Blister packaging trays are a popular choice for packaging small to medium-sized items, such as pills, tablets, and electronics.

They provide a secure and protective environment for the products, keeping them safe from damage during shipping and storage.

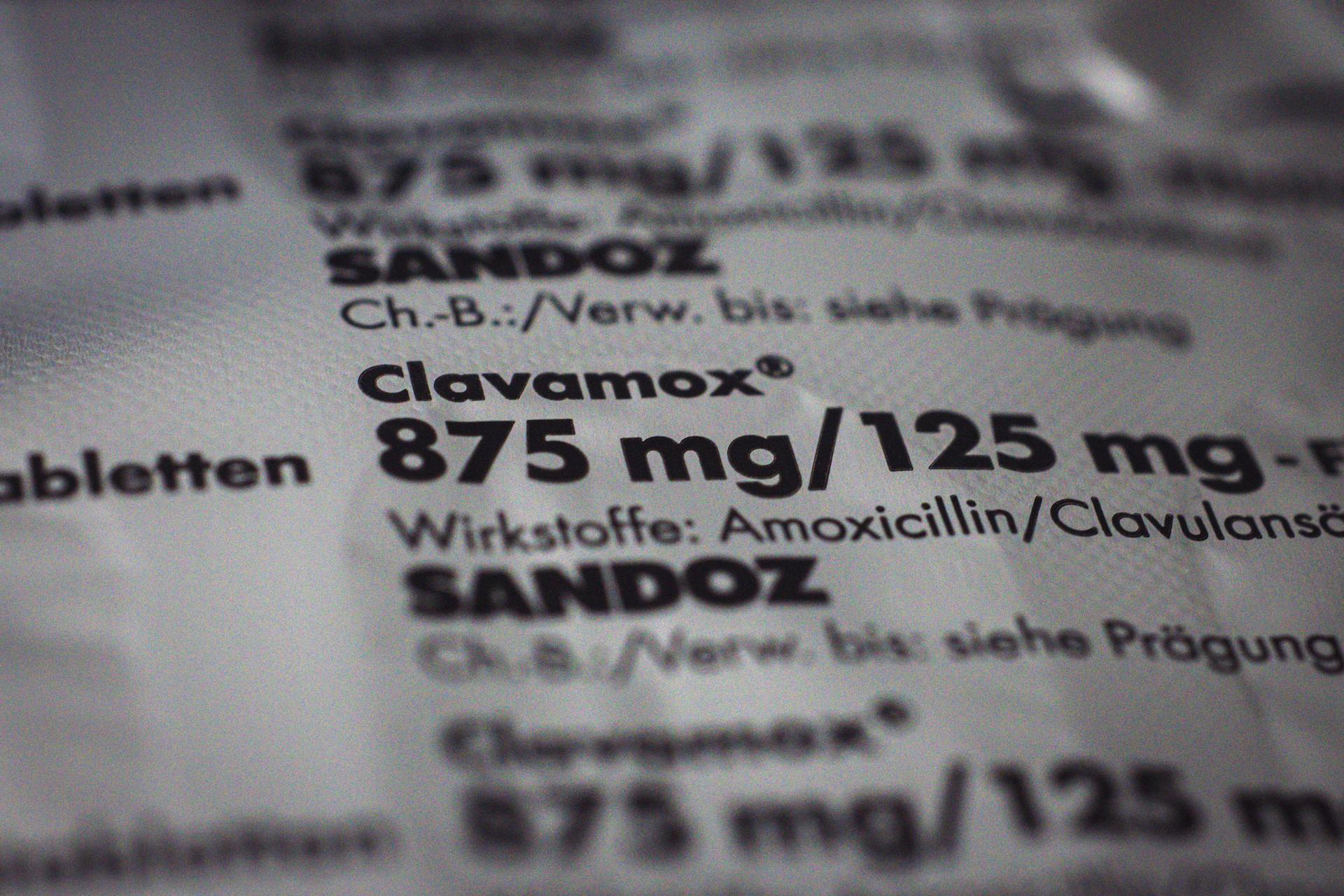

Blister packaging trays are often used in the pharmaceutical industry, where they help to keep medications organized and easy to dispense.

This type of packaging is also commonly used in the electronics industry, where it helps to protect sensitive devices from scratches and damage during shipping.

If this caught your attention, see: Blister Packaging Machine Pharmaceutical Industry

Materials and Manufacturing

Blister packaging trays are made from a variety of materials, including HIPS and PET.

These materials are commonly used because they offer a good balance of durability and flexibility. For example, the Europack Machines plastic blister tray is made from HIPS and PET.

The thickness of the material can also vary, with some trays having a thickness of 0.5 - 2 mm, while others can be as thick as 1 - 3 mm. This allows manufacturers to choose the right material and thickness for their specific needs.

Some common uses for plastic blister trays include packaging inserts or shipping trays. The Europack Machines plastic blister tray is designed for packaging, and is made from plastic with a thickness of 0.5 - 2 mm.

Here are some common materials used to make blister packaging trays:

- PET

- PVC

- PE

- PP

- Polystyrene

What is Thermoforming?

Thermoforming is a process of heating thermoplastic sheet and placing it over a mold, under vacuum, until cooled.

Thermoplastic sheet can be made from various materials, including PET, PVC, PE, PP, and Polystyrene.

Blister tray thermoforming specifically involves the formation of blister trays with cavities through heating and use of pressure, sometimes with a plug-assist feature.

The thickness of the material determines whether the manufacturing process uses rolled sheets (thin gauge) or pre-cut stacked sheets (heavy gauge).

Thin gauge material is commonly used in disposable packaging, especially in retail markets.

Heavy or thick gauge material is used for permanent components in items like refrigerators, automobiles, and spas.

To produce good quality blister packaging, attention must be paid to the blister forming mold and processing technology.

Readers also liked: Packaging Materials Foam Sheets

Abs Plastic

ABS Plastic is a versatile and durable material used in various applications, including packaging and manufacturing. It's a type of thermoplastic that can be molded and shaped to create complex designs.

ABS stands for Acrylonitrile Butadiene Styrene, a combination of three different materials that make it strong and impact-resistant. This property makes it ideal for applications where durability is a must.

ABS plastic trays are commonly used in packaging and shipping due to their ability to protect fragile items during transit. Europack Machines, a manufacturer, offers ABS plastic trays in various colors, including blue and black.

The thickness of ABS plastic trays can range from 0.5 to 2 mm, depending on the intended use. This thickness provides the necessary strength and protection for the items being packaged.

Here's a comparison of the thickness of ABS plastic trays with other materials:

ABS plastic trays are also known for their high durability and resistance to impact, making them an excellent choice for packaging and shipping. However, it's essential to note that ABS plastic is not as eco-friendly as some other materials, such as PET or PVC.

Overall, ABS plastic trays offer a range of benefits, including durability, impact resistance, and versatility. However, it's crucial to consider the environmental impact of using ABS plastic in packaging and manufacturing.

Related reading: Opening Plastic Blister Pack

Recycled - 30-100% Recyclable

Recycled packaging is a game-changer for the environment.

Recycled blister packaging can be made from 30-100% recyclable material.

The experimental methods used to test this packaging meet several international standards, including ISO 15985, which is widely recognized across the globe.

In the EU, this packaging meets the stricter standards set by EN ISO 15985.

In North America, it meets the standards set by ASTM d5511 in the USA and Canada.

In China, the packaging meets the national standards set by GB / T 33797-2017 and GB / T 20197-2006.

Manufacturers

Manufacturers play a crucial role in creating customized packaging solutions. Thermoformed trays, for example, are a reliable option that can be tailored to display products effectively.

These trays have durability and visibility, making them ideal for showcasing items. They also ensure safety during transportation, which is a significant advantage.

Blister trays, another type of packaging solution, are often used to firmly fix and display products.

Uses and Applications

Blister packaging trays are incredibly versatile and can be used in a variety of industries.

Blister trays are designed to protect medications from moisture, air, and contaminants, prolonging shelf life and preserving potency. This is especially important for medications that require precise storage conditions.

Blister packaging trays are also used in the packaging of consumer goods, such as toys and hardware. This type of packaging is ideal for products that require individualized packaging and protection.

In addition to consumer goods, blister trays are used in the packaging of food products. This type of packaging is perfect for products that need to be kept fresh and protected from contaminants.

Blister trays are a cost-effective solution for manufacturers, with low production costs and the ability to be produced in large quantities. This makes them an ideal choice for mass distribution.

Here are some of the best uses of blister trays:

- Toys

- Hardware

- Consumer goods

- Medicines

- Food products

Uses of Pills

Pills are an essential part of medication, and their packaging plays a crucial role in ensuring their safety and effectiveness.

Blister packaging pills trays are designed to protect medications from moisture, air, and contaminants, prolonging shelf life and preserving potency.

Individual pills are encapsulated in blister packs, which reduces the risk of damage, degradation, or loss of efficacy during storage and transportation.

This protective function ensures that the medication remains safe for consumption throughout its intended shelf life, maintaining the manufacturer's quality standards.

Blister packs are divided into individual dose compartments, making it easy for patients to manage their medications and take them as prescribed.

This functionality improves patient adherence to medication regimens and enhances overall health outcomes.

The blister packaging pill tray is designed with safety features, such as child-resistant locks, to prevent unauthorized access to medications.

These safety features are especially vital for households with children, reducing the risk of accidental ingestion.

Blister packaging provides visible evidence of tampering, ensuring consumers of the product's safety and integrity.

Any alteration or breach in the packaging is easily detectable, which safeguards the medication from potential contamination or adulteration.

Blister packaging is also a cost-effective solution for manufacturers, with low production costs and the ability to be produced in large quantities.

This minimizes overall packaging expenses while still providing sufficient protection and display functions, making it ideal for mass distribution.

For more insights, see: Shelf Stable Packaging

Where to Use

Blister trays are incredibly versatile, and you can use them to package a wide range of products.

Toys, for example, are a great fit for blister trays. They keep fragile items safe and secure, making them ideal for packaging small toys and games.

Hardware is another area where blister trays shine. They protect delicate parts and make it easy to identify the contents of each tray.

Consumer goods, like household items and electronics, also benefit from blister tray packaging. It keeps them organized and protected during shipping and storage.

Medicines, of course, require special care, and blister trays are designed to meet those needs. They keep pills and medications secure and easy to dispense.

You can also use blister trays for food products, such as snacks or spices. This keeps them fresh and protected from contamination.

Here are some of the best uses for blister trays:

- Toys

- Hardware

- Consumer goods

- Medicines

- Food products

Difference Between Strip

Blister packaging trays are widely used in various industries, but have you ever wondered how they differ from strip packaging? Blister packaging has a cold-formed cavity that protects products from tampering and environmental damage.

Blister packaging is limited to the use of plastic material only, whereas strip packaging has a wide range of materials, including plastic, regenerated cellulose, foil, and paper.

Strip packaging has a larger packaging section compared to blister packaging, which is because it lacks pre-formed cavities. This makes it a more versatile option for packaging products.

The manufacturing process of strip packaging involves the formation of a cavity around the product during the sealing stages, rather than having a pre-formed cavity like blister packaging.

For more insights, see: Plastic Blister Pack

Customization and Options

Blister packaging trays can be made from a variety of materials, including PVC, PET, and aluminum foil, each with its own unique properties and benefits.

The design of the blister tray can be customized in many creative ways, depending on how the pills need to be shaped. The size, number of compartments, and even their geometrical shapes can all be altered for specific needs.

You can choose from a range of seal types, including heat seals, cold seals, and peelable seals, depending on how securely the contents should be packaged and how easily they need to be accessed.

Here are some customization options available for blister packaging pills trays:

Customization options can help you differentiate your product and make it more appealing to your customers.

Clear Slides for Retail & Crafts

ClearBags offers a range of slide blister trays perfect for retail, crafts, hardware, and fishing tackle items. These trays feature crystal clear PET materials and are made with food-safe materials, making them ideal for a variety of products.

Available in packs of 25, these trays are easy to use and customize. Simply slide a custom card through the back flaps and secure it with a stapler or heat sealer.

Fast retail-ready stock solutions are a big plus, and ClearBags delivers. Their slide blister trays are perfect for products like fishing tackle, crafts, hardware, pet supplies, and bath products.

Here are some key features of ClearBags' slide blister trays:

- Available in packs of 25

- Easy to use and customize

- Fast retail-ready stock solution

- Food safe materials, recyclable

- Ideal for fishing tackle, crafts, hardware, pet supplies, bath products and more!

Custom Guide

Customization options for blister packaging are vast, and it's essential to consider various factors to ensure you get the right fit for your product. You can choose from a range of materials, including PVC, PET, and aluminum foil, each with its unique characteristics.

The design of the blister tray can be customized to suit your needs, with options for shape, size, and number of compartments. This allows you to tailor the packaging to your product's specific requirements, making it more attractive and functional.

Printing and branding options are also available, enabling you to differentiate your product and convey essential information to users. You can print your logo, insert, or any other visuals that will make your product stand out.

Seal types can be customized to accommodate different products, with options like heat seals, cold seals, and peelable seals available. This ensures that your product is securely packaged while also providing easy access for consumers.

Here are some key customization options to consider:

By considering these customization options, you can create blister packaging that not only protects your product but also enhances its appeal and functionality.

Benefits and Advantages

Blister packaging trays offer several benefits and advantages that make them a popular choice for various industries.

Blister trays help maintain the freshness of your product, which is especially important for food and pharmaceutical products.

One of the key advantages of blister trays is that they offer secure packaging, ensuring that your product stays safe and protected during transportation and storage.

Blister trays also provide a visually appealing packaging solution, allowing clients to visualize the product before making a purchase.

Here are some of the benefits of blister trays in a nutshell:

- Blister trays help in maintaining the freshness of your product.

- The serving size is easily managed with blister trays.

- Blister trays offer attractive packaging.

- Blister trays provide secure packaging.

- Blister trays help in product customization.

Quality Control and Assurance

Quality Control and Assurance is a top priority for blister packaging tray manufacturers.

We conduct leakage tests to ensure that blister trays don't leak, which can damage the products inside.

Leakage tests are a crucial step in the quality control process.

Blister trays are also put through durability tests to see if they can withstand different environmental factors like heat and wear and tear.

These tests help determine if the blister trays can hold up over time.

In addition to durability tests, strength tests are conducted to ensure that blister trays are strong enough to hold products until they reach the final customer.

Will Provide Free Samples

Elsepack will provide you with free blister tray samples upon your request.

If you're interested in getting a sample, be aware that you'll have to cover any shipping charges that may apply.

Ultimate FAQ Guide

Blister packaging trays are a popular choice for product packaging, and for good reason. They offer a unique combination of protection, visibility, and convenience that's hard to beat.

You can use blister trays in a variety of settings, including retail stores, pharmacies, and even online marketplaces. They're perfect for showcasing small to medium-sized products, such as cosmetics, electronics, and pharmaceuticals.

The size limitations for blister trays are relatively flexible, but they typically range from small to large. You can find blister trays in various sizes to fit your specific product needs.

Blister trays are made from a variety of materials, including plastic, paper, and foil. The choice of material depends on the product being packaged and the desired level of protection.

Material thickness is indeed critical in blister trays, as it affects the overall strength and durability of the packaging. Thicker materials provide better protection, but may also increase costs.

You have two main options when it comes to blister trays: stock and custom. Stock blister trays are pre-made and widely available, while custom blister trays are designed to your specific specifications.

Here are the key differences between blister trays and clamshell trays:

Blister trays can be thermoformed to create a wide range of shapes and sizes. This process allows for complex designs and intricate details.

ISO 14000 compliance is important when importing blister trays, as it ensures that the packaging meets environmental standards.

The benefits of blister trays thermoforming include increased flexibility, reduced material waste, and improved product protection.

Blister trays are different from strip packaging in that they provide individual product protection, whereas strip packaging holds multiple products together.

The advantages of blister trays include improved product visibility, ease of use, and reduced packaging waste.

Elsepack, a leading blister tray manufacturer, offers a range of services, including 2D and 3D drawing creation. They can complete this process in a relatively short amount of time.

Elsepack has a minimum order quantity (MOQ) for blister trays, which ensures that they can meet your specific production needs.

Elsepack provides free blister tray samples, allowing you to test their quality and design before placing a large order.

Elsepack's delivery times for blister tray orders are relatively fast, depending on your location and production schedule.

Elsepack takes quality control seriously, using a variety of methods to ensure that their blister trays meet high standards.

Elsepack can help with shipping blister trays from China, making it easier to get your products to market.

Elsepack offers a range of blister tray color options, allowing you to customize your packaging to fit your brand.

Yes, Elsepack can brand personalized logos on blister trays, adding an extra layer of customization to your packaging.

On a similar theme: Custom Quality Control Stickers

Q1: Industries Using

Blister packaging trays are widely used in various industries to protect products from damage. They're a popular choice in the pharmaceutical and medical sectors, where they safeguard drugs and pills from tampering, moisture, and other environmental damage.

The pharmaceutical industry relies heavily on blister packaging trays to ensure the integrity of their products. In fact, they're used to package medicines, which require special protection.

Consumer goods, electronics, and food packaging also benefit from blister packaging trays. These industries use them to shield their products from damage, just like the pharmaceutical industry.

You can find blister packaging trays used in a variety of products, including toys, hardware, and food products. They're a versatile packaging solution that offers protection and convenience.

Here are some examples of industries using blister packaging trays:

- Toys

- Hardware

- Consumer goods

- Medicines

- Food products

Q5: Can Be Recycled?

Some types of blister packs can be recycled, but this success varies depending on the materials used in creating the packaging.

Aluminum foil blister packs have a higher recycling rate than plastic-only packs.

Plastic-only blister packs have to undergo complex procedures for them to be recyclable.

Continual advancement in technologies is aimed at enhancing the recyclability of blister packaging.

A different take: Pet Plastic Tray

Frequently Asked Questions

What is the difference between a blister pack and a bubble pack?

A blister pack is a small, individual package, while a bubble pack is a larger, customized version of a blister pack. Essentially, bubble packs are bigger and more tailored to specific needs than traditional blister packs.

Featured Images: pexels.com