Intermodal train cars are designed to carry various types of cargo, including shipping containers, trailers, and even cars. They're a crucial part of modern transportation, allowing for efficient and cost-effective movement of goods.

There are several types of intermodal train cars, each with its own unique features and benefits. For example, well cars are designed to carry shipping containers, while autorack cars carry new and used vehicles.

Intermodal train cars are often equipped with specialized features, such as retractable roofs and adjustable flooring. These features enable the cars to accommodate different types of cargo and make loading and unloading easier.

In addition to well cars and autorack cars, intermodal train cars also include flatcars, which can carry a wide range of cargo, including heavy machinery and oversized loads.

For more insights, see: Small Cargo Trailer to Pull behind Car

Delivering Efficiency

TrinityRail offers a variety of intermodal equipment to help you efficiently load and unload your products.

Conventional flat cars and double-stack intermodal well cars are just a few examples of the products they provide.

Their equipment is designed to meet your rail transportation needs.

TrinityRail's products can help you streamline your logistics and reduce costs.

Recommended read: Moving Companies That Move Cars and Furniture

Types of Intermodal Train Cars

Well cars are the most common type of intermodal train car, designed to carry containers two-high, making railroads more efficient and profitable.

They were first introduced in the late 1970s by Southern Pacific and Sea-Land, and their usage expanded significantly in 1984 with the development of American President Lines' stack trains.

Well cars can be configured in different ways, with 5-platform cars having 40-foot wells or three-platform cars with 53-foot wells.

The most common well-car configuration today is 5-platform cars with 40-foot wells or three-platform cars with 53-foot wells.

Some well cars have hitches to handle trailers if needed.

Uni-level railcars are another type, designed for a single deck, with a typical inside length of 81'6" and an outside height of 18'6".

Tri-level railcars, on the other hand, have three decks of vehicles in a fully-enclosed space, ideal for smaller products and can hold up to 14-15 vehicles.

Here's a comparison of the specifications of uni-level and tri-level railcars:

Uni-Level

Uni-Level railcars are a type of intermodal train car that features a single deck. They are ideal for transporting taller vehicles.

The clearance code for Uni-Level railcars is Plate J. This is important to note when planning routes or navigating rail yards.

Uni-Level railcars have a maximum inside length of 81'6" and a maximum inside width of 10'0". This allows for efficient use of space on the railcar.

The tare weight of a Uni-Level railcar is 88,300 pounds. This is the weight of the railcar itself, without any cargo.

The load limit of a Uni-Level railcar is 131,700 pounds. This is the maximum weight of cargo that the railcar can safely carry.

Here is a summary of the key specifications for Uni-Level railcars:

The deck configuration of a Uni-Level railcar is a single deck. This is in contrast to bi-level and tri-level railcars, which feature multiple decks.

The draft gear on a Uni-Level railcar is cushioning at the end of the railcar. This helps to absorb shocks and reduce wear on the railcar.

Box Car

A box car is a type of intermodal train car designed for carrying cargo in a box-like structure. It's one of the most common types of train cars you'll see on the tracks.

The inside dimensions of a box car can vary, but the one we're looking at has an inside length of 60'9" and an inside width of 9'6". That's spacious enough to accommodate a variety of goods.

The height of the inside space is 13 feet, which is standard for many box cars. This allows for easy loading and unloading of goods, making it a versatile option for transporting cargo.

The outside dimensions of a box car are slightly larger, with an outside length of 68'5" and an outside width of 10'8". The height is 17 feet, which is taller than the inside space.

The weight capacity of a box car is significant, with a tare weight of 82,500 pounds and a load limit of 203,500 pounds. The gross weight on rail (GWR) is 286,000 pounds, which is the maximum weight the car can carry on the rail.

Here are some key features of this box car:

- Inside Length (ft): 60'9"

- Inside Width (ft): 9'6"

- Inside Height (ft): 13'

- Outside Length (ft): 68'5"

- Outside Width (ft): 10'8"

- Outside Height (ft): 17'

- Tare Weight (lbs.): 82,500

- Load Limit (lbs.): 203,500

- Gross Weight on Rail (GWR, lbs.): 286,000

Econo Stack/Twin Stack

The Econo Stack and Twin Stack well cars are a type of intermodal train car designed to support double-stacked containers. They feature a bulkhead at each end to provide additional support.

These cars are not ideal for stacking 53-foot containers, but 45-foot containers can still be stacked on top. This is a significant limitation for railroads looking to maximize their cargo capacity.

The empty weight of Econo Stack and Twin Stack cars is notably higher than other well cars, which has made them less popular with railroads.

Recommended read: Double Stack Container Train

Ship Automotive Parts or Vehicles

Shipping automotive parts or vehicles is a complex process that requires careful planning and execution. Norfolk Southern offers specialized solutions for shipping finished vehicles or automotive parts.

Finished vehicles can be shipped in dedicated auto racks, which are designed to protect the vehicles during transit. These racks are typically 53 feet long and can accommodate multiple vehicles.

Automotive parts can be shipped in a variety of intermodal train cars, including covered hoppers and box cars. Covered hoppers are ideal for shipping large quantities of parts, while box cars are better suited for smaller shipments.

Norfolk Southern's automotive shipping solutions can help reduce transit times and increase efficiency. By using intermodal train cars, shippers can save time and money compared to traditional over-the-road transportation.

Trailers

Trailers have a long history in intermodal service, dating back to 1936 when they were first used on flatcars.

Trailers used for rail service traditionally had to be built sturdier than highway trailers due to the forces experienced in switching operations.

Today, the modifications to trailers are more minor, with reinforcement at key points and lift pads, thanks to the use of articulated equipment.

The most common trailer lengths are 28 feet and 53 feet, with 28-foot units being favored by UPS and LTL carriers.

Fifty-three-foot trailers mimic standard truck size and have largely replaced the traditional 45-foot railroad-supplied trailer.

Trailers with level floors and no heaters or refrigerators (dry vans) predominate, but "reefer" units with diesel-powered heating and cooling units are used for temperature-sensitive cargo.

Flatbed trailers are used for loads that don't need protection from the weather, similar to flatcars.

Trailers make up less than 10% of the intermodal market, but are still in demand by large customers like UPS, especially in dense lanes.

See what others are reading: Small Car Trailer Lightweight Cargo Trailers

Equipment Overview

Intermodal trains are a common sight, making up 49% of the 34 million units of freight carried by U.S. railroads last year.

Most intermodal trains have railcars owned by TTX, a railcar pooling company, whose fleet includes over 140,000 cars hauling intermodal or automobile traffic.

These TTX cars are recognizable by their yellow paint and reporting marks that begin with "TT".

Well Cars

Well cars are a type of intermodal railcar that allows for double-stacking of containers, making them a game-changer for transporting containers efficiently.

These cars are designed to carry containers as low as possible in "wells" to maximize space, and they're commonly used for transporting 40-foot international containers.

Early double-stack well cars employed bulkheads to secure the top row of containers, but these added extra weight and limited the use of upper wells.

Since the mid-1980s, well cars have been built without bulkheads, relying instead on interbox connectors to hold containers in place, just like on ships.

Today, the most common well-car configurations are 5-platform cars with 40-foot wells or three-platform cars with 53-foot wells.

Larger containers often ride on top of smaller containers, and some "all-purpose" well cars have hitches to handle trailers if needed.

The use of well cars has greatly expanded since ocean shipper American President Lines developed a network of stack trains in 1984, allowing railroads to carry containers in profitable quantities.

Bi-Level

Bi-level railcars offer a versatile option for automotive manufacturers, with various specifications to choose from. They can be used to transport vehicles of different heights and types.

The inside length of a bi-level railcar is typically 89'4", while the outside length is 93'10". The inside width is 9'10" and the outside width is 10'7".

The tare weight of a bi-level railcar is around 98,700 pounds, while the load limit is 98,900 pounds. The gross weight on rail (GWR) is 176,500 pounds.

Bi-level railcars have a cushioning draft gear at the end of the railcar and a bi-level deck configuration with two decks. The deck heights range from 87" to 89" on the bottom deck (A) and 94'10" on the top deck (B).

89' Frame

The 89' Frame railcar is a versatile piece of equipment with a range of specifications that make it suitable for various transportation needs.

It has an inside length of 84'9" and an inside width of 9'0", making it a compact yet efficient option.

The railcar's outside dimensions are slightly larger, with an outside length of 93'11" and an outside width of 9'3".

The 89' Frame railcar has a relatively low outside height of 6'3", which can be beneficial for transportation in areas with lower overhead clearance.

Its tare weight is a significant 67,500 pounds, indicating the weight of the railcar itself without any cargo.

The load limit of the railcar is 157,400 pounds, which is the maximum weight of cargo it can safely carry.

The gross weight on rail (GWR) for the 89' Frame railcar is 220,000 pounds, representing the combined weight of the railcar and its maximum cargo load.

3 Thoughts on Today's Equipment

Intermodal service has a rich history, and understanding its evolution is key to appreciating the complexity of today's equipment. Intermodal service started in the early 1920's, using containers.

The integration of motor freight and rail freight service was a game-changer, providing improved service to customers at lower charges. However, the government regulators had to put a stop to it, ordering the railroads to raise container charges to non-competitive levels in 1931.

The railroads have been trying to adapt to changing user needs, but some feel they miss out on opportunities by focusing too much on longer haul trips. Planned and scheduled correctly, they could expand their service to shorter trips and still earn a decent return on investment.

There's more to intermodal service than meets the eye, and understanding its history and development is crucial for appreciating the complexity of today's equipment.

Usage and Capacity

Double-stack well cars are used on various rail networks around the world, with different countries having unique requirements and capabilities. In Australia, double-stack trains operate between Perth, Adelaide, Darwin, and Parkes, NSW with 6.5 m (21 ft 4 in) clearances.

The maximum weight capacity of articulated well cars is 120,000 lb (54,000 kg) per well, which is sufficient for two containers stacked, given that highway weight limits in the US restrict most containers to less than 60,000 lb (27,000 kg).

Well cars in the US can also carry semi-trailers in addition to containers, known as "all-purpose" well cars.

Recommended read: Car Shipping Companies from Us to Canada

40 Well

The 40 Well is a versatile option for intermodal transportation. Our company offers a range of 40' well cars, including articulated and stand-alone models.

These well cars are a key part of our intermodal product line, designed to meet the needs of various industries and applications. They can be used in a variety of settings, from transporting goods to equipment and supplies.

Usage

Double-stack trains are used in various countries around the world, each with their own unique requirements and capabilities. In Australia, for example, double stack trains operate on routes with 6.5 m (21 ft 4 in) clearances.

Double-stack trains are also used in China, where they run under 25 kV AC overhead lines using X2H and X2K type wellcars manufactured by CRRC. Initial tests were done with a standard 8 ft 6 in (2.59 m) container and a reduced height 8 ft 0 in (2.44 m) container on top.

In Kenya, the Mombasa-Nairobi standard gauge railway operates double-stacked trains using X2K type wellcars manufactured by CRRC, with the first such trains launched on October 1, 2018. The same type of wellcars are also used in Panama on the Panama Canal Railway.

The United Kingdom has specific requirements for intermodal well wagons, which must be able to transport 9 ft 6 in (2.9 m) high intermodal containers on routes with a loading gauge of W9 or smaller.

For another approach, see: 2 Bike Carrier for Car

History and Advantages

The history of the intermodal train car is a fascinating one. Southern Pacific Railroad, along with SeaLand, devised the first double-stack intermodal car in 1977.

The first double-stack car was designed by SP and ACF Industries that same year, marking the beginning of a new era in intermodal transportation. The initial design was slow to gain traction, but by 1984, American President Lines and the Thrall Company were working together to refine the concept.

The first all "double stack" train left Los Angeles for South Kearny, New Jersey in 1984, under the name of "Stacktrain" rail service. This pioneering effort paved the way for the widespread adoption of double-stack intermodal cars.

History

The Southern Pacific Railroad, along with SeaLand, devised the first double-stack intermodal car in 1977. This innovation marked a significant turning point in the history of rail transportation.

The first double-stack car was designed by SP and ACF Industries in 1977. It was a slow start to becoming an industry standard, but eventually, it gained traction.

American President Lines started working with the Thrall Company in 1984 to develop a refined well car. This collaboration led to the creation of a more efficient and effective double-stack car.

The first all "double stack" train left Los Angeles for South Kearny, New Jersey in 1984, under the name of "Stacktrain" rail service.

Delivering Sustainable Supply Chains through Rail's Advantages

As environmental impact becomes a top priority for enterprises, rail shipping leaders are stepping up to deliver more sustainable supply chains. Rail shipping is a key player in this effort.

TrinityRail is preparing for the future of rail shipping and for sustainability, recognizing the importance of reducing environmental impact in supply chains. By leveraging rail's environmental advantages, businesses can make a significant difference.

Rail shipping is an efficient way to transport goods, and TrinityRail offers a wide range of intermodal equipment and flat cars designed to help load, unload, and deliver products efficiently. This can lead to cost savings and reduced carbon emissions.

From conventional flat cars to double-stack intermodal well cars, TrinityRail provides products and services tailored to meet rail transportation needs. This variety of options enables businesses to choose the best solution for their specific requirements.

Challenges and Solutions

Intermodal train cars face significant challenges, particularly when it comes to transitioning between different modes of transportation. One major issue is the need for manual labor to transfer containers, which can be time-consuming and labor-intensive.

The average time spent on container transfer is around 30 minutes per transfer. This can add up quickly, especially in high-traffic areas.

Innovative solutions are being developed to address these challenges. For example, automated transfer systems can significantly reduce transfer times, with some systems able to complete a transfer in as little as 10 minutes.

The use of standardized container sizes and types can also help streamline the transfer process. This can reduce the need for manual labor and minimize the risk of errors or damage during transfer.

With the right solutions in place, intermodal train cars can run more efficiently and effectively, reducing costs and improving customer satisfaction.

Equipment and Features

Intermodal trains are a common sight, making up 49% of the 34 million units of freight carried by U.S. railroads last year.

TTX, a railcar pooling company owned by all Class I railroads, owns a massive fleet of over 140,000 cars, mostly hauling intermodal or automobile traffic.

You can spot TTX cars by their yellow paint and reporting marks that begin with "TT."

Individual railroads, like BNSF, also own intermodal cars, but their fleet size is significantly smaller.

The majority of containers and trailers used in intermodal service are owned by entities other than railroads, usually their customers.

These customers include ocean shipping lines, trucking companies, and third-party leasing companies, who dominate the ownership of "boxes" – as trailers and containers are called.

Frequently Asked Questions

How long is an intermodal railcar?

An intermodal railcar is 53 feet long, accommodating containers of various lengths from 20 to 53 feet. Its single platform design allows for efficient transportation of multiple container sizes.

How many intermodal containers does a train have?

A typical 120-car train can haul 240 intermodal containers. This capacity is based on standard car lengths and double-stacked container configurations.

Sources

- https://www.trinityrail.com/railcars/flat-intermodal/

- https://en.wikipedia.org/wiki/Well_car

- https://www.norfolksouthern.com/en/ship-by-rail/shipping-tools/equipment/intermodal-automotive-equipment

- https://www.trains.com/trn/train-basics/abcs-of-railroading/whats-behind-todays-intermodal-equipment/

- https://www.trainworld.com/shop-scale/o-scale/rolling-stock/well-car.html

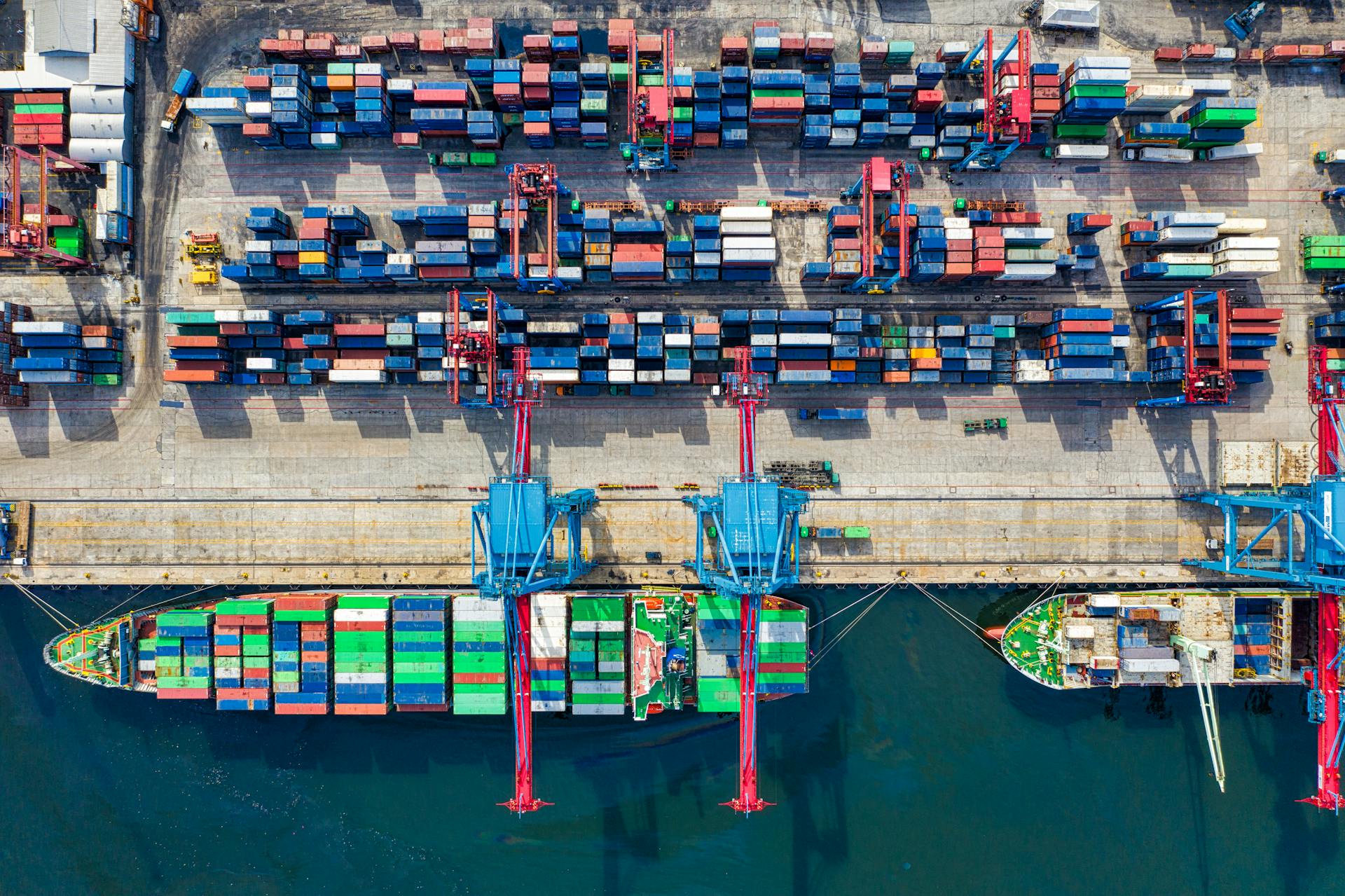

Featured Images: pexels.com