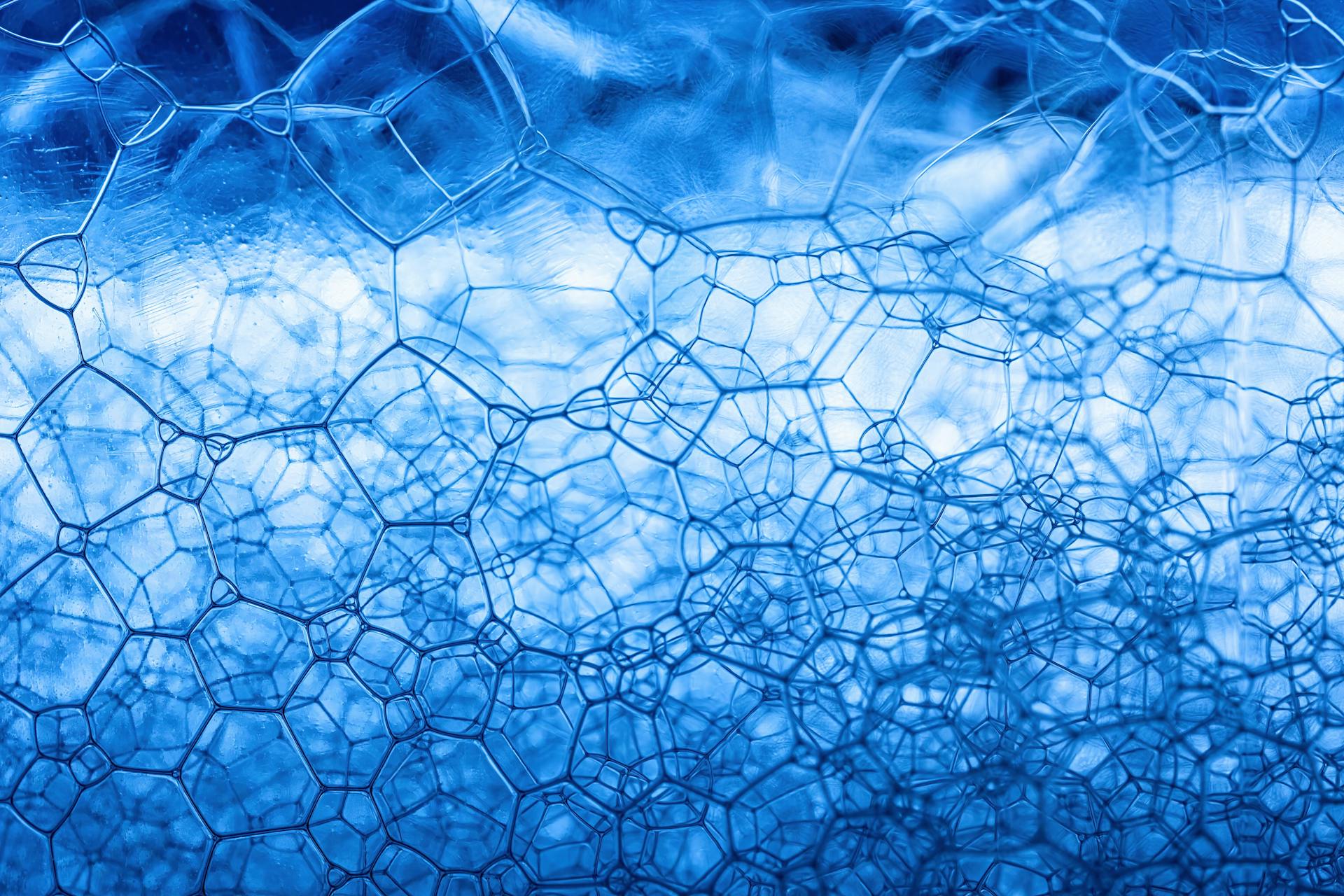

Flexible PU foam comes in various types, each with its unique characteristics and applications. These types include open-cell foam, which is known for its breathability and moisture-wicking properties.

Open-cell foam is commonly used in bedding and mattresses due to its ability to regulate temperature and provide comfort.

Closed-cell foam, on the other hand, is denser and more rigid, making it suitable for applications that require insulation and shock absorption.

Closed-cell foam is often used in construction materials, such as rigid foam boards, to provide thermal insulation and protect buildings from weathering.

Flexible PU foam can also be formulated to have specific properties, such as flame retardancy or electrical conductivity, depending on the intended application.

A different take: Spray Foam Insulation Truck

Flexible PU Foam Types

There are several types of flexible PU foams available, including FlexFoam-iT! III, IV, V, VI, VIII, X, 17, and 25.

These foams are two-component castable flexible foams that expand many times their original volume, making them strong and versatile.

You can choose from different densities, including 3, 5, 8, 10, 17, and 25 pounds.

The FlexFoam-iT! series is ideal for various applications, such as arts, crafts, industrial, and special effects.

A + B mixture can be used to achieve vibrant colors by adding color pigments.

The Pillow Soft foams are very soft and used for padding/cushion, specialty bed, and orthopedic pillow material applications.

They have very good physical and rebound properties after curing.

Here's a breakdown of the FlexFoam-iT V options:

The FlexFoam-iT 17 option is available in a 5-gallon unit, weighing 51.70 kg.

Pillow Soft

Pillow Soft foams are very soft and used for padding/cushion, specialty bed, and orthopedic pillow material applications.

These foams have very good physical and rebound properties after curing.

You can achieve vibrant colors with Pillow Soft foams by adding color pigments.

Pillow Soft foams are part of the FlexFoam-iT! series, which includes various flexible polyurethane foam options.

The FlexFoam-iT! series offers flexible foams in a range of densities, including 3, 5, 8, 10, 17, and 25 pounds.

See what others are reading: Soft Packing Foam

Flex-It

Flex-It is a brand of flexible polyurethane foam that offers a range of products for various applications. FlexFoam-iT! III, for example, is a two-component castable flexible foam available in densities ranging from 3 to 25 pounds.

FlexFoam-iT X is another product in the Flex-It line, offering a flexible foam with a density of 160 kg/m3. It's available in 1 and 7 kg sets.

FlexFoam-iT 14 is a self-skinning flexible urethane foam with a density of 220 kg/m3, ideal for art and industrial applications. It's available in 1.27 kg and 10.35 kg sets.

FlexFoam-it 7 FR is a flame retardant polyurethane foam, perfect for applications where fire safety is a concern.

Flex-It foams are known for their softness and flexibility, making them ideal for applications like furniture and upholstery, automotive seating, and bedding and mattresses.

Here are some key characteristics of Flex-It foams:

Flex-It foams are also used in medical and orthopedic applications, such as wheelchair cushions and orthopedic supports.

FormX 60

FormX 60 is a type of flexible foam that comes in different weights and sets. It's a 2-component foam with a density of 60 kg/m3.

You can buy FormX 60 in various weights, including 1.35 kg, 3.33 kg, and 10 kg. These weights are part of pre-set packages, which makes it easy to get the right amount for your project.

If you need a specific weight, you can choose from the available options. For example, if you want 1.35 kg, you can buy the set labeled as such.

Polyester & Polyether

Polyester & Polyether are two main types of flexible urethane foam products supplied by Foam Products Corporation.

These foam materials are generally less expensive than other foam products due to their multiple impact protection.

Both Polyester and Polyether foams are constructed using high-grade polyurethane.

FPC can fabricate custom foam packaging using either of these polyurethane foams.

On a similar theme: Pu Foam Products

Tuff Stuff and Similar Products

Flexible urethane foam products, like Tuff Stuff, have many qualities that make them a go-to choice for various applications.

These products are flexible and have an open cell structure, allowing them to thrive in wet environments.

This makes them a preferred option for many applications, including those where water or moisture is present.

Some of the key features of flexible urethane foam products include their ability to withstand wet conditions and their flexible capabilities.

Flex-It IV & 15

Flex-It IV & 15 are part of the FlexFoam-iT product line, which offers flexible foams for various applications.

FlexFoam-iT IV - Tuff Stuff comes in two sizes: 0.83 kg and 6.81 kg. The 0.83 kg version is a trial size, while the 6.81 kg version is a 1 gallon unit.

The FlexFoam-iT IV - Tuff Stuff has a mix ratio of 80A:100B by weight, and a scale is required for accurate mixing.

You can choose from two different sizes of FlexFoam-iT 15: 1.35 kg and 25 kg. The 1.35 kg version has a foam density of 25 lb/ft³, and a cure time of 2 hours.

Here is a summary of the Flex-It IV & 15 products:

Tuff Stuff

Tuff Stuff is a type of foam that's known for its high tear strength and stiffness. It's also slightly harder to compress compared to other FlexFoam-iT! products.

This foam is ideal for making lightweight props that can withstand rough handling, such as those used in the Halloween industry. I can imagine how useful it would be for making decorations that need to be durable.

FlexFoam-iT! 4 Tuff Stuff has a mix ratio of 80:100 by weight, which requires a gram scale for accurate measurement. This is crucial for achieving the right consistency.

The mixture expands about 10 times its original volume, depending on the mass and mold configuration. This means you'll need to use a mold that's large enough to accommodate the expanded foam.

Tack-free time for this foam is about 20 minutes, which is relatively fast. This allows you to work quickly and efficiently, but it also means you need to be prepared to mix and pour the foam within 25 seconds at room temperature.

Here are some key specifications for FlexFoam-iT! 4 Tuff Stuff:

- 0.83 kg (trial size) or 6.81 kg (1 gallon unit)

- 4-lb flexible polyurethane foam

- 80A:100B by weight mix ratio (requires a scale)

- Net weight: 1.8 lbs (trial size) or 15.00 lbs (1 gallon unit)

Foam Applications

Flexible polyurethane foam is incredibly versatile and has a wide range of applications. It's widely used in the furniture industry for cushioning seats, backs, and arms of sofas, chairs, mattresses, and pillows.

Flexible polyurethane foam is also commonly employed in the automotive industry for cushioning and comfort in car seats, headrests, armrests, and interior padding. This is because it provides a soft and pliable texture, allowing it to conform to the shape of objects and provide a comfortable cushioning effect.

Some of the key applications of flexible polyurethane foam include:

- Furniture and upholstery

- Automotive seating

- Bedding and mattresses

- Packaging and padding

- Medical and orthopedic applications

These applications take advantage of the foam's unique properties, such as its softness and flexibility, resilience, breathability, durability, and versatility.

How to Make Squishies with Liquid Expanding

To make squishies with liquid expanding foam, you'll need Smooth-On FlexFoam-iT! III liquid expanding urethane foam. This type of foam is specifically designed for crafting and is a popular choice among squishy makers.

The process involves mixing the liquid foam with a catalyst to create a foam that can be molded and shaped. The mixture will expand rapidly, so make sure to work in a well-ventilated area and follow the instructions carefully.

You can create a variety of shapes and designs with this foam, from simple shapes like spheres and cubes to more complex designs like animals and objects. The key is to experiment and have fun with the process.

The liquid expanding foam is a great choice for making squishies because it's soft, flexible, and easy to work with. It's also a relatively inexpensive material, making it a great option for crafters on a budget.

To achieve the best results, make sure to follow the instructions provided with the FlexFoam-iT! III liquid expanding foam and use the recommended amount of catalyst. This will ensure that your foam is the right consistency and will hold its shape well.

How to Repair a Flat Tire

Repairing a flat tire is a relatively straightforward process that can be done at home with the right materials. FlexFoam-iT! foam is a popular choice for tire repair due to its ease of use and permanent results.

You can use FlexFoam-iT! foam to repair a tire permanently. See the example in the article section "How To Repair a Flat Tire Using FlexFoam-iT! 25" for a step-by-step guide.

To start, you'll need to clean the tire and remove any debris. This will ensure a smooth surface for the foam to adhere to.

FlexFoam-iT! foam is a versatile product that can be used for various applications, including tire repair. The example in the article section "How To Repair a Flat Tire Using FlexFoam-iT! 25" demonstrates its effectiveness.

Apply the foam to the punctured area, following the instructions provided with the product. Make sure to use the correct amount of foam for the size of the tire.

FlexFoam-iT! foam is a permanent solution that can withstand normal tire wear and tear. It's a cost-effective alternative to replacing a tire entirely.

Repairing an Archery Target

Repairing an archery target can be a challenge, but it's not impossible. You can use FlexFoam-iT! 15 urethane foam to repair one.

This type of foam is specifically designed for repairs and can be shaped to fit the damaged area of the target. It's a great solution for archers who want to extend the life of their equipment.

In one example, FlexFoam-iT! 15 was used to repair an archery target, and the results were impressive. The foam was able to fill in the damaged area and provide a smooth surface for the arrows to hit.

This type of repair can be done at home with minimal equipment, making it a cost-effective solution.

How to Repair a Tractor Seat

Repairing a tractor seat can be a DIY-friendly project with the right materials. FlexFoam-iT! 15 is one such material that can be used to give new life to a damaged John Deere tractor seat.

Using FlexFoam-iT! 15 is a great way to repair a damaged tractor seat because it can be molded to fit the original shape of the seat.

Foam Production and Technical Information

Flexible pu foam is a versatile material that can be produced in a range of densities, from 3 to 25 pounds per cubic foot. This allows for a variety of applications, from padding and cushioning to gasket material.

The process of producing flexible urethane foam begins with two streams of liquid, one containing the polyol and the other containing the isocyanate. Other additives are also present in these liquids.

To produce the desired density, the levels and concentrations of these ingredients are adjusted. This allows for the creation of foam products with different degrees of hardness and flexibility.

Here's a breakdown of the densities and expansion rates of some of the FlexFoam-iT! products:

Castable

Castable flexible polyurethane foams are available in various densities, including 3, 5, 8, 10, 17, and 25 pounds. These foams are known as FlexFoam-iT! III, 4, V, 6, VIII X, 17 & 25.

They are two-component castable flexible foams that are strong and versatile, making them ideal for various applications such as padding/cushion material and gasket material.

Additional reading: Pu Foam Material

A + B mixture expands many times its original volume, allowing for a significant increase in size. This property makes them suitable for creating custom shapes and designs.

Vibrant colors can be achieved by adding color pigments to the foam mixture. This feature makes them appealing for arts and crafts applications.

The surface finish of the cured Flex Foam-iT! 17 foam approaches that of a urethane elastomer, indicating a high level of quality and durability.

Foam Production

The process of flexible urethane foam production involves mixing two streams of liquid, one containing polyol and the other containing isocyanate, along with other additives and gas to create foam.

Adjusting the levels and concentrations of these ingredients allows for the production of a variety of densities, degrees of hardness, and flexibilities in polyurethane foam products.

The introduction of gas is a crucial step in turning the material into foam, enabling the creation of flexible urethane foam products.

To achieve the desired properties in polyurethane foam products, manufacturers can adjust the levels and concentrations of the ingredients used in production.

Since 1962, Foam Products Corporation has been committed to providing excellent customer service while remaining cost-effective, making them a reliable partner for businesses in need of flexible urethane foam products.

Technical Information

Foam density is a crucial factor in determining the quality and performance of foam products. It can range from 3 lb/ft³ to 25 lb/ft³.

The expansion rate of foam is another important consideration. For example, FlexFoam-iT! III has an approximate expansion rate of 15 times, while FlexFoam-iT! 23 FR has an expansion rate of 2 times.

Foam density and expansion rate are closely related. A higher density foam will generally have a lower expansion rate. For instance, FlexFoam-iT! 14 has a density of 14 lb/ft³ and an expansion rate of 4 times.

Here's a table summarizing the density and expansion rates of some FlexFoam-iT! products:

Understanding the technical specifications of foam products can help you make informed decisions about which product is right for your needs.

Improving Castings' Surface Finish with Back Pressure

Back pressure is a game-changer for improving the surface finish of foam castings. By applying back pressure, manufacturers can achieve a tighter cell structure, resulting in better foam castings.

This technique is particularly useful for creating custom-made foam inserts for electronics or other delicate equipment. Back pressure helps to reduce the size of the cells, making the foam more rigid and durable.

A tighter cell structure also means less porosity, which can be a major issue in foam production. By minimizing porosity, manufacturers can create foams that are more resistant to moisture and other environmental factors.

The benefits of back pressure are evident in the improved surface finish of foam castings. This is especially important for applications where aesthetics are a top priority, such as in the production of custom foam inserts for electronics or other delicate equipment.

Intriguing read: Custom Pu Foam Blocks

Foam Products and Overview

Flexible pu foam products come in a range of formulations, each with its own unique properties. For example, FlexFoam-iT! III has an approximate 18X expansion ratio.

The different formulations of flexible pu foam have varying expansion ratios, with FlexFoam-iT! III having the highest at 18X. Other formulations, such as FlexFoam-iT! V and FlexFoam-iT! 6, have an approximate 10X expansion ratio.

Flexible pu foam is a versatile material that can be used in a variety of applications, including furniture and upholstery, automotive seating, and medical products. It's commonly used in the furniture industry for cushioning seats, backs, and arms of sofas, chairs, mattresses, and pillows. Flexible pu foam is also used in packaging and padding to safeguard delicate items during shipping and handling.

Overview

FlexFoam-iT! products are a range of foam materials with varying expansion ratios.

FlexFoam-iT! III has an 18X expansion ratio by volume.

The expansion ratio of FlexFoam-iT! 4 is approximately 10X when measured by weight.

FlexFoam-iT! V and 6 have a 10X expansion ratio by volume.

FlexFoam-iT! VIII has an 8X expansion ratio by volume.

FlexFoam-iT! X has a 6X expansion ratio by volume.

FlexFoam-iT! 17 has a 3.5X expansion ratio by volume.

FlexFoam-iT! 25 has a 2X expansion ratio by weight.

FlexFoam-iT! urethane casting foams have a 2 hour demold time.

Products

Flexible urethane foam products are incredibly versatile and have a wide range of applications.

Their ability to thrive in wet environments makes them a preferred option for many applications.

One of the most notable qualities of flexible urethane foam is its flexibility, which allows it to be used in a variety of settings.

Here are some examples of the many qualities of flexible urethane foam:

- Endless number of applications

- Flexible capabilities

- Ability to thrive in wet environments

How to Cast a Prop Engine Block

Casting a prop engine block is a great project for anyone looking to work with flexible PU foam. The surface finish of the cured foam approaches that of a urethane elastomer, making it a great choice for engine blocks.

You can achieve a smooth surface finish by following the right steps. This is particularly important when working with engine blocks, as a smooth finish can help improve airflow and overall engine performance.

FlexFoam-iT! 17, a type of flexible PU foam, is a great option for casting engine blocks. The surface finish of the cured foam is comparable to a urethane elastomer, making it a reliable choice.

With the right tools and techniques, you can achieve a professional-looking finish on your engine block. This is especially important if you're planning to use your engine block in a high-performance application.

Here's an interesting read: Pu Foam Block

Frequently Asked Questions

Is a PU foam mattress good?

PU foam mattresses have a moderate lifespan, lasting 2-5 years with good quality, but may be prone to sagging and other issues

What is the difference between flexible and rigid PU foam?

Flexible PU foam has an open-cell structure with interconnected pores, while rigid PU foam has a closed-cell structure with non-interconnected pores. This difference in structure affects their properties and uses.

Sources

- https://www.smooth-on.com/product-line/flexfoam-it/

- https://formx.eu/hidden-products/pu-flexible-foams/index.php

- https://chemicalformulaservices.com/product/polyurethane-foam-flexible-formula/

- https://www.fpcfoam.com/foam-products-manufacturer/polyurethane-foam-distributor/polyurethane-flexible-foam/

- https://www.isotecintl.com/products/flexible-foam/

Featured Images: pexels.com