Markings on pallets play a crucial role in the supply chain, helping to identify and track goods as they move from one place to another.

These markings are not just a matter of aesthetics, but are actually required by regulations to ensure safe handling and transportation of goods.

The type of marking used on a pallet depends on the type of product being stored or shipped, with some markings indicating the pallet's contents and others providing information about its handling requirements.

For example, a pallet marked with a warning label may indicate that the contents are hazardous or fragile, requiring special care when handling.

Importance and Classification

Pallet markings serve as a universal language, conveying crucial information about the pallet's origin, treatment, and suitability for specific uses.

These markings ensure compliance with international regulations, preventing the spread of pests and diseases, and indicating ownership.

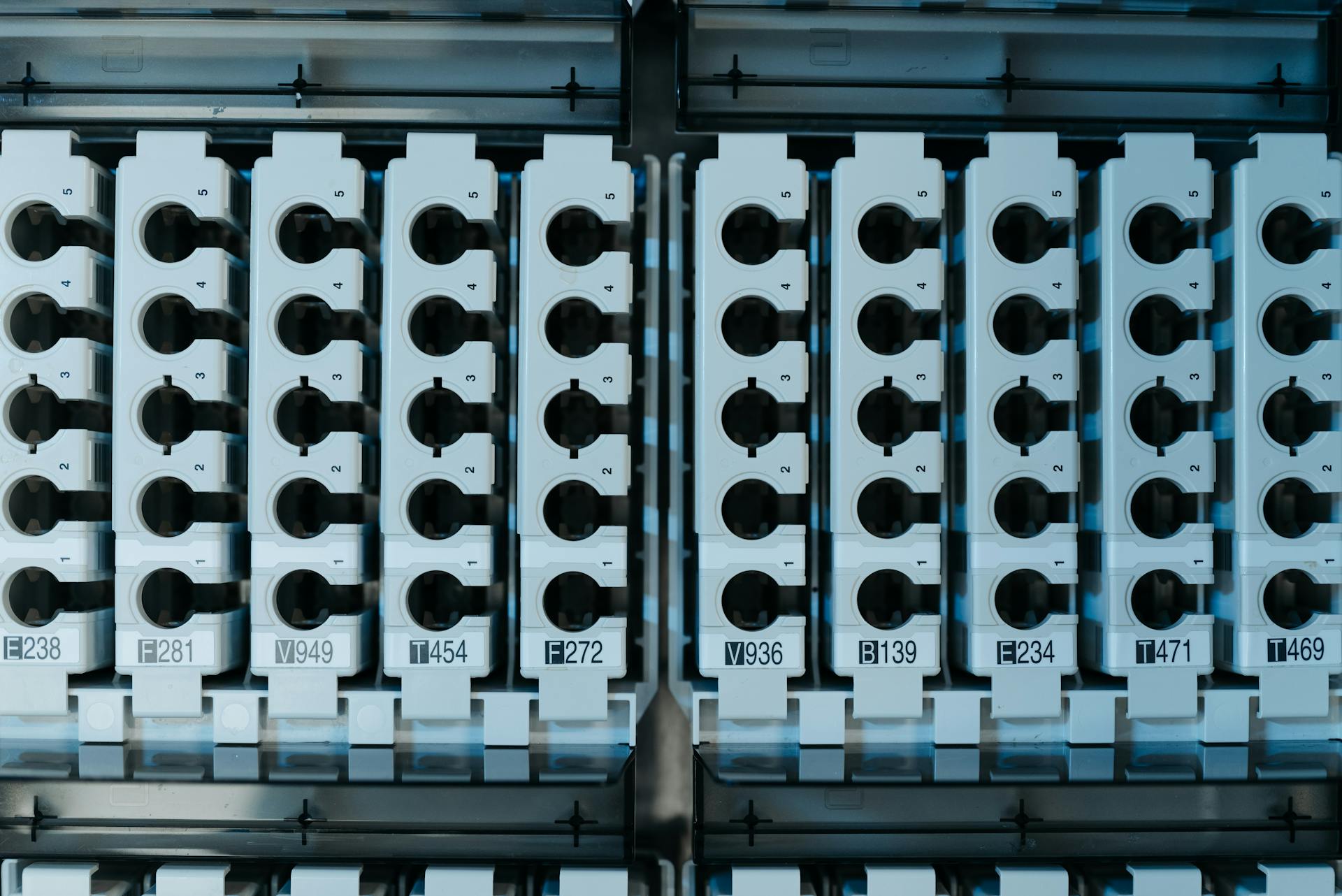

Serial numbers help in tracking and quality control, identifying when and where the pallet was produced.

Businesses rely on these markings for smooth customs clearance and maintaining supply chain integrity.

For individuals, especially DIY enthusiasts, knowing these symbols can safeguard against using chemically treated or unsafe pallets.

Why They Are Important

Pallet markings are a vital part of international regulations, ensuring compliance and preventing the spread of pests and diseases.

These markings convey crucial information about the pallet's origin, treatment, and suitability for specific uses, serving as a universal language for businesses and individuals alike.

For businesses, smooth customs clearance and maintaining supply chain integrity depend on accurate pallet markings.

Serial numbers help track and control pallet quality, identifying when and where the pallet was produced.

Types and Their Classification

There are various types of markings on pallets, each serving a unique purpose. These markings can be categorized based on their function and purpose.

ISPM 15 Markings are used to indicate compliance with international phytosanitary standards. They help ensure that the pallet meets the necessary regulations for exporting and importing goods.

Manufacturer’s Marks or Branding show the pallet’s producer and sometimes its ownership. This information is crucial for tracking the origin and ownership of the pallet.

Load Capacity Markings specify the maximum weight the pallet can safely carry. This is essential for ensuring the safe transportation of goods.

Unique identifiers like License Numbers are assigned to manufacturers or treatment providers by the national plant protection organization. These numbers ensure accountability and track the origin of the pallet.

Quality Grade Markings reflect the pallet’s condition and suitability for reuse. This information helps determine whether the pallet can be reused or if it needs to be replaced.

QR Codes and Digital Markings provide traceability and additional data via technology. This feature allows for easy tracking and monitoring of the pallet’s history.

Environmental Markings highlight sustainable or recycled materials used in the pallet. This information promotes eco-friendly practices and responsible sourcing.

Industry-Specific Markings are tailored symbols for sectors like chemicals or pharmaceuticals. These markings ensure that the pallet meets the specific regulations and standards of the industry.

Colored Pallets serve as visual indicators of ownership or specific uses. This feature helps identify the pallet's purpose and ownership at a glance.

Here is a breakdown of the types of markings on pallets:

Regulations and Standards

Industry-specific pallet markings are crucial for certain industries, such as pharmaceuticals or food, which require additional markings to indicate compliance.

ISPM 15 markings are a globally recognized standard that signals to government border inspection services that a solid wood pallet or packaging has been treated with heat or methyl bromide treatment in accordance with the standard.

The ISPM 15 stamp includes the IPPC logo, the country code, the producer or treatment provider code, and the treatment method code.

ISPM 15 stamps are designed to signal compliance to customs inspectors without the need for further investigation or related paperwork.

The ISO 3166-2 codes for each country appear on IPPC stamps, allowing you to identify the country of origin for wood packaging, including pallets.

ISPM-15 markings also indicate the method of treatment, which can be heat treatment (HT) or fumigation with methyl bromide (MB).

Intriguing read: Are Chep Pallets Heat Treated

Industry Specific

Industry Specific pallet markings are crucial for certain industries, like pharmaceuticals or food, which require additional markings to indicate compliance.

These industries have specific standards that must be met to ensure safe handling and storage of products.

Pharmaceuticals, for example, may require special markings to indicate the type of product and its handling requirements.

In the food industry, pallets may need to be marked with information about the product's ingredients and any allergens present.

ISPM 15

ISPM 15 is a guideline developed to prevent the international transport and spread of diseases and insects that could negatively affect plants or ecosystems.

The ISPM 15 program is a globally recognized standard developed by the International Plant Protection Convention (IPPC) to prevent the international spread of pests and diseases through wooden packaging materials.

Pallets used in international shipping must comply with ISPM 15 standards, which mandate that all solid wood packaging materials be treated either by heat or fumigation and then marked with a specific stamp indicating compliance.

The ISPM 15 stamp includes the IPPC logo, the country code, the producer or treatment provider code, and the treatment method code.

Check this out: Us Postal Service Priority Mail International Tracking

This stamp is crucial for safeguarding agriculture and forests by ensuring that wooden packaging used in international trade does not harbor harmful pests.

The ISPM 15 stamp was designed to signal the pallet being compliant to customs inspectors without the need for further investigation or related paperwork to prove compliance.

ISPM 15 markings signal to government border inspection services that a solid wood pallet or solid wood packaging has been treated with heat or methyl bromide treatment in accordance with the standard.

The marking includes the symbol for IPPC, the country code, wood packaging or treatment facility identification, and a method of treatment, such as heat treatment (HT) or methyl bromide (MB).

The ISO 3166-2 codes for each country appear on IPPC stamps, allowing you to identify the country of origin for wood packaging, including pallets.

Currently accepted practices for treatment include heat treatment using conventional steam or dry kiln heat chamber (HT), heat treatment using dielectric heating (DT), and fumigation with methyl bromide (MB).

Curious to learn more? Check out: Packaging Pallets

Marks for Oversight Organizations

In the world of pallets, there are organizations that oversee the quality of pallets in rental pools. EPAL, the European Pallet Association, uses an EPAL inside an oval mark to identify EPAL pallets.

EPAL only oversees the quality of their pallets, not asserting ownership. This is a key distinction from other pools that oversee pallet quality.

The 9BLOC pallet program in the U.S. is another example of an organization that oversees pallet quality. They, like EPAL, focus on ensuring the quality of the pallets in their pool.

Until 2015, the Canadian Pallet Council also played a role in overseeing pallet quality.

Pallet Markings

Pallet markings are a crucial aspect of the supply chain. They provide traceability and indicate ownership, which is essential for avoiding legal issues.

A company's logo may be stamped on the pallet, especially if it's part of a pallet pooling system, denoting ownership and responsibility.

Markings should be durable, clear, and easy to read, typically applied using indelible ink, branding, or stamping methods. This ensures quick identification and compliance during inspections.

The PRL (Pallet Return Logistics) stamp indicates a pallet is part of a rental or pooling system, designed for efficient return and reuse within specific supply chains.

You might enjoy: Part Pallets

Ippc Symbol

The IPPC symbol is a stylized wheat ear within a rectangle, and it's a crucial mark for pallets that meet international phytosanitary standards.

This symbol certifies that the pallet is safe for cross-border movement, giving you peace of mind when shipping goods internationally.

The IPPC symbol is a key indicator of ISPM 15 compliance, which is essential for international shipping and reuse of pallets.

If you see this symbol on a pallet, you can be confident that it has been treated according to international standards.

For another approach, see: Shipping Pallets

Load Capacity

Load capacity markings are a crucial aspect of pallet markings. These symbols or numbers specify the maximum load the pallet can carry.

Loads exceeding the marked capacity can compromise the integrity of the pallet and the goods it carries. Safety is a top concern, and adhering to these limits is essential.

The load capacity markings serve as a warning to handlers and transporters about the maximum weight the pallet can safely carry. It's not just about avoiding damage, but also about preventing accidents.

Ignoring these markings can have serious consequences, including damage to goods, injuries to handlers, and even accidents during transport.

Pallet Markings

Pallet markings are an essential part of the supply chain, providing crucial information about the pallet's ownership, treatment, and quality.

A company's logo may be stamped on the pallet, especially if it's part of a pallet pooling system, which denotes ownership and should be respected to avoid legal issues.

The ISPM 15 stamp is a must-have for pallets that have been treated according to international standards, ensuring they are safe for international shipping and reuse.

EPAL pallets are widely used across Europe and are identified by an EPAL inside an oval mark, which signifies that the pallet meets the stringent standards set by the European Pallet Association.

The EPAL mark is a guarantee of quality and reliability, making it a popular choice for many businesses.

PRL stamps indicate that a pallet is part of a rental or pooling system, designed for efficient return and reuse within specific supply chains.

The markings on pallets should be durable, clear, and easy to read, typically applied using indelible ink, branding, or stamping methods, to ensure quick identification and compliance during inspections.

Worth a look: Ems International Tracking Number

Identification and Verification

Manufacturer's marks or branding on pallets are a crucial aspect of identification and verification. These markings provide traceability and indicate ownership, which should be respected to avoid legal issues.

A company's logo may be stamped on the pallet, especially if it's part of a pallet pooling system. This denotes ownership.

When examining a pallet for treatment, look for the ISPM 15 stamp and the treatment code, such as "HT" or "MB". The absence of these markings likely means the pallet hasn't been treated according to international standards.

Broaden your view: Wooden Pallet Treatment

How to Identify Treated Pallets

To identify treated pallets, start by looking for the ISPM 15 stamp and treatment code. This is a crucial step in ensuring the pallet meets international standards.

The treatment code will be marked adjacent to the IPPC symbol, which is a two-letter ISO country code indicating where the pallet was treated. For example, "DE" for Germany or "FR" for France.

Additional reading: How to Tell If Pallets Are Treated

Check for the ISPM 15 stamp and treatment code, such as "HT" or "MB". If you don't see these markings, it's likely the pallet hasn't been treated according to international standards.

Here are some common treatment codes to look out for:

Manufacturer's Marks

Manufacturer's Marks are a crucial aspect of pallet identification and verification. They provide traceability and indicate ownership, which is essential for avoiding legal issues.

A company's logo may be stamped on the pallet, especially if it's part of a pallet pooling system. This denotes ownership and should be respected.

Red and blue pallets are also used to declare ownership, with CHEP's blue pallets being a notable example. CHEP owns millions of these distinctively marked pallets.

Pallet paint color is also used to help identify pallets, with some companies using specific colors to denote ownership. In North America, PECO Pallet is known for its red pallets with white lettering.

It's essential to recognize the markings of proprietary pallets in your locale to avoid potential legal complications.

You might like: Chep Pallets Weight

QR Codes

QR codes are a game-changer for tracking and verifying information. They're often used on modern pallets, allowing for digital tracking and instant access to a pallet's history and specifications.

These digital markings, like QR codes, can provide a wealth of information at a glance. This is especially useful for supply chain management and inventory tracking.

By scanning a QR code, you can quickly retrieve detailed information about a pallet, including its contents, origin, and destination. This level of transparency is a major advantage in today's fast-paced logistics industry.

QR codes can be found on a variety of items, from pallets to shipping containers, and are often used in conjunction with RFID tags for added security and efficiency.

Printing and Colors

Pallet stamps or brands can signify different pallet models or sizes, such as the CP (chemical) pallet pool, which includes nine different models (CP1 through CP9).

Major pallet poolers often paint their pallets using a distinctive color to prevent pallet loss. This color selection considers factors like UV and scuff resistance, differentiation from other competing poolers, marketing and aesthetic values, and cost.

Pallets can also be marked with a specific color to denote their ownership or pool name, such as EPAL (European Pallet Association) pallets, which make up the world's largest pool.

Here are some examples of pallet markings that can be printed or painted:

- EPAL mark (European Pallet Association e. V.) on corner blocks

- IPPC marking (International Plant Protection Convention) on center blocks

- Unique marking

- Logo marking

- 2D Codes

- Alphanumeric information

Pallets can be marked using inkjet printers, such as the REA JET HR, which offers a maintenance-free, cartridge-based printing technology.

Inkjet Printing

Inkjet printing is a popular method for marking pallets, and it's used for a variety of purposes. The REA JET HR inkjet printer is a great example of this technology, offering maintenance-free, cartridge-based printing that's clean and environmentally friendly.

One of the key benefits of inkjet printing is its flexibility, allowing for small batches, order-related print jobs, and large batches to be marked with ease. The REA JET GK 2.0 PA software extension can store information about how many blocks are to be marked and what print content is to be printed, making it a great tool for managing pallet marking.

Pallets can be marked with a range of information, including the EPAL mark (European Pallet Association e. V.) on corner blocks, IPPC marking (International Plant Protection Convention) on center blocks, unique markings, and logos.

Here are some common applications of inkjet printing on pallets:

- Marking of one-way and returnable pallets

- EPAL mark (European Pallet Association e. V.) on corner blocks

- IPPC marking (International Plant Protection Convention) on center blocks

- Unique marking

- Logo marking

- 2D Codes

- Alphanumeric information

- Small series marking

- Variable print content

- Large series marking

Inkjet printing can be used to mark a wide range of pallets, from disposable to reusable, and from wood to plastic, corrugated cardboard, or steel.

Colours of Objects: Why Are They Painted?

Coloured pallets are often used in the logistics industry, but did you know that they're usually rented and still belong to the company that branded them? This can cause legal complications if you try to use one.

Red pallets are a common sight, but they're not just any ordinary pallet. They can be from PECO or LPR, two companies that own a significant number of red pallets.

If you're wondering about the blue pallets you see around, they're likely owned by CHEP. This company has a large fleet of blue pallets that are used in various industries.

Brown pallets are also a thing, and they're usually owned by IPP. This company uses brown pallets for their operations in Europe.

Here's a quick reference guide to the colours and companies mentioned:

- Red pallets: PECO or LPR

- Blue pallets: CHEP

- Brown pallets: IPP

Frequently Asked Questions

How to tell what a pallet is made of?

To identify the type of wood used to make a pallet, look for differences in color, grain pattern, and weight. Heavier pallets are often made of hardwoods, while lighter ones are typically made of softwoods.

How to tell if pallets have been treated?

To identify treated pallets, look for initials such as HT (heat-treated), KD (kiln dried), or MB (methyl bromide treated) near the IPPC logo. This information can help you determine if the pallets meet international phytosanitary standards.

Sources

- https://quicargo.com/blog/markings-on-a-pallet-what-do-they-mean-an-extended-guide/

- https://blog.eurosender.com/pallet-markings/

- https://packagingrevolution.net/the-importance-of-pallet-markings/

- https://www.rea-jet.com/en/solutions/applications/pallet-marking

- https://www.liveabout.com/pallet-markings-what-do-they-mean-2878162

Featured Images: pexels.com