The Omnicell Blister Pack is a game-changer for hospitals and pharmacies. It reduces error risk by up to 90%, which is a huge improvement over traditional packaging methods.

With the Omnicell Blister Pack, medications are precisely organized and labeled, making it easier to identify the right medication and dose. This reduces the likelihood of medication errors.

The Omnicell Blister Pack also saves time by streamlining the dispensing process. It can dispense up to 100 medications per hour, which is a significant increase over traditional packaging methods.

By using the Omnicell Blister Pack, pharmacies and hospitals can improve patient safety and efficiency.

See what others are reading: Blister Pack Medication

Benefits of Omnicell Blister Pack

Omnicell blister packs are designed to improve patient care and healthcare outcomes.

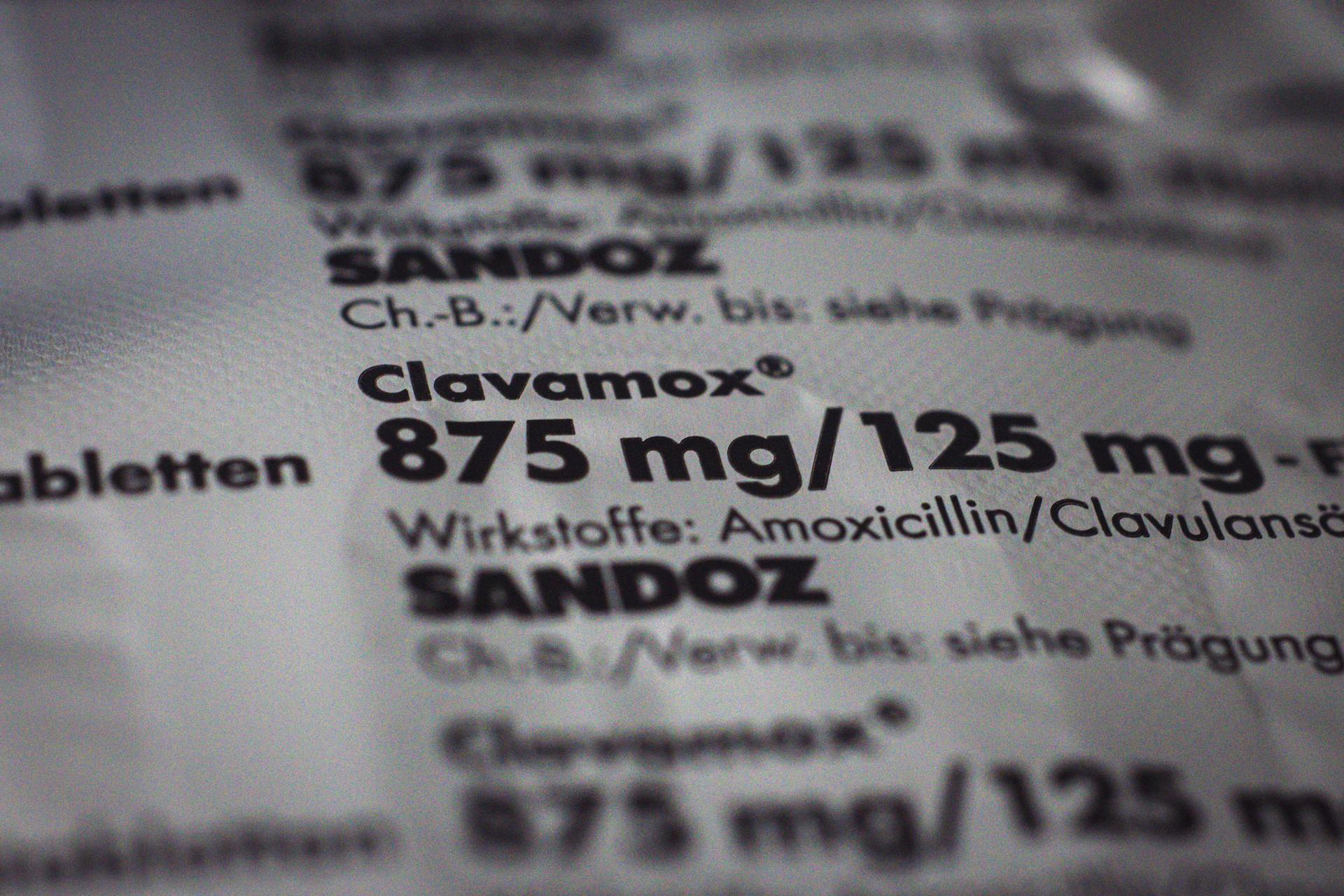

Omnicell's SureMed+ cards are made up of two components: a paperboard card and a thermoformed blister tray.

The paperboard card is printed on-site at the pharmacy with patient and drug information, including patient name, drug name, dosing, administration time, and more.

Cards may be printed in up to eight colors, utilizing Omnicell-qualified printers.

Intriguing read: Blister Card Sealing Machine

Free Up Time

Freeing up time is a valuable benefit of the Omnicell Blister Pack, particularly for pharmacists. With the VBM 200F, production time for blister cards is significantly reduced, allowing pharmacists to focus on more important tasks.

This automation enables pharmacists to automatically check blister adherence cards, streamlining their workflow and saving time.

Blister Packaging Benefits: Part III

Omnicell's blister packaging solutions are designed to provide patient and healthcare benefits, particularly in single and multi-dose applications.

Omnicell produces blister cards with up to eight colors, utilizing Omnicell-qualified printers, which allows for customizable patient and pharmacy details.

The SureMed+ card, used by Holyoke Health Center, is a seven-day, four-time pass cold-seal, bi-fold card that comes in both single-dose and multimed applications.

Single-dose cards come in 14, 28, 30, 31, 32, 60, 62, and 90-day cavities with four different depths, while multimed cards come in 28, 30, 31, and 35-cavity configurations in varying depths.

The multimed card is made up of two components: a paperboard card and the thermoformed blister tray, which are provided separately.

A unique perspective: Unit Dose Pack

Holyoke purchases both custom cards and blisters in quantities of 250/box, allowing for efficient and cost-effective packaging.

The VBM 200F machine is used to dispense medications into the blister cavities, and a vision system photographs the meds before placing them into the cavities.

The machine cross-references each medication based on size, shape, and color, ensuring accurate filling and minimizing errors.

The technician scans the RFID-tracked tray to pull up the patient order and images of all the medications filled into the tray, and then prints the patient-specific card that corresponds to the filled tray.

The packs are manually sealed using an alignment guide and rubber roller, and the printer is separate from the VBM machine, allowing for flexibility and customization.

The content that prints to each of the cards can be customized based on the requirements of the pharmacy, typically including patient and pharmacy details, a 3D barcode, drug dosage instructions, and prescribing physician information.

Curious to learn more? Check out: Blister Pack Machine Pharmacy

Omnicell's Blister Packaging Solution

Omnicell's MPS EXL-Packaging press is a record-breaking 118 feet long, making it an impressive addition to their facility.

The press produces blister packaging at speeds of over 500 ft/min and can handle complex applications in a single pass.

Omnicell's press is equipped with hot air dryers, automatic unwinders, inspection technology, and a stacker, making it a comprehensive solution for blister packaging production.

It prints better, has quicker changeovers, is fully automated, modular, and easy to maintain, exceeding Omnicell's expectations and becoming a valuable asset to their operations.

Omnicell's press also features Connectivity solutions, allowing MPS technicians to remotely support and update the machine, providing a hassle-free experience for the company.

With this solution, Omnicell is well-equipped to handle the increasing demands of the pharma packaging market and is confident in their ability to produce high-quality blister packaging.

Curious to learn more? Check out: Blister Pack Trays

Reducing Error Risk

Omnicell's Blister Packaging Solution is designed to minimize errors and ensure patient safety. The VBM 200F machine uses barcode, RFID, and Vision Check technologies to audit each blister card throughout the filling process.

The Vision Check technology photographs the medications dispensed into the blister cavity, cross-referencing each medication based on size, shape, and color. This ensures that the correct medication is placed in the correct cavity.

The machine also flags potential errors, such as medications that appear to be touching, allowing the technician to review and address the issue. This reduces the risk of errors and ensures that each patient receives the correct medication.

The VBM 200F machine is supported by an HP printer, which allows for customized printing of patient and pharmacy details, as well as a 3D barcode that links the card to the filling report. This helps to streamline the process and reduce errors.

The machine does not seal the card to the blister, but rather the packs are manually sealed using an alignment guide and rubber roller. This ensures that the card and blister are securely attached, reducing the risk of errors and ensuring patient safety.

Omnicell Increases Production with EXL-Packaging Flexo Press

Omnicell increases production with EXL-Packaging flexo press to meet the demands of the market. This was a crucial decision, as they were already at max press capacity with their existing packaging.

The new MPS EXL-Packaging 680 flexo press is equipped to produce complex blister packaging in a single pass, with a record length of 118 feet. It includes various OEM niche equipment, such as hot air dryers, automatic unwinders, inspection technology, and a stacker.

Omnicell's MPS press produces at speeds of over 500 ft/min, making it an incredibly efficient solution. Chris Hayes, Manufacturing Engineer at Omnicell, praises the press, saying "It prints better, has quicker changeovers, is fully automated, modular and easy to maintain."

The press was equipped with Connectivity solutions, allowing MPS technicians to remotely access and support the machine. This has been a game-changer for Omnicell, enabling them to troubleshoot and update the press with ease.

Omnicell's SureMed+ blister cards are used by Holyoke Health Center, which procures them from Omnicell's St. Petersburg facility. These cards are made up of a paperboard card and a thermoformed blister tray, with patient and drug information printed directly onto the card.

You might enjoy: Blister Pack Packaging

The cards and blisters are provided separately, with Holyoke purchasing custom cards and blisters in quantities of 250/box. The machine used by Holyoke, the VBM 200F, is supported by an HP printer, which prints the patient-specific card that corresponds to the filled tray.

Omnicell's MPS EXL-Packaging press has become a valuable asset to their St. Petersburg operations, exceeding all expectations and meeting the increasing demands of the pharma packaging market.

About

Omnicell's Blister Packaging Solution is designed to streamline medication management and improve patient safety.

Omnicell is a leading provider of medication management solutions, with a rich history of innovation in the healthcare industry.

Their blister packaging solution is specifically designed to reduce medication errors and improve patient outcomes.

By using Omnicell's blister packaging solution, healthcare facilities can reduce the risk of medication errors by up to 95%.

This solution is also designed to improve patient safety by reducing the likelihood of medication mix-ups and overdoses.

Omnicell's blister packaging solution is a key component of their comprehensive medication management system.

Their solution is designed to work seamlessly with existing pharmacy systems, making it easy to integrate into existing workflows.

By using Omnicell's blister packaging solution, healthcare facilities can also reduce costs associated with medication waste and errors.

Sources

- https://www.omnicell.co.uk/the-future-of-retail-pharmacy/monitored-dosage-system-automation/vbm-200f-blister-card-packaging-automation/

- https://www.mps-printing.com/news/omnicell-increases-pharmaceutical-blister-packaging-production-with-mps-exl-packaging-flexo-press

- https://www.packaging-gateway.com/news/omnicell-introduces-new-adherence-blister-packaging-solution-suremed-blister-cards-4675784/

- https://issuu.com/cpublish/docs/pia_march_22_/s/15192872

- https://www.healthcarepackaging.com/design-materials/adherence-delivery/article/13295675/blister-packaging-yields-patient-healthcare-benefits-part-iii

Featured Images: pexels.com