Shrink film is a versatile packaging solution that offers a range of benefits for businesses and consumers alike.

Shrink film is made from a type of plastic called polyethylene, which is a thermoplastic that can be melted and molded into various shapes and sizes.

The shrink film packaging process involves wrapping the product in a plastic film that is then heat-sealed to create a tight, secure package. This process can be done on-site or in a factory setting.

Shrink film is widely used in various industries, including food, pharmaceuticals, and electronics, due to its ability to provide a protective and tamper-evident seal.

Additional reading: Shrink Film Packaging Machine

Compatibility

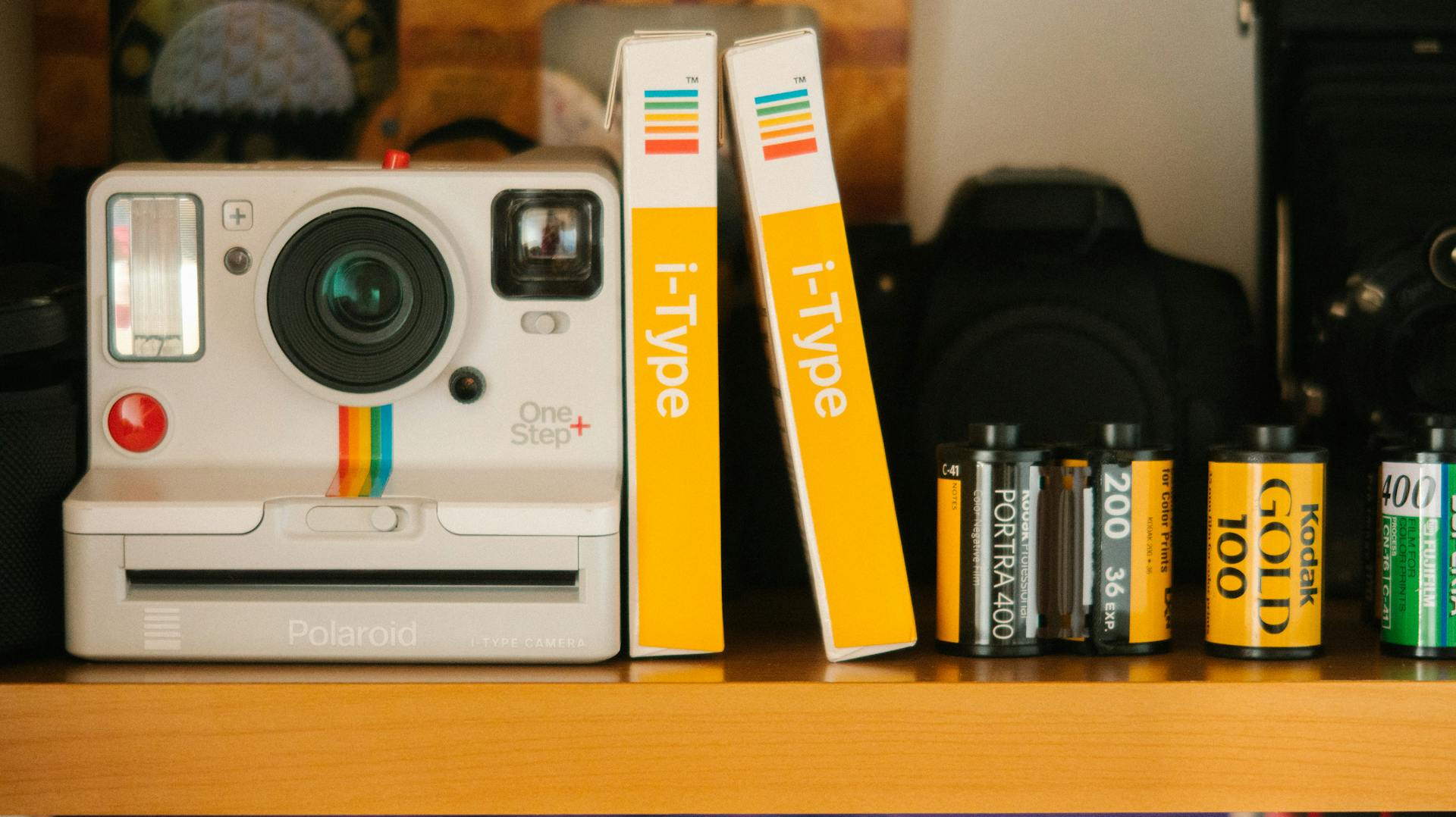

Grafix Inkjet Shrink Film is designed to work with a variety of printers, but it's not meant for any specific brand.

The coating is specifically designed for dye-based ink, but it may also work with pigment-based inks in some cases.

Testing the film first is always recommended to ensure it works with the printer ink before printing your final design.

This is especially important if you're unsure about the type of ink your printer uses.

Product Packaging

Shrink film is a versatile packaging option that can waterproof, weatherproof, and tamperproof products of any size with just a roll of film and a heating source.

It's an easy process to use, requiring minimal equipment and expertise, making it accessible to businesses of all sizes.

Shrink film brings a layer of confidence to consumers, providing a protective shine that sets products apart from the competition.

The flexibility and durability of shrink film make it a popular choice for product packaging, with many companies employing it to package their products effectively.

Product Packaging Essentials

Shrink film is a game-changer for product packaging, allowing you to waterproof, weatherproof, and tamperproof your products with just a roll of film and a heating source.

It's an easy process that requires minimal equipment, making it a great option for businesses of all sizes. The right kind of shrink film is essential, and there are different types available to suit various products.

Using shrink film can bring a layer of confidence to your consumer, and the protective shine of shrink wrap when applied appropriately can really make your products stand out. This can be a major advantage in a competitive market.

The cost of shrink film varies, but it's a worthwhile investment for businesses looking to improve their product packaging.

Product Packaging Characteristics

Product Packaging Characteristics are crucial for protecting and presenting your products. Shrink film is a popular choice for product packaging, and its characteristics can greatly impact the success of your packaging strategy.

One key characteristic of shrink film is its ability to conform to the shape of the product, providing a tight and secure fit. This is made possible by the film's ability to shrink when heat is applied.

Shrink film can also be designed to be transparent or opaque, depending on the needs of the product. Transparency can be beneficial for showcasing the product, while opacity can help to conceal packaging details.

Another important characteristic of shrink film is its ability to be printed on, allowing for custom branding and labeling. This can be a cost-effective way to add a professional touch to your packaging.

The clarity of the film is also a significant characteristic, as it can affect how well the product is visible. Clear film is ideal for showcasing products, while hazy or opaque film may not provide the same level of visibility.

The strength and durability of the film are also critical characteristics to consider, as they can impact the safety and security of the product during shipping and storage. A strong and durable film can help to prevent damage and ensure that the product arrives at its destination in good condition.

Shrink film can also be designed to be recyclable, which is a major advantage for companies looking to reduce their environmental impact.

I Want to Wrap Up

Shrink film is an easy process that requires just two basic elements: the right kind of shrink film and heat. With a roll of shrink film and a heating source, you can waterproof, weatherproof and tamperproof just about anything, regardless of size.

Using shrink film can bring a layer of confidence to your consumer and stand out with the protective shine of shrink wrap when applied appropriately. Many companies employ this option to package their products, given the flexibility, durability, and other valuable advantages of using shrink film.

To find the best film for your packaging needs, you should consider the type of shrink packaging line you have. If you have a manual, semi-manual, or automatic shrink packaging line, you can find the best film for it.

Packages Per Roll

Understanding Packages Per Roll is crucial for optimizing your product packaging.

The Packages Per Roll Calculator is a valuable tool to determine your ideal bag length, also known as your cut-off.

Your cut-off is the maximum length of a roll that allows you to achieve the desired number of packages.

This calculation is essential to ensure you're not wasting material by cutting too many rolls.

Knowing your ideal bag length helps you accurately estimate the number of packages you can expect to achieve per roll.

For instance, if you're using a 10-inch roll, you might be able to get 8-10 packages depending on your cut-off.

Features and Benefits

Shrink film offers a range of features and benefits that make it an attractive packaging solution. Shrink film is available in a variety of types, thicknesses, clarities, strengths, and shrink ratios, allowing you to create the precise type of layering and protection for your product.

Durable and long-lasting, shrink film provides product protection during distribution and in-store handling, thanks to its high tensile strength. This means that your products will arrive at their destination in pristine condition, ready for sale. Shrink film also reduces waste by allowing for longer rolls, which result in fewer changeovers and less roll handling, increasing equipment uptime and improving labor utilization.

Some of the key features of shrink film include:

- Abuse- and tamper-resistant shrink film

- Save valuable warehouse space by eliminating other bulky packaging materials

- Increase fulfillment velocity by automating the production line

- Wraps a wide range of product shapes, weights, and sizes

Opti

Opti shrink films from SEALED AIR are a great choice for packaging products. They offer a balance of strength, optics, performance, and affordability.

With Opti shrink films, you can package products in a variety of sizes and shapes. This versatility is thanks to the film's ability to conform to different shapes and sizes.

One of the benefits of Opti shrink films is that they minimize "dog ears" in tight packs. This means your products will look neat and tidy, even after shrink wrapping.

Opti shrink films work easily on most shrink systems, making them a convenient choice for packaging operations. This is especially important for high-speed operations where efficiency is key.

The Opti shrink film range includes options for high-speed operations, as well as softer films for lightweight, easy-to-bend, and heat-sensitive products. This means you can choose the right film for your specific needs.

By choosing Opti shrink films, you can maximize the appearance of your shrinked products. This is a great way to enhance the visual appeal of your products and make them more attractive to customers.

Here's a comparison of some of the key features of Opti shrink films:

- Multi-purpose shrink films with extra stiffness for high-speed operations

- Softer shrink films for lightweight, easy-to-bend, and heat-sensitive products

- Versatile shrink film for products of various sizes and shapes

Features & Benefits

Our shrink films offer a range of features and benefits that can enhance your packaging process. Here are some key advantages:

Durability and tensile strength provide product protection during distribution and in-store handling.

Film weight reduction significantly saves on raw materials and energy during manufacturing.

Longer rolls result in fewer changeovers and less roll handling, increasing equipment uptime and improving labor utilization.

Our recycle-ready* shrink films have a RIC4 designation.

*Degree of recyclability will vary depending on scope and availability of collection, sortation, and recycling programs.

Some of our shrink films are also abuse- and tamper-resistant, making them a great option for protecting valuable products.

You can save valuable warehouse space by eliminating other bulky packaging materials.

Increasing fulfillment velocity is also possible by automating the production line with our shrink films.

Our shrink films can wrap a wide range of product shapes, weights, and sizes, making them a versatile option for many applications.

Here are some of the key features and benefits of our shrink films:

Our shrink films are also made of 100% recyclable materials, making them a sustainable option for your packaging needs.

They offer superb clarity and glossy shelf appearance, making them optimal for consumer products where presentation is critical.

Our films are durable and less affected by temperature changes, and they feature excellent tensile strength and propagation to tear.

They can also shrink quickly and completely, resulting in a finished good as soon as it comes out of the shrink tunnel.

Quality and Durability

SEALED AIR brand and CRYOVAC brand shrink films are strong and durable, performing better than significantly thicker competitive materials.

Each master roll of Clysar film is tested in the company's R&D laboratory to ensure it conforms to standards and specifications.

Our films can wrap a wide range of product shapes, weights, and sizes, including large consumer goods, oddly shaped, and smaller "pick and pack" parcels.

Every roll of film is verified to be converted to your specifications, checking for correct width, diameter, footage, and other physical attributes.

Clysar's Recyclable* Films, such as Clysar EV-HPG, Clysar ULTRA LEG, and others, are prequalified for Store Drop-off by How2Recycle.

Cost and Sustainability

Shrink film is a cost-effective and sustainable option for packaging. It's recyclable, which is a major plus for businesses looking to reduce their environmental impact.

POF shrink film, in particular, is made of 100% recyclable materials. This makes it an attractive choice for companies prioritizing sustainability. The heat-sealing process for POF shrink film also doesn't release harmful vapors, unlike PVC.

By using shrink film, businesses can reduce their packaging costs in several ways. They can eliminate corrugated packaging for heavy products, for example, or package lightweight items in polybags. This not only saves money but also minimizes shelf footprint and opens up space in facilities.

Sustainability

POF and PE shrink films are recyclable, making them a more sustainable option for Consumer Packaged Goods businesses.

This is a significant advantage as sustainability becomes increasingly important in the industry. In fact, POF shrink film does not release harmful vapors during the heat-sealing process, unlike some other materials.

One of the key benefits of POF shrink film is its ability to be made from 100% recyclable materials. This not only reduces waste but also helps to minimize the environmental impact of packaging.

POF shrink film is also durable and less affected by temperature changes, which means it can withstand various conditions without compromising its performance.

What Is the Cost?

The cost of implementing shrink wrap film into your process is a crucial consideration.

You can reduce the cost of packaging by removing corrugated packaging from multi-pack products altogether.

New technologies can help optimize packaging for cost reduction by down-gauging or selecting a lower-width film.

Conducting a film audit with a packaging specialist can help identify options for cost reduction.

To understand and evaluate the cost of implementing shrink wrap film, ask yourself some essential questions.

These questions will help determine your priorities and identify the right shrink wrap film packaging line for your company.

Cost Reduction

You can significantly reduce packaging costs by using shrink film, which is strong and durable enough to replace corrugated packaging in multi-pack products. Heavy products can be securely wrapped in shrink film without the need for a corrugated tray.

Lightweight items like single-serve chips can be packaged in a polybag, minimizing your shelf footprint and freeing up space in your facility. This also reduces the cost of packaging.

New technologies allow you to down-gauge or select a lower-width film to further optimize your packaging for cost reduction. Conducting a film audit with a packaging specialist can help you identify available options.

The first step in understanding the cost of implementing shrink wrap film is to ask yourself essential questions, which will help determine your priorities and identify the right shrink wrap film packaging line for your company.

Materials and Properties

Shrink film is made from polyethylene, a type of polyolefin formed with the addition of ethylene during polymerization.

Polyethylene comes in three main forms: High-Density Polyethylene, Low-Density Polyethylene, and Linear Low-Density Polyethylene, each with its own unique properties.

Shrink film is loosely placed over items and shrinks when heat is applied, creating a tight seal of protection.

Polyvinyl Chloride (PVC)

Polyvinyl Chloride (PVC) is a versatile material that has been widely used in various applications due to its lightweight and inexpensive nature. It was once the most commonly used shrink packaging material in the world.

PVC is durable and long-lasting, making it suitable for construction projects and houseware products. It's also used in rigid constructs like blister and clamshell packaging.

In its flexible form, PVC is applied to shrink film and bagging, making it a convenient option for packaging. However, its use has declined due to health concerns and sustainability issues.

PVC poses health dangers during creation and incineration, which has led to its replacement with other materials.

Polyethylene (PE)

Polyethylene (PE) is a type of polyolefin formed with the addition of ethylene during polymerization.

It's used in various forms of flexible protective packaging, such as shrink film and stretch film, which perform differently for each application.

High-Density Polyethylene is one of the most common forms of PE.

Low-Density Polyethylene and Linear Low-Density Polyethylene are the other two common forms of PE.

These different forms of PE have unique properties that make them suitable for specific uses.

Moisture Vapor Transmission Rate

Moisture Vapor Transmission Rate is a measure of how much moisture will or will not travel through a film. This characteristic is crucial for maintaining the shelf life of your package.

If low moisture transmission into or out of your package is important, you should pay attention to this characteristic. Modified atmosphere packaging can help reduce or eliminate fog by controlling the moisture levels.

The MVTR characteristic is essential for preventing moisture-related issues in packaging.

Try Different Formulations

When working with shrink wrap film, it's easy to get stuck with a single formulation. However, different formulations can reduce re-wraps and improve packaging efficiency.

A different formulation may be just what you need to reduce re-wraps. This is because there could be more than one kind of shrink wrap film that works for a particular product.

You'll want to make sure you know the storage requirements of your shrink film to get the most out of it. This is because climate-compromised packaging can be a major issue.

Shrink packaging is best stored in temperatures between 30 and 77 degrees Fahrenheit.

Tips and Tricks

You can add designs to Shrink Film with permanent markers, paint pens, and rubber stamps before and after baking. This means you can get creative with your designs and add them at different stages of the process.

Yes, you can use inkjet printers with Grafix Shrink Film, which is indicated by the Inkjet Shrink Film Tip Card.

Helpful Hints

You can get creative with Shrink Film by adding designs with permanent markers, paint pens, or rubber stamps before and after baking.

Yes, you can use inkjet printers to print designs onto Shrink Film, but you'll need to check the Inkjet Shrink Film Tip Card for specific instructions.

Adding designs to Shrink Film is a great way to make it more personalized and unique.

You can use permanent markers, paint pens, and rubber stamps to add designs to Shrink Film before or after baking, giving you flexibility in your creative process.

Shrink Film is a versatile material that can be customized in many ways, making it perfect for crafters and DIY enthusiasts.

Adjust Your Width

Adjusting your film width can make a big difference in your packaging costs. Reducing your film width from 12 inches to 11 inches can save you 4.2% in materials cost alone.

You might be surprised to learn that PVC shrink film and other shrink wrap films come in a variety of sizes, not just full-inch increments. This means you have more options than you think when it comes to finding the perfect width for your products.

Custom-sizes will indeed have a higher cost, but if you're packaging millions of products per year, you'll see savings regardless. It's a worthwhile investment in the long run.

Here are some potential savings based on reducing your film cut-off length:

Keep in mind that these savings are based on reducing your film cut-off length, not just adjusting your film width. By understanding your ideal shrink film width and minimizing film cut-off, you can reduce waste and improve overall packaging costs.

It Has Issues

PVC film has a more brittle nature after shrinking, making it less ideal for bundling multiple items together. This can lead to breakage and other issues down the line.

It's also worth noting that PVC film can leave carbon deposits on the sealer, requiring regular maintenance for consistent operation. This can be a real hassle, especially if you're not used to dealing with this type of material.

As a #3 recyclable material, PVC film is unable to be recycled in most cases. This means you'll need to find alternative ways to dispose of it, which can be a challenge.

Proper handling and maintenance are key to getting the most out of PVC film.

Understanding Shrink Film

Shrink film is a type of material made up of polymer plastic film that shrinks tightly over whatever it is covering when heat is applied. This can be done using a handheld heat gun or a heat tunnel on a conveyor.

Shrink force, typically measured in PSI, tells you the amount of force the shrink film will exert on your product. If you're packaging a multi-pack that needs to be tightly contained without damaging, understanding your shrink force is very helpful. High shrink force films, like polyolefin films, are typically used for this purpose.

Shrink films come in different thicknesses (gauge) and widths to meet your most demanding shrink wrap needs. They can be made from various materials, such as LDPE, LLDPE, monolayer, and co-extruded films.

Here are some characteristics of shrink films:

- High tensile strength and puncture resistance enables gauge reduction and cost savings

- Superior wrapping strength

- Excellent sealability

- Tailored MD shrink or preferred balanced shrink

- Excellent performance in commercial heat tunnels and with handguns

Cryovac

Cryovac shrink films offer enhanced merchandising appeal, making products stand out on store shelves.

One of the key benefits of Cryovac shrink films is their outstanding resistance, providing excellent protection for products against damage and tampering.

This added protection also helps maintain pack integrity, ensuring that products are fully wrapped and secure.

Cryovac shrink films come on longer rolls, which means fewer changeovers and less roll handling, resulting in higher productivity and equipment uptime.

This also leads to a lower carbon footprint, thanks to reduced material use and significant material source reduction.

You can even recycle Cryovac shrink films at 18,000 retail store drop-off locations across the United States.

Stealthwrap

StealthWrap is an innovative solution for packaging that's definitely worth exploring. It's a type of shrink film that can replace up to 1,000 cartons with just one roll of film, saving valuable warehouse space.

This film is also 100% recyclable, making it a more sustainable option for businesses. You can recycle it at over 18,000 store drop-off locations nationwide.

One of the benefits of StealthWrap is that it's available in different colors, including box brown to mimic corrugate, and dark gray by special order. This allows businesses to customize their packaging to match their brand identity.

StealthWrap is also recognized for its innovation, being a finalist for the Dow 2018 Packaging Innovation Award.

The Science Behind

Shrink film is a versatile polymer material used for packaging finished goods. It's amazing how something so simple can be so effective.

The molecules of a shrink film sheet or tube are randomly intertwined, meaning they're coiled and twisted with no particular alignment. This is what makes shrink film so flexible and adaptable.

Heat is applied to the film, which catalyzes it to shrink tightly around the item placed within. This process can be achieved using a conveyor heat tunnel or an electric or gas heat gun.

The molecular structure of shrink film is what allows it to change shape in response to heat. The molecules reorient from their initial random pattern to fit the mold of their contents.

When cooled properly, the film's molecular characteristics are set, so it remains in this stretched state until sufficient heat energy is applied for the molecule chains to shrink back to their original form.

The Difference Between

Shrink film and stretch film may look similar, but they serve very different purposes. Shrink film is designed to shrink when heat is applied, creating a tight seal around items.

Shrink film typically stretches to around 50-75% before breakage occurs, whereas stretch film can stretch up to 300%. This makes stretch film ideal for palletizing multiple items.

The elastic memory of shrink film allows it to cling to itself and keep a tight layer of protection around items. This is a key difference between shrink and stretch film.

If this caught your attention, see: Black Stretch Film Wrap

Calculators and Tools

The Shrink Film Width Calculator helps you identify the ideal shrink film width for your product, reducing waste and improving overall packaging costs.

You can use this calculator to ensure you're not over- or under-ordering shrink film, which can save you money and resources.

By using the Shrink Film Width Calculator, you can make informed decisions about your packaging needs and optimize your shrink film usage.

Reduce Gauge

New shrink film technologies allow for gauges as low as 38, a significant reduction from the old days of 100, 75, 60, and 45 gauges.

Understanding the ideal gauge of shrink film for your product is crucial for costs and protection throughout its lifecycle.

New technologies have made it possible to achieve the same integrity at a lower gauge, which can lead to cost savings.

If you're unsure how to tell if your shrink film has been compromised, look for signs like sticky rolls, bagging, and sagging.

Sticky rolls can be a sign of overheated film, which can cause downtime on the packaging line.

Avoid using rolls that are stuck together or show bagging within their layers to prevent interference with machine tracking.

Using compromised rolls can lead to wasted time and resources, so it's essential to identify and replace them promptly.

Width Calculator

Calculators and tools can make a big difference in reducing waste and improving packaging costs. One tool you should consider is a shrink film width calculator.

You can use this calculator to identify the ideal shrink film width for your product. This can help you reduce waste and improve overall packaging costs.

Reducing your film width from 12 inches to 11 inches can save you 4.2% in materials cost alone. That's a significant savings, especially if you're packaging millions of products per year.

Custom-sizes will have a higher cost, but using high volumes will still bring savings. It's worth exploring different options to find the best fit for your business.

Films

Shrink films are made up of polymer plastic film that shrinks tightly over whatever it is covering when heat is applied.

Sigma Plastics Group of Companies has been manufacturing shrink films at many of their locations for years, and their expertise in this industry is impressive.

Shrink films come in a number of thicknesses (gauge) and widths to meet your most demanding shrink wrap needs. They produce both blown film and cast film, and shrink films and printed shrink films are available.

Some characteristics of Sigma Plastics Group of Companies' shrink films include high tensile strength and puncture resistance, which enables gauge reduction and cost savings.

Here are some of the characteristics of Sigma Plastics Group of Companies' Shrink Films:

- High tensile strength and puncture resistance enables gauge reduction and cost savings

- Superior wrapping strength

- Excellent sealability

- Tailored MD shrink or preferred balanced shrink

- Excellent performance in commercial heat tunnels and with handguns

Sigma Plastics Group of Companies offers a complete range of shrink films, including poly to poly shrink applications, manufactured from LDPE, LLDPE, monolayer, and co-extruded materials.

Featured Images: pexels.com