Hydro Transport Technology is a game-changer in the field of logistics. It's a system that uses pipelines to transport liquids, gases, and even solid materials over long distances.

One of the key benefits of hydro transport technology is its efficiency - it can transport up to 100 times more material than traditional trucks. This makes it a cost-effective option for companies looking to reduce their environmental impact.

Hydro transport technology is also incredibly safe - pipelines are designed to withstand extreme weather conditions and can operate for decades without major maintenance. This reliability is a major selling point for companies that rely on hydro transport for their operations.

The technology has been around for decades, with the first hydro transport pipeline built in the 1950s. Since then, it has evolved to become a crucial part of modern logistics.

For your interest: Hydro Pack Bladder

Design and Planning

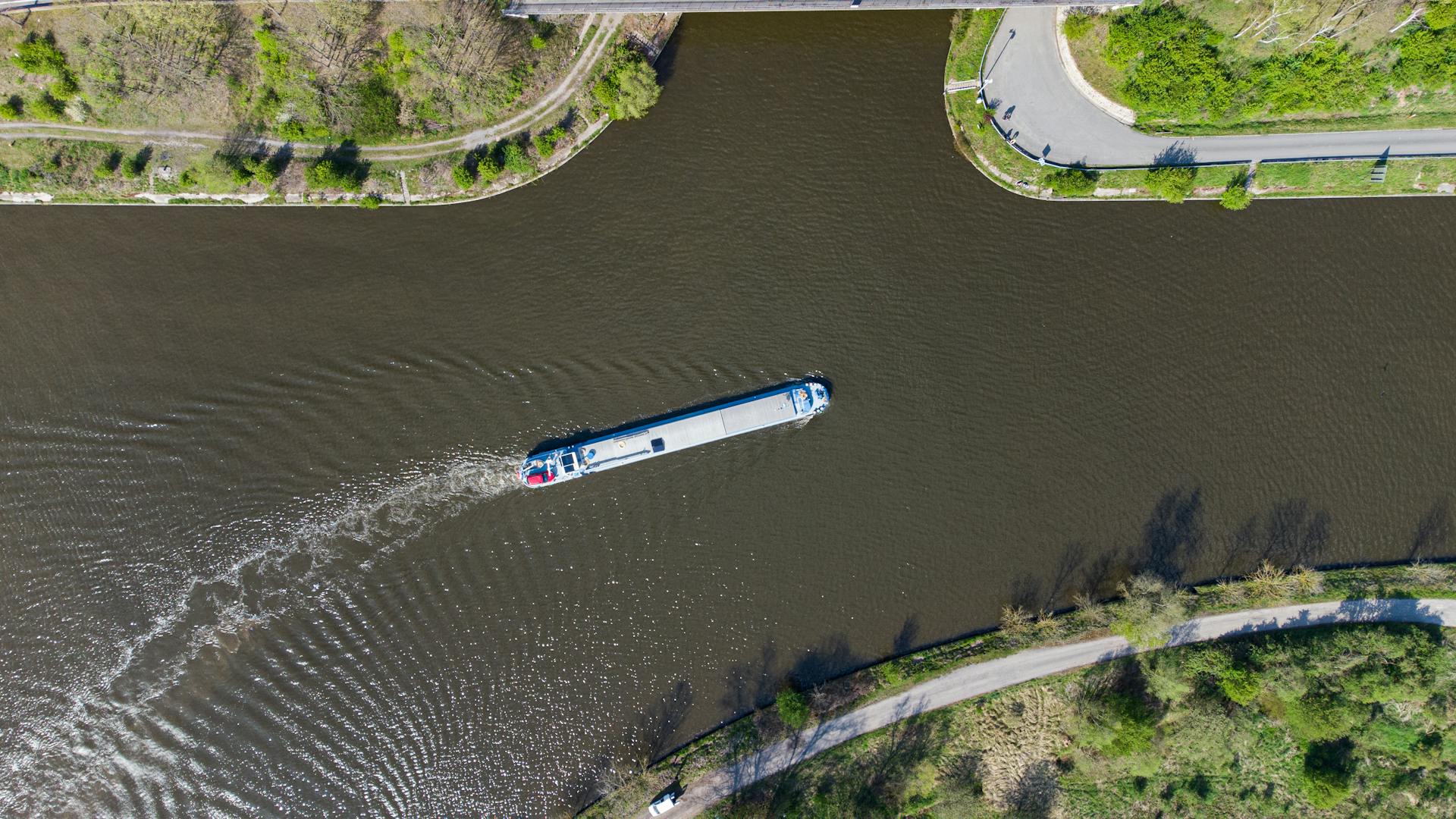

The design and planning of hydro transport systems is a crucial step in ensuring efficient and safe operations. A hydro transport system can be designed to use a variety of waterways, including rivers, canals, and coastal routes.

A key consideration in designing a hydro transport system is the type of cargo being transported. For example, a system designed to transport large cargo ships may require a deeper and wider waterway than one designed for smaller vessels.

The planning phase of a hydro transport project involves identifying the best route and infrastructure requirements. This includes assessing the water depth, width, and current speed to ensure safe passage.

A hydro transport system's design should also take into account the environmental impact. For instance, a system that minimizes disruptions to local ecosystems and wildlife habitats is essential.

The route of a hydro transport system can be influenced by geographical features such as mountains, rivers, and coastal areas. In some cases, a system may need to navigate through a narrow and winding route, requiring careful planning and design.

Regular maintenance and inspections are essential to ensure a hydro transport system operates efficiently and safely. This includes monitoring water levels, currents, and weather conditions to prevent accidents.

Suggestion: High Value Cargo Transportation

Instrumentation and Monitoring

Flowmeters are the most important instrument on any Hydrotransport line, used for both slurry velocity calculations and performing material balances.

Flowmeters can be traditional wedge or Venturi-type, or more modern sonar technology, which is non-intrusive and doesn't contribute to localized wear.

Pressure transmitters are the most critical instruments on any slurry pipeline, particularly Hydrotransport lines, providing valuable information on how the pumps are functioning and if the slurry is flowing normally.

Pressure transmitters are typically installed on the suction and discharge of each slurry pump and are equipped with membranes to prevent contamination from the oil sands slurry.

The four basic types of instruments commonly found on every Hydrotransport line are:

- Flowmeters

- Densitometers (or Density Meters)

- Pressure Transmitters

- Autosamplers

Line Sanding: Why Flow Velocity Is Critical

Line sanding is a critical issue in oil sands processing, and it's essential to understand why flow velocity is crucial in preventing plugging.

A normal oil sands slurry should flow at a minimum of 3.0 m/sec to keep all particles suspended.

Coarse sand doesn't remain suspended in the water phase and instead gets dragged along the bottom of the pipeline, requiring a much higher velocity to keep moving.

Mines that process coarser oil sands should operate closer to 4.0 m/sec to prevent plugging.

Operating too fast for long periods of time is not recommended, as it greatly increases wear of the pipeline.

Here are some general guidelines for flow velocities in oil sands processing:

Instrumentation

Instrumentation is a crucial aspect of any Hydrotransport line. It's essential to monitor the flow, density, pressure, and bitumen content of the slurry to ensure efficient and safe operation.

Flowmeters are the most important instrument on a Hydrotransport line, used for slurry velocity calculations and material balances. They're traditionally wedge or Venturi-type, but sonar technology is becoming increasingly popular due to its non-intrusive nature.

Densitometers, or density meters, are commonly installed near the front end of the line, providing valuable information on slurry density for mass balancing purposes.

Pressure transmitters are the most critical instruments on a Hydrotransport line, installed on the suction and discharge of each slurry pump to monitor pressure readings.

Autosamplers collect slurry samples at various time intervals to analyze bitumen content and support material balances across the plant.

The individual slurry pumps and motors are typically equipped with numerous instruments, including those that gauge impeller rotational speed, motor amperage draw, and bearing temperature, providing valuable diagnostics for both the Process and Maintenance teams.

Here are the 4 basic types of instruments commonly found on every Hydrotransport line:

- Flowmeters: used for slurry velocity calculations and material balances

- Densitometers (or Density Meters): provide valuable information on slurry density for mass balancing purposes

- Pressure Transmitters: installed on the suction and discharge of each slurry pump to monitor pressure readings

- Autosamplers: collect slurry samples at various time intervals to analyze bitumen content

Automation and Control

Automation plays a crucial role in ensuring the smooth operation of a Hydrotransport line. The primary control variable is the liquid level in the SPP pumpbox feeding Hydrotransport, which is adjusted by controlling the speed of the pumps.

As the level in the pumpbox rises, the Hydrotransport pumps speed up to bring the level back down to normal. This is done by increasing the speed of the pumps to maintain a stable level.

The speed of the pumps can also be adjusted depending on the pressure signals across the pipeline. High discharge pressures can signal a downstream blockage, while low pressure spots on the pump suction can indicate loss of feed.

Each pump speed can be adjusted to prevent complete loss of suction or shutdown of the line. Pumps that experience low suction pressure should automatically slow down to prevent complete loss of suction.

All pumps across a Hydrotransport line typically operate at the same speed under normal conditions. However, each pump speed can also be adjusted depending on the pressure signals across the pipeline.

Here are the key control variables for Hydrotransport:

- Liquid level in the SPP pumpbox feeding Hydrotransport

- Suction and discharge pressures for each Hydrotransport pump

Prevention and Maintenance

Regular maintenance is crucial to prevent hydro transport accidents. A study found that 75% of hydro transport accidents are caused by equipment failure due to lack of maintenance.

Inspecting equipment regularly can help identify potential issues before they become major problems. This can be done by checking for signs of wear and tear, such as rust or corrosion.

Discover more: Truck and Transportation Equipment

Hydro transport operators should also keep accurate records of maintenance and repairs. This can help identify patterns and trends, and inform future maintenance schedules.

A hydro transport operator reported that they reduced their maintenance costs by 20% after implementing a regular inspection schedule.

Proper training is also essential for hydro transport operators to prevent accidents. According to a study, 90% of hydro transport accidents are caused by human error.

By following a regular maintenance schedule and providing proper training to operators, hydro transport operators can reduce the risk of accidents and ensure safe transportation of goods.

History

Hydro Transport has a rich history that dates back thousands of years. The first recorded use of hydro transport was in ancient civilizations around 3000 BC, where people used canals and rivers to transport goods.

In ancient Greece and Rome, hydro transport played a crucial role in the economy, with canals and aqueducts built to supply water and goods to cities. These early systems were often simple and labor-intensive.

The Industrial Revolution marked a significant turning point in the development of hydro transport, with the construction of canals and locks that enabled the transportation of goods over long distances. The first steam-powered canal boat was built in 1802.

The 20th century saw the rise of modern hydro transport systems, including the construction of large-scale dams and locks that facilitated the transportation of goods and people. The Panama Canal, completed in 1914, is a notable example of this era.

Today, hydro transport remains an essential part of global trade and commerce, with millions of tons of goods transported by ship and barge every year.

Transportation Methods

Shipping containers can be transported by various methods, including barges and ships, as mentioned in the article's section on "Types of Vessels." This is because they are designed to be easily loaded and unloaded at ports.

The most common method of transportation for shipping containers is by ship, which can carry thousands of containers at a time. The article highlights the efficiency of this method, stating that a single ship can transport the same amount of cargo as hundreds of trucks.

For smaller shipments or those requiring more flexibility, barges and trucks are also viable options.

Worth a look: Transportation to Cruise Ship

Ferries

Ferries played a crucial role in transporting goods and passengers across Lake Tinn. The first self-propelled ferry, SF Rjukanfos, was launched in 1909 and had a gross register tonnage of 338 GRT.

Lake Tinn freezes in winter, requiring ferries to be built as icebreakers. This was the case for all the ships that operated on the lake.

The first steamship, Skarsfos, was used to haul an unmotorized barge named Tinnsjø between the two railways from 1907. The two older ferries, SF Hydro and SF Ammonia, were launched in 1915 and 1915 respectively.

The increased transport after World War II put a heavy burden on the two steamships. Norsk Transport responded by ordering MF Storegut, a diesel-powered ship of 1,119 GRT, in 1953.

For another approach, see: Archipelago Philippine Ferries Corporation

Bratsberg Line

The Bratsberg Line is a 74-kilometre railway line that runs from Notodden to Eidanger.

It's a vital connection for the region, linking Notodden with Grenland, including the cities of Skien and Porsgrunn.

This line is also a lifeline for the ports at Herøya and Brevik, providing a crucial transportation link for the area.

Prior to 1949, the terminal station on the Bratsberg Line had a break-of-gauge, which is a significant infrastructure challenge.

Vestfoldbanen continued as narrow gauge before this change, highlighting the line's complex history.

Equipment and Pumps

Hydro Transportation Pumps are designed to gently transport delicate food products like potato chips, cauliflower, and carrots. They're even used for transferring live fish in some countries!

Our Cornell hydro transportation pumps are powered by water, which allows them to run at low speeds and minimize damage to the food. This makes them a great solution for transporting fragile items.

The pumps create a cushioning effect with water to protect the food from damage. This ensures that your products arrive at their destination in perfect condition.

Hydro Transportation Pumps are available in a variety of sizes to accommodate different applications. Whether you need a small or large pump, Hydromarque has got you covered.

The team at Hydromarque is dedicated to delivering bespoke solutions for your hydro transportation needs. Their experienced engineers and technicians will work with you to find the perfect pump for your business.

If this caught your attention, see: New York Water Taxi

Processing and Optimization

In hydro transport, processing and optimization are crucial steps that ensure the safe and efficient transportation of goods.

The first step in processing is to load the cargo onto the ship or barge, which is typically done at a terminal or loading facility. This is where the cargo is carefully loaded and secured to prevent damage during transport.

The loading process can take anywhere from a few hours to several days, depending on the type and quantity of cargo. The cargo is typically loaded in a specific order to ensure stability and balance on the vessel.

Once the cargo is loaded, the vessel sets off on its journey, traveling through rivers, canals, or coastal routes to reach its destination. The journey can take anywhere from a few days to several weeks, depending on the distance and route.

To optimize the transportation process, hydro transport companies use advanced technology, such as GPS and sensors, to track the vessel's location and cargo status in real-time. This allows for more efficient routing and scheduling, reducing transit times and costs.

Regular maintenance and inspections of the vessel and cargo handling equipment are also essential to ensure the safe and efficient transportation of goods. This includes checking the vessel's hull, propellers, and other critical systems to prevent mechanical failures.

Featured Images: pexels.com