at chill stores and integrate seamlessly with current ERP systems. This allows for real-time order, product, and delivery management.

A key feature of this palletizer is its stainless design, making it easy to clean and maintain. This is particularly important in food processing environments where hygiene is a top priority.

This palletizer is capable of processing 12 parcels at a time, making it a highly efficient addition to any facility.

TS 28 ST/AL

The TS 28 ST/AL snake palletiser series is a great example of automation in action, with a throughput of 9 pallets per minute.

It's designed to automatically palletize ends sleeves, which is a precise and efficient process.

This palletizing process uses a picking system that places the ends sleeves on the pallet according to different layouts, ensuring product stability.

The TS 28 ST/AL series is perfect for companies looking to streamline their operations and increase productivity.

Its ability to handle a high volume of pallets per minute makes it an ideal solution for businesses with large production needs.

A unique perspective: Air Freight Cost per Kg

LayerIP

LayerIP is a game-changer for efficient packaging.

This compact and flexible module allows the automatic palletization of one or several lines.

The XAPACK PACKAGING design and manufacture of LayerIP ensures the automatic palletization of cases or burdens in either columnar or crossed pallets.

With a throughput of 70 p/h, LayerIP can handle a significant volume of products.

This level of automation and integration can greatly reduce labor costs and increase productivity.

ETP

The ETP is a game-changer in automation and integration. It can handle up to 10 positions in its tray warehouse.

This system allows for bottles to be inserted into trays row by row, making it a more efficient process. The palletizing area is also a key feature of the ETP.

The ETP is designed to work with upside trays, which come in various sizes: 1200×800, 600×800, 1200×1000, and 600×1000 mm.

One of the benefits of the ETP is its ability to handle unsteady bottles without pushing or sliding them. Instead, the bottle is elevated by the neck and introduced softly into the tray.

The ETP is flexible and can be adjusted to work with different tray sizes, including one or two trays per level. This flexibility is a major advantage in terms of optimizing transport costs per bottle.

Here are some key features of the ETP:

- Automatic positioning of inverted tray in the last layer of the pallet

- Automatic plastic sheet supply between layers (from roll of film) to protect the bottles neck from touching the cardboard

- Pallet doser and output pallet accumulation by roller or chain conveyor

The ETP's ability to introduce 1 or 2 rows of bottles more than other automatic systems is a significant advantage in terms of transport costs per bottle.

ECAM+PFC+RPZ

ECAM+PFC+RPZ is a comprehensive automation solution that streamlines packaging processes. It's designed to increase efficiency and reduce labor costs.

The PFC (Automatic Tray Former) is a key component of this system, capable of folding and gluing cardboard sheets to form trays using a hot melt system.

This system is particularly useful for warehouses, where trays, top frames, or sheets need to be stored and managed efficiently. Automatic tray formers can significantly reduce manual labor and minimize errors.

Here's a breakdown of the PFC's features:

- Tray, top frame, or sheet warehouses.

- Automatic tray former with hot glue application.

- Automatic plastic sheet supply between layers (from roll of film) to protect the bottles neck from touching the cardboard.

- Pallet warehouse.

- Output roller or chain conveyor for pallet accumulation or transportation to wrapping/strapping area.

- Automatic wrapping machine integration.

- Automatic strapping machine integration.

- Mobile carriage to cover different palletizing lines for transporting pallets long-distance without obstructing transit areas with fix conveyors.

The RPZ (Robust Packaging Zone) is another crucial aspect of ECAM+PFC+RPZ, providing a robust and reliable packaging solution that can handle high-volume production. By integrating this system, businesses can ensure consistent quality and efficiency in their packaging processes.

Filled Machines

Filled machines play a crucial role in automating various tasks in a production line. For instance, the PEM system is a semi-automatic solution ideal for low production rates, where the tray and pallet supply are done manually.

One key feature of the PEM system is its automatic pallet doser. This feature ensures that pallets are loaded efficiently, reducing manual labor and increasing productivity.

The PEM system also includes pallet conveyors and end of line equipment such as wrapping, strapping, and labeling. These features streamline the production process, making it more efficient and cost-effective.

Gripper Moving

The RA-C series robots have a "curtain" type gripper.

This type of gripper allows for a smooth and efficient movement of the product layer.

The RA-C series robots are the fastest palletizer of the range, moving the complete product layer.

Their gripper design enables them to handle a variety of products with ease.

The "curtain" type gripper is a key feature of these robots, making them ideal for palletizing tasks.

Confirming Integration and Compatibility

Seamless integration with your existing production line is essential for efficiency. It's crucial to choose a palletizing system that's compatible with other machinery, like conveyors or stretch wrapping equipment.

Your chosen system should be able to connect with production management tools to offer real-time insights. This can help you track performance and identify areas for improvement.

Integration with other machinery can streamline your production process and reduce downtime. By choosing a compatible system, you can ensure a smooth workflow.

Systems that connect with production management tools can provide valuable data and analytics. This can help you make informed decisions and optimize your production line.

In addition to hardware compatibility, consider the software integration of your palletizing system. This can help you stay on top of production metrics and make adjustments as needed.

Automation

Automation is a game-changer for companies looking to streamline their operations and boost efficiency. TopTier's floor-level palletizers can revolutionize your material handling processes by enhancing your packaging operations and delivering better results.

With the right automation system, you can say goodbye to manual labor and hello to increased productivity. TopTier's palletizers are designed to make your packaging operations more efficient.

By investing in automation, you can reduce labor costs and minimize the risk of human error. TopTier's systems are built to last and can withstand the demands of a busy production line.

TopTier offers floor-level palletizers that can help you achieve your goals and take your business to the next level. Request a quote today to learn more about how their palletizers can benefit your company.

Take a look at this: Logistics Automation Market

Solutions and Options

With over 34 years of experience in end-of-line palletizing, AND&OR offers customized projects tailored to your specific needs. They have a wide range of robot families to choose from, depending on load weight and gripper type.

You can select from various gripper types, such as gripper pressing laterally, which is suitable for palletizing and depalletizing 5-gallon bottles, or for palletizing bags.

AND&OR also provides a variety of additional elements for loading unit preparation and storage, including automatic cardboard trays former systems, pallets feeding systems, pallets conveyors, pallets wrapping and labelling, and more.

Some of the key solutions and options available include:

- Cartesian boxes palletizer – PPM Series, which can input products at 90º and has the option to input at the line height or at a higher height.

- Flexible palletizer/Robot solutions, which can be customized to fit your production speeds and available space.

- Floor-level palletizers from TopTier, which can enhance your packaging operations and deliver better results for your company.

Project with Pal 4.0 and Double Infeed

In an end-of-line palletizing project, the Pal 4.0 and double infeed system can handle different products, such as cases, trays, or shrink-wrapped packs, reaching a total capacity of up to 130 pieces per minute.

AND&OR offers customized projects adapted to your needs, with more than 34 years of experience in the industry. They provide after-sales service guarantee, ensuring that their systems continue to run smoothly after installation.

This system is ideal for companies that need to automate their palletizing operations, allowing for easy format change and high autonomy. It's also designed to be light, fast, and persistent, ensuring maximum process efficiency and long maintenance intervals.

Here are some of the key benefits of the Pal 4.0 and double infeed system:

- Total capacity of up to 130 pieces per minute

- Handles different products, such as cases, trays, or shrink-wrapped packs

- Easy format change and high autonomy

- Light, fast, and persistent design for maximum process efficiency

Ra-C Series

The Ra-C series is a robotic palletizer that can handle a wide range of products, including packs, boxes, and filled bottles.

It's a fully automatic system, which means it can operate on its own without any manual intervention, making it a great option for high-volume production.

The Ra-C series can process up to 10,000 pallets per hour, which is impressive, especially when you consider it can also handle lower volumes, down to 1,000 pallets per hour.

This flexibility makes it a great choice for companies with varying production needs, as they can adjust the system to suit their requirements.

The Ra-C series includes the supply of cardboard or plastic sheets, which is convenient and saves time.

It's a great option for companies looking to streamline their production process and increase efficiency.

A unique perspective: Pallets per Truckload

Cube 800

The CUBE 800 is a highly efficient robotic palletizer that can handle a throughput of 8 pallets per minute.

Its compact design allows for easy movement within a factory, and it can be installed in various locations to service different production lines.

The palletizer has a self-supporting structure with wheels, making it easy to relocate as needed.

The CUBE 800 can create pallets that are 800 mm wide and 800 mm long.

This level of flexibility and compactness makes the CUBE 800 a valuable addition to any production line.

Cardboard Box APS 620 Ergon

The Cardboard Box APS 620 Ergon is a great option for small-scale production. It can handle a throughput of 20 pieces per minute.

This ultra-compact palletizer is perfect for low-speed production plants, making it easy to integrate into existing operations. Its compact design also makes it a great choice for facilities with limited space.

The APS 620 can create pallets with widths of 1,000 mm or 800 mm, and a length of 1,200 mm. This flexibility makes it a versatile solution for a variety of cardboard box packaging needs.

Its easy installation, management, and maintenance are just a few of the benefits that make the APS 620 a popular choice among manufacturers.

Worth a look: Cardboard Pallets

Tower APS 1570 Series

The Tower APS 1570 series is a single-column system based on two Cartesian axes motion.

It's designed for palletizing cases, bundles, trays, and other commonly used packs.

This system is composed of several modules that can be configured in a customized manner depending on the logistical needs of the user.

The APS 1570 series is suitable for a variety of applications, including palletizing cases, bundles, trays, and other commonly used packs.

Automatic Tray Former

Automatic tray former systems are a crucial component in modern packaging operations. They enable efficient and accurate formation of trays from cardboard sheets.

In compact models, automatic tray formers are equipped with hot glue application for secure bonding. This feature is particularly useful for creating sturdy trays that can withstand handling and shipping.

The automatic tray former can fold and glue cardboard sheets to form trays, as seen in the flexible model that combines a desk, tray former, and palletizing robot. This combination offers a high degree of flexibility and customization.

Some tray formers are designed to work with specific types of cardboard sheets, such as those measuring 1200×800, 600×800, 1200×1000, or 600×1000 mm. This ensures compatibility and optimal performance.

Automatic tray formers are often integrated with other packaging equipment, such as palletizers and layer configuration desks, to create a seamless packaging process.

On a similar theme: Slip Sheets vs Pallets

Cartesian Boxes – PPM Series

The Cartesian Boxes – PPM Series palletizer is a great option for automating your packaging operations.

It can input products on the line or at 90º, giving you flexibility in your production setup.

Depending on the model, it's possible to input at the line height or at a higher height, with the pallet stuck on the floor or in motion.

This palletizer is designed to work efficiently, with a maximum production speed of 500 layers per hour when using high input.

It's a compact and versatile solution that can be tailored to your specific needs.

Here are some key features of the Cartesian Boxes – PPM Series palletizer:

- Pack and/or boxes palletizer

- Products input on the line or at 90º

- Maximum production speed: 500 layers per hour (high input), 300 layers per hour (low input)

Bags

Bags are a crucial part of many industries, and automating their handling is a game-changer.

The RD series robots are designed for bags palletizing, making them a reliable choice for this task.

To set up an automatic bags palletizing robot, you'll need to install it at the end of the line, where it can pick up bags from a conveyor belt.

The anthropomorphic robot model used will depend on the specifications of your line, ensuring a tailored solution for your needs.

A gripper designed specifically for your line requirements will be used to pick up the bags, providing a secure and efficient way to handle them.

Here are some key features of the automatic bags palletizing robot:

- Bags conveyor from the line to the pick-up area.

- Anthropomorphic robot, model selected depending on line specifications.

- Gripper designed depending on line requirements.

Understanding and Budgeting

End-of-line palletizing can be a cost-effective solution for businesses, with a typical payback period of around 12-18 months, according to industry estimates.

To determine the feasibility of end-of-line palletizing, businesses should consider the cost of the system, which can range from $50,000 to $200,000 or more, depending on the complexity of the application.

A key factor in budgeting for end-of-line palletizing is the cost of labor savings, which can be substantial, with some companies reporting a reduction in labor costs of up to 70% after implementing the system.

If this caught your attention, see: End Rider Pallet Truck

Understanding Your Needs

Understanding your specific operational requirements is crucial to finding the right palletizing solution. Assessing the nature of your products is a good place to start.

Consider the weight of your products, as this can greatly impact the type of system you need. Fragile items may require gentle handling, while heavier goods may need robust equipment.

The dimensions of your products are also important to consider. This will help you determine the size and type of palletizing equipment you need. The speed and volume of your production line will also dictate whether you need a semi-automated or fully automated solution.

Budgeting and ROI

Budgeting and ROI considerations can be a challenge, but it's essential to look beyond upfront costs. A system that enhances productivity, reduces labor costs, and minimizes product damage can often pay for itself over time.

You want to find a balance of quality and affordability to get proper value for your money. This is crucial when making significant investments like a palletizing system.

Consider the long-term return on investment, not just the short-term costs. A solution that saves you money in the long run is often worth the initial investment.

Proper budgeting can help you make informed decisions and avoid costly mistakes.

Related reading: How Much Can I Sell Used Pallets for

Cobot and Automation

Cobot and Automation is revolutionizing end-of-line packaging by offering flexible, efficient, and safe automation solutions.

Cobot palletizers can improve efficiency and reduce operational costs. ONExia's cobot palletizers can significantly improve your efficiency, reduce operational costs, and increase accuracy.

The PalletizUR is a compact and versatile solution, while the PalletizCRX offers high precision, and the PalletizHD provides heavy-duty capabilities. ONExia has a solution to meet your needs, whether you're looking for compact versatility or heavy-duty capabilities.

Contacting ONExia for a free consultation can help you choose the perfect cobot palletizer for your business.

Frequently Asked Questions

What is the meaning of end of line packaging?

End-of-line packaging refers to the outermost layer protecting products during shipping and distribution. It ensures easy loading and unloading of containers from transportation.

What does palletizing mean in shipping?

Palletizing is the process of packaging goods onto pallets for secure shipment, typically using straps or wrapping to stabilize the cargo. This efficient method allows for easy stacking and transportation of goods.

How big is the palletizer market?

The palletizer market size was valued at USD 2.6 Billion in 2022. Discover the latest market trends and growth projections in our comprehensive guide.

What are the different types of palletizers?

There are two main types of palletizers: conventional and robotic, each suited for different environments and product sizes. Conventional palletizers excel in uniform product settings, using mechanical means for efficient stacking.

Sources

- https://scottautomation.com/en-us/products/materials-handling-logistics/end-of-line-palletising-systems

- https://onexia.com/blog/the-role-of-a-cobot-palletizer-in-end-of-line-packaging/

- https://www.toptier.com/en-us/blog/choosing-the-right-palletizing-end-of-line-solution

- https://www.directindustry.com/industrial-manufacturer/end-of-line-palletizer-210764.html

- https://andyor.com/en/robots-palletizers/

Featured Images: pexels.com