Old corrugated containers are incredibly versatile and have been a staple in packaging for over 100 years. They're made from paperboard, a sturdy material that's also highly recyclable.

The average American uses over 100 pounds of paper packaging each year, with old corrugated containers making up a significant portion of that. This means there's a constant stream of used containers waiting to be recycled.

One ton of recycled old corrugated containers can save up to 17 trees, 7,000 gallons of water, and 4,100 kilowatt-hours of electricity. That's a significant environmental impact, especially considering how easy it is to recycle them.

For more insights, see: Customs Convention on Containers

What Is Cardboard?

Cardboard is a type of packaging material made from unbleached, unwaxed paper.

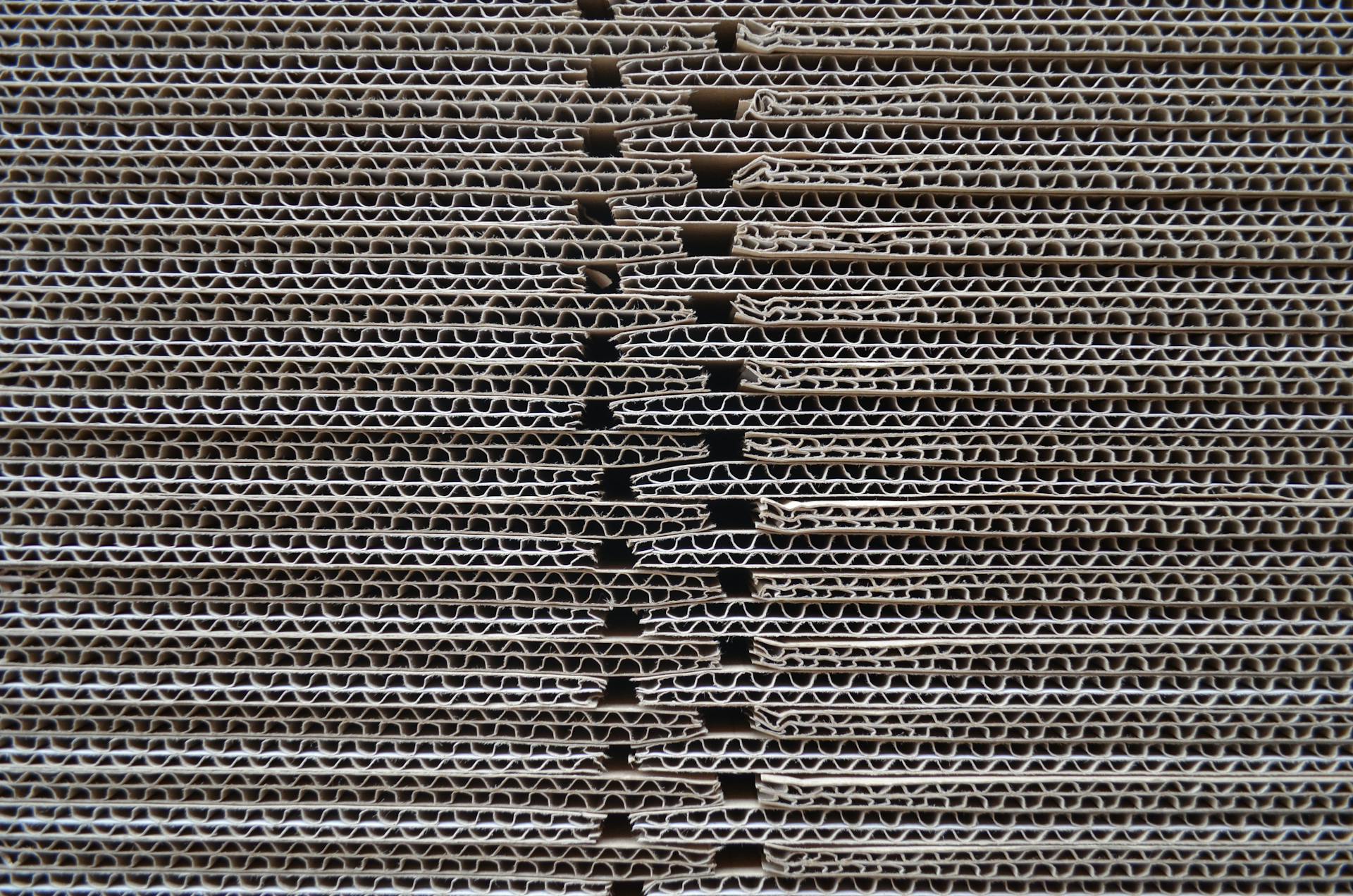

It features a ruffled or corrugated inner liner, which gives it its distinctive structure.

Cardboard is commonly used for boxes and containers, and it's often referred to as a recyclable material.

Old Corrugated Cardboard (OCC) is a specific type of cardboard that's used within the waste management and recycling industry.

Characteristics and Types

Old corrugated containers (OCC) are a type of container that's easily recognizable by its characteristic wavy inner layer, also known as fluting. This corrugated design provides structural strength and rigidity, allowing boxes to hold their shape under weight and resist crushing.

The corrugated design also provides some level of insulation, making OCC useful for shipping temperature-sensitive items. This is especially important for industries that require precise temperature control, such as food and pharmaceuticals.

OCC containers come in various types, including open-top containers, tunnel containers, and double door containers. These designs facilitate the shipment of items with varying heights and streamline the loading and unloading process.

Explore further: Los Angeles Trash Pickup Large Items

Characteristics of OCC

OCC is easily recognizable by its characteristic wavy inner layer, also known as fluting, which provides structural strength and rigidity.

This corrugated design allows boxes to hold their shape under weight and resist crushing. It's quite impressive to see how well they can withstand heavy loads.

The fluting also provides some level of insulation, making OCC useful for shipping temperature-sensitive items. This is especially important for products that require precise temperature control during transportation.

Types and Applications of OCC

Old corrugated carton selection is available in various types to cater to different applications. Open-top containers are perfect for shipping items with varying heights.

Tunnel containers and double door containers make the loading and unloading process more streamlined. This is especially useful in warehouses and logistics centers where time is of the essence.

Refrigerated ISO containers made from old corrugated cardboard OCC can maintain a controlled environment to preserve the quality of perishable items. This is crucial for the transportation of temperature-sensitive goods.

Explore further: Corrugated Metal Containers

Recycling Process

Recycling old corrugated containers is a straightforward process. It's a crucial step in reducing waste and conserving natural resources.

The first stage of recycling OCC involves collecting and sorting the boxes. This is where recyclers separate the OCC from other types of waste.

Contamination from food waste, plastic liners, or other non-paper components can complicate the recycling process. However, with responsible use and disposal, OCC can continue to play a crucial role in our global recycling efforts.

Explore further: Pet Recycling Company

To recycle OCC effectively, it's essential to remove all non-paper materials beforehand. This includes materials like bubble wrap, wood skids, plastic bags, Styrofoam, and plastic wrapping.

The recycling process for OCC involves several stages, including breaking down and pulping the boxes to separate the individual fibers. The pulp is then cleaned to remove any inks, adhesives, or other contaminants.

Here's a breakdown of the steps involved in recycling OCC:

- Collection and sorting of OCC

- Breaking down and pulping the boxes

- Cleaning the pulp to remove contaminants

- Compressing and flattening the OCC to ease handling, storing, and transportation

- Delivering the compressed OCC to a paper production mill

By following these steps, recyclers can turn old corrugated containers into new paper products, such as unbleached Kraft paperboard, recycled paperboard, and new corrugated containers.

On a similar theme: City of New Braunfels Trash Pickup

Benefits and Impact

Old corrugated containers, or OCC, have a significant impact on the environment. One of the key benefits of OCC is its recyclability, making it one of the most recycled materials globally.

OCC recycling can significantly reduce the demand for virgin paper pulp. This reduction in demand helps to conserve natural resources.

Properly managed OCC recycling can also reduce deforestation. By reusing OCC, we can minimize the need to cut down trees for paper production.

As a result, OCC recycling plays a crucial role in preserving our planet's forests.

Worth a look: Is Wrapping Paper Recyclable Waste Management

Understanding OCC

Old corrugated containers, or OCC, are a type of material that's widely used for shipping and storing goods. They're crafted from old corrugated cardboard, which is prized for its strength and recyclability.

OCC is easily recognizable by its characteristic wavy inner layer, also known as fluting. This corrugated design provides structural strength and rigidity, allowing boxes to hold their shape under weight and resist crushing.

The versatility of OCC makes them suitable for various industries, ensuring that goods are securely transported from one point to another. They're also useful for shipping temperature-sensitive items, thanks to their insulation properties.

The material used in OCC containers is not only sturdy but also environmentally friendly. Old corrugated cardboard is widely recognized for its recyclable properties, aligning with sustainable practices by minimizing waste.

Here are some key characteristics of OCC:

- Prohibitive materials may not exceed 1%

- Total outthrows may not exceed 5%

- Moisture content: not exceed 12%

OCC containers can be packed in bales, with a weight of 20-23MT per 40HQ container.

Comparison and Details

Old corrugated containers (OCC) come in different grades, with OCC 11 and OCC 12 being two distinct categories. OCC 11 mainly includes corrugated containers used for paper recycling, often with kraft, jute, or test liners.

The OCC 12 waste paper specification, also known as DS OCC or Double Sorted Corrugated, consists of double corrugated containers from supermarkets, commercial, and industrial facilities. These materials are specially sorted to be free of boxboard and off-shore corrugated materials, wax, and plastic.

Prohibitive materials for OCC grade 12 should not exceed half of 1%, while total out-throws should not exceed 2%. Other acceptable papers may not exceed 30%.

Here are some common types of waste paper that can be accepted in OCC 12 recycling programs:

- Old New Paper waste

- Waste paper

- Over Issue News Paper

Newspapers are often used by mills to make more newsprint, tissue, and other products, as they are a lower-grade paper.

Frequently Asked Questions

How much is baled cardboard worth per ton?

According to Recycling.com, the price of baled cardboard has ranged from $20 to $210 per ton over the last 5 years. Check the latest market trends for the most up-to-date pricing information.

Sources

- https://tradexglobalusa.com/service/old-corrugated-cardboard-occ

- https://www.iwrecycling.com/glossary/occ-old-corrugated-cardboard/

- https://www.alibaba.com/showroom/old-corrugated-container.html

- https://intercotradingco.com/recycling-old-corrugated-containers-occ/

- https://www.cleflavron.com/item/68/old-corrugated-containers--occ--grade-11-and-grade-12

Featured Images: pexels.com