A corrugated paperboard production line is a complex system that requires careful planning and setup to produce high-quality products.

The first step in setting up a corrugated paperboard production line is to select the right raw materials, including paper pulp, glue, and other additives.

A typical corrugated paperboard production line consists of multiple machines, including a corrugator, slitter, and folder-gluer.

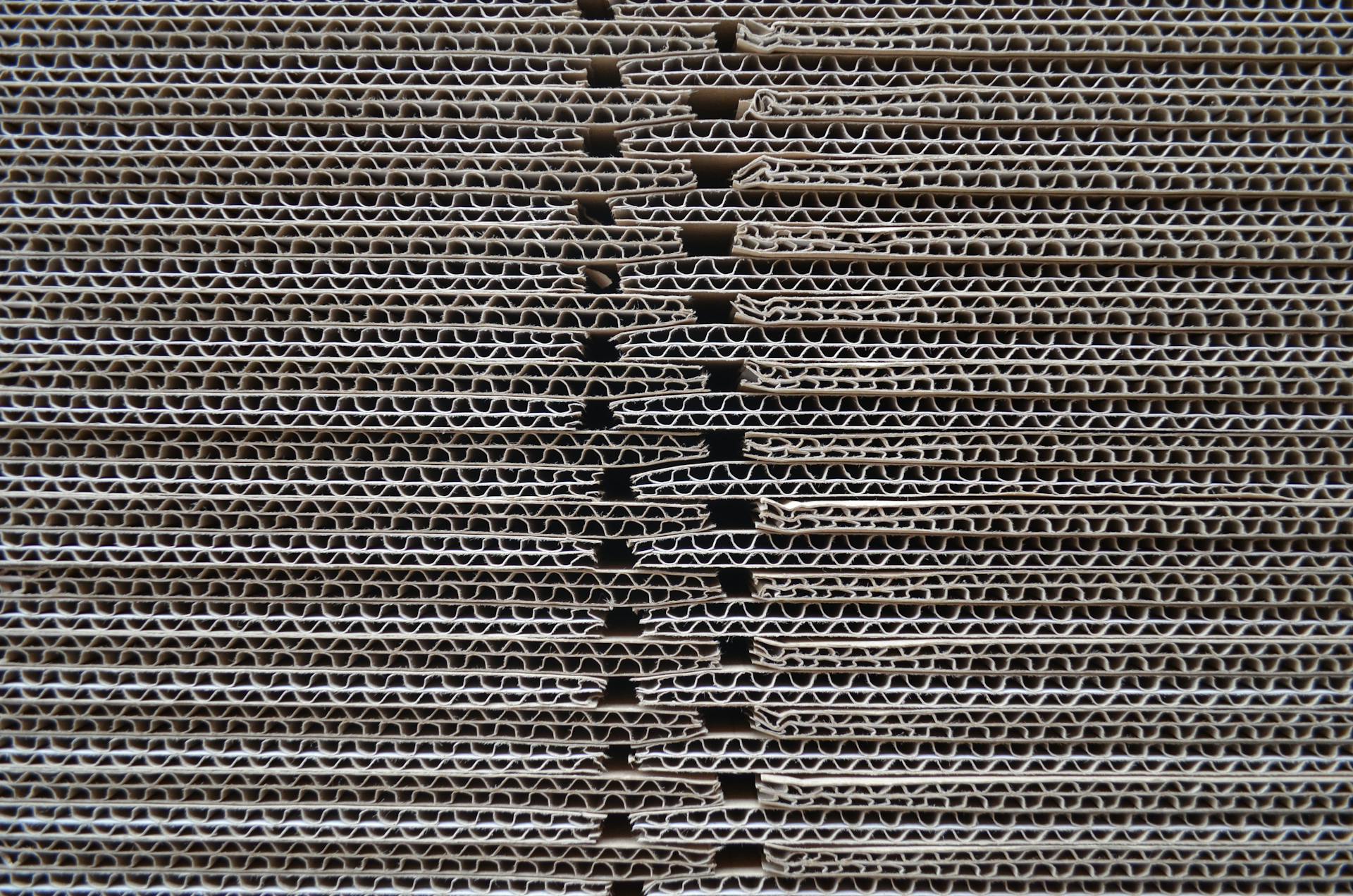

The corrugator is responsible for creating the corrugated fluting, which is the wavy pattern that gives corrugated paperboard its strength.

The slitter cuts the corrugated sheet into individual blanks, which are then fed into the folder-gluer.

The folder-gluer folds and glues the blanks together to form the final product.

The production line can be customized to produce a variety of products, including boxes, containers, and packaging materials.

For another approach, see: Glad Wrap Products

What Is a Production Line?

A production line is a series of machines and equipment that work together to produce a specific product, in this case, corrugated board.

The corrugated board production line is composed of two separate parts: the wet and the dry process equipment. The wet process equipment consists of a roller rack, auto feed machine, pre-heater, bridge, glue, double-sided machine, etc.

See what others are reading: Modified Atmosphere Package Gas Equipment

The production line has several parts, including flat hanging board and corrugated board, glued together with a groove in the center, and cut to the desired size. It also includes ink printing rollers for applying customer graphics.

The dry process equipment is made up of a CNC cutter, groove press, and stacking machine. These machines are used for cutting, indentation, cross-cutting, and stacking the corrugated board as required.

A corrugated line is a corrugated board production line that uses a drum support, one side corrugated board forming machine, and a rotary cutter. This production line can produce single-side corrugated board continuously.

The production line uses coil and potato or corn starch glue to produce the corrugated board. It can also produce more than 3 layers of corrugated board using a glue or veneer machine.

Take a look at this: Corrugated Board Cutting

Corrugated Paperboard Production Line

A corrugated paperboard production line is a complex system that requires careful planning and execution. The line includes various independent machines that work together to form the corrugated board.

One type of corrugated paperboard production line is the WJ150 Corrugated Cardbord Production Line, which is just one of many models available. The WJ180 Corrugated Cardbord Production Line and WJ200 Corrugated Cardbord Production Line are also popular options.

A key feature of a corrugated paperboard production line is its ability to produce high-quality cardboard with high physical index and speed. The line's equipment is designed to be energy-efficient, reducing unit energy consumption. The maximum mechanical speed of a 5-ply corrugated cardboard production line can reach up to 300m/min.

The width of a corrugated cardboard production line can vary, typically ranging from 1400 to 2800mm. The line's machines are designed to be easy to operate and maintain, with features such as positive pressure cassette type quick roll change single face corrugator and double motor upper and lower independent drive double-sided machine.

Here are some key specifications of a 5-ply corrugated cardboard production line:

A complete corrugating board production line includes the following machines: positive pressure cassette type quick roll change single face corrugator, double motor upper and lower independent drive double-sided machine, and equipment with high stability, low noise, and long life.

Equipment and Safety

The corrugated paperboard production line uses a variety of equipment, including corrugators, slotters, and cutters, which can be hazardous if not handled properly.

A key piece of equipment on the production line is the corrugator, which can reach temperatures of up to 200°C.

To ensure operator safety, the production line is equipped with fire suppression systems and emergency stop buttons.

The corrugator's hot rolls and steam-heated cylinders require regular maintenance to prevent accidents.

Intriguing read: Southern California Packaging Equipment

Board Working Principle

A corrugated board production line can be as simple as a single-side corrugated production line made up of a reel rack, a one-side corrugated board-forming machine, and a rotating cutting unit.

The process involves continuously manufacturing and cutting the paper to the required size with a roll material and a potato or cornstarch binder.

Corrugated board is made without sun or sun drying, which is a distinct feature of this production method.

The glue machine or veneer is used to produce more than 3 layers of corrugated board simultaneously.

Equipment on the Line

The Corrugated Cardboard Production Line is a complex system that includes various machines to form the corrugated board. This line can be divided into several sections, each with its own set of equipment.

The Corrugated Line is equipped with a Positive pressure cassette type quick roll change single face corrugator, which allows for efficient and high-speed production. This machine is capable of reaching a maximum mechanical speed of 300m/min.

A Complete Corrugating Board Production Line includes the following machines:

The WJ260 Corrugated Cardboard Production Line is a high-speed production line that can produce cardboard at a speed of up to 300m/min. This line is equipped with a variety of machines, including the Positive pressure cassette type quick roll change single face corrugator.

Worth a look: Corrugated Board Production

Line Precautions

When working with equipment, safety should always be the top priority. Proper precautions can prevent accidents and ensure a smooth operation.

First and foremost, make sure the power supply is good and the connection is in accordance with the specification and request of the equipment. This might seem obvious, but it's essential to avoid any electrical shocks or malfunctions.

To prevent damage to the machine, never move locked device parts. This can cause irreparable harm and lead to costly repairs.

Before starting the machine, inspect the chain and belt for any foreign matter. If you find any, clean it out to ensure the machine functions normally.

It's also crucial to minimize transmission damage by opening the machine as little as possible. Regular inspection of drive components and fasteners can help prevent damage and keep the machine running smoothly.

To maintain the machine's performance, periodically oil the drive part. This will keep the device running smoothly and prevent any issues down the line.

Here are some essential precautions to keep in mind:

- Shut down the electricity for all tests and repairs.

- Use a low concentration of detergent to wipe the belt, and avoid washing it with solvent to prevent corrosion.

- Avoid dry glue after work to prevent interference with the following work.

- Do not let non-professional personnel open the distribution box or replace the cables.

- Regularly inspect drive components, fasteners, and adjust them in time.

Cardboard Line

A cardboard line is a crucial part of the corrugated paperboard production line, responsible for forming the corrugated board.

The cardboard line is made up of various independent machines, including the Corrugated Cardboard Making Machine and the Single Face Corrugated Cardboard Making Machine.

Recommended read: Polythene Bag Making Machine

These machines are designed to produce high-quality corrugated cardboard with a high physical index and high speed.

The WJ150 Corrugated Cardboard Production Line, WJ180 Corrugated Cardboard Production Line, WJ200 Corrugated Cardboard Production Line, and WJ260 Corrugated Cardboard Production Line are some of the examples of cardboard lines available.

A complete corrugating board production line includes the following machines, such as the Positive pressure cassette type quick roll change single face corrugator and the Double motor upper and lower independent drive double-sided machine.

Here are some key specifications of the 5 Ply Corrugated Cardboard Production Line:

The cardboard line is designed for high-accuracy, sustainability, and ease of operation, with a high safety level, high productivity, and remote monitoring capabilities.

Frequently Asked Questions

What is the difference between paperboard and corrugated board?

Paperboard is typically a single or multi-layered material, while corrugated board is made of multiple layers of heavy paper, making it thicker and sturdier. This difference in structure affects their primary uses, but innovative packaging solutions often combine the two for unique benefits.

How is corrugated fiberboard made?

Corrugated fiberboard is made by steaming and pressing a middle layer of paper into a wavy shape, creating columns of air between outer layers. This process, called corrugation, produces a strong and lightweight structure ideal for shipping and handling.

What is the profit margin in corrugated box manufacturing?

The typical profit margin in corrugated box manufacturing ranges from 4% to 10%, influenced by raw material costs, labor, and operational expenses. Understanding the factors affecting margins is crucial for businesses in this industry.

Sources

- https://www.aopackmachine.com/corrugated-cardboard-production-line-faq-guide/

- https://nlmachinery.en.made-in-china.com/product/AtORhGzygUVM/China-1800mm-5-Ply-Automatic-Corrugated-Board-Production-Line.html

- https://www.corrugated-line.com/wj150-1600-%E2%85%A03-ply-corrugated-cardboard-production-line.html

- https://www.llypack.com/corrugated-line/61588843.html

- https://www.corrugated-line.com/automatic-corrugated-carton-production-line-machine-wj180-1800-%E2%85%A03-ply.html

Featured Images: pexels.com