The St Fergus Gas Terminal is a vital piece of infrastructure in the North Sea oil and gas industry. It's located in Aberdeenshire, Scotland, and plays a crucial role in processing and exporting natural gas.

The terminal is situated near the village of St Fergus, which is about 30 miles north of Aberdeen. This strategic location allows for easy access to the North Sea and the UK's gas network.

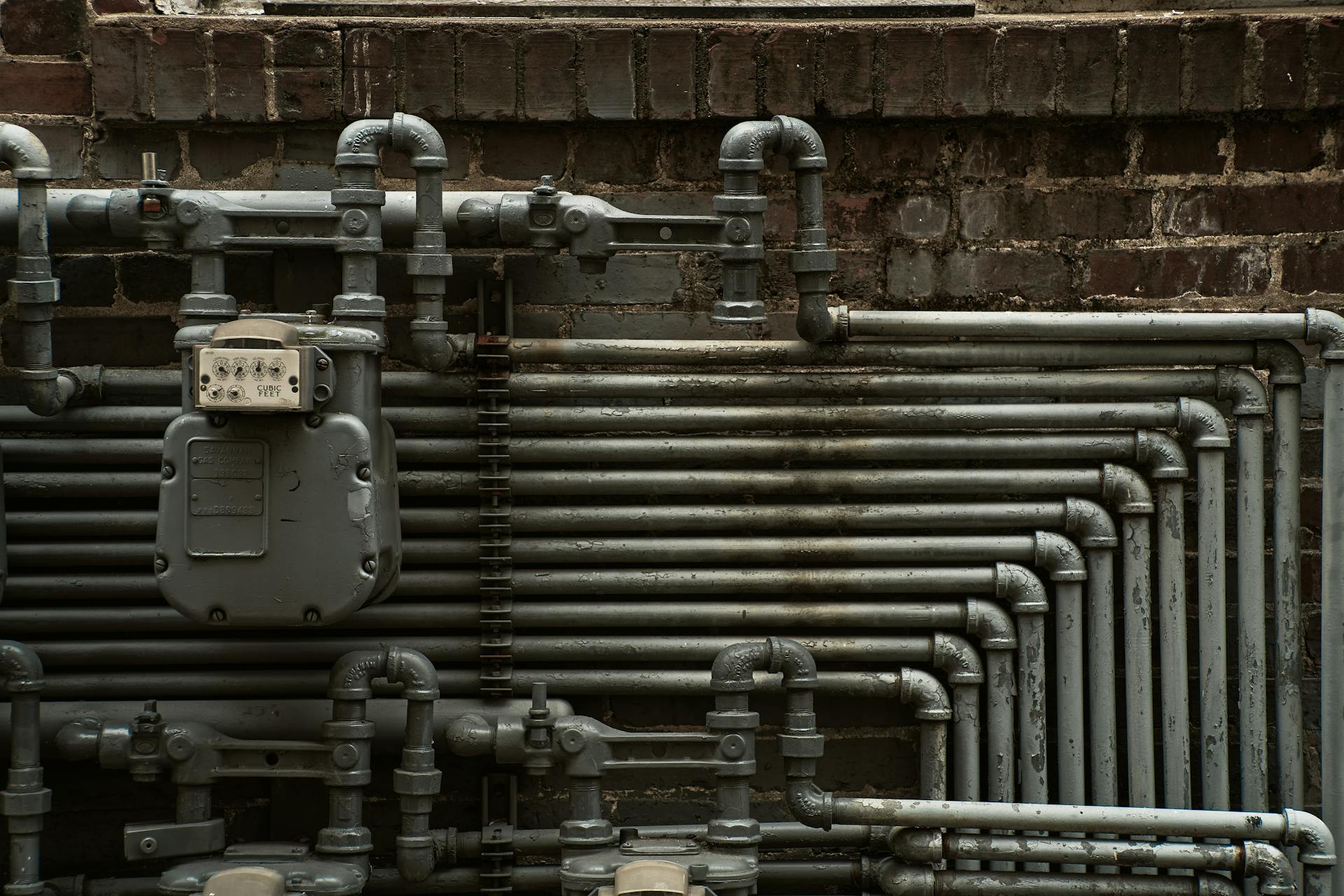

The terminal's infrastructure includes a complex system of pipelines, processing units, and storage facilities. This infrastructure is designed to handle large volumes of gas and liquids, making the St Fergus Gas Terminal a critical hub for the industry.

You might enjoy: Liquefied Natural Gas Terminal

Introduction

Located on the North-East coast of Scotland, the St Fergus Gas Terminal is a crucial part of Great Britain's energy system.

It provides access to gas from the UK Continental Shelf (UKCS) and Norway, which it feeds into the gas National Transmission System (NTS).

The terminal regularly supplies between 25% and 50% of the country's natural gas.

St Fergus is wholly owned and operated by National Gas.

The main terminal receives treated gas from three sub-terminals, currently owned by Shell, Ancala, and North Sea Midstream Partners (NSMP).

Expand your knowledge: St Lawrence Seaway System

Comprehensive Infrastructure

The St Fergus Gas Terminal has a comprehensive infrastructure that allows for efficient transportation and processing of gas.

The terminal is connected to the FUKA Pipeline, which plays a crucial role in the gas transportation service.

This pipeline system enables the terminal to offer full transportation and processing services, making it a vital component of the gas industry.

You might like: Bonny Gas Transport

Project Details

The St Fergus Gas Terminal is an impressive operation, and here are some key details about it.

The terminal is operated by Shell UK Limited and owned by a joint partnership between Shell and ExxonMobil, with each company holding a 50% stake.

The partnership between Shell and ExxonMobil extends to the parent company level as well, with both companies sharing equal ownership.

The terminal has a current capacity of 1,165.38 million cubic feet per day, which is a significant amount of natural gas.

Here's a quick rundown of the terminal's key statistics:

The terminal has been in operation since 1982, making it a long-standing presence in the region.

Project Details

The project details are quite fascinating. Shell UK Limited is the operator of this project.

The ownership of the project is split equally between Shell and ExxonMobil, with each company holding 50% of the shares.

The parent company is also a joint venture between Shell and ExxonMobil, with each company owning 50% of the shares.

The current capacity of the project is 1,165.38 million cubic feet per day, which is a significant amount of natural gas.

The proposed capacity of the project is not specified in the provided information.

The pipeline stretches for 448 kilometers, which is a substantial length for a project of this nature.

The diameter of the pipeline is 36 inches, a relatively standard size for a pipeline of this capacity.

The project has been in operation since 1982, making it a long-standing and established project.

Here's an interesting read: St. Johns River Shipbuilding Company

Phase III

Phase III of the project involved expanding and modifying the existing processing plant at St Fergus to accommodate gas from different fields.

The composition of gas varies between each field, and St Fergus was designed to handle Frigg gas. The plant was modified to process richer gas from the Alwyn Field, which began in 1987.

Extra underground storage tanks and a nitrogen-injection unit were added to the terminal as part of the Phase III project. The fire pond was also enlarged to accommodate the increased gas processing capacity.

The project was completed in two stages, with further development in 1992 and 1993 to accommodate gas from Miller and BP’s Bruce Field. The three gas trains can nominally process 36 million standard cubic metres a day.

National Gas Appoints Murphy

National Gas has appointed Murphy to deliver a critical infrastructure project at the St Fergus Gas Terminal in Scotland. This project is a major investment for National Gas.

The project, known as the Medium Combustion Plant Directive (MCPD) Compressor Project, will help keep the facility compliant with emissions regulations. It's a big deal for National Gas to meet these targets by 2030.

Murphy will design, construct, and commission three low-emission compressor units as part of the project. This will involve a range of work, including civil, electrical, control, and instrumentation.

The project includes all associated work, such as process, mechanical, and piping work, along with OEM rotating equipment. This is a complex task that requires a lot of expertise.

Murphy will work alongside its engineering partner Worley as part of the project. They're a trusted team that will help deliver the project on time.

The St Fergus Gas Terminal provides access to gas from the UK Continental Shelf (UKCS) and Norway. It supplies a significant amount of the country's natural gas, around 25-50%.

The main terminal also receives treated gas from three sub-terminals, currently owned by Shell, Ancala, and North Sea Midstream Partners (NSMP). This is an important part of the country's energy infrastructure.

The project is expected to be completed in 2029. This is a tight deadline, but Murphy is confident in its ability to deliver.

Operational Performance

We're proud of our operational performance at the St Fergus Gas Terminal, where we've achieved a remarkable 99% availability since 2016 (excluding planned outages).

Our commitment to safety has led to leading HSE performance, which is a testament to the hard work and dedication of our team.

Consistently achieving the RoSPA Gold Award is a notable accomplishment, demonstrating our focus on safety and excellence.

We've also achieved ISO 14001 Environmental Compliance Standard, which recognizes our efforts to minimize our environmental impact.

In addition to our environmental credentials, we've also earned ISO 9001 Quality Management System accreditation, ensuring that our processes are efficient and effective.

Here are some key statistics that highlight our operational performance:

- 99% availability since 2016 (excluding planned outages)

- Leading HSE performance

- Consistently achieve RoSPA Gold Award

- ISO 14001 Environmental Compliance Standard

- ISO 9001 Quality Management System accreditation

Environment and Community

The St Fergus Gas Terminal has made a concerted effort to minimize its environmental impact, a commitment that dates back to its planning stages. Total, the company behind the terminal, was granted permission on condition that it took measures to protect the environment.

The sand dunes near the terminal were restored and vegetation replaced after the pipelines were pulled ashore. This was a significant step in land development, as it marked a change in how authorities considered environmental impact when examining planning applications.

The Dunes Committee, formed by the University of Aberdeen, still meets biannually to monitor the condition of the sand dunes. This committee was a direct result of the university's environmental concerns over the construction of the terminal.

Total has been awarded ISO 14001, an international standard for environmental management, in recognition of its efforts to minimize damage to the environment. This achievement is a testament to the company's commitment to sustainability.

Environmental initiatives at St Fergus have included planting 2000 hardwood trees in 1991 and extensive recycling campaigns. These efforts demonstrate the company's dedication to reducing its ecological footprint.

St Fergus also actively engages with the local community, hosting Open Days for the families of employees and primary-age school parties. This engagement has helped to build strong relationships between the company and the local residents.

The company has also funded the construction of the St Fergus village hall and bowling green, further demonstrating its commitment to the local community.

Frequently Asked Questions

What does a gas terminal do?

A gas terminal is a facility that handles the entire lifecycle of liquefied natural gas (LNG), from loading and unloading to processing and storage. It's a crucial hub for the safe and efficient transfer of LNG, enabling the transportation and distribution of this vital energy source.

Sources

- https://nsmp-limited.com/our-assets/st-fergus-gas-terminal/

- https://www.nationalgas.com/our-businesses/gas-terminals

- https://www.energyvoice.com/oilandgas/natural-gas/567057/national-gas-st-fergus-project/

- https://frigg.industriminne.no/en/2018/09/14/st-fergus-gas-terminal/

- https://www.gem.wiki/Far_North_Liquids_And_Associated_Gas_System_(Flags)_Pipeline

Featured Images: pexels.com