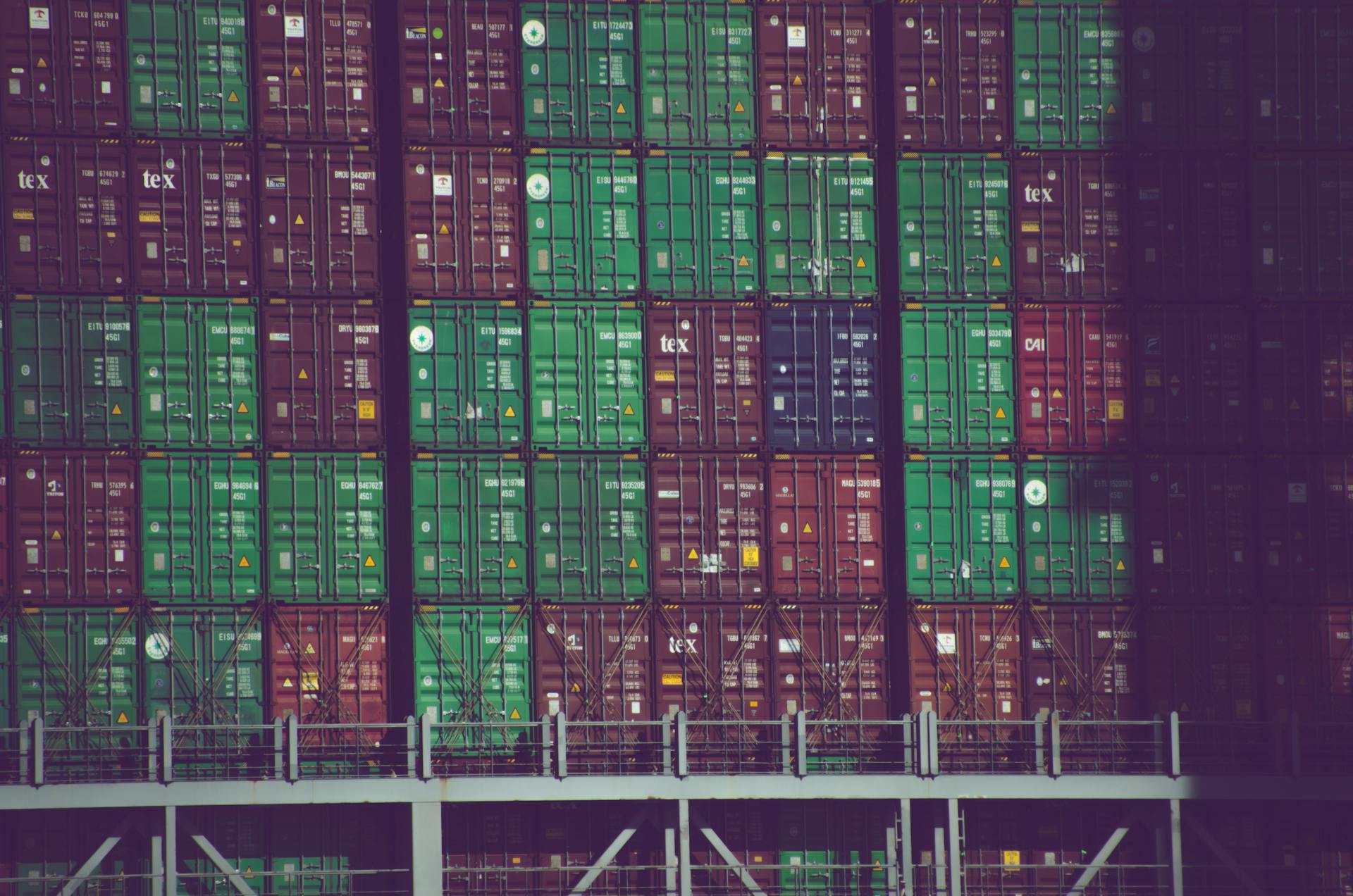

A double stack container train is a game-changer in the world of logistics. It can carry two rows of containers stacked on top of each other, increasing its cargo capacity by 50% compared to a standard single-stack train.

This design allows for more efficient use of space, enabling trains to carry more containers without increasing their length. The extra capacity can lead to significant cost savings for shipping companies.

The double stack design also enables trains to travel at higher speeds, reducing transit times and increasing the frequency of deliveries. This can be a major advantage for businesses that rely on just-in-time shipping.

If this caught your attention, see: Old Corrugated Containers

Technical Details

A double stack container train is a game-changer for logistics, allowing for two rows of containers to be stacked on top of each other. This increases cargo capacity without requiring a larger train.

The maximum height of a double stack train is around 20 feet, which is achieved by using taller containers and specialized railcars. This allows for more efficient use of space on the rail network.

The weight of a double stack train can be substantial, with some trains weighing over 15,000 tons. This requires specialized locomotives and rail infrastructure to handle the load safely.

Worth a look: Double Door Shipping Containers

Weights

Container weights are a crucial aspect of rail transport. A common limit for railways is 8 tonnes per meter train length and 22.5 tonnes per axle.

Double-stacking doesn't always use the load capacity of the railway. A four-axle container car can take 90 tonnes, but a single container is limited to 30.5 tonnes.

A 20-foot container is limited to 24 tonnes, and two such containers can fit into a car for a 40-foot container. Three can fit if double-stacking is allowed.

The North American railways permit two 53-foot containers or four 20-foot containers. A maximum length train in Europe can have 50 container cars with a total weight of 2,250 tonnes.

Double-stacking requires allowing higher train weight to be meaningful, as it saves costs. In the US, the AAR coupler used allows much higher train weight.

For your interest: 5 Plastic Containers

Sizes and Clearances

Double-stack cars come in various sizes, with well lengths of 40 ft, 48 ft, and 53 ft being the most common. These sizes are directly related to the standard sizes of the containers they carry.

The heights of double-stack cars range from 8 ft to 9 ft 6 in, with some cars being taller, known as "high cube" containers.

Double-stack trains require a higher clearance above the tracks, or loading gauge, than other forms of rail freight. This is a significant consideration for railroads, especially in North America where electrification is less widespread.

To accommodate double-stack trains, railroads have invested in raising bridges and tunnel clearances along their routes.

CSX lists three clearance heights above top of rail for double stack service: 18 ft 2 in, 19 ft 2 in, and 20 ft 2 in.

The last clearance, 20 ft 2 in, offers the most flexibility, allowing two high cube containers to be stacked.

Stacking

Stacking is a crucial aspect of double-stack rail freight, and it's essential to understand the various patterns and requirements involved.

Double-stack cars can carry two 20 ft containers in the bottom position.

In North America, where intermodal traffic is heavy, double-stack trains are most common. The standard unit length of containers is 40 feet, with load-bearing points at the ends.

Take a look at this: Double Stacked Pallets

Forty-foot containers can be stacked on top of 20-foot containers if there are two 20-foot containers in a row. However, 20-foot containers cannot be stacked on top of 40-foot or longer containers.

The possible double-stacking patterns are:

- Two 20 ft in lower and one 40 ft (or longer) in upper stack (allowed in India, China, US)

- One 40 ft in lower and another 40 ft (or longer) in upper stack (allowed in India, US)

- Two 20 ft in lower and another set of two 20 ft in upper stack

Container coupling holes are all female, and double male twistlocks are required to securely mate container stacks together.

Usage and Impact

Double stack container trains have a significant impact on supply chains, particularly for long haul domestic freight. Intermodal shipping is often 10-25% less costly than over the road trucking.

For shippers that operate long haul over the road lanes, intermodal shipping can be a game-changer, expanding capacity and reducing costs. This is especially true when trucking capacity is hard to find.

Intermodal freight is vastly more energy efficient than over the road trucking due to the rail portion of the route, making it an effective way to create a more green supply chain.

Additional reading: U Haul Auto Transport Trailer Weight

North America

In North America, intermodal containers shipped by rail are primarily 53 feet long, reflecting the common maximum length for highway semi-trailers.

Major domestic intermodal carriers include J. B. Hunt, Swift, Schneider National, and Hub Group.

The 53-foot length is a standard for highway semi-trailers, but it's worth noting that container ships only take 40-foot, 20-foot, and some 45-foot containers.

90% of the containers on container ships are 40-footers, and 90% of the world's freight moves on container ships, making 81% of the world's freight move by 40-foot containers.

Most of these 40-foot containers are owned by non-U.S. companies like Maersk, MSC, and CMA CGM, with leasing companies like Textainer, Triton International, and CAI Leasing being the only U.S. 40-foot container companies.

Some Class I railroad companies in the U.S. have implemented improvement programs to remove obstructions to double-stack trains, which can carry two levels of containers.

Here are some notable double-stack projects in North America:

- Heartland Corridor (Norfolk Southern Railway) — $320 million

- Norfolk Southern Crescent Corridor — $2.5 billion (estimate)

- National Gateway (CSX Transportation) — $700 million

- Commonwealth Railway — $69 million

- Chicago Region Environmental and Transportation Efficiency Program — $3 billion (estimate)

- Cross-Harbor Rail Tunnel proposed to connect rail freight lines in New Jersey with Long Island, New York. — $10–14 billion (estimate)

- Continental Rail Gateway (Canadian Pacific Railway), proposed tunnel between Detroit, Michigan and Windsor, Ontario to replace the existing Michigan Central Railway Tunnel. — $400 million

Usage

Double stack trains are being used in various parts of the world, including Australia, China, Kenya, Panama, and the United Kingdom.

Australia has implemented double stack trains between Perth, Adelaide, Darwin, and Parkes, NSW, with 6.5 m clearances. Inland Railway between Melbourne and Brisbane is also being built for the same purpose.

In China, double stacked container trains are being used under 25 kV AC overhead lines. Initial tests were done with a standard 8 ft 6 in container and a reduced height 8 ft 0 in container on top, later increasing to a 9 ft 6 in hi-cube and a standard 8 ft 6 in container on top.

The Mombasa-Nairobi standard gauge railway in Kenya operates double-stacked trains using X2K type wellcars. These trains were first launched on October 1, 2018.

The Panama Canal Railway runs double stack trains using well cars manufactured by Gunderson Inc.

The small structure gauges and consequently small loading gauges on British railways mean that intermodal well wagons are required to transport 9 ft 6 in high intermodal containers on routes where the loading gauge is W9 or smaller.

You might enjoy: Mini Cargo Container

Choke Points

Choke points are a major hindrance to the efficient operation of double-stack trains. Low bridges and narrow tunnels in various locations are the main culprits, preventing these trains from passing through until costly upgrades are made.

The Heartland Corridor, a project initiated by Norfolk Southern Railway, is a notable example of efforts to remove such obstructions.

8 Responses to

Double stacked containers and road trains have been a topic of discussion, with some seeing them as a publicity stunt rather than a viable alternative to rail transport.

Gary Fields, a commenter, notes that these containers may only be suitable within the Port region, and that rail trains can be slow and unreliable.

The Port of Singapore experimented with double stack containers about two decades ago, but it's unclear if they're still using this method.

Gary Fields also points out that double stack road trains have a limited life and are not suitable for roads due to their low speed and high risk of tipping over.

You might like: Double Pallet Truck

In fact, even the fastest train freight shipments in the UK are outstripping intermodal, making it seem like a less effective option.

Here are some key points to consider:

- Double stack containers may only be suitable within the Port region.

- Double stack road trains have a limited life and are not suitable for roads.

- Freight trains can be slow and unreliable.

- The fastest train freight shipments in the UK are outstripping intermodal.

Freight trains can be frustrating for transport shippers, especially when relying on single rail tracks.

Gary Fields suggests that a train on rails would be a more effective option, but it's unclear if this is being explored.

Double Stacking in Supply Chains

Double stacking is a game-changer for supply chains, especially for long haul trucking. It provides the necessary capacity and reduces freight costs by 10-25% compared to over the road trucking.

Double stacking is a key component in how railroads manage intermodal traffic capacity and plan the number of well cars required for bookings. This helps to ensure that freight can be moved efficiently and effectively.

Intermodal shipping is often a great way to reduce shipping costs and expand capacity for shippers that operate long haul over the road lanes. In fact, intermodal shipping is typically 10-25% less costly than OTR trucking.

The rail portion of the intermodal route makes it vastly more energy efficient than over the road trucking, making it an attractive option for companies looking to create a more green supply chain.

On a similar theme: B Pallets

History and Context

The double stack container train has a rich history that's worth exploring. The concept of double stack intermodal cars was first introduced in 1977 by the Southern Pacific Railroad and SeaLand's Robert Ingram.

In 1976, SP and Robert Ingram jointly designed the first double stack car with ACF Industries. The design was initially slow to gain traction as an industry standard.

The turning point came in 1984 when American President Lines started working with the Union Pacific Railroad, paving the way for the first all double-stack train to leave Los Angeles, California for South Kearny, New Jersey under the "Stacktrain" rail service.

You might enjoy: How to Stack Boxes on Pallets

Other Countries

In other countries, the adoption of double-stack trains varies greatly. Europe has a more restricted loading gauge and train weights, making double-stack cars impractical.

Many countries have low overhead wiring, making it difficult to accommodate double-stacking. For example, India is building some freight-only corridors with higher overhead wiring, at 7.45 m (24.4 ft) above rail.

Australia has double-stack trains operating between certain routes, with 6.5 m (21 ft) clearances. India's Mundra Port operates double stack diesel trains on 1,676 mm (5 ft 6 in) gauge using flatcars, making it one of the few countries to commercially double stack 9 ft 6 in (2,896 mm) tall containers on a train.

Here are some countries and their double-stacking capabilities:

- Australia - double stack trains operate between Perth, Adelaide, Darwin and Parkes, NSW with 6.5 m (21 ft) clearances

- India - Mundra Port operates double stack diesel trains on 1,676 mm (5 ft 6 in) gauge using flatcars

China is using double stacked container trains under 25 kV AC overhead lines. The Netherlands has built a freight rail, the Betuweroute, with tunnels that can accommodate double stack trains, although the current catenary wire is too low.

History

The double-stack intermodal car was first introduced by Southern Pacific Railroad and SeaLand's Robert Ingram in 1977. They jointly designed the car with ACF Industries in 1976.

The design was initially slow to become an industry standard. However, in 1984, American President Lines started working with Union Pacific Railroad, which helped popularize the concept.

The first all double-stack train, dubbed "Stacktrain", left Los Angeles, California for South Kearny, New Jersey that same year. It transferred from Union Pacific to the Chicago and North Western Railway and then to Conrail along the way.

A different take: Container Train Car

Frequently Asked Questions

What is a double stack container?

Double stacking refers to the practice of placing shipping containers on top of each other to maximize cargo space. This efficient method increases the overall capacity of a vessel or terminal

How many 40ft containers can a train carry?

A typical 120-car train can haul up to 240 40ft containers, assuming double stacking and no other limitations

Featured Images: pexels.com