Corrugated board thickness is a crucial factor in determining the overall quality and performance of the board. Typically, corrugated board thickness ranges from 0.5 to 1.5 mm.

A standard B-flute corrugated board is around 1.2 mm thick. This thickness provides a good balance between strength and cost.

The thickness of corrugated board also affects its weight and density. A thicker board will generally be heavier and more dense than a thinner one.

Check this out: Craft Paper Thickness

Cardboard Types and Grades

Cardboard Types and Grades are more important than you might think. Cardboard thickness is crucial for shipping products safely and efficiently.

The right type of cardboard can make all the difference in protecting your products during transit. Single face cardboard is the least durable type, making it best suited for lining interior boxes for secondary product protection.

Single wall cardboard is the most common type, consisting of one medium piece of fluted liner glued between two pieces of liner board. It's ideal for products that aren't easily breakable.

Related reading: Single Face Corrugated Board

Double wall cardboard provides an extra layer of security and makes boxes more feasible for stacking. It's usually used for industrial containers or heavy products.

Triple wall cardboard is essentially a cardboard substitute for wooden crates. It's ideal for shipping heavy, industrial grade products.

Here's a quick guide to corrugated cardboard types:

Cardboard Manufacturing and Measurement

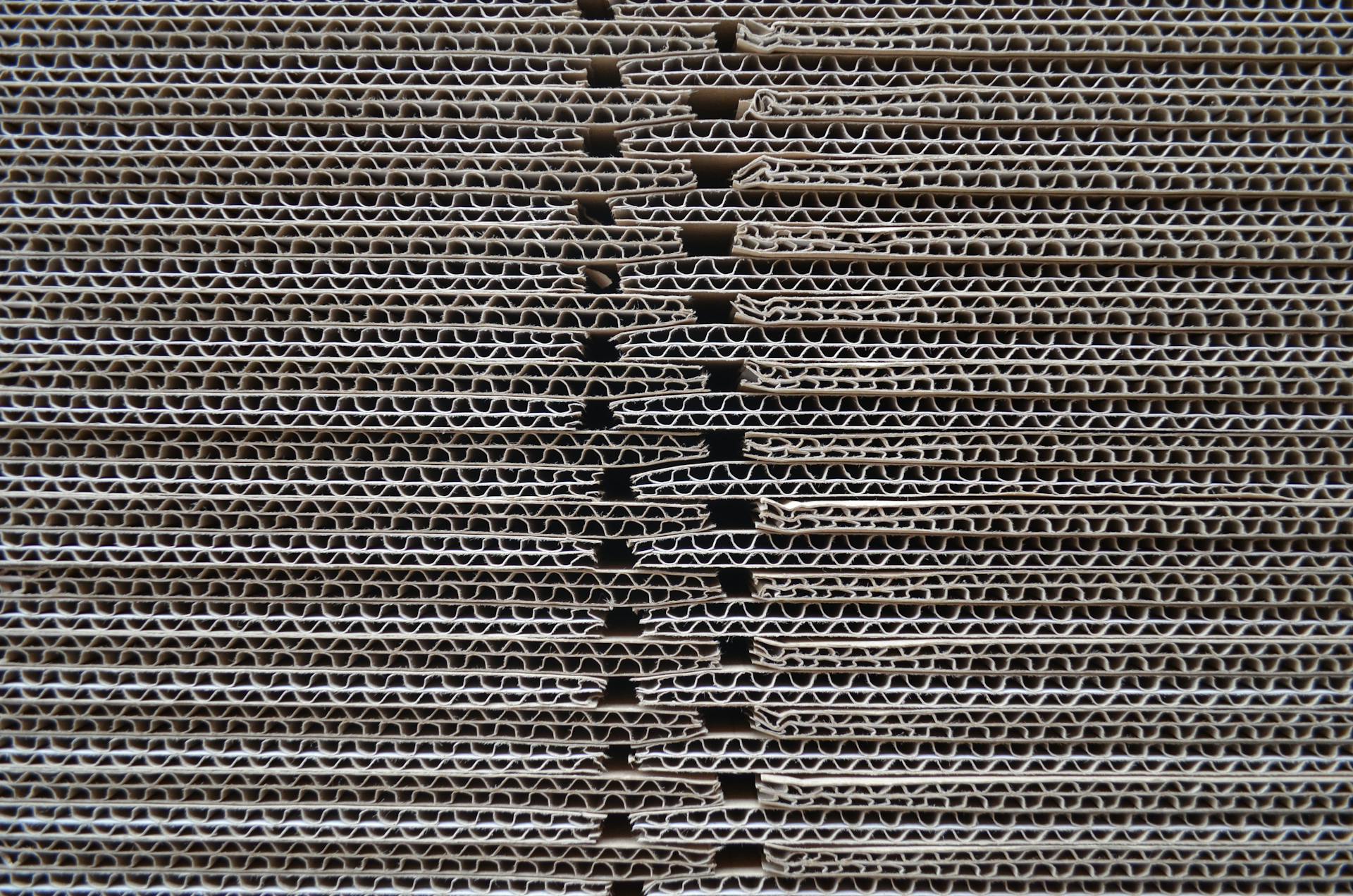

Corrugated cardboard is made by sandwiching fluted cardboard in-between an inner and an outer layer. Additional layers of liner and corrugation can be applied to up the levels of rigidity and strength.

There are several ways to measure cardboard thickness, including grams per square meter (GSM), point (PT), flute, and board. You can choose the right board thickness for your product by knowing the differences between each method.

Corrugated board thickness can range from 3-10mm, depending on the type of board. Here's a summary of the different types of corrugated board thickness:

How Is Made?

Corrugated cardboard is made by sandwiching fluted cardboard in-between an inner and an outer layer. This process creates a strong and rigid material.

The inner layer is typically made of a lightweight paper material, while the outer layer is often made of a heavier-duty paperboard. This combination provides excellent structural integrity.

Additional layers of liner and corrugation can be applied to increase the levels of rigidity and strength. This is especially useful for heavy-duty applications or for items that need to withstand rough handling.

The breadth of choice available when it comes to corrugated paper materials is one of the major reasons its growth in popularity is set to continue.

Core Measurement Methods of Cardboard

Cardboard thickness is measured in various ways, but did you know that grams per square meter (GSM) is one of the most common methods?

GSM measures the weight of cardboard per square meter, which can range from 150 to 1000 GSM or more. The higher the GSM, the thicker and heavier the cardboard.

There are also other methods like point (PT), flute, and board, which are used to measure cardboard thickness. Let's take a closer look at each of these methods.

Broaden your view: Kraft Paper Thickness

Cardboard thickness can also be measured using the flute method, which categorizes cardboard into different flute types such as A, B, C, E, and more. Each flute type has its own unique characteristics and applications.

Here's a quick rundown of the most common flute types:

Understanding these different measurement methods can help you choose the right cardboard thickness for your product.

Cardboard Box Profiles and Sizes

Corrugated board thickness is a crucial factor in determining the strength and performance of a cardboard box. The thickness of a corrugated box is determined by the type of corrugated paperboard used.

You can choose from a range of flute profiles, each with its own unique characteristics. For example, the A Flute is 5mm thick, while the B Flute is 3mm thick and a versatile all-rounder used in all types of packaging.

The most common flute choice is the 105 GSM WBF, which provides a good balance between strength and performance. However, the best choice for you will depend on the specific needs of your product and packaging.

Broaden your view: Saran Wrap Thickness

Here are some common flute profiles and their corresponding thicknesses:

The thickness of a corrugated box is also measured in microns, with different flute profiles offering varying levels of crush resistance and printability. For example, the E Flute has a thickness of 1300-1600 microns and provides strong crush resistance and a high-quality surface for printing.

Corrugated board thickness is not the only factor to consider when choosing a cardboard box. You should also consider the size and type of box you need, as well as the weight and fragility of the products you are packaging.

Choosing and Using Cardboard Boxes

Cardboard boxes come in a variety of thicknesses, with a standard thickness of 3/16 inch being the most common.

You can find cardboard boxes in different sizes and shapes to suit your needs, from small boxes for shipping small items to large boxes for moving furniture.

A 3/16 inch thick cardboard box can hold up to 35 pounds of weight, making it suitable for shipping lighter items.

Intriguing read: Cardboard Pizza Boxes

The corrugated board thickness affects the box's strength and durability, so it's essential to choose the right thickness for the job.

The weight capacity of a cardboard box also depends on its size and shape, with larger boxes able to hold more weight.

For example, a large box with a 3/16 inch thick corrugated board can hold up to 50 pounds of weight.

Cardboard boxes are also recyclable and can be reused multiple times, making them a sustainable packaging option.

The corrugated board thickness affects the box's recyclability and reusability, with thicker boards being more durable and long-lasting.

For more insights, see: Kraft Paper Boxes

Cardboard Board Types

Corrugated cardboard comes in various thickness grades, each with its own unique characteristics. The most common types of corrugated board are E, S, B, C, EB, and BC flutes.

The E flute is the thinnest, measuring 1.3-1.6mm in thickness, and is ideal for smaller cartons and die-cuts applications. It provides strong crush resistance and a high-quality surface for printing.

Related reading: E Flute Corrugated Board

The B flute is the most common type, measuring 2.6-3.0mm in thickness, and offers a good all-round performance. It's seen in various applications, including die-cut and regular cases.

Here are the different types of corrugated board flutes:

Single-Wall Board

Single-Wall Board is a popular choice for packaging lightweight products. It's the most common and cost-effective type of corrugated box.

Single-Wall Board has a thickness range of approximately 3-5mm. This makes it suitable for products that are not easily impacted during transport.

This type of board is often used for packaging stationery, clothing, and small electronics. Its lightweight and economical features make it an ideal choice for these types of products.

Here's a quick rundown of Single-Wall Board's key characteristics:

Triple-Wall Board

Triple-Wall Board is a top-notch option for packaging large and heavy items.

It's the thickest type of corrugated paperboard, with a thickness range of typically between 7-10mm.

This makes it ideal for applications that require a high load-bearing capacity, such as packaging heavy equipment, machinery, and automotive parts.

The extremely high load-bearing capacity of Triple-Wall Board is perfect for items that will face substantial impact or pressure during transportation.

Here are some key features of Triple-Wall Board at a glance:

- Thickness Range: 7-10mm

- Applications: Heavy equipment, machinery, automotive parts

- Features: High load-bearing capacity, ideal for items facing impact or pressure

Cardboard Resources

Corrugated cardboard is a popular choice for packaging due to its flexibility, strength, and affordability. The growth in e-commerce, accelerated by Covid-19, has driven demand for corrugated packaging.

Corrugated packaging is a sustainable option, making it a great choice for businesses looking to reduce their environmental impact. The corrugated packaging industry is continuing to grow and evolve.

The popularity of corrugated packaging is cemented, with its benefits including flexibility, strength, and affordability. Corrugated board grades offer a range of options to suit different needs.

The ideal time to explore the benefits of corrugated packaging is now, with its popularity and demand continuing to rise.

Frequently Asked Questions

How thick is double wall corrugated in inches?

Double wall corrugated is approximately 5/16" thick, equivalent to about 0.3125 inches. This thickness provides added strength and durability.

Sources

- https://www.aopackmachine.com/cardboard-thickness-guide/

- https://industrialphysics.com/knowledgebase/articles/guide-to-corrugated-cardboard-thickness-grades/

- https://cspackaging.com/2019/07/18/corrugated-box-sizes-and-thicknesses-guide/

- https://www.mtdpack.com/corrugated-box-size-and-thickness-guide/

- https://www.packagingstrategies.com/articles/96269-corrugated-board-and-material-grades

Featured Images: pexels.com