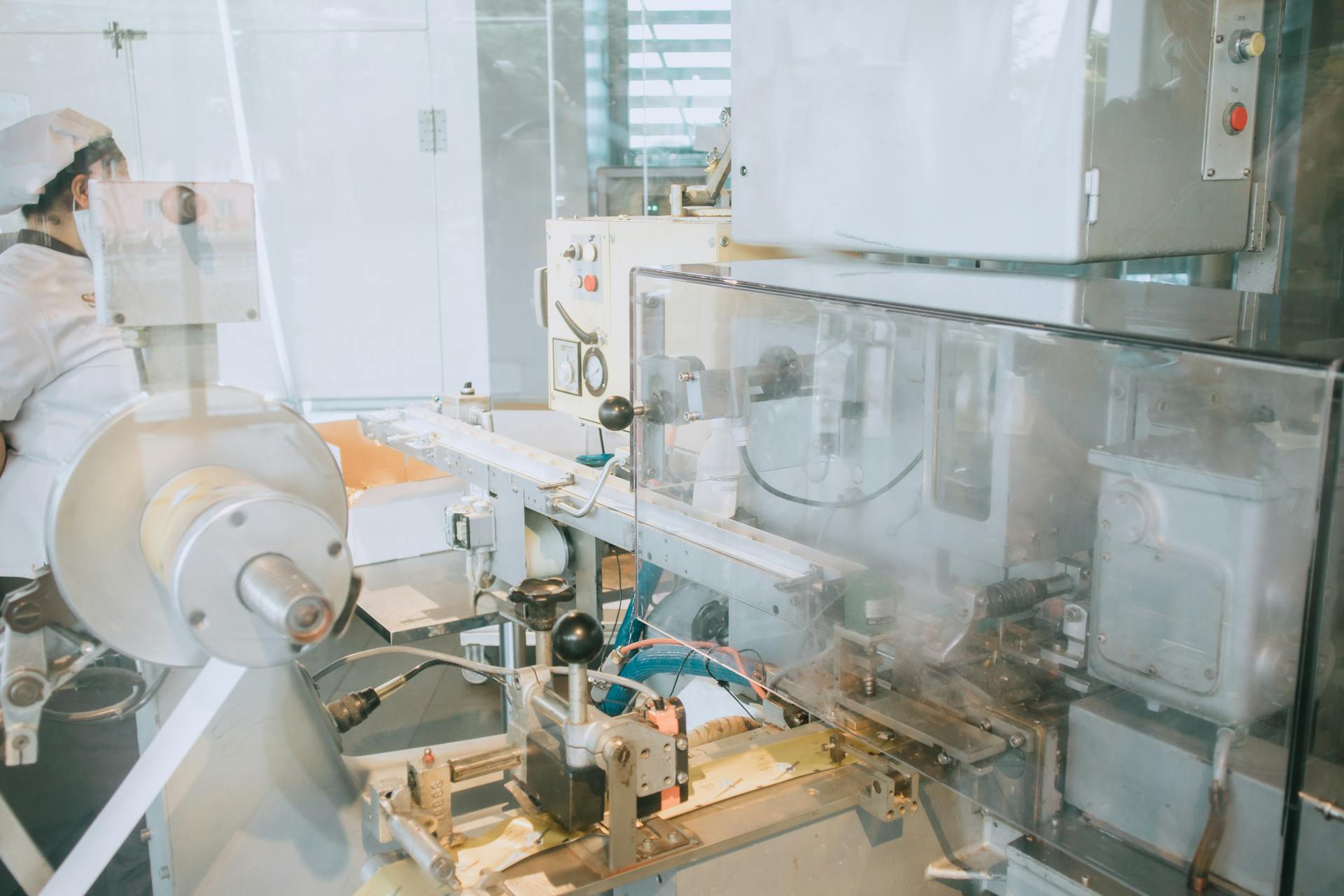

An in-line palletizer is a machine that automatically stacks products onto pallets, streamlining the packaging process for manufacturers. This efficient technology is commonly used in industries such as food, beverage, and pharmaceuticals.

In-line palletizers can process up to 100 products per minute, depending on the machine's design and the products being handled. This high-speed capability makes them ideal for high-volume production lines.

The key benefit of an in-line palletizer is its ability to reduce labor costs and increase productivity. By automating the palletizing process, manufacturers can allocate their workforce to more value-added tasks.

For your interest: Stretch Wrap Machine Repair

Key Features and Benefits

High-speed inline palletizers are equipped with advanced features that maximize efficiency, including robotic or conventional palletizing systems, high-speed processing, automated layer forming, advanced sensor technology, and space-saving design.

Robotic systems offer flexibility, while conventional systems provide structured stacking, and the choice depends on production needs. High-speed processing enables these palletizers to handle thousands of products per hour, cutting down packaging time and improving overall throughput.

These machines are designed to integrate into existing production lines, optimizing floor space while maintaining high efficiency. Their compact structure ensures they do not disrupt the workflow while enhancing productivity.

Inline palletizers can adapt to various product sizes and configurations, making them an ideal choice for expanding operations. They reduce dependency on manual labor, freeing up employees to focus on more valuable tasks and lowering operational costs.

Here are the key features of high-speed inline palletizers:

- Robotic or conventional palletizing systems

- High-speed processing

- Automated layer forming

- Advanced sensor technology

- Space-saving design

By automating the palletizing process, businesses can significantly boost their operational efficiency, reduce labor costs, and minimize the risk of product damage during handling and transportation.

Key Features

High-speed inline palletizers are equipped with advanced features that maximize efficiency, such as robotic or conventional palletizing systems, which can adapt to different production needs.

Robotic systems excel in adaptability, while conventional systems offer structured stacking.

These machines can handle thousands of products per hour, drastically cutting down packaging time and improving overall throughput.

If this caught your attention, see: B Pallets

Automated layer-forming mechanisms arrange products systematically, enhancing pallet stability and reducing the risk of product damage during transport.

Advanced sensor technology, including cameras and motion sensors, makes real-time adjustments to maintain accuracy and improve efficiency.

In-line palletizers are designed to seamlessly integrate into existing production lines, optimizing floor space while maintaining high efficiency.

Most in-line palletizers need 20-50 packages loaded per minute, with a stacking accuracy of no more than 5 mm deviation.

Highly functional software systems allow for changes to be induced while the processes are still in progress, ensuring no downtimes during operations.

An in-line palletizer consists of several key elements, including robotic or conventional palletizing systems, high-speed processing, automated layer forming, and advanced sensor technology.

Benefits of Automation

Automation is a game-changer for businesses, and it's not just a buzzword. By automating tasks, you can significantly boost your operational efficiency.

Increased efficiency is one of the primary benefits of automation. High-speed inline palletizers, for example, can handle large volumes of products swiftly, reducing downtime and increasing overall throughput.

Manual palletizing requires multiple workers, leading to higher labor costs and potential inefficiencies. By using an inline palletizer, you can reduce dependency on manual labor and free up employees to focus on more valuable tasks.

Automation also minimizes the risk of product damage during handling and transportation. An inline palletizer ensures uniform stacking, reducing product losses due to mishandling.

In addition to these benefits, automation can also improve workplace safety. Heavy lifting and repetitive manual stacking can lead to workplace injuries, including muscle strains and back problems. Automating the palletizing process eliminates these risks, providing a safer working environment.

Here are some key statistics on the benefits of automation:

Automation is a smart investment for businesses looking to improve their operational efficiency, reduce costs, and enhance workplace safety.

Applications and Industries

In-line palletizers are used in a variety of industries, each with unique demands and requirements. They're a crucial tool for businesses looking to streamline their operations and improve efficiency.

In the food and beverage industry, in-line palletizers are used to eliminate bottlenecks and handle different sizes and types of packaging. This flexibility is essential for operations that require adaptability.

High-speed palletizers are used in industries such as food and beverage, pharmaceuticals, and consumer goods. These machines can handle a wide range of products, from bottled drinks to cleaning supplies.

In the food and beverage industry, in-line palletizers help reduce operational costs by minimizing labor-induced errors. They also improve business efficiency and enhance operational efficiency due to safety and hygiene considerations.

In pharmaceuticals, high-speed palletizers are used to stack and transport products with extreme care, ensuring product safety. This is particularly important in industries where product quality and safety are paramount.

You'll find high-speed palletizers in a wide range of industries, including:

- Food and Beverage: Bottled drinks, packaged foods, and canned goods.

- Pharmaceuticals: Products that require careful stacking and transportation.

- Consumer Goods: Cleaning supplies, electronics, and more.

Machine Function and Automation

An in-line palletizer's primary goal is to achieve perfect speed and accuracy in handling products, efficiently reducing human efforts and increasing the packing process's productivity.

The machine's technical parameters include workload, cycle time, and stacking accuracy, with some in-line palletizers capable of loading 20-50 packages per minute with a stacking accuracy of up to 5 mm deviation.

With highly functional software systems, changes can be induced while the process is in progress, minimizing downtimes during operations.

In-line palletizers consist of several key elements, including a combination of high-end robotics and precision engineering that enables them to format and stack products with precision.

A fresh viewpoint: Stacking Pallets

Machine Function in Automation Operations

In automation operations, the machine function plays a crucial role in increasing productivity and reducing human efforts. The primary goal of an in-line palletizer is to achieve perfect speed and accuracy in handling products.

A good number of in-line palletizers need to load 20-50 packages per minute, which is a significant increase in productivity. These machines can achieve a stacking accuracy of up to 5 mm deviation.

The operation of a high-speed inline palletizer involves a structured process that includes product infeed, sorting and layer formation, pallet placement, stacking process, and final output. This entire process is completed in a matter of seconds.

Key elements of an in-line palletizer include a conveyor system, sensors, robotic arms, and software systems. These elements work together to ensure efficient and precise product handling.

Some in-line palletizers have a throughput of up to 10,000 p/h, making them ideal for high-volume production lines.

Robotic Efficiency and Performance Comparison

Robotic palletizers are a great option for plants with numerous product ranges, as they can accommodate multiple varying product sizes and shapes.

Their flexibility is a major advantage, allowing them to adapt to changing production needs. However, this flexibility comes at a cost, as robotic palletizers may not be as efficient as inline palletizers on homogeneous products.

Inline palletizers, on the other hand, perform better when a stable product size is compressed to accelerate discharge in a continuous flow system.

They are generally more efficient on homogeneous products than robotic palletizing systems with fewer production agendas.

Layer PAL 4.0

The PAL 4.0 Continuous palletiser is a high-speed machine capable of handling 40 to 100 cases per minute.

It's designed for lines running at a moderate pace, with a throughput of 40 to 100 cases per minute. This makes it suitable for various industries that require efficient palletizing.

The PAL 4.0 Continuous palletiser can create up to 9 pallet layers per minute and produces 90 pallets per hour. This level of performance is impressive, especially when considering the machine's compact design.

You might like: Pallet Jack Machine

The PAL 4.0 Continuous palletiser is specifically designed for high-speed single lines, making it an excellent choice for manufacturers looking to streamline their production processes.

Here are some key specifications of the PAL 4.0 Continuous palletiser:

This machine is an excellent addition to any production line, offering a high level of efficiency and productivity.

Palletizing Systems and Equipment

In-line palletizers come in different types, each designed to suit specific production environments and industries. High-level in-line palletizers operate from an elevated position, making them ideal for high-speed production lines.

These palletizers ensure smooth and efficient stacking while minimizing manual labor. They're perfect for stacking lightweight and uniform products.

Low-level in-line palletizers, on the other hand, function at ground level, making them ideal for facilities with space constraints. They provide easy access for maintenance and operation.

Robotic in-line palletizers utilize advanced robotic arms to handle products with precision and flexibility. They're ideal for businesses that deal with a variety of product shapes, sizes, and packaging styles.

Here are the key differences between the three types of in-line palletizers:

Types

There are three main types of in-line palletizers: high-level, low-level, and robotic palletizers. Each type is designed to suit different production environments and industries.

High-level in-line palletizers operate from an elevated position, making them suitable for high-speed production lines. They ensure smooth and efficient stacking while minimizing manual labor.

Low-level in-line palletizers, on the other hand, function at ground level, making them ideal for facilities with space constraints. They provide easy access for maintenance and operation.

Robotic in-line palletizers utilize advanced robotic arms to handle products with precision and flexibility. They're ideal for businesses that deal with a variety of product shapes, sizes, and packaging styles.

Here's a quick rundown of the key characteristics of each type:

- High-Level In-Line Palleti

- Operate from an elevated position

- Suitable for high-speed production lines

- Efficient for stacking lightweight and uniform products

Low-Level In-Line Palletizers:

- Products are fed at ground level

- Commonly used in facilities with limited space

- Easier maintenance due to ground-level access

Robotic In-Line Palletizers:

- Use robotic arms to pick and place products onto pallets

- Offer flexibility in handling different product shapes and sizes

- Ideal for businesses with diverse product lines

Palletizing Systems and Equipment

Palletizing systems and equipment are designed to efficiently and safely stack products onto pallets.

The Mizar Layer Forming system is a phase of pack rotating and layer forming that arranges packs according to a specific configuration required for palletising.

Manipulators are used to translate and/or rotate the product to form and compact the layer, minimizing shocks or stress, especially for fragile or unstable products.

The Mizar Layer Forming system is flexible and extremely precise, handling any type of pack, even the most delicate.

There are three variants of manipulators: Cartesian, robot, or gantry manipulators, all using brushless motorised gripping heads to guarantee maximum precision and optimal control of the clamping force.

The forming belt is driven by brushless motors to ensure maximum stability of the packs.

The Orion series palletizer has a throughput of 300, 600, or 240 p/h, meeting various customer requirements.

The TS 28 ST/AL Snake palletiser series automatically palletizes ends sleeves using a picking system that places the ends sleeves on the pallet according to different layouts.

The Mizar Advance - Layer forming system is a gantry layer forming system designed by OCME to enhance performance in layer forming processes to any palletizers.

This system is suitable for several products in the food and beverage sectors.

The PAL 4.0 Continuous palletiser is ideally suited for lines running at 40 to 100 cases / min, up to 9 pallet layers / min and outputs up to 90 pallets per hour.

Here are some key characteristics of palletizing systems and equipment:

- Mizar Layer Forming system: flexible and precise, handling any type of pack

- Manipulators: Cartesian, robot, or gantry variants, using brushless motorised gripping heads

- Orion series palletizer: throughput of 300, 600, or 240 p/h

- TS 28 ST/AL Snake palletiser series: automatic palletizing of ends sleeves using a picking system

- Mizar Advance - Layer forming system: gantry layer forming system for food and beverage sectors

- PAL 4.0 Continuous palletiser: throughput of 40-100 cases / min, up to 9 pallet layers / min

Robotic Ra-C Series

The Robotic Ra-C Series is a fully automatic palletizing system designed for flexibility. It can handle packs, boxes, or filled bottles with ease.

This system is generally installed at the end of the filling line, making it a convenient addition to any production process. Throughput can range from 1,000 to 10,000 packs per hour, depending on the specific needs of the operation.

Understanding and Choosing a Palletizer

To choose a palletizer that meets your needs, it's essential to understand your palletizing requirements. Start by examining the size, shape, and weight of your products, as well as the throughput of your operations to determine the volume and pace required.

The physical restrictions within your facility should also be taken into account, ensuring that the palletizer can fit with other equipment within the existing facility plan. Additionally, consider the degree of automation required, whether semi-automated or fully automated, based on your labor requirements and costs.

Here are some key factors to consider when choosing a palletizer:

- Product Type: What kind of products will you be stacking? Make sure the palletizer can handle the size, shape, and weight of your items.

- Speed Requirements: How many units do you need to palletize per hour? Different models have different throughput capabilities, so choose one that matches your production volume.

- Space Availability: Palletizers come in different sizes, so it’s important to ensure you have enough floor space for the machine and any associated equipment.

- Budget: While palletizers can be a significant investment, the cost savings in labor and efficiency can make them worth it.

Understanding Palletizing Needs

To effectively choose a palletizer, it's essential to understand your palletizing needs. This involves examining the basic characteristics of your product range, including size, shape, and weight.

The throughput of operations is also crucial to consider, as it will help you determine the volume and pace required for different operations. This will in turn help you decide on the right palletizer for your facility.

Physical restrictions within your facility, such as space and equipment, must be taken into account to ensure the palletizer fits seamlessly with other machinery. This will prevent any potential bottlenecks or inefficiencies.

A unique perspective: Palletizer Machine

The degree of automation required is another critical factor, with options ranging from semi-automated to fully automated. This decision should be based on labor requirements and costs, as well as your company's budget and resources.

Assessing your future product lines and scalability options is also vital, as it will help you choose a palletizer that can adapt to changing production needs. This will ensure you're not stuck with a palletizer that can't keep up with your business's growth.

Is Right for You?

If you're considering investing in a palletizer, it's essential to assess your production volume. A high production volume can benefit from a palletizer, especially if you're dealing with fast and consistent palletizing.

High labor costs or a shortage of workers can also make a palletizer a game-changer. In such cases, a palletizer can help bridge the gap and increase efficiency.

Available space and budget are crucial considerations. You'll need to ensure you have enough floor space for the machine and any associated equipment, and that your budget can accommodate the investment.

To determine the right palletizer for your business, consider the following factors:

Your product type, size, shape, and weight are also critical factors. Make sure the palletizer can handle your items, and choose a model that matches your production volume and speed requirements.

Frequently Asked Questions

What is the purpose of a palletizer?

A palletizer is used to stack and orient products into a single, manageable load. It streamlines product handling and storage for efficient shipment and storage.

What does a palletizing robot do?

A palletizing robot picks up products from a conveyor or layer table and positions them on a pallet, efficiently stacking and organizing goods. It uses a gripper, such as a mechanical, suction, or magnetic one, to handle the products with precision.

Sources

- https://www.afasystemsinc.com/high-speed-inline-palletizer/

- https://loyal-machine.com/blog/what-is-an-in-line-palletizer/

- https://www.directindustry.com/industrial-manufacturer/in-line-palletizer-116357.html

- https://www.afasystemsinc.com/what-is-a-high-speed-in-line-palletizer/

- https://www.ocme.com/en/orion-advance-p281

Featured Images: pexels.com