Corrugated cardboard pizza boxes are a staple in the food delivery industry, but have you ever stopped to think about how they're made and what makes them so effective?

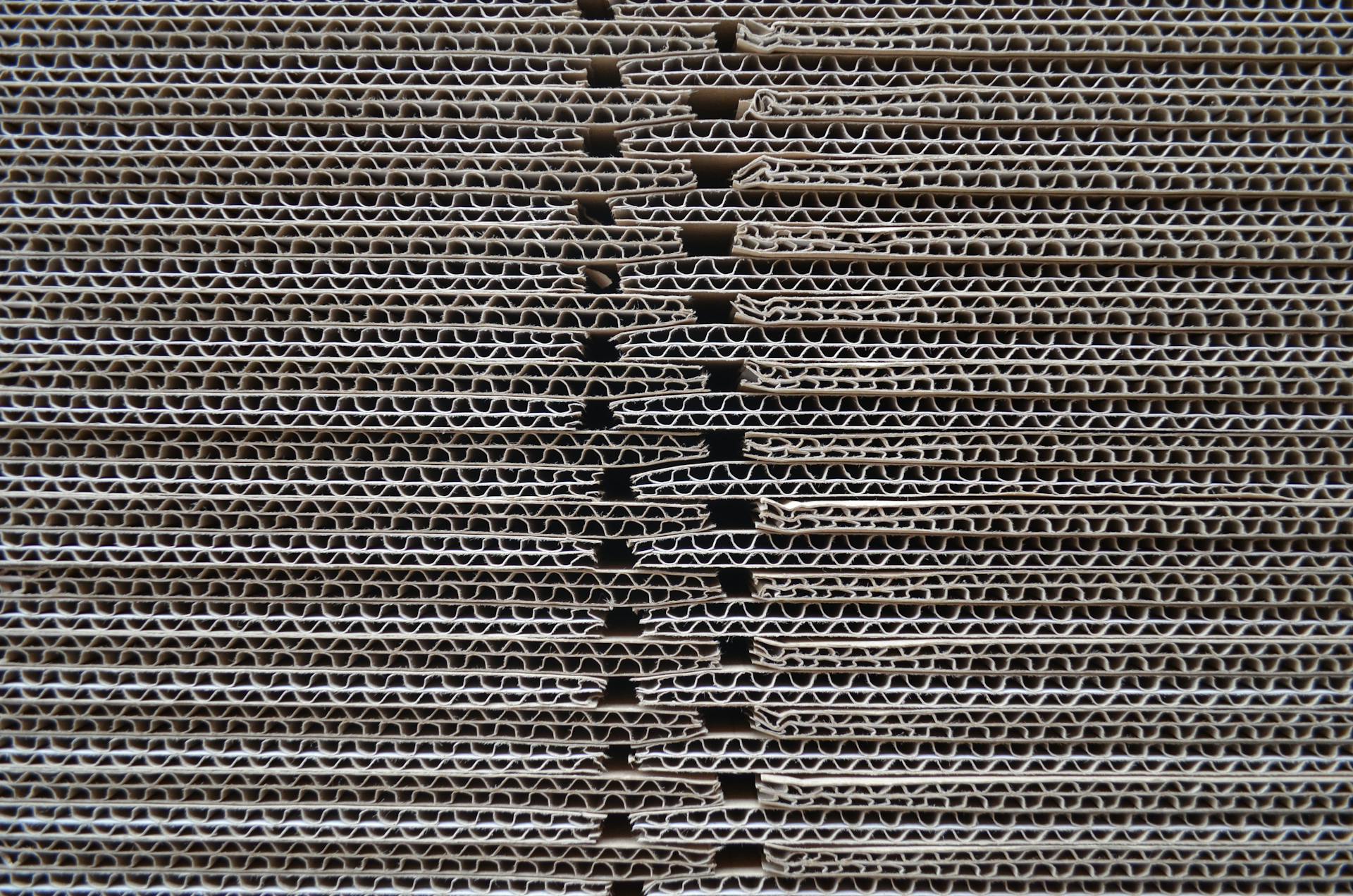

The corrugated cardboard used in pizza boxes is made from a combination of paper pulp and glue, which is then pressed into a fluted shape to create the signature wavy pattern.

This unique design provides excellent cushioning and protection for the pizza during transportation, which is essential for keeping the food hot and fresh.

A standard pizza box is typically 12 inches wide, 12 inches deep, and 2-3 inches tall, making it the perfect size for a standard pizza.

Choosing a Box

Corrugated cardboard pizza boxes are a great option because they must be hygienic to protect the pizza.

You can also consider plain pizza boxes, which are a cost-effective option for smaller pizzerias or those looking to reduce costs further.

Plain boxes offer all the benefits of corrugated cardboard, including insulation, strength, and cost-effectiveness.

Recommended read: Corrugated Cardboard Cost

They can be purchased in bulk at a lower price point, making them a great choice for businesses on a budget.

You can still stamp or label these boxes with your business's information as a way to brand without breaking the bank.

Corrugated cardboard boxes are ideal for pizza packaging because they absorb oil and moisture, preserving the flavor and crispness of the pizza.

Material

Corrugated cardboard is a favorable material for pizza boxes due to its strength, which is crucial for protecting the pizza during transport.

The corrugated design provides a sturdy structure that can withstand stacking, carrying, and even being dropped without collapsing.

It's amazing how well corrugated cardboard holds up under the weight of the pizza and any additional toppings, maintaining its shape and integrity from the store to your home.

Box Options and Customization

Corrugated cardboard pizza boxes offer a range of options to suit different needs and budgets. You can choose from traditional and innovative styles, including pizza slice boxes.

Corrugated cardboard pizza boxes come in various materials, such as Kraft/Kraft, White/White, White/Kraft, and 100% recycled kraft board. They're also available in different sizes, ranging from 6” to 30”.

These boxes can be custom-printed with your logo, promotional messages, or decorative designs, making them a great marketing tool. The surface of corrugated cardboard holds ink well, resulting in vibrant and noticeable designs.

Here are some common corrugated pizza box options:

Box Options

When choosing a pizza box, you have a variety of options to consider. You can opt for traditional or innovative styles, including pizza slice boxes.

We offer different materials, such as kraft/kraft, white/white, white/kraft, and 100% recycled kraft board. Sizes range from 6” to 30” to fit your specific needs.

You can also choose from different flute designs, including B, D, E, or F flutes. This will affect the overall structure and durability of the box.

Our boxes meet FDA requirements for food contact packaging, ensuring they are safe for use with your pizza.

If you want to improve recyclability, consider using single-face inserts as a physical grease barrier at the bottom of the pizza box.

Suggestion: White Postal Box

Customizability

Corrugated cardboard is highly customizable, making it an excellent option for branding. This is especially evident in the pizza industry, where businesses often print their logos, promotional messages, or other decorative designs directly onto the box.

The surface of corrugated cardboard holds ink well, which makes these custom designs vibrant and noticeable.

Customization isn't just for aesthetics; it serves as a marketing tool, transforming a plain pizza box into a brand advertisement.

Recycling and Sustainability

Corrugated cardboard pizza boxes are a great example of eco-friendly packaging. They are 100% recyclable.

The most important raw material of corrugated cardboard is paper. While other packaging types can take 4,000 years to degrade in nature, corrugated cardboard dissolves in just three months.

This is another reason why corrugated cardboard is used for the packaging of pizzas. It's a recyclable material that can help reduce environmental damage.

Every day, a huge number of pizzas are packed, and the environmental damage the packaging of these pizzas might create is a great concern. That's why we produce reusable pizza boxes.

Recommended read: How to Cover a Box with Material

Production and Design

We offer a wide variety of print techniques for your company's logo and slogans on our corrugated cardboard pizza boxes. Our design process allows for customization in detail as you wish.

A locked pizza box is a sealed box that's completely locked after the pizza is put inside, requiring the customer to tear a part of it or destroy it to open it. This design ensures the customer feels safer, as no one can touch their food on the way.

Our production process includes putting sealing and tearing parts on the box to create a sealable pizza box.

Consider reading: Ice Cream Packaging Design

What Are Box Design Basics?

A well-designed box is essential for representing your company. Pizza boxes should be able to endure oil and moisture from hot pizza.

The design of a pizza box should balance carrying a company's brand and style. We offer a variety of print techniques for your company's logo and slogans.

Customization is key, as these boxes will represent your company. It is only fair to want the best representation.

Core Process of a Locked Box Production and Design

Locked boxes are produced and designed to provide a secure and safe way for customers to receive their pizzas. Many people prefer their pizzas in a locked box due to various reasons.

The production process involves creating a box that is completely sealed after the pizza is put inside. This is done by adding sealing and tearing parts to the box.

The design of a locked pizza box allows the customer to feel safer, as no one can touch their food on the way. This is especially important for customers who are particular about their food being handled carefully.

Sealing and tearing parts are added to the box to ensure it remains closed until the customer is ready to open it. This is a crucial step in the production process of a locked pizza box.

Intriguing read: Chamber Vacuum Sealing Machine

Where to Buy and Wholesale

To buy wholesale pizza boxes is a smart way to ensure you never run out of packaging. You can purchase Ankutsan top-quality wholesale boxes in the sizes and colors you need.

Pizza box prices vary depending on several factors, including sizes, designs, styles, and numbers.

For another approach, see: Cake Box Sizes

10 Locations or Less?

If you're a small business with 10 locations or less, you have some great options for packaging your products. Corrugated pizza box options are a great choice, as they're affordable and can be customized with your brand's logo.

For specialty items, consider using clamshells, which are perfect for small items like desserts or snacks. Take-n-Bake pizza boxes are another great option for businesses that offer a make-your-own pizza service.

If you're looking to add some extra flair to your packaging, consider printing or customizing your boxes with your brand's name, logo, or message. This can help make your product stand out on store shelves and online.

Consider reading: Flexible Packaging for Small Coffee Roasters

Where to Buy Wholesale

Buying wholesale is a smart way to ensure you always have the necessary items, such as pizza boxes, on hand. Wholesale purchases are generally more profitable than buying in smaller quantities.

You can purchase wholesale pizza boxes from suppliers like Ankutsan, which offers top-quality boxes in various sizes and colors. Their wholesale boxes are fast-consumed items that require regular restocking.

Pizza box prices vary depending on factors like size, design, style, and quantity. To determine the best price for your needs, it's best to contact the supplier directly.

Plain Boxes Usage and Take-N-Bake

Plain boxes are a great option for smaller pizzerias or those looking to reduce costs. They're available in bulk at a lower price point, making them a cost-effective choice.

You can still brand your plain boxes by stamping or labeling them with your business's information. This is a great way to add a personal touch without breaking the bank.

Plain boxes offer all the benefits of corrugated cardboard, including insulation, strength, and cost-effectiveness. They're a reliable choice for pizza boxes.

If you're looking for a more customized take-n-bake pizza box, you can choose from sizes ranging from 5” to 18” and B, D, or E flutes. These boxes are also available in kraft or white board.

Plain Boxes Usage

Plain boxes are a great option for smaller pizzerias or those looking to reduce costs. They offer all the benefits of corrugated cardboard, including insulation, strength, and cost-effectiveness, without the added expense of customization.

You can purchase plain boxes in bulk at a lower price point, making them a cost-effective choice.

Plain boxes can still be stamped or labeled with the business's information, allowing you to brand without breaking the bank. This is a great option for those who want to keep costs down while still maintaining a professional image.

Plain boxes are widely used and can be found in a range of sizes, from 6” to 30”.

Take-N-Bake

Take-N-Bake boxes are a convenient option for food packaging. They're available in sizes ranging from 5” to 18” in diameter.

The Take-N-Bake Pizza Boxes can be customized with up to 4 color printing options.

You can choose from different flute options, including B, D, or E flutes.

If you want to showcase your product, consider adding a custom-shaped, fog-free cello window to your Take-N-Bake box.

These boxes meet FDA requirements for food contact packaging, so you can have peace of mind when using them for your products.

Here are some key features of Take-N-Bake Pizza Boxes:

- Sizes: 5” to 18”

- Flute options: B, D, or E

- Board options: Kraft or white

- Printing options: Up to 4 colors

- Custom feature: Fog-free cello window

- Compliance: Meets FDA requirements

Insulation and Heat Retention

Corrugated cardboard is a great material for pizza boxes because it's an excellent insulator. It traps air within its wavy inner layer, which helps keep the pizza warm from the pizzeria to your plate by reducing heat loss through the box.

The ideal temperature for pizza consumption is between 70 and 85 °C (158 and 185 °F). This means the box needs to retain heat well to keep the pizza at the right temperature.

The corrugated layer in the cardboard box helps maintain the crust's crispness by minimizing condensation within the box, which can make the pizza soggy. This is especially important because consumers consider a temperature between 70 and 85 °C (158 and 185 °F) to be ideal for pizza consumption.

To prevent the pizza from getting soggy, the box needs to allow some air to escape, which is why pizza boxes have airing holes and some diffusion through the cardboard.

Quality Matters

Quality Matters is not just a phrase, it's a promise. Smurfit Westrock takes food safety as seriously as you do, with their liners, mediums, and finished products routinely tested by independent, certified laboratories.

Their commitment to quality is evident in their manufacturing process, which meets FDA requirements for food contact and USDA Dairymen's surface swab standard. This ensures that their pizza boxes are safe for consumers.

Smurfit Westrock sources raw materials responsibly, using renewable energy sources in their containerboard manufacturing. This approach not only reduces their environmental impact but also contributes to a more sustainable future.

Their pizza boxes are made in North America from U.S. and Canadian materials, making them a reliable choice for foodservice providers. With over 30 years of experience in pizza box manufacturing, Smurfit Westrock has established itself as a leader in the industry.

Their unique manufacturing techniques, which include inline pre-print, corrugating, and die-cutting, enable them to produce high-quality pizza boxes that keep food fresh and brands front of mind.

Frequently Asked Questions

What is a disadvantage of corrugated cardboard?

Corrugated cardboard is prone to deformation and shape loss under extreme pressure, making it a less-than-ideal choice for applications where durability is crucial. It's also not weatherproof, making it vulnerable to rain and snow.

What are two reasons why corrugated cardboard is used as packaging for cooked pizzas?

Corrugated cardboard is used as packaging for cooked pizzas due to its strength and adaptability, making it a reliable choice for protecting the food during transport. Additionally, it's often made from recycled materials and is recyclable itself, reducing waste and environmental impact.

Sources

- https://en.wikipedia.org/wiki/Pizza_box

- https://www.ankutsan.com/en/blog/the-ultimate-guide-to-choosing-the-best-pizza-box

- https://www.westrock.com/products/corrugated-containers/corrugated-pizza-boxes

- https://shop.kevidko.com/news/why-are-pizza-boxes-made-from-corrugated-cardboard/

- https://www.ankutsan.com/en/products/corrugated-cardboard-box/pizza-boxes

Featured Images: pexels.com