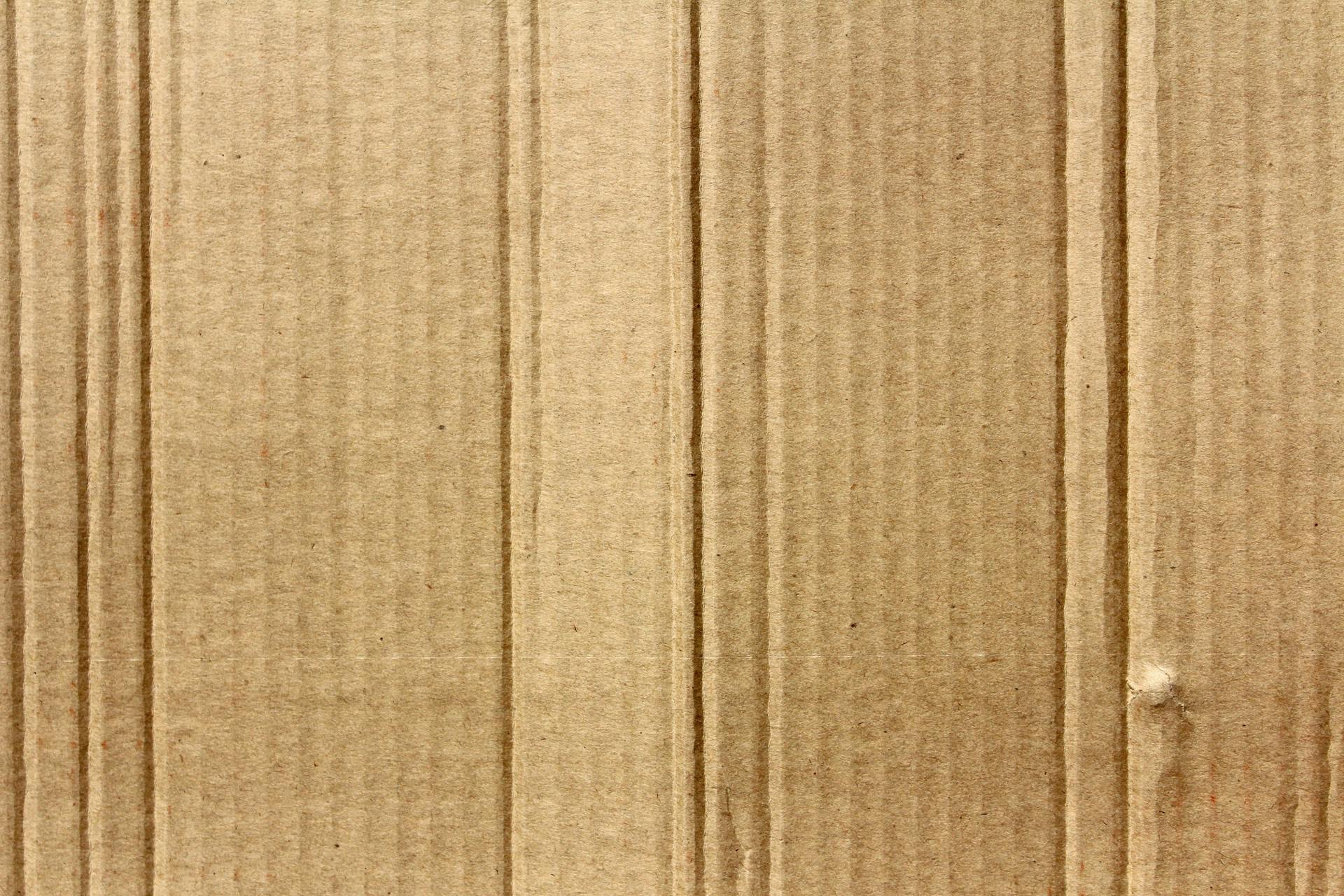

Corrugated board is a versatile material that has been a staple in packaging and shipping for over a century. It's made from paper pulp, which is pressed and molded into a wavy pattern to create its signature strength and durability.

One of the most common uses for corrugated board is in shipping boxes, which account for over 90% of all corrugated board production. These boxes are designed to protect fragile items during transit and can be customized to fit specific products.

From boxes to displays, corrugated board's versatility knows no bounds. Its lightweight and easy-to-assemble nature makes it an ideal material for trade show displays and point-of-purchase displays.

Expand your knowledge: White Foam Packing Material

What is Corrugated Board?

Corrugated board is made up of three layers: two liners and a layer of arched paper called fluting. This unique construction creates pockets of air that increase resistance against shocks and rough handling.

The fluting layer is positioned between the two liners, giving corrugated board its strength and durability. This design allows it to withstand heavy loads and harsh environments.

Corrugated board is a type of cardboard that is manufactured with advanced systems for extra strength. This makes it a reliable choice for packaging solutions.

The combination of the three layers in corrugated board provides a level of protection that single-sheet cardboard cannot match. This is why corrugated board is often used for shipping and storing fragile items.

Types of Corrugated Board

Corrugated board comes in various types, each with its own strengths and uses. Single face boards are the cheapest to produce but are also the least durable, making them suitable only for extra protection on already packaged products.

Single wall boards are the most common type and consist of a fluted layer between two liners. They're often used for shipping cartons due to their standard strength and protection. Single wall boards are also a popular choice for businesses looking for eco-friendly packaging options.

Double face boards incorporate two corrugated sheets between three liners, making them stronger than single wall boards. They're ideal for shipping or storing heavy machinery parts or for providing extra protection for fragile items. Triple face boards, on the other hand, are the strongest available and consist of three corrugated sheets between four liners.

Triple Wall

The triple wall corrugated board is a sturdy option that's perfect for heavy-duty applications. It consists of three fluted layers with a liner between each and one on each end.

This type of board is extremely durable and can even substitute wooden crates in some cases. For example, a hybrid corrugated box can combine the natural resistance of wood with the lightness of corrugated cardboard.

Triple wall boxes are traditionally used for shipping chemical containers due to their properties. They can also combine flute profiles due to their different layers, allowing for customizable cushioning strength, compression strength, and thickness.

If you're looking for a board that can handle heavy items, triple wall is an excellent choice. It's also cost-efficient, making it a great option for businesses on a budget.

Take a look at this: Triple Wall Corrugated Cardboard Sheets

Single Wall Board

Single Wall Board is the most common style of corrugated cardboard and is considered the standard. It consists of a fluted layer between two liners, making it especially useful for shipping cartons.

This type of board is often used for protective cushioning in boxes, and many places sell it by the roll, offering companies bulk packaging material. Corrugated materials are easy to recycle, making Single Wall corrugated boards attractive to businesses looking for eco-friendly packaging options.

Single Wall boards are a great choice for businesses that need a balance of strength and protection. They're widely available and can be used for a variety of applications, from shipping boxes to packaging materials.

Here's a brief overview of the characteristics of Single Wall boards:

Overall, Single Wall boards are a reliable and versatile option for businesses that need a basic level of protection and strength for their packaging needs.

Flute Types

Corrugated packaging can vary in thickness depending on user requirements and needs. The different types of flute compositions are A-flute, C-flute, B-flute, E-flute and F-flute, which progressively get thinner in that order.

A-Flute is the largest flute size, measuring 1/4” thick and providing the highest protection and cushion qualities, making it ideal for packaging fragile items.

B-Flute, on the other hand, is 1/8” thick and has excellent puncture and crush resistance, making it a good choice for various packaging or as additional material for padding and dividing.

C-Flute is 3/16” thick and is one of the most versatile flute grades, offering average crush resistance, stacking strength, and printing properties.

E-Flute is 1/16” thick and is often used as an alternative for paperboard folding cartons, but can also be used for cosmetics, fragile glass, ceramics, and other small and delicate products.

F-Flute is 1/32” thick and has protective qualities similar to E-Flute, but with an even smoother surface for high-quality printing applications.

Here's a quick comparison of the different flute grades:

Benefits and Uses

Corrugated board is incredibly sturdy and can carry a wide range of weights, making it suitable for nearly any item. It's used to transport 95% of all consumer goods in North America, and its benefits are numerous.

One of the main advantages of corrugated board is its protection and durability. It can absorb impacts and offer cushioning support, making it ideal for shipping fragile items. This is especially important for e-commerce packaging, where items need to withstand harsh conditions during transit.

Corrugated board is also environmentally friendly, made from recycled fibers that make it easier to recycle. This is a top choice for sustainability-conscious businesses looking for eco-friendly packaging options.

Specifications

Understanding the various corrugated box specs is crucial to protect and support your products before shipping or storing them.

Corrugated boxes come with many elements that can be changed and customized, such as the flute type, which affects the box's strength and durability. The flute type can be single, double, or triple, with single flute boxes being the most common.

The corrugated box's flute direction can also be customized, with options including flute to flute, flute to edge, and edge to edge. This affects how the box will be printed and the overall appearance of the finished product.

For more insights, see: Single Wall Corrugated Board

The corrugated box's flute height, or the distance between the flutes, can also be adjusted to suit specific needs. A taller flute height provides more strength and support, but may also make the box more expensive.

The corrugated box's edge crush resistance is another important factor to consider. This measures the box's ability to withstand pressure and maintain its shape.

Benefits of Packaging

Corrugated cardboard packaging is a popular choice for transporting consumer goods, with 95% of all goods in North America being shipped in this type of packaging. It's sturdy and can carry a wide range of weights, making it suitable for various industries.

One of the main benefits of corrugated cardboard packaging is its ability to provide excellent protection and durability for items during transit. It can absorb impacts and offer cushioning support, making it ideal for shipping fragile items.

Corrugated cardboard is also a great option for businesses looking to reduce their environmental impact. It's made from recycled fibers, making it easier to recycle and reducing waste.

Customization is another key benefit of corrugated packaging. The shape, thickness, and graphics can be easily customized to meet specific business needs.

Here are some of the key benefits of corrugated packaging at a glance:

- Protection and Durability

- Environmentally friendly

- Customizable

In addition to its protective qualities, corrugated cardboard can also be shredded into an eco-friendly void filler, reducing waste and the carbon footprint of shipping.

Corrugated boxes are also very cost-efficient, with a minimal amount of labor and tools needed to manufacture them. This makes them one of the least expensive cartons available.

Their lightweight nature also saves shipping costs, making them a great option for businesses looking to reduce their packaging expenses.

Overall, corrugated cardboard packaging offers a range of benefits that make it an ideal choice for businesses and consumers alike.

Applications and Solutions

Temporary warehouse solutions can be achieved with corrugated boxes, which can be used as makeshift shelves, dividers, or storage units.

Their lightweight nature makes it easy to move and assemble them, while their sturdiness ensures they can hold their shape. And when you're done, it's easy to recycle them.

Corrugated boxes offer increased flexibility and versatility for companies that need more specialized custom solutions, allowing you to select various features depending on your needs.

You can customize your corrugated boxes to meet multiple functions, such as selecting different board grades, types, and flute profiles to deliver additional capabilities.

How Boxes Are Made

Corrugated boxes are made using a unique process that involves a corrugator, which creates the flutes and glues the peaks of the arches to the liner using high-temperature steam.

The corrugator runs the liners and medium through it to create the corrugated box. The liners and medium are the foundation of the box, and the corrugator combines them to create the distinctive corrugated shape.

A machine cuts the box to its desired size and specifications, scoring it where it will fold. This scoring process is crucial for the box's final shape.

A trimmer cuts the flaps according to the box type and any necessary handles. This customization allows for a wide range of box types and sizes.

A folding machine bends the board along the scored lines to create the box, applying glue to help it hold its shape. This folding process is where the box takes its final form.

You can add a coating or finish to the box for additional protection and properties. Aqueous coats provide further protection from dirt and wear, while ultraviolet (UV) finishes cure the box under strong UV lights to make it more scratch-resistant.

Explore further: Create a New Document of Labels Using the Avery

Double Wall

Double wall boards offer a unique combination of strength and versatility. They consist of two fluted layers with a liner in between and one on each end, making them more resistant to stacking pressure.

This design allows them to be stacked more easily, which is a big plus for heavy objects. Double wall boards are commonly used for larger, heavier objects.

One of the most common types of flutes used in double wall boards is EB, but BC flutes are also widely available.

Suggestion: One Sided Corrugated Cardboard

Point-of-Sale Displays

Point-of-sale displays can be created from repurposed materials like corrugated cardboard, which not only cuts costs but also reinforces a brand's commitment to sustainability.

Repurposed corrugated boxes can be transformed into eye-catching product holders, signage, or display units for promotions and events.

Using recycled materials for point-of-sale displays is a great way to reduce waste and show customers that you care about the environment.

These displays can be temporary or seasonal, making them perfect for short-term promotions or events that don't require long-term storage.

By choosing eco-friendly materials for your point-of-sale displays, you can appeal to customers who value sustainability and are more likely to support your brand.

Additional reading: Free on Board Shipping Point

Temporary Warehouse Solutions

Temporary Warehouse Solutions can be a game-changer for businesses undergoing renovations or in need of temporary setups.

Corrugated boxes are incredibly versatile and can be used to create makeshift shelves, dividers, or storage units. They're lightweight, making it easy to move and assemble them as needed.

Their sturdy nature ensures they hold their shape, even when holding heavy loads. You can easily recycle them when you're done with the temporary setup.

Temporary solutions like these can help businesses save time and money by avoiding the need for permanent installations.

Here's an interesting read: An Export Strategy Is Used When a Global Company

Outdoor Composting

Outdoor composting is a great way to reduce waste and create nutrient-rich soil for your garden. Corrugated cardboard is a perfect addition to compost piles, providing a carbon-rich ingredient that helps speed up the decomposition process.

You can layer corrugated cardboard into your compost pile to create a balanced mix of "green" and "brown" materials. This will help your compost break down faster and more efficiently.

Using corrugated cardboard as a weed barrier under mulch is another great outdoor composting solution. It prevents weeds from growing and reduces the need for plastic mulch.

Biodegradable seedling planters made from corrugated cardboard are a wonderful alternative to traditional plastic pots. These planters break down into nutrient-rich soil, reducing waste and creating a healthy environment for your plants.

A fresh viewpoint: Can You Use Packing Peanuts in Bottom of Planters

Custom Solutions

Custom Solutions offer increased flexibility and versatility for companies that need more specialized solutions. Corrugated boxes can be customized to meet multiple functions.

You can choose various features depending on your needs, from different board grades to personalized marketing needs. This allows you to create a box that can withstand your shipping conditions or support even your heaviest or more fragile products.

Thicker flutes, higher grades, and board types can deliver additional capabilities, such as increased protection and strength. You can also print images and words on the exterior liners of corrugated boxes to strengthen your marketing efforts.

Customization capabilities include selecting colors, fonts, symbols, and logos that meet your branding standards. This creates a look your customers will recognize every time.

Some common types of corrugated boxes include the Tab Lock Roll End, Roll End 3 Flaps Tuck, and Roll End Tuck Front. These styles can be used for various packaging needs, from construction to thickness.

These are just a few examples of the many custom solutions available for corrugated boxes.

Sustainability and Recycling

Corrugated board is an eco-friendly packaging solution that's also highly recyclable. In fact, around 96% of all boxes get recycled, making it an industry that helps keep waste out of landfills.

The recyclable materials in corrugated boxes can be reused around seven to 10 times to create new boxes or other paper products. This closed-loop recycling process reduces the need for raw materials and minimizes waste.

Corrugated cardboard packaging is made from a combination of recycled materials, with about 50% of the box coming from other recycled boxes. This reduces the environmental impact of manufacturing new boxes.

One way to reuse corrugated boxes is to shred them into an eco-friendly void filler. This green alternative to plastic or foam materials can help reduce your carbon footprint while cutting waste.

Old corrugated containers (OCC) are a valuable source of fiber for recycling. They can be compressed and baled for cost-effective transport, and then processed into new paper and fiber products.

Here are some interesting statistics about corrugated box recycling:

- 96% of all boxes get recycled

- About 50% of the box comes from other recycled boxes

- Recycled materials can be reused around 7-10 times

Customization and Options

Corrugated boards offer a range of customization options to suit your needs.

You can choose from different board types, coatings, and treatments, such as flame resistance, to ensure the right properties for your application.

Custom solutions are also available, allowing you to select various features like board grades, types, and flute profiles to meet multiple functions.

Thicker flutes, higher grades, and board types can provide increased protection and strength, making them ideal for shipping conditions or supporting heavy or fragile products.

You can even print images and words on the exterior liners of corrugated boxes, strengthening your marketing efforts and allowing you to choose colors, fonts, symbols, and logos that match your branding standards.

Prototypes for Development

Creating prototypes is a crucial step in product development, and corrugated cardboard is a perfect material for the job. It's incredibly versatile and allows you to test and refine different styles or structures before committing to full production.

Corrugated cardboard is a low-cost option that can save you time and resources. Its affordability makes it an attractive choice for experimenting with packaging and product designs.

You can use corrugated cardboard to test new product designs and packaging structures. This can be a game-changer for companies looking to innovate and improve their products.

With corrugated cardboard, you can create quick prototypes that help you refine your ideas. This iterative process can save you a lot of time and money in the long run.

By testing and refining your designs with corrugated cardboard, you can ensure that your final product meets your standards.

Customizable

Customizable corrugated boxes offer a range of options to suit different needs. They come in various board types, coatings, and treatments, such as flame resistance.

You can choose the right properties for your specific requirements. For example, you can select a board grade that provides increased protection and strength.

Printing options are also available, allowing you to create effective marketing and branding materials. Corrugated boxes can have better graphics than many other materials.

You can include your logo and other information about the products inside for true personalization. This is especially useful for e-commerce companies or those shipping goods to an online audience.

Different board grades, types, and flute profiles can deliver additional capabilities. Thicker flutes, higher grades, and board types can offer increased protection and strength.

Customized corrugated boxes can be used to create prototypes for product development. This allows you to test and refine different styles or structures before committing to full production.

Custom solutions are available for companies that need more specialized packaging. You can select various features depending on your needs, from different board grades to personalized marketing needs.

Comparison and Materials

Choosing the right materials for your corrugated board is crucial for its durability and sustainability. Kraft Paper liners are the most sustainable option, but they're also the most expensive.

They consist of 70-80% "virgin" chemical pulp fiber, making them very stiff and durable.

Test Paper liners, on the other hand, are less expensive and use more recycled fiber content. However, this also makes them less durable and more difficult to print on.

Here's a comparison of the most commonly used liners:

Cardboard vs. What's the Difference?

Cardboard is generally made of paper stock or heavy paper pulp, but it's not very protective on its own.

It's often used in folded cartons for smaller products or as structural support inside a box to keep its shape during transit.

Cardboard can be used to keep a box's shape, but it's not the best option for protecting items during shipping.

Corrugated cardboard, on the other hand, has three fiberboard layers that offer increased durability and protection.

This material resists bending and is a great choice for shipping large packages or sending multiple products.

The chart below compares cardboard and corrugated cardboard, making it easy to see the difference between the two materials.

Liners Materials

Kraft Paper liners are the most sustainable option available, but also the most costly. They consist of 70-80% "virgin" chemical pulp fiber, making them very stiff and durable.

Test Paper liners, on the other hand, are less expensive due to their higher recycled fiber content, but are also less durable. This higher recycled fiber content can make the paper more difficult to print on.

Flute Paper Liners come in two varieties: Semi-Chem and Waste Based Fluting. Semi-Chem uses virgin fibers and a neutral sulphite semi-chemical process, while Waste Based Fluting uses 100% recycled fibers.

Here's a quick rundown of the liners:

- Kraft Paper liners: 70-80% "virgin" chemical pulp fiber, very stiff and durable, most sustainable option

- Test Paper liners: less expensive, less durable, higher recycled fiber content

- Flute Paper Liners: Semi-Chem uses virgin fibers, Waste Based Fluting uses 100% recycled fibers

Frequently Asked Questions

What are the disadvantages of corrugated board?

Corrugated board is prone to deformation and shape loss under extreme pressure, and it's not weatherproof, making it vulnerable to rain and snow. This can compromise the integrity of the packaging and its contents.

What is the difference between cardboard and corrugated board?

Cardboard is a single-layer material, whereas corrugated board is a multi-layered material with greater strength and durability due to its fluted layer. This key difference makes corrugated board ideal for shipping and packaging.

Sources

- https://en.wikipedia.org/wiki/Corrugated_fiberboard

- https://creopack.com/en/blog/what-is-corrugated-cardboard-packaging/

- https://covenantpackaging.com/7-surprising-ways-to-use-corrugated-cardboard-in-your-business-and-beyond/

- https://www.buyboxes.com/blog/what-is-a-corrugated-box/

- https://pakfactory.com/blog/corrugated-box-101/

Featured Images: pexels.com