Implementing a pick and pack solution can significantly reduce labor costs and increase efficiency in warehouse operations. According to studies, a well-designed pick and pack system can reduce labor costs by up to 30%.

In a typical warehouse, manual picking can account for up to 60% of total labor costs. By automating this process, businesses can free up staff to focus on higher-value tasks.

A key benefit of pick and pack solutions is their ability to optimize order fulfillment, with some systems able to process up to 1,000 orders per hour. This is particularly important for e-commerce businesses, where fast and accurate order fulfillment is crucial to customer satisfaction.

Worth a look: Pick Pack and Ship Warehouse

What is Pick and Pack?

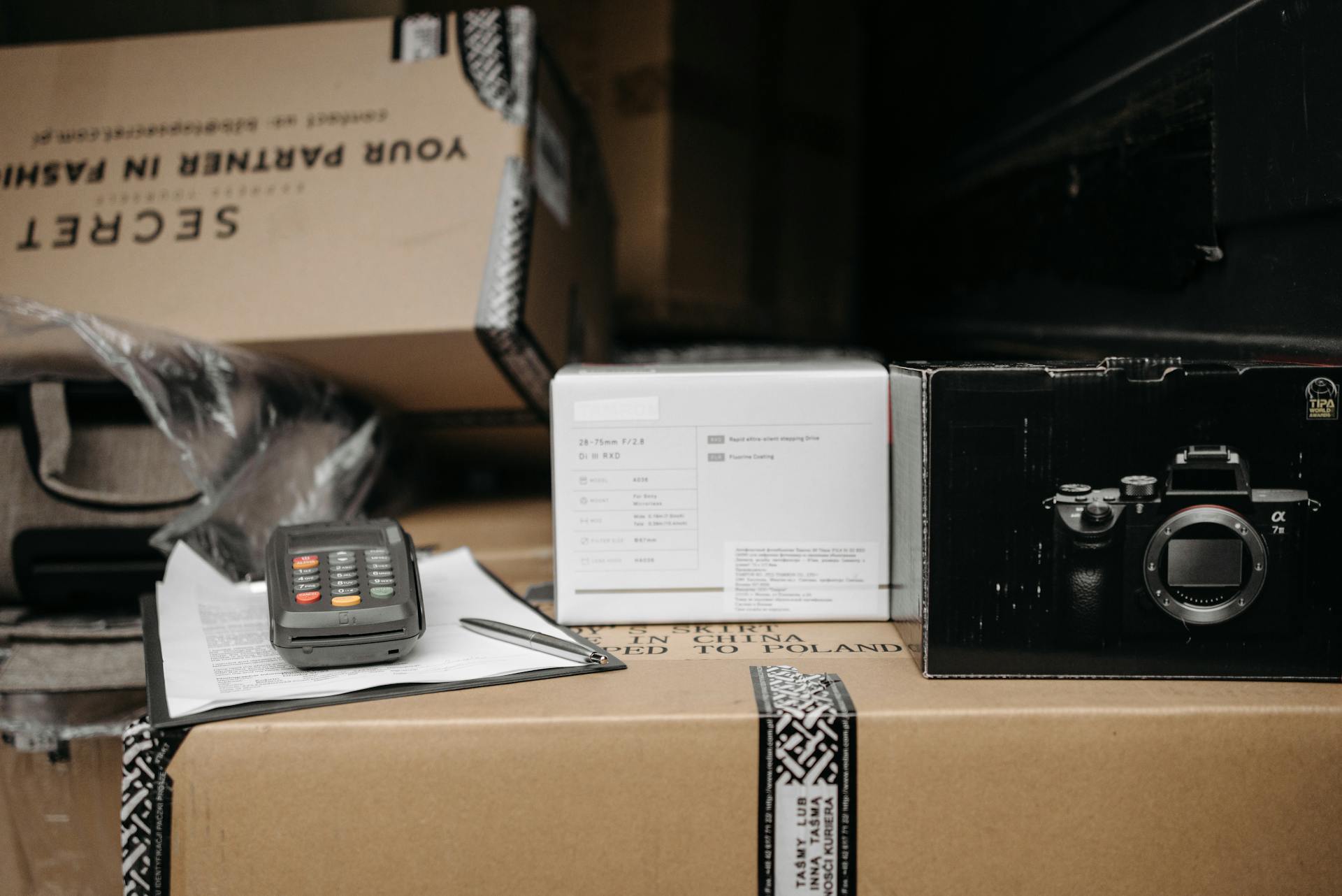

Pick and pack is a fulfillment method that involves picking the right products from a warehouse and packing them for shipping. This process can be done manually or with the help of technology.

A key benefit of pick and pack is that it allows businesses to offer a wide range of products to their customers, even if they don't have a large inventory. This is because pick and pack enables businesses to pick and pack products from multiple locations.

Pick and pack can be done in a variety of ways, including batch picking, where multiple products are picked and packed together. This method is often used for large orders.

In a typical pick and pack operation, products are first identified and picked from the warehouse using a variety of methods, including barcode scanning and radio frequency identification (RFID).

Benefits

Using a pick and pack solution can greatly benefit your business. It ensures orders are shipped on time.

Having easy access to items in your warehouse is crucial for efficiency. This is one of the benefits of using a pick and pack service. By having all items in one location, you can quickly find what you need.

Less handling time is another advantage of pick and pack solutions. This reduces the risk of damage or errors, and also saves you money on labor costs. In fact, pick and pack services can limit freight charges and other costs.

Using a pick and pack service also increases customer satisfaction. Orders are shipped quickly and accurately, which builds trust with your customers. In fact, quick turnaround times are a key benefit of pick and pack solutions.

Here are some of the key benefits of pick and pack solutions:

- Easy access to items

- Less handling time

- Limits freight charges and other costs

- Increases customer satisfaction

- Ensures orders shipped on time

- Eliminates collecting items from different storage facilities

- Quick turnaround times

Pick and Pack Methods

As your ecommerce business grows, you may need to adapt your warehouse picking and packing methods to keep up with demand. Startups and early-stage companies can often get by with picking items one at a time.

For small businesses with limited daily order picking requirements, piece picking is a suitable option. Team members pick one order at a time and take the items to a packing station.

Your pick and pack system should match your inventory and order complexity. This means scaling up to more advanced methods as your business grows and demand increases.

Methods

As your ecommerce business grows, you may need to adapt your warehouse picking and packing methods to meet demand. Startups and early-stage companies can often get away with picking items one at a time, but this method may not be efficient for larger operations.

Advanced warehouse picking methods can create speed, especially when you're selling more products. Your pick and pack system should match your inventory and order complexity.

Picking items one at a time is a simple method that can work for small businesses, but it may not be the most efficient way to handle high volumes of orders.

Piece

Piece picking is a great option for small businesses with limited daily order picking requirements, as it allows team members to focus on one order at a time.

It's a straightforward method where team members pick the items for each order and take them to a packing station.

This approach works well for businesses with a small volume of orders, as it helps to maintain efficiency and accuracy.

For instance, a small business with only a few daily orders can effectively use piece picking to fulfill their customers' needs.

Piece picking is a simple yet effective method that can be easily implemented in a small business setting.

Batch

Batch picking is an efficient method that organizes orders into groups based on where items are in the warehouse. This allows team members to pick more orders at once.

Batch picking typically requires a Warehouse Management System (WMS) to guide staff on when to pick items and from where. A WMS helps streamline the process and reduce errors.

Companies with higher customer orders can benefit from batch picking, making it a suitable option for both small and large businesses.

A fresh viewpoint: Warehouse Pick Pack Work

Kitting

Kitting is a specialized kind of pick and pack service where your warehouse assembles various SKUs into a different, single SKU to create a subscription pack or promotional bundle.

Packing for kitting requires adjusting warehouse packing techniques, which can happen monthly or as new promotions arise.

A fresh viewpoint: Warehouse Pick and Pack

Warehouse Setup and Management

A well-organized warehouse is key to efficient pick and pack operations. This is where "slotting" comes in, a warehouse operations strategy that manages how fulfillment teams minimize travel and search time.

Slotting involves identifying the most efficient route through the warehouse to speed up the pick and pack process. This may include tactics like separating visually similar items to avoid picking errors.

Popular items shouldn't be placed too close together to prevent traffic jams. Efficient path instructions can also help reduce errors and contribute to accurate and timely order fulfillment.

A Very Narrow Aisle (VNA) System can significantly increase storage capacity, allowing for more efficient order processing and quicker pick and pack service. Elevated ceilings for vertical storage maximize space and facilitate rapid order fulfillment.

Wire-guided aisles ensure fast and precise movement of machines, enhancing safety and efficiency in warehouse operations. Turret pickers revolutionize the picking process, enabling quick and accurate handling of large quantities of items.

By using a pick and pack company, businesses can access a comprehensive inventory management system and tracking services. This ensures all orders are fulfilled quickly and accurately.

Pick-and-pack services provide detailed information about orders, such as which items were picked and packed, when they were shipped out, and where they are in the shipping process. This helps businesses keep track of their inventory more easily and ensures orders go out quickly and correctly.

Here's an interesting read: Pick N Pack Order Fulfillment Services

Order Management and Fulfillment

With almost four decades of experience, pick and pack companies like Phase V Fulfillment have honed their skills to provide top-notch order management and fulfillment services.

Experience shows that accuracy matters at every stage of the process, especially during packing, where warehouse teams can check picking accuracy one last time to ensure the right quantities of the right items go in the box.

Having a simplified system in place can help streamline every process, making it easier to manage orders from initial entry to packing and delivery.

Pick and pack companies provide a comprehensive inventory management system and tracking services to ensure all orders are fulfilled quickly and accurately.

Here are some key benefits of partnering with a pick and pack company:

- Extensive experience with almost four decades of handling pick and pack operations.

- A simplified system that streamlines every process and simplifies the complex.

- Accurate results with a focus on 100% accuracy, reducing the risk of returns and reverse logistics costs.

By leveraging these benefits, businesses can optimize their supply chain, reduce costs, and improve customer satisfaction.

Packaging and Shipping

When shipping items, it's essential to use the right packing materials to prevent damage. Infill, like shredded cardboard and packing peanuts, provides cushioning and helps prevent items from shifting in boxes during shipping.

Using the right infill can make a big difference in the safety of your items. For larger items, you may need custom infill, including molded inserts or a mix of infill types. This will ensure that your items are properly protected during transit.

Branded infill can also complement branded packaging, creating a cohesive look for your shipped items.

Right-Sized Box

Using the right-sized box is crucial for optimizing carrier costs. It can help prevent expensive returns or loss.

Boxes that are too big wind up costing you more in shipping costs than you'd otherwise have to pay. This is because larger boxes take up more space on trucks and planes, increasing fuel costs and labor expenses.

But using the right-sized box helps minimize these costs. It also reduces the risk of damage during shipping, which can be costly to fix.

Damages during shipping can be costly to fix, but using the right-sized box can help prevent them. This is especially true for fragile items that require extra care.

Recommended read: Tetra Pack Boxes

Protect Items with Infill

Protecting your items during shipping is crucial, and infill is a great way to do it. Infill, like shredded cardboard and packing peanuts, provides a lot of cushioning and helps prevent items from shifting in boxes.

Shredded cardboard and packing peanuts are effective infill options, but for larger items, you may need custom infill, such as molded inserts or a mix of infill types.

Branded infill can be a nice touch, especially if you're using branded packaging. It adds a professional touch to your shipping and can make a good impression on your customers.

Check this out: Where to Recycle Packing Peanuts

Use Proper Tape

Using the right tape is crucial for securing your packages properly. You'll want to choose the right type of tape for the job.

Filament tape is great for extra strength, and reinforced gummed tape is a good choice for both strength and environmental sustainability. Duct tape is also an option, but it's not always the best choice.

How you apply tape matters too. Taping corners can help prevent crushing, and multi-directional taping tactics can provide extra security.

Optimizing Pick and Pack

By implementing pick-and-pack methods, businesses can save time, which is especially beneficial to those with limited staff who need to get orders out quickly.

Pick-and-pack methods allow businesses to have a service take care of the time-consuming tasks in the warehouse, freeing up staff to focus on other areas of the business.

This can lead to increased productivity and efficiency, allowing businesses to handle a higher volume of orders without sacrificing quality.

Time-Saving

Pick-and-pack methods can save businesses a significant amount of time, which is especially beneficial to those with limited staff.

By outsourcing pick and pack operations to a third-party logistics (3PL) provider, businesses can free up hours that would have been spent in the warehouse.

This time-saving advantage can help businesses get orders out quickly, which is crucial for customer satisfaction and loyalty.

With a 3PL service taking care of pick and pack, businesses can scale up their resources to meet increased demand and stay competitive.

Curious to learn more? Check out: 3pl Pick and Pack

Optimize for Dimensional Weight

Optimizing for dimensional weight is a game-changer for businesses that ship large or heavy items. This pricing structure measures the size of a package to calculate a weight equivalency.

Shipping large items can be expensive, but compact packaging can reduce your pick and pack fee based on packaging materials and your dimensional weight.

If you ship items that are subject to dimensional weight pricing, consider using packaging materials that minimize space and weight. This can lead to significant cost savings on shipping.

By optimizing for dimensional weight, you can save money on shipping and make your business more competitive.

Suggestion: Packing Materials

Software and Integration

To ensure a seamless pick and pack process, you need software that integrates all the moving parts.

Fulfillment center staff need to know who is handling which orders and when items are ready to flow to the next stage.

Your warehouse management system is key to tying together information on overall workflows, fulfillment status, and productivity.

The complexity of your setup and integrations may be determined by a 3PL's warehouse management software when partnering with them.

Make sure you understand what it takes to be onboarded with a 3PL before moving forward, to avoid any technical hiccups.

On a similar theme: Order and Delivery Management System

Outsourcing

Outsourcing can be a game-changer for businesses with fluctuating order volumes. A 3PL can provide scalable and cost-effective solutions, allowing you to adapt to changing market trends and seasonal fluctuations.

Outsourcing the pick and pack process eliminates the need for substantial upfront investments in warehouse space and other resources. This shift to variable costs provides financial flexibility and allows businesses to allocate resources strategically.

Cost considerations play a crucial role in the decision-making process. A 3PL may be able to provide a favorable pick and pack fee based on order fulfillment and SKU volumes.

Outsourcing can help you avoid the extra stress of rapid growth. As your business grows, a 3PL can provide logistical capacity without the need for additional investments.

Here are some key benefits of outsourcing pick and pack operations:

- Cost Efficiency: Eliminate the need for your own warehousing, reducing overheads significantly

- Scalability at Your Fingertips: As your business grows, so does your logistical capacity, without the extra stress

- Accelerated Delivery Times: Products are shipped from the nearest point, reducing transit times

- Unmatched Expertise: Drawing on years of experience across various sectors, a 3PL offers tailored solutions for your specific needs

Outsourcing can also provide precision and accuracy in every step of the pick and pack process. A 3PL can prioritize precision and accuracy, handling your orders with care and attention to detail.

Choosing a Service Provider

Choosing a Service Provider is a crucial step in finding the right pick and pack solution for your business.

Research is key, so take the time to read reviews and ask for referrals from other customers to get a sense of the service provider's reputation and capabilities. SHIPHYPE, for example, is a great option that can help businesses get started quickly with their comprehensive range of services.

A picking and packing service provider like SHIPHYPE specializes in handling small quantities and ensuring accurate order fulfillment. They're perfect for smaller businesses with many individual orders.

Why Choose Phase V Fulfillment?

Choosing a reliable service provider is crucial for the success of your business. You should consider a provider that offers precision and accuracy in every step of the pick and pack process.

Phase V Fulfillment prioritizes precision and accuracy, handling orders with care from meticulous inventory management to quality control. This ensures that your orders are fulfilled correctly and efficiently.

A customized solution is also essential for your business growth. Phase V Fulfillment offers fully customizable pick and pack solutions tailored to your unique requirements, allowing you to adapt to changing needs without missing a beat.

Scalability is another key factor to consider. Phase V Fulfillment's services scale with your business growth, ensuring that you can focus on growing your business without worrying about logistical capacity.

Reducing lead times and improving customer satisfaction are also important benefits of outsourcing your pick and pack operations to Phase V Fulfillment. Their streamlined processes and cutting-edge technology ensure that orders are picked, packed, and shipped with speed and efficiency.

Here are some key benefits of choosing Phase V Fulfillment:

- Precision and accuracy in every step of the pick and pack process

- Customized solutions tailored to your unique requirements

- Scalability to accommodate your business growth

- Speed and efficiency in order fulfillment

- Cost-effectiveness through reduced overhead costs

- Advanced reporting and analytics tools for informed decision-making

Competitive Pricing

Pick and pack service providers offer competitive pricing, which can be a game-changer for businesses on a tight budget.

This means businesses can get the items they need for a lower cost than if they purchased them outright.

Things to Consider When Choosing a Service Provider

Choosing the right service provider is crucial for your business's success.

Research is key. Look up what other customers are saying about the company before making a decision.

SHIPHYPE provides a comprehensive range of services that can help businesses get started quickly. Their team can answer any questions and provide additional information about their pick and pack services.

Consider the size of your business and its needs. If you have a lot of products and not much space to store them, a service provider can be a lifesaver.

A service provider can help you save time and ensure your customers get their orders correctly and on time. They're especially helpful if you sell products online or through catalogs.

Look for a service provider with a deep understanding of the 3PL pick and pack market. This will ensure your orders are fulfilled quickly and efficiently.

It's essential to understand the differences between a pick and pack service provider and a fulfillment center. A service provider mainly focuses on finding, packing, and shipping individual customer orders.

If you have a smaller business with many individual orders, a picking service provider might be the way to go. But if you have a bigger pick and pack operation with more complex needs, a fulfillment center could be a better fit.

Suggestion: Tagg Logistics Order Fulfillment Center

Phase V Fulfillment Services

At Phase V Fulfillment Services, we've implemented cutting-edge warehouse designs to maximize efficiency and speed. Our Very Narrow Aisle (VNA) System allows for significantly increased storage capacity, enabling faster order processing and quicker pick and pack services.

One of the key features of our warehouse design is the use of elevated ceilings for vertical storage. This maximizes vertical space, enabling us to store more products and facilitate rapid order fulfillment.

Our wire-guided aisles ensure fast and precise movement of our machines, enhancing safety and efficiency in our warehouse operations. This results in faster pick and pack times.

We also utilize advanced turret pickers to revolutionize the picking process. These machines enable quick and accurate handling of large quantities of items, streamlining our pick and pack operations.

As a pick and pack company, we understand the importance of accurate and timely order fulfillment. By leveraging these cutting-edge technologies, we're able to provide faster and more efficient services to our clients.

Additional reading: Bcc Packing Efficiency

Advanced Strategies and Technologies

We use technology to determine the perfect box size, balancing protection with cost and environmental considerations.

Our state-of-the-art pick and pack software allows us to track orders in real time, so you can rest assured that we’re on top of every order from start to finish.

We can kit items for orders that include multiple products, enhancing the customer unboxing experience.

Customized packaging options are available to include your branding elements, making every delivery special.

We often provide this customized service for monthly subscription boxes.

Frequently Asked Questions

What is the average pick and pack fee?

The average pick and pack fee ranges from $0.20 to $5.00 per item, depending on the fulfillment center. This cost can add up quickly for large or multi-item orders.

Featured Images: pexels.com