End of line packaging machines can significantly boost productivity and efficiency in manufacturing operations. These machines can process up to 200 products per minute, streamlining the packaging process.

Investing in end of line packaging machines can also lead to a reduction in labor costs. According to industry estimates, a single machine can replace up to 10 manual laborers, freeing up resources for more strategic tasks.

By automating the packaging process, manufacturers can minimize errors and ensure consistent product quality. This is particularly important in industries where product quality is critical, such as food and pharmaceuticals.

Implementing end of line packaging machines can also help companies adapt to changing market demands. For example, a machine can be easily reconfigured to accommodate different product sizes and packaging types.

Additional reading: End Cap

What Is Packaging?

Packaging is the process of preparing products for distribution and sale. It involves protecting the product during transportation and storage, and making it visually appealing to consumers.

There are different types of packaging, but the most common one is end-of-line packaging. This is the last step before the product leaves the manufacturer's dock and is sent to a store or warehouse.

End-of-line packaging typically involves placing the finished product into a case or carton, conveying it to be palletized, and receiving stretch wrapping. This process prepares the product for shipping and helps prevent damage during transportation.

Packaging is crucial for the success of a product. It can make or break a product's sales and reputation, and can even affect the consumer's perception of the product's quality.

Check this out: End-of-line Palletizing

End of Line Packaging Machines

End of Line Packaging Machines is a crucial step in the packaging process, ensuring products are safely and efficiently loaded into cases or trays for shipping. Automatic case packers, like those offered by Combi, can save time and increase accuracy by placing products into pre-formed cases.

Combi's drop packers, pick and place packers, and horizontal case loaders are just a few examples of the many options available for end of line packaging. These machines come in a range of loading configurations to suit different industries and budgets.

A different take: Lift End Gate

To streamline your end of line packaging process, consider investing in a case erector, which can form cases for packaging products at high speeds and reduce the need for manual labor. A Combi automatic case erector can be a durable and reliable solution for various industries.

Here's a quick rundown of the different types of end of line packaging machines:

End of Line Packaging Machines

Automatic case packers can save you time and increase accuracy by placing products into pre-formed cases. This is especially helpful in high-speed production environments.

Combi offers a range of case packer options, including drop packers, pick and place packers, horizontal case loaders, and semi-automatic packing machines.

Case erectors are an automated solution that forms cases for packaging products, folding and sealing the bottom flaps at high speeds. This reduces the need for manual labor and increases efficiency.

At Combi, you can find durable and reliable automatic case erector solutions for various industries and budgets. They can be standalone machines or integrate seamlessly with your existing packaging line.

Industrial case sealers help keep products secure by sealing up the remaining openings of the case, usually offered in tape or hot-melt glue options. This ensures that your products arrive at their destination safely and securely.

Intriguing read: Case Palletizing

Innovative Carton Technology

Innovative carton technology is a game-changer in the packaging industry. It ensures that your products arrive safely at the point of sale and are attractively presented.

The SOMIC 434 cartoning machine is a prime example of this technology, offering versatility and performance that sets standards in carton packaging. It can be used to pack products in tray cartons, wraparound cartons, or tray cover cartons.

One of the key benefits of the SOMIC 434 is its highly efficient format changeovers. This means that you can easily switch between different packaging configurations without wasting time or resources.

With a tray former, you can ensure that your cartons have square, stable loads with straight sides and properly applied glue. This results in a consistent product that's perfect for packaging.

Here are some of the key features of the SOMIC 434:

- Highly efficient format changeovers

Equipment Types

Tray forming machines are used to ensure square, stable loads with straight sides and properly applied glue for a consistent product.

They work at a high-speed using strong glue systems, erecting trays quickly and consistently for great results every time.

A Combi tray former can form a wide variety of tray styles, including slotted trays, trays with lids, and custom configurations.

A different take: Vacuum Formed Trays

Primary Equipment Purpose

The primary purpose of end-of-line packaging equipment is to protect the finished product during the transportation process.

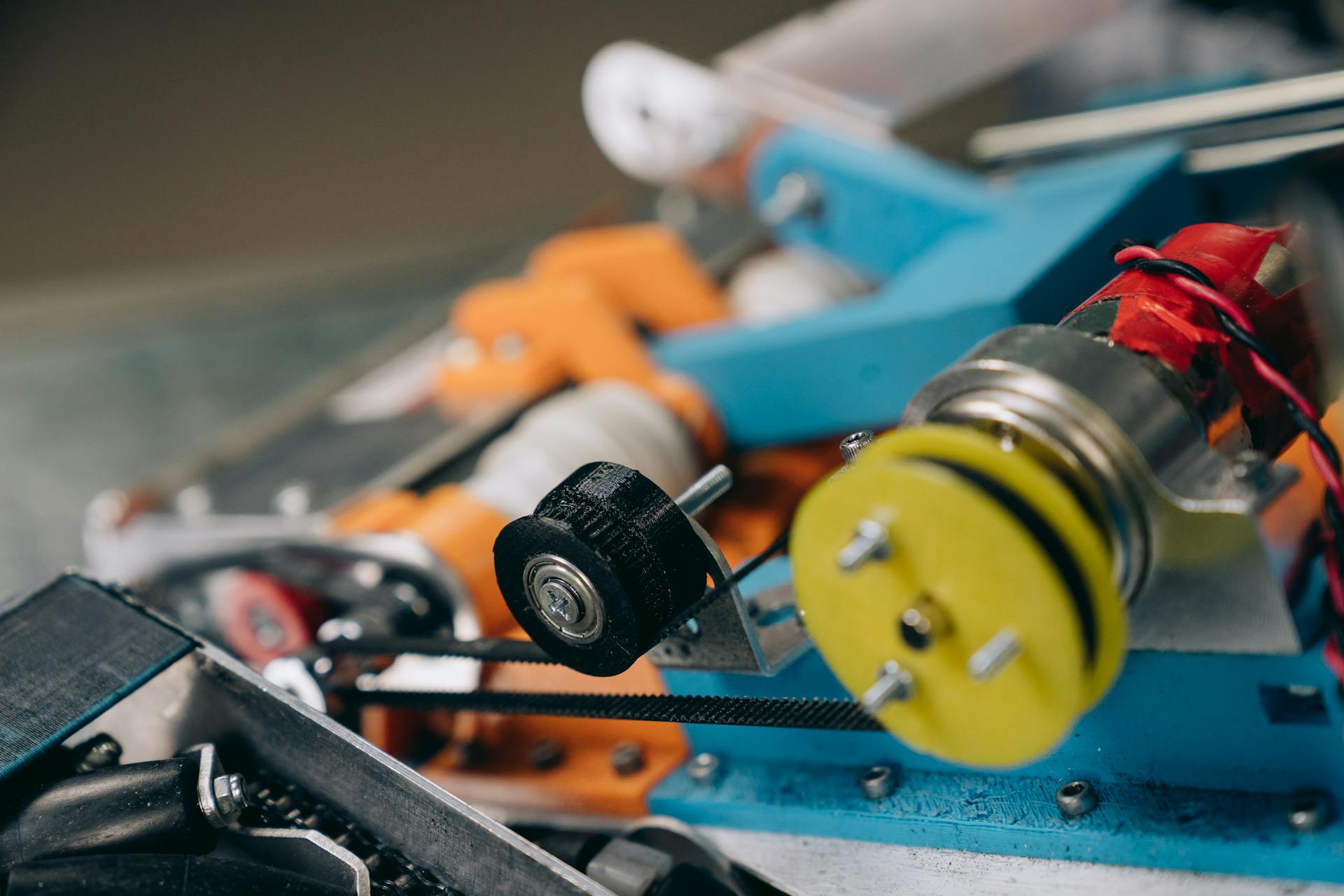

End-of-line packaging is the most consistent part of the packaging process, with many OEMs using robotics to maximize flexibility and automation in their equipment.

Its main goal is to safeguard the product from damage, which is crucial for maintaining its quality and integrity.

End-of-line packaging tends to have less overlap compared to Primary and Secondary Packaging, making it a more streamlined process.

Types of Machines

OMNI has engineered parts for various end-of-line packaging equipment types, including tray packing machines, case packers, case sealers, and more.

Tray forming machines are a type of equipment that ensures square, stable loads with straight sides and properly applied glue for a consistent product.

Here are some examples of machines that OMNI has worked with:

- Tray Packing

- Case Packers

- Case Sealers

- Case Erectors

- Shrink and Stretch Wrappers

- Palletizing Automation / Robotic Palletizer

- Bundling

- Labeling

A Combi tray former can form a wide variety of tray styles, including slotted trays, trays with lids, and custom configurations.

For more insights, see: Blister Packaging Tray

Robotic Palletizing

Robotic palletizing is a game-changer for packaging operations, automating the process of stacking cases onto pallets and reducing the need for manual labor.

This technology increases efficiency in both packaging and distribution processes, making it a valuable addition to any end-of-line packaging system.

Robotic palletizers are compact and portable, providing a flexible solution for a variety of applications.

Here are some key benefits of robotic palletizing:

- Automation reduces the need for manual labor

- Increased efficiency in packaging and distribution processes

Combi offers a compact, portable end-of-line palletizing solution that's perfect for companies looking to streamline their operations.

Speed

Automated end-of-line packaging systems can work much faster than manual labor, leading to higher throughput and increased productivity.

These machines can handle large volumes of products and packaging materials with minimal downtime, resulting in a smoother production line.

The SOMIC 434, for example, is designed to offer maximum performance on a compact footprint, making it an extremely efficient packaging process.

This compact design allows for more space to be utilized in a production line, making it ideal for businesses with limited space.

Recommended read: Corrugated Paperboard Production Line

Accuracy

Automated packaging solutions are highly accurate, reducing the risk of errors or damage to products during the packaging process.

This accuracy can save time and money by reducing the need for redoing the work or quality control inspections, along with replacing damaged materials or even products.

Automated packaging solutions are designed to minimize human error, which can be a significant factor in packaging mistakes.

Consistency

Consistency is key when it comes to equipment that performs the same tasks repeatedly. This ensures consistent quality.

Equipment designed to repeat tasks can improve overall product quality. I've seen this firsthand in manufacturing facilities where consistency is crucial.

Consistent performance also helps during shipping, where products need to withstand various conditions. This can lead to higher customer satisfaction rates.

Equipment consistency can be a game-changer for businesses that rely on precise and repeatable tasks.

Related reading: Custom Quality Control Stickers

Versatile vs Custom Machines

Multipurpose machines offer a more efficient solution than custom machines, allowing for greater flexibility and adaptability in packaging operations. They can handle multiple product sizes and seal cases using different materials, such as tape or hot melt glue.

Custom machines, on the other hand, are often inflexible and require costly modifications to accommodate changes in packaging requirements. This can lead to downtime and reduced productivity.

Automated end-of-line packaging systems can work much faster than manual labor, resulting in higher throughput and increased productivity. They can handle large volumes of products and packaging materials with minimal downtime.

One of the key benefits of multipurpose machines is their ability to optimize production lines and allocate floor space more efficiently. This is especially important for manufacturers dealing with high volumes of products.

Format changeovers are easier and more efficient with multipurpose machines, thanks to automated technology that minimizes downtime and increases efficiency. In fact, some machines can achieve time savings of up to 70 percent during format changeovers.

Individual collating and grouping systems, such as those offered by SOMIC, provide a high-performance solution for product handling. These systems can guarantee reliable picking, reorientation, and grouping before cartoning, even for large quantities and heavier products.

Multipurpose machines often offer a lower-maintenance and space-saving solution compared to custom machines. They also provide a more energy-efficient option, making them a more practical choice for manufacturers.

Check this out: Large Custom Stickers for Boxes

Compact Footprint

Compact Footprint is a game-changer in the packaging industry. Machines like the SOMIC 434 are designed to deliver maximum performance in the smallest possible space.

This means you can save valuable floor space for other important operations. The SOMIC 434's compact footprint is a perfect example of efficient packaging.

With a machine like the SOMIC 434, you can produce all desired cardboard packaging. It's a versatile solution that can adapt to your needs.

In fact, the SOMIC 434 is so space-efficient that it's an extremely compact and space-saving machine. This is especially important for manufacturers who need to make the most of their available space.

Stainless Steel Frame

The stainless steel frame is a game-changer in terms of durability and hygiene. It's made from a robust stainless steel material that's resistant to corrosion.

This makes it perfect for use in demanding environments where cleanliness is crucial. Its ease of cleaning is unmatched.

The stainless steel frame also provides a long service life for the machine, thanks to its stable nature. This means you can rely on it to keep running smoothly for a long time.

The integrated electrical installation within the stainless steel frame is a space-saving design that optimizes the machine's performance.

Intriguing read: Bike Frame Box

LED Corner Lighting

LED corner lighting is a game-changer for machine visibility. It shows the operating status of the machine at all times and from a distance.

This means you can tell whether the machine is in normal operation, a test run, or packaging mode from afar. This is an additional contribution to safety in the work process.

The LED corner lighting is a thoughtful design feature that makes it easy to see what's going on with the machine.

Simple Operation

Simple operation is a top priority for any packaging machine, and the SOMIC 434 delivers. Its intuitive touchscreen control makes it easy to adjust all machine settings with just a few taps.

With the SOMIC Quick Change technology, format changeovers are significantly faster. This means you can adapt to different packaging formats in no time, minimizing downtime and maximizing performance.

Benefits of Automation

Automated end-of-line packaging systems can significantly reduce labor costs by minimizing the need for manual labor. This is a huge advantage for businesses that rely heavily on manual labor in their packaging process.

By automating tasks, you can reduce the risk of workplace injuries that often occur from repetitive or physically demanding tasks. This is a major concern for companies that prioritize employee safety and well-being.

Automated systems require less manual labor, which can lead to a more efficient and streamlined packaging process. This, in turn, can increase productivity and reduce downtime.

With automated end-of-line packaging systems, you can expect to see a significant reduction in labor costs. This can be a game-changer for businesses that are looking to cut costs and improve their bottom line.

SOMIC Machines

SOMIC machines are designed to deliver top performance and sustainability. They offer multi-format flexibility, which means they can handle various packaging tasks with ease.

Their innovative technologies minimize energy consumption without sacrificing performance. This makes them particularly durable and environmentally friendly.

SOMIC machines are built to last, with a robust design that ensures maximum stability. This leads to an incomparable longevity of the system.

Their lamella chain is a high-performance solution that efficiently picks up, reorients, and groups products before cartoning. It's perfect for large quantities and heavy products.

The lamella chain's tool-less format changeover system allows for quick format changes, taking just minutes to switch between upright and horizontal grouping tasks.

SOMIC machines are designed to meet customer requirements for efficiency and versatility. They're the perfect choice for companies looking for future-oriented technology that protects the environment.

By sourcing assemblies and components from local suppliers, SOMIC reduces its ecological footprint. This approach also guarantees consistently high quality and fast, reliable supply of necessary parts.

Worth a look: High End Packaging Companies

Challenges and Solutions

Custom machines can be a major obstacle in end-of-line packaging, as they often aren't flexible enough to adapt to changing packaging needs.

Specialized, single-purpose equipment can lead to more downtime and higher maintenance costs, and can also limit the overall floor space available for other operations.

Manufacturers can avoid downtime caused by machine changeovers and reduce maintenance costs by using versatile and durable machines that offer a broader range of capabilities.

With the right machines, manufacturers can enjoy greater flexibility in their packaging processes, making it easier to adapt to changing demands.

Sustainability

Sustainability is a top priority for companies that want to make a positive impact on the environment. SOMIC's new 434 packaging machine generation represents a commitment to sustainable packaging solutions.

The machines are designed with low wear and high energy efficiency in mind, making them particularly durable and environmentally friendly. This focus on sustainability doesn't come at the cost of performance.

By using innovative technologies, SOMIC is able to minimize the energy consumption of their packaging machines. This approach ensures that the machines can meet customers' requirements for efficiency and versatility.

SOMIC's commitment to sustainability also extends to their supply chain. They source many of their assemblies and components from local suppliers, reducing the need for long-distance transportation and minimizing their ecological footprint.

A binding code of values forms the basis for all of SOMIC's supplier relationships, ensuring that their partners share their commitment to sustainability.

Addressing Common Solution Challenges

End-of-line packaging machines can be a major challenge due to their inflexibility. They're often designed to perform specific tasks, but this can lead to more downtime and higher maintenance costs.

Custom machines can also be a problem, as they're not always flexible enough to adapt to changing packaging needs. This can hinder productivity and increase costs.

Specialized, single-purpose equipment can require a lot of space, limiting the overall floor space available for other important operations. This can be suboptimal for manufacturers.

Wayne Automation's approach to end-of-line packaging addresses these concerns by providing machines that are versatile and durable. With a broader range of capabilities, manufacturers can avoid downtime caused by machine changeovers and reduce maintenance costs associated with specialized equipment.

Suggestion: Southern California Packaging Equipment

Frequently Asked Questions

What is EOL packaging?

EOL packaging is the final stage of manufacturing where products are prepared for distribution and sale through secure and attractive packaging. This crucial phase ensures products are ready for the market.

What machine is used to make packaging?

Bagging machines are used to package items into bags for distribution or sale. They come in various types, suitable for different industries and product types.

What are the components of a packaging line?

A packaging line typically consists of conveyor systems, filling machines, capping and sealing machines, and labeling machines, all working together to efficiently package products. These components ensure accurate and precise packaging, streamlining the production process.

Sources

- https://omnitechnologies.com/end-of-line-packaging/

- https://blog.combi.com/news/automated-end-of-line-packaging-solutions-maximize-efficiency-productivity

- https://www.dssmith.com/products-services/packaging-machinery/end-of-line-packaging-machines

- https://www.somic-packaging.com/en/solutions/end-of-line-packaging-machine-somic-434.html

- https://wayneautomation.com/news/end-of-line-packaging/

Featured Images: pexels.com