Intermodal transport is a game-changer for freight shipping. It allows for the efficient transfer of goods between different modes of transportation, such as trucks, trains, and ships.

This approach has been shown to reduce transportation costs by up to 30% compared to traditional methods. By using a combination of modes, intermodal transport can also decrease transit times and increase the speed of delivery.

Intermodal transport is not just about saving time and money, but also about reducing the environmental impact of transportation. According to a study, intermodal transport can reduce greenhouse gas emissions by up to 20% compared to traditional methods.

History of Intermodal Transport

Shipping companies had to pack cargo by hand in small packages into ships, trucks, and trains. This process was not cost-effective and seriously slowed transportation, with packages constantly being lost.

The constant slow loading and unloading even composed the majority of transportation costs. It wasn't until logistics companies began applying logic used by the United States Military and English rail car owners to create containers that reduced transportation costs and increased the capability of intermodal shipping.

Additional reading: Less-than-truckload Shipping

The innovators in charge of transport thought something was lacking in efficiency, and it was possible to ship more freight at lower costs. In 1977, intermodal transport innovator Malcom McLean started encouraging the use of "double stack cars" on rail lines.

The first intermodal containers appeared on the scene in 1955, developed by Malcom McLean and Keith Tantlinger. These containers were 8 ft x 8 ft x 10 ft and had a locking mechanism at their corners so they could stack high, and cranes could easily lift them.

1950s-60s

The 1950s and 1960s were pivotal decades for intermodal transport. In the 1950s, Europe began trying to create standard containers to use for shipping around the continent and saw some success. Intermodal transport became possible in 1955 when the first intermodal container appeared on the scene, developed by Malcom McLean and Keith Tantlinger.

These early containers were 8 ft x 8 ft x 10 ft in size and had a locking mechanism at their corners, allowing them to stack high and be easily lifted by cranes. The US government began using these containers to ship supplies to Vietnam. However, within the United States, several companies were using different sizes of containers, leading to a lack of standardization.

Many companies used 24-foot long containers, others used 35-foot long containers, and others even tried to develop bigger containers. Without standardization, shipping became a guessing game according to the company you partnered with. International shipping companies, the railroad companies of the United States and many European countries, and trucking companies met to standardize containers in the late 1960s.

The standard size 8 feet and 6 inches for steel containers became widely adopted, allowing shippers to anticipate reliable capacity. Intermodal transport quickly became more feasible and popular with the rail industry and many logistics companies for its potential to significantly reduce costs.

For your interest: Jinhui Shipping and Transport

The 1980s: Rail Freight Development

The 1980s saw significant development in rail intermodal freight transportation, with double stack cars becoming the norm by 1984. These cars carried two stacks of intermodal containers in a "well" car, unlike flat cars, which lowered the height of the containers and concentrated the center of gravity more safely.

Double stack cars enabled intermodal shipments to carry more cargo and avoid highway congestion entirely, significantly increasing efficiency exponentially. This development allowed for faster final delivery and made rail transportation a particularly efficient means of cargo transit.

The introduction of double stack cars built upon the innovations of earlier intermodal transport pioneers, such as Malcom McLean, who started encouraging their use in 1977. By the 1980s, intermodal transport had continued to progress, with improvements in container design and technology.

The use of cranes in the 1980s made it easier to remove containers from trains and move them between modes of transport, further streamlining the process. This was a significant improvement over the earlier "circus style" ramps that required trucks to pull containers down.

You might enjoy: Bakfiets Cargo Bicycle

Types of Intermodal Transport

Intermodal transport comes in various forms, each with its own strengths and weaknesses.

Direct truck transport combines ships with trucks for inland transportation, making it a cost-effective option for international shipping.

This method is particularly suitable when speed isn't a major concern, but cost-effectiveness is desired.

Direct barge transport, on the other hand, involves using large ocean vessels and smaller barges to move goods between international seaports and inland terminals accessible by rivers, canals, and other inland waterways.

Barge combined transport is similar to rail combined, moving goods across various regions, including coastal and inland waterways, with initial pickup or final delivery via truck on road networks.

It's particularly useful for moving goods from coastal ports to inland waterway terminals and onwards to their final destination using trucks.

Explore further: Moving Freight Companies

Direct Truck

Direct truck is a popular choice for international shipping, especially when cost-effectiveness is desired over speed.

This method combines ships for ocean transport with trucks for inland transportation, making it a common choice for companies looking to save on shipping costs.

In the United States, many rail lines terminate in or around Chicago, Illinois, serving as a common relay point for containerized freight moving across the country.

Explore further: Common Carrier

Trucks are frequently used to connect ocean and rail segments of a global intermodal freight movement, often referred to as drayage, and is typically provided by dedicated drayage companies or by the railroads.

A container destined for the east coast from the west will arrive in Chicago via the Union Pacific or BNSF Railway and have to be relayed to one of the eastern railroads, either CSX or Norfolk Southern.

If this caught your attention, see: Intermodal Drayage Company

Rail Combined

Rail Combined is a type of intermodal transportation that combines the efficiency of trains with the flexibility of trucks. This method is ideal for shippers who need to transport goods over long distances but don't have access to rail.

Trains can travel long distances quickly and efficiently, but they often require a rail connection to and from the final destination. Rail Combined solves this problem by using trucks for initial pick-up and final delivery, allowing shippers to reach a wider geographical area.

Related reading: Cheap Pallet Trucks

This method is particularly useful for shippers who need to transport goods to areas without rail access. For example, as mentioned in the example, a shipper in Chicago can use Rail Combined to transport goods to Shanghai, China.

Here's a summary of the advantages of Rail Combined:

- Combines the efficiency of trains with the flexibility of trucks

- Expands geographical coverage by allowing trucks to pick up and deliver goods in areas without rail access

- Can transport goods over long distances quickly and efficiently

Handling

Intermodal transport is a complex system that requires specialized equipment to handle containers efficiently. Containers come in standard sizes, with the most common lengths being 20, 40, 45, 48, and 53 feet.

The three common sizes of containers are one TEU (20-by-8-foot), two TEU (40-by-8-foot), and highcube (40-by-8-foot × 9-foot-6-inch). These sizes allow for easy transfer between modes of transportation.

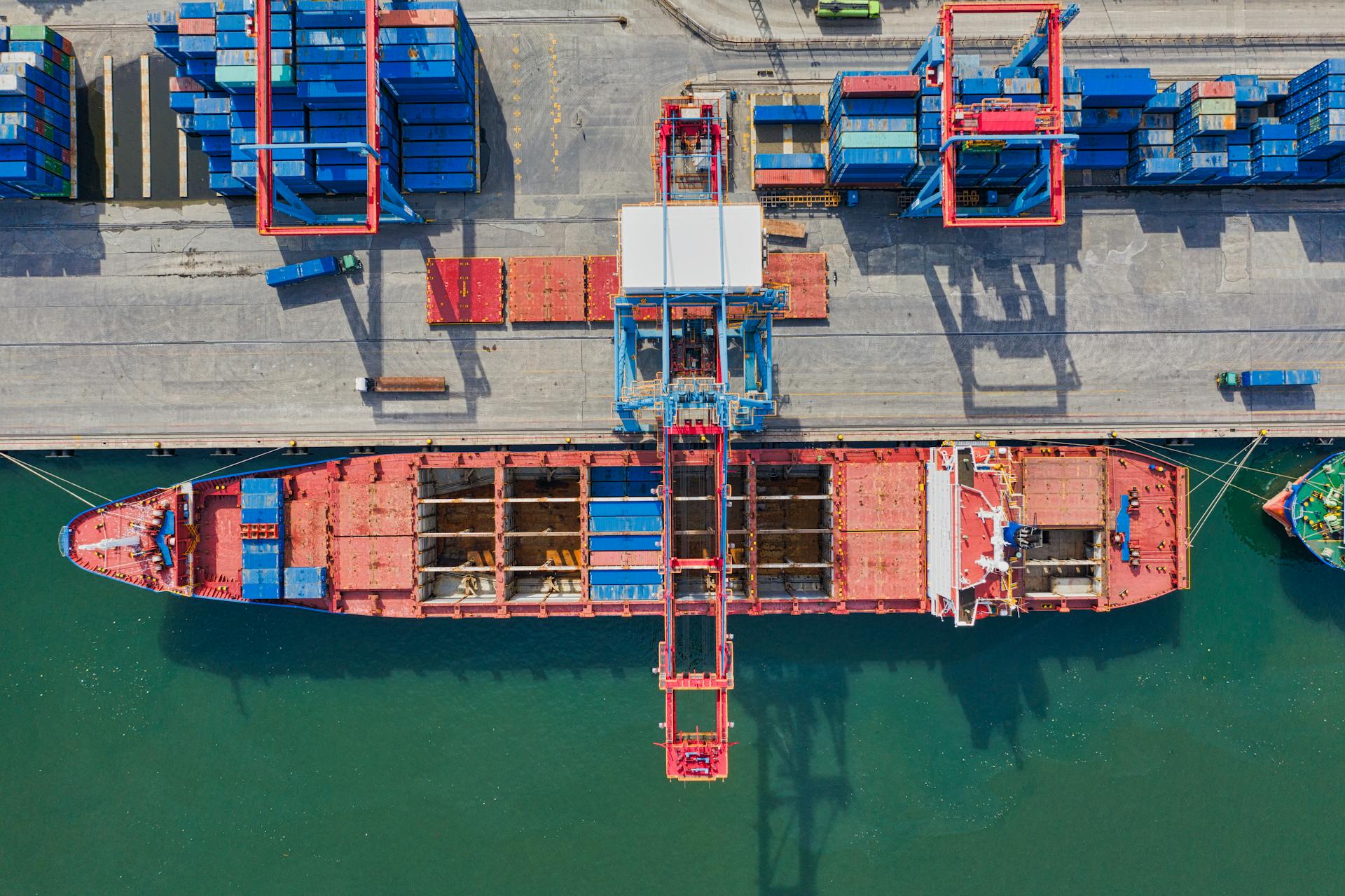

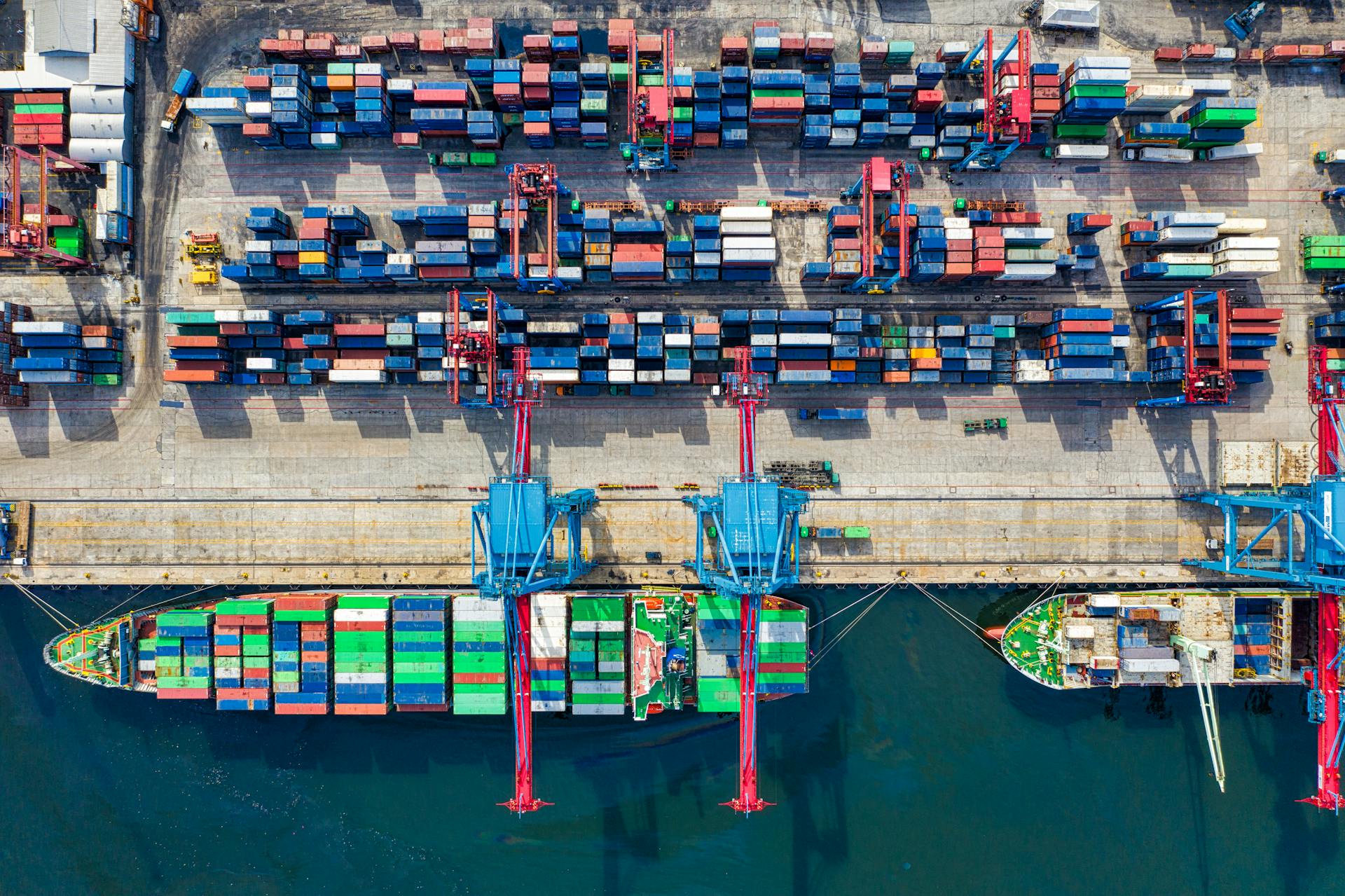

Handling equipment is designed with intermodality in mind, assisting with transferring containers between rail, road, and sea. Container gantry cranes are used to transfer containers from seagoing vessels onto trucks or rail wagons.

Straddle carriers and rubber tyred gantry cranes can straddle container stacks as well as rail and road vehicles, allowing for quick transfer of containers. Grappler lifts grip the bottom of a container rather than the top, making them a versatile option.

On a similar theme: Truck and Transportation Equipment

Reach stackers are fitted with lifting arms as well as spreader beams for lifting containers to truck or rail and can stack containers on top of each other. Sidelifters are road-going trucks or semi-trailers with cranes fitted at each end to hoist and transport containers.

Forklift trucks in larger sizes are often used to load containers to/from truck and rail. Flatbed trucks with special chain assemblies can pull containers onto or off of the bed using the corner castings.

Here are some examples of handling equipment:

Load Securing

Load securing is a crucial aspect of intermodal transport. It's estimated that up to 25% of accidents involving trucks can be attributed to inadequate cargo securing.

Cargo that's not properly secured can be a recipe for disaster, causing severe accidents, loss of cargo, loss of lives, and even environmental hazards.

There are various methods and materials available to stabilize and secure cargo in containers. Conventional load securing methods like steel banding and wood blocking & bracing have been around for decades.

Discover more: Cargo Scanning

In recent years, new and innovative load securing methods have emerged, including polyester strapping and lashing, synthetic webbings, and Dunnage Bags, also known as air bags.

Here are some common load securing methods used in intermodal containers:

- Steel banding

- Wood blocking & bracing

- Polyester strapping and lashing

- Synthetic webbings

- Dunnage Bags (also known as air bags)

Sizes and Weights

Sizes and Weights are crucial factors to consider when it comes to intermodal transport.

There are five standard container sizes used today, and they're all about the same height and width, at 8'6″.

The standard sizes are: the 20-foot long unit, the 40-foot long unit, the 45-foot long unit, the 48-foot long unit, and the 53-foot long unit.

All of these containers have a maximum capacity of 36,000 kg, including the weight of the container itself.

The ISO measures the volume of these containers using the TEU – the "twenty-foot equivalent unit" – which indicates how much cargo can fit inside.

For your interest: Port of Long Beach Transportation

Examples and Applications

Intermodal transport is used in various industries, such as agriculture and construction, where heavy equipment and machinery need to be transported over long distances.

In the construction industry, intermodal transport is used to move large building materials like cranes and excavators between job sites.

For example, a company in the United States used intermodal transport to move a 300-ton crane from a factory in California to a construction site in New York.

Intermodal transport is also used in the agriculture industry to move large equipment like tractors and combines between farms.

Agricultural companies in Australia use intermodal transport to move heavy machinery like tractors and harvesters from ports to rural areas.

Intermodal transport allows for faster and more efficient transportation of goods, reducing transit times by up to 50%.

This is especially beneficial for companies that need to transport perishable goods, like food and electronics, over long distances.

In the article, we discussed how intermodal transport is used in various industries, including agriculture and construction.

It's worth noting that intermodal transport is not limited to these industries and can be applied to any industry that requires the transportation of heavy goods.

Consider reading: Heavy Transport Helicopter

Shipping: Core Meaning

Shipping is about transporting goods from one place to another, often by sea, land, or air. It's a crucial part of intermodal transport, allowing goods to be moved efficiently and effectively.

The core meaning of shipping can be seen in the various types of transport, such as container shipping, which involves loading goods into large containers that can be easily transferred between ships, trains, and trucks. This type of shipping is often used for international trade.

Shipping can also involve breakbulk cargo, where goods are loaded and unloaded individually, rather than in containers. This method is often used for oversized or heavy cargo.

Intermodal transport relies on shipping to connect different modes of transport, such as sea and land. For example, shipping goods from a port to a rail terminal allows them to be transferred to trains for further transport.

Shipping companies play a vital role in the supply chain, ensuring that goods are delivered on time and in good condition. They often work closely with other transport providers to ensure seamless transitions between modes of transport.

Shipping can be a complex process, involving multiple stakeholders and modes of transport. However, with the right planning and coordination, it can be a highly efficient and effective way to move goods.

Take a look at this: High Value Cargo Transportation

Key Benefits

Intermodal transport can save shippers 10%-15% of the cost of a shipment compared to truckload, with roughly half of the fuel surcharge of a truckload move.

One of the biggest advantages of intermodal transport is its potential to mitigate climate change by fostering fuel efficiency and limiting environmental damage.

Intermodal transportation can ship massive loads of items and containers safely and reliably, increasing capacity and reducing the need for multiple transportation methods.

By streamlining the shipping process, intermodal transport eliminates the need for longshoremen to sort packages within containers, reducing costs and time.

Its carbon footprint is lower than many other means of shipping, making it a more environmentally friendly option.

Disadvantages and Challenges

Intermodal transport has its downsides, just like any other mode of transportation. The major disadvantages of intermodal transportation are its complexities.

Intermodal transportation involves multiple modes of transport, which can lead to increased costs. The cost of switching between modes can be high, making it less efficient than a single-mode transport.

One of the biggest challenges of intermodal transportation is coordinating different modes of transport. This requires careful planning and communication between different stakeholders, which can be time-consuming and costly.

Risk for Damage

Handling freight quickly and not opening it can lead to damage that goes unnoticed. The risk of damage increases with each handoff, making it a significant challenge in the shipping process.

The more freight changes hands, the higher the risk of damage becomes, as mentioned earlier. This is because each handoff presents an opportunity for something to go wrong.

Freight is often handled quickly, which can lead to a lack of attention to detail and an increased risk of damage. This can result in costly repairs or even replacement of the damaged items.

Suggestion: How Does Truck Transportation Lead to Inventory

Environmental Impact

Intermodal transportation is a sustainable means of shipping due to its fuel efficiency. This is because it relies on reusable materials and reduces the use of trucks to avoid traffic and fuel waste.

The reliance on reusable materials in intermodal transportation is a significant factor in its environmental benefits.

Tracking and Inventory

In the past, tracking and inventory management in intermodal transport was a laborious and inefficient process. Companies used paper and pen to keep track of massive loads of cargo, which meant high inventory costs and uncertain delivery times.

This outdated method was mainly due to the lack of technology that could accurately trace intermodal transport. Even in the 1980s, technology wasn't equipped to provide customers with accurate delivery times.

The change came with the development of shipping software in the 21st century. This new technology used the internet and enhanced computer systems to foster lower costs for inventory and information tracking.

Now, when a container arrives at a ramp, it's easy to enter it into a shared system between companies. This allows shippers to provide an accurate estimate of when a container will arrive at its final destination.

Companies can also use data from these information systems to track arrival time and fuel efficiency, and even estimate carbon footprint.

Discover more: Premium Palletizing and Transport Systems

Intermodal Transport Modes

Intermodal transport modes offer a range of options to suit different needs. There are four standard methods of intermodal transport, which differ among countries that use this method of cargo transport.

Direct truck is a common choice for international shipping, combining ships for ocean transport with trucks for inland transportation. It's a cost-effective option when speed isn't a major concern.

Rail combined utilizes the efficiency of trains for long hauls, while also offering the flexibility of trucks for initial pick-up and final delivery. This mode expands geographical coverage, as shippers or consignees don't need to have direct rail access.

Barge combined transport moves goods across various regions, including coastal and inland waterways, with initial pick-up or final delivery via truck on road networks. It's particularly useful for moving goods from coastal ports to inland waterway terminals and onwards to their final destination using trucks.

Multimodal transport involves a single contract with a single carrier, and cargo is not necessarily in a shipping container, such as less-than-container load shipments.

Here's a summary of the intermodal transport modes:

- Direct truck: combines ships and trucks for ocean and inland transport

- Rail combined: uses trains for long hauls and trucks for initial pick-up and final delivery

- Barge combined: moves goods across various regions using barges and trucks

- Multimodal: a single contract with a single carrier, often for less-than-container load shipments

Direct Rail

Direct rail is a cost-effective solution for large cargo volumes traveling long distances internationally. It leverages trains for inland transportation and ships for overseas movement.

For direct rail to be possible, the shipper or consignee needs to be directly linked to a rail terminal. This is the only way to ensure a seamless transfer of containers between trains and ships.

Direct rail offers significant cost savings, especially for large cargo volumes. This is because trains can carry heavy loads over long distances, reducing the need for multiple transfers and handling.

To take advantage of direct rail, shippers and consignees need to have a rail access point. This could be a rail terminal or an inland depot that is connected to the rail network.

Direct Barge

Direct barge transport is typically used to move goods between international seaports and inland terminals accessible by rivers, canals, and other inland waterways.

Large ocean vessels are used in conjunction with smaller barges to facilitate this type of transport.

Direct barge transport can only connect directly to shippers/consignees if they own a barge terminal as part of their factory setup.

This means that shippers without a barge terminal may not be able to use direct barge transport as a viable option.

You might like: Inland Waterway Transport

Shipping

Shipping is a vital part of intermodal transport, allowing goods to be transported by sea, river, and coast. The first container ship made its debut in 1931, but it wasn't until the 1950s that containerization became a reality.

Container ships are custom-built to hold containers, with some vessels capable of holding thousands of containers. Their capacity is often measured in TEU (twenty-foot equivalent unit) or FEU (forty-foot equivalent unit). For example, a vessel that can hold 1,000 40-foot containers or 2,000 20-foot containers can be said to have a capacity of 2,000 TEU.

The largest container ships in regular operation can carry over 15,000 TEU, but they require specialized deep water terminals and handling facilities. The container fleet available, route constraints, and terminal capacity play a large role in shaping global container shipment logistics.

In 2020, 1.85 billion metric tons of freight reached their destination through at least a partial journey on a container ship. This number shows that container ships account for a significant portion of the world's shipping.

Intriguing read: Transportation to Cruise Ship

Container ships use two general sizes of containers for shipping: the 20-foot long container and the 40-foot long container. Unlike rail, ships use these two sizes due to their high capacity.

Container ships operate on rivers, canals, seas, and oceans, and can move freight between major ports both domestically and internationally. They transfer freight on rivers, canals, seas, and oceans and can move freight between major ports both domestically and internationally.

Here are some key facts about container ships:

- Container ships can hold thousands of containers.

- Their capacity is often measured in TEU or FEU.

- The largest container ships can carry over 15,000 TEU.

- Container ships use 20-foot and 40-foot long containers.

Aircraft

Aircraft is the fastest-developing of the intermodal transportation methods. It grew by another seven percent in the last year.

The American market uses aircraft for urgent freight, often shipping items in the "bellies" of passenger planes using smaller containers. These are not typically ISO containers.

In contrast, Europe often uses smaller freight containers that fit in planes when not shipping in passenger planes. This approach is also used in the American market.

Boeing patented a plane five years ago that can fit the 20-foot intermodal container, opening up new possibilities for this sector.

For more insights, see: Boat and Yacht Transportation Market

Intermodal Transport Process

The intermodal transport process involves coordinating multiple modes of transportation to efficiently move goods from one place to another. This process typically begins with the preparation of goods for transport, which includes packaging and labeling.

The first step in the intermodal transport process is loading the goods onto a container or trailer, which is then transported to a terminal or port. From there, the goods are transferred to a new mode of transportation, such as a ship or train.

The intermodal transport process can be complex, involving multiple stakeholders and modes of transportation. However, with careful planning and coordination, it can be a cost-effective and efficient way to move goods over long distances.

Transloading

Transloading is a process where the contents of a container are unloaded and sorted to be placed on different transportation methods. This is often necessary when the final destination requires a different mode of transportation, such as from truck to train or ship to truck.

Transloading involves unloading the container and sorting through it to put the freight on different transportation methods. This can be a time-consuming and labor-intensive process.

In contrast to intermodal shipping, which moves entire steel containers without sorting through the contents, transloading requires manual handling of the freight. This is because the container needs to be opened and the contents reloaded onto different vehicles.

Transloading can be a necessary step in getting freight to its final destination, but it can also increase costs and reduce efficiency.

Route and Infrastructure

When choosing an intermodal transport route, the distance between locations is a crucial factor. The farther apart the origin and destination, the more cost-effective intermodal shipping becomes.

Intermodal shipping relies on well-maintained infrastructure, which can be a challenge in areas with limited rail networks. Congested ports and underdeveloped intermodal terminals can also disrupt the shipping process.

Researching the availability and quality of infrastructure along your chosen route is essential to making an informed decision. This will help you avoid potential delays and disruptions.

Key Factors and Considerations

Choosing the right intermodal transportation method involves several key factors, like considering the type of cargo and its value.

For dry, bulk goods that can be containerized, intermodal is a great option. However, perishables, hazardous materials, or oversized cargo might require specialized handling or temperature control.

The value of your goods is also crucial, as high-value cargo may be at risk of delays or damage during transfers between modes. In such cases, air freight might be a better option despite the higher cost.

Intermodal shipping can save shippers 10-15% of the cost of a shipment compared to truckload, and roughly half of the fuel surcharge of a truckload move.

A unique perspective: How Much Is Insurance for a Transportation Company

Cargo Characteristics

Intermodal transportation is well-suited for dry, bulk goods that can be containerized.

The type of cargo is a crucial factor in choosing the right mode of transportation. For instance, perishables, hazardous materials, or oversized cargo might require specialized handling or temperature control.

High-value cargo can be a challenge for intermodal transportation, as the potential risk of delays or damage during transfers between modes might outweigh the cost savings.

Operational Needs

Operational needs require careful consideration to ensure smooth logistics. Delivery time requirements are crucial, taking into account both schedule frequency and transit time.

To meet tight deadlines, factor in the schedule frequency of the intended intermodal solution. This will help you avoid delays and ensure timely delivery of your cargo.

Robust tracking systems are essential for intermodal shipping, allowing you to monitor cargo movement across different modes and carriers. Clear communication and information sharing throughout the journey are also vital for successful intermodal shipping.

You might like: Drones for Delivery

Standardization and Markings

The International Standardization Organization (ISO) came up with the dimensions and standards that transport containers must meet today.

Containers must meet these standards so they can be used in shipping, and once they do, they become certified "ISO containers".

These ISO containers have specific dimensions, but the first intermodal containers developed by Malcom McLean and Keith Tantlinger were 8 ft x 8 ft x 10 ft.

All shipping containers approved by the ISO must have several codes marked on their outside, including the manufacturer, the port of origin, its owner, and its use.

These markings allow each person managing the shipping process to track the containers if needed.

Markings

Shipping containers have specific markings that provide crucial information about their manufacturer, port of origin, owner, and use.

These markings help track the containers throughout the shipping process.

Each container must have the manufacturer's code marked on it.

The port of origin is also indicated through a specific code.

The owner's information is included to ensure the container can be identified and returned to them.

These markings make it easier for everyone involved in the shipping process to access the necessary information.

Standardized Iso

Standardized containers are a game-changer in shipping, and it's all thanks to the International Standardization Organization. They came up with the dimensions and standards that transport containers must meet today.

To become certified "ISO containers", they must meet these standards. This ensures that containers can be used in shipping without any issues.

The International Standardization Organization's standards are crucial for efficient shipping. It saves time and resources by allowing containers to be easily transported and stored.

ISO containers have specific dimensions, which are critical for safe and secure shipping.

You might enjoy: Air Transport International

Multimodal Transport

Multimodal transport offers a single contract system, where you make a contract with one company that will organize the intermodal transportation.

This streamlined process simplifies logistics and reduces administrative tasks.

You must contract and plan each separate step with standard intermodal transportation.

Intermodal Transport Industry

The intermodal transport industry experienced significant growth in the 1960s due to the standardization of containers and the development of container ships.

With standard-size containers measuring 8 feet and 6 inches, shippers could anticipate a reliable capacity, making intermodal transport more feasible and popular.

By the late 1960s, intermodal transport became the premier means of transit for freight on the seas and railroad tracks.

Regional manufacturing facilities and hubs linked to rail yards allowed freight to transfer between different modes and reduced congestion from seaports or larger ports, increasing the possibilities of intermodal transport.

Container ships specifically outfitted for efficient shipping became a key component of intermodal transport, enabling international bulk shipping to become more efficient.

Today: Freight Shipping Ramp Development

Intermodal transport has made significant strides in recent decades, but one major issue was the underdeveloped intermodal ramp system.

The earlier "circus style" ramps were less efficient because they required trucks to pull containers down, rather than using cranes to move them.

In the 1980s, the industry started using cranes to move containers, making it easier to remove them from trains and transfer them between modes of transport.

This improvement greatly enhanced the efficiency of intermodal transport.

Top Shipping Liner Companies by TEU Capacity

The intermodal transport industry is a complex network of shipping companies, routes, and terminals. One key aspect of this industry is the size of container ships, which can hold thousands of containers.

For example, the largest container ships in regular operation can carry in excess of 15,000 TEU, or twenty-foot equivalent units. These vessels are custom-built to hold containers and are typically stacked up to seven units high on board.

The largest container ships are limited by the capacity of important sea routes such as the Panama and Suez canals. The largest size of container ship able to traverse the Panama canal is referred to as Panamax, which is presently around 5,000 TEU.

Here's a list of the top 20 container shipping companies by TEU capacity, based on data from 6 January 2016:

- A.P. Moller-Maersk Group - 2,996,188 TEU capacity, 585 ships

- Mediterranean Shipping Company - 2,678,779 TEU capacity, 496 ships

- CMA CGM - 1,819,351 TEU capacity, 460 ships

- Evergreen Marine Corporation - 931,849 TEU capacity, 195 ships

- Hapag-Lloyd - 930,398 TEU capacity, 174 ships

- COSCO - 870,222 TEU capacity, 162 ships

- CSCL - 684,640 TEU capacity, 134 ships

- Hamburg Süd - 645,889 TEU capacity, 136 ships

- Hanjin Shipping - 626,217 TEU capacity, 104 ships

- OOCL - 561,522 TEU capacity, 104 ships

- MOL - 554,425 TEU capacity, 98 ships

- Yang Ming Marine Transport Corporation - 538,912 TEU capacity, 102 ships

- APL - 535,007 TEU capacity, 86 ships

- UASC - 512,785 TEU capacity, 57 ships

- NYK Line - 495,723 TEU capacity, 104 ships

- K Line - 386,265 TEU capacity, 66 ships

- Hyundai Merchant Marine - 379,392 TEU capacity, 57 ships

- Pacific International Lines - 362,131 TEU capacity, 147 ships

- Zim - 358,264 TEU capacity, 82 ships

- Wan Hai Lines - 215,244 TEU capacity, 85 ships

Frequently Asked Questions

Why is it called intermodal?

Intermodal shipping is called as such because it involves moving freight by two or more modes of transportation, such as trucks, trains, and cargo ships, in a seamless and efficient manner. This name reflects the key benefit of intermodal shipping: the ability to easily transition between different modes of transportation.

What is the most common intermodal transportation?

The most common form of intermodal transportation is rail-to-truck, where goods are shipped by rail for the majority of the journey and then transferred to trucks for the final leg. This efficient method combines the benefits of rail and truck transportation for a seamless delivery experience.

What is an example of intermodal transfer?

An example of intermodal transfer is transporting goods from trucks to trains at a rail yard, allowing for efficient long-distance travel. This process involves loading containers or trailers onto trains for final delivery by truck

Sources

- https://en.wikipedia.org/wiki/Intermodal_freight_transport

- https://www.maersk.com/logistics-explained/transportation-and-freight/2024/09/06/intermodal-transportation

- https://www.inboundlogistics.com/articles/intermodal-transportation/

- https://www.dsv.com/en-us/our-solutions/modes-of-transport/road-transport/intermodal

- https://www.cevalogistics.com/en/glossary/intermodal-transportation

Featured Images: pexels.com