Cross dock warehouse solutions are designed to streamline the supply chain process, reducing transit times and increasing efficiency. By eliminating the need for intermediate storage, cross dock warehouses can save up to 40% of the total transportation cost.

In a typical cross dock warehouse, goods are received, sorted, and then shipped out to their final destination in a single day. This process can be completed in as little as 6-8 hours.

Cross dock warehouses are particularly useful for companies that have a high volume of shipments, as they can process up to 200,000 pounds of goods per day.

What Is a Cross Dock Warehouse?

A cross-dock warehouse is a logistics facility where products are received and directly transferred to outbound transportation, bypassing long-term storage.

This model is ideal for time-sensitive deliveries, high turnover inventory, and businesses prioritizing operational efficiency.

Products are typically processed within 24 hours, making it a great solution for companies that need to move goods quickly.

Cross-dock warehouses act as temporary hubs, processing goods in a matter of hours, unlike traditional warehouses that store products for extended periods.

Think of it like a train station where passengers gather and wait briefly to board a nonstop commuter rail to the city, goods are received, rearranged, and sent out efficiently.

Warehouse Solutions

Cross-dock warehouses require perfect organization and efficient design to succeed. Successful cross docking demands tremendous efficiency and speed from equipment, with goods traveling throughout the facility via power pallet trucks and conveyor belts at the fastest pace possible.

To achieve this, cross-dock warehouses come in various formations based on the number of doors required and the central space needed to move inbound items to the outbound area of the warehouse. Small-to-medium-sized cross docks are usually an I-shape or narrow rectangle to maximize the use of central doors.

Automated sorting and handling systems are also crucial in cross-dock warehouses, streamlining operations and reducing reliance on manual labor. Technologies like robotic arms, conveyor belts, and automated guided vehicles (AGVs) ensure faster and more accurate sorting of goods, reducing errors and minimizing delays.

Here are some warehouse design best practices to consider:

- I-shape or narrow rectangle for small-to-medium-sized cross docks

- X-shape for docks larger than 200 doors

- T-shape for dock sizes between 150–200 doors

By implementing these design best practices and leveraging automated sorting and handling systems, cross-dock warehouses can achieve optimal efficiency and speed, ensuring seamless and cost-effective operations.

Choosing the Right Solution for Your Business

Choosing the right solution for your business can be overwhelming, but it doesn't have to be. To make an informed decision, you need to consider factors like demand variability and customer awareness.

Businesses with unpredictable demand should consider post-distribution cross docking, which offers greater flexibility to adapt to fluctuating market conditions. This approach is especially useful for businesses that can't accurately forecast their customer's needs.

On the other hand, pre-distribution cross docking is a better choice for businesses with predictable demand. By accurately forecasting their customer's needs, businesses can enjoy greater efficiency and cost savings.

Here are some key considerations to keep in mind:

By assessing the pros and cons of each approach, you can make an informed decision that meets your business needs.

Flexible Purchase and Rental Options

We offer flexible purchase and rental options to meet the unique needs of your business.

Our solution providers will help you choose a material handling fleet configuration that meets the requirements of your facility.

You can choose between new, pre-owned, and short-term rental options to fit your budget and needs.

Our solution providers will help you select a rental plan with the right equipment specifications and condition to meet your seasonal or other temporary work increases.

We can help you supplement your fleet during high-volume periods, so you can stay up and running even when the pressure is highest.

Our scheduled maintenance, truck service, and comprehensive parts inventory ensure that you're always ready to go.

Worth a look: Florida Keys Rental with Boat Dock

Innovation in Warehousing

Innovation in warehousing is transforming the way businesses operate, and it's exciting to see the impact it's having. Automation is revolutionizing logistics, with advanced sorting and handling systems like robotic arms, conveyor belts, and automated guided vehicles (AGVs) streamlining operations and reducing reliance on manual labor.

These systems ensure faster and more accurate sorting of goods, reducing errors and minimizing delays. Machine learning and artificial intelligence will enhance automation, allowing systems to predict demand surges and optimize workflows.

Real-time data and analytics are becoming a cornerstone of logistics operations, with cross-dock warehouses leveraging data analytics tools to monitor inventory levels, track shipments, and improve decision-making. Predictive analytics and IoT (Internet of Things) devices will enhance cross-dock operations by providing actionable insights, enabling businesses to anticipate challenges and respond quickly.

The future of cross-dock warehouses is looking bright, with technological advancements heavily influencing its development. Autonomous vehicles and drones are set to revolutionize cross-docking logistics, reducing transit times and increasing delivery accuracy.

Here are some key innovations transforming the way cross-docking facilities operate:

- Automated sorting and handling systems

- Real-time data and analytics

- Autonomous vehicles and drones

These innovations enable businesses to process higher volumes of goods more accurately, making cross-docking even more efficient. With the rise of e-commerce and omnichannel retailing, cross-dock warehouses are adapting to handle orders from multiple sales channels, allowing businesses to process retail, online, and direct-to-consumer orders simultaneously.

Cold Chain

Cold Chain solutions are crucial for maintaining the quality of perishable goods like food and pharmaceuticals. This involves specialized handling to ensure the goods remain fresh and effective during transportation.

Refrigerated zones and advanced monitoring systems are used to maintain optimal conditions during the transfer process. This is particularly important for cross-dock warehouses that incorporate temperature-controlled environments to support cold chain logistics.

IoT devices and blockchain technology will enhance cold chain reliability by providing real-time temperature tracking and transparency. This will give companies greater control over their supply chains and allow them to respond quickly to any issues that arise.

Here are some ways Cold Chain solutions can benefit your business:

- Reduced spoilage and waste

- Improved product quality

- Enhanced supply chain transparency

Warehouse Design and Layout

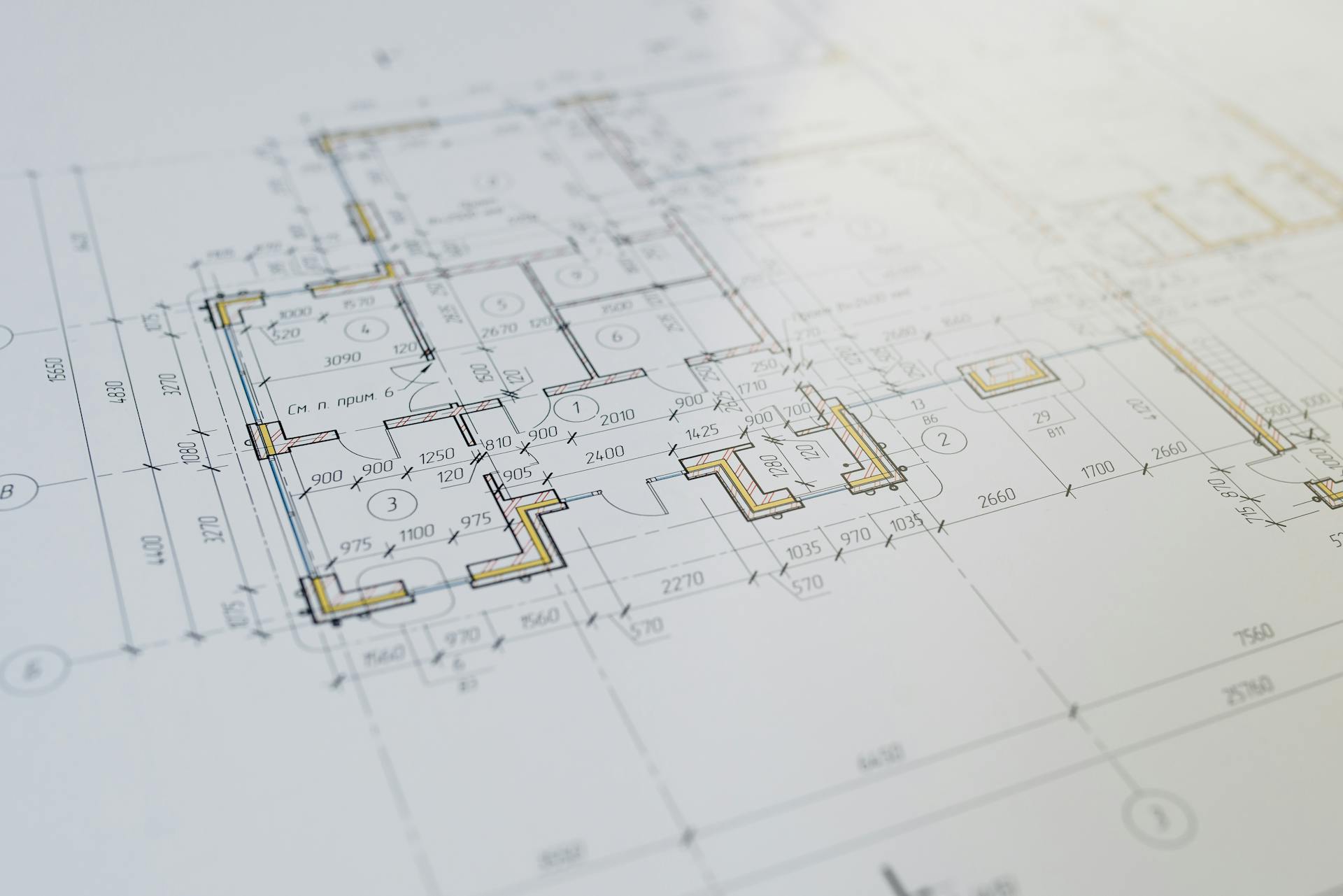

A well-designed warehouse is crucial for efficient cross docking operations. Successful cross docking requires perfect organization within the warehouse, which starts with the right facility design.

Cross docks come in various formations, with small-to-medium-sized ones typically being an I-shape or narrow rectangle to maximize central doors. For larger docks, alternative shapes like X-shapes or T-shapes are recommended to expand the central area and make distant doors closer.

The shape of the warehouse should be based on freight flow patterns and factors like goods turnover, distance, gates, and buffer spacing. More dock doors don't necessarily mean more efficiency, and placing them on opposite walls can lead to congestion.

Warehouse Design Best Practices

In cross docking, many deliveries occur in a single day, so suppliers must utilize technology like Electronic Data Interchange (EDI) to stay informed in real time about deliveries that must be dispatched that day.

Successful cross docking requires perfect organization within the warehouse.

Suppliers can't rely on manual processes to plan shipments in precise time slots because it's just too complex.

Here are 3 facility design best practices to consider: organization, organization, and more organization.

Broaden your view: On Time Cross Docking

Warehouse Layout

A well-designed warehouse layout is crucial for efficient cross docking operations.

Small-to-medium-sized cross docks are usually an I-shape or narrow rectangle to maximize the use of central doors. This shape helps to streamline the flow of goods and reduce congestion.

The optimal shape of each cross docking warehouse depends on freight flow patterns and factors like goods turnover, distance, gates, and buffer spacing.

More dock doors don't necessarily correlate to more efficient cross docking facilities.

Placing dock doors on the opposite wall far away would lead to efficiency-killing congestion.

A better layout would be doors on only one wall or 90 degrees to each other, allowing high-speed forklifts to travel between incoming and outgoing doors quickly.

Ample space for pallet staging activities near shipping doors is also essential, and aisles should be oversized in high-traffic areas.

Warehouse Operations

Warehouse operations are the backbone of any successful cross dock warehouse solution. To achieve efficient operations, suppliers must utilize technology like Electronic Data Interchange (EDI) to stay informed in real time about deliveries that must be dispatched that day.

Perfect organization within the warehouse is crucial for successful cross docking. Here are three facility design best practices to consider: minimizing congestion, maximizing storage capacity, and optimizing workflow.

To minimize congestion, inbound and outbound tracks must arrive and operate in the correct order. This means that misalignment, such as outbound trucks arriving ahead of the goods they’re scheduled to deliver, can lead to overcrowding and traffic jams in the dock.

In cross docking, product transportation is essential for keeping operations efficient, productive, and safe. This can be achieved through the use of material handling equipment, such as cross dock solutions, which deliver safe, rugged, and operator-friendly performance.

To further enhance warehouse operations, technological advancements can be leveraged. Some key innovations transforming the way cross-docking facilities operate include automation, tracking, and inventory management systems.

Pre-Distribution Cross Docking offers several benefits, including cost savings, better inventory management, and supply chain visibility. However, it also presents complex operations, dependent on accurate demand forecasting, and less inventory visibility.

Here are some of the key benefits of implementing a cross dock warehouse solution:

- Cost Savings: Reduces warehousing costs such as long-term storage and inventory holding

- Better Inventory Management: Facilitates just-in-time inventory practices which reduces excess inventory

- Supply Chain Visibility: Provides greater visibility into the supply chain so more informed decisions can be made

Benefits and Features

Cross docking can lead to significant cost savings across the supply chain by minimizing inventory levels and eliminating unnecessary storage and transportation. This can result in lower inventory holding costs, transportation expenses, labor costs, insurance premiums, and administrative overhead costs.

By reducing inventory levels, businesses can also reduce the risk of cargo damage, which can benefit overall profitability and increase customer satisfaction. In fact, research shows that 41% of customers prefer to receive their orders within 24 hours, making cross docking an important strategy in meeting these demands.

Cross docking speeds up the order fulfillment process by eliminating storage and handling time, allowing products to reach customers faster and increasing customer satisfaction. This is particularly beneficial for businesses seeking to optimize their fulfillment strategy and process orders quickly.

Readers also liked: Last Mile Transportation Solutions

Pros and Cons

Cross docking offers several benefits that can improve your business operations. Reduced Costs is one of the main advantages, as it can save you money on inventory holding costs, transportation expenses, labor costs, insurance premiums, and administrative overhead costs.

According to research, 41% of customers prefer to receive their orders within 24 hours, making cross docking an important strategy in meeting these demands. This is achieved through more Efficiency, as products bypass storage altogether by moving directly from inbound to outbound docks.

Cross docking speeds up the order fulfillment process by eliminating storage and handling time, allowing products to reach customers faster and meeting tight delivery deadlines. Quicker Order Fulfillment is a significant benefit, increasing customer satisfaction and improving your business reputation.

Reducing the risk of Cargo Damage is another advantage of cross docking, as there is less handling involved in the supply chain. This benefits your overall profitability and increases customer satisfaction.

Cross docking is also a more Environmentally Friendly option than warehousing, reducing the environmental footprint linked to energy consumption, land use, and transportation emissions.

However, there are also some potential drawbacks to consider. Inventory Shortage is a possible issue, as products move quickly and there may be limited time for inventory management and replenishment.

To mitigate this risk, you can introduce improved inventory management practices, such as automated systems, real-time data analytics, and vertical storage systems. This will help maintain adequate inventory levels and prevent stockouts.

Implementing cross docking requires a significant upfront investment in technology, infrastructure, and operational resources. You'll need a Big Budget to Begin, which can be a challenge for some businesses.

To ensure the success of your cross docking strategy, you'll need to invest in new technologies and systems. This can be a steep learning curve for employees, which can slow down the distribution process.

Sustainability in

Sustainability is becoming a top priority for businesses, and cross-dock warehouses are adopting eco-friendly practices to reduce their environmental impact. This shift is driven by regulatory requirements and consumer expectations.

Cross-docking facilities are implementing sustainable practices to minimize their ecological footprint. For example, they're reducing energy consumption and waste generation.

Businesses are adopting eco-friendly practices to meet regulatory requirements and consumer expectations. This includes implementing sustainable practices in their cross-dock warehouses.

The future of cross-docking will likely emphasize sustainability, as companies strive to reduce their environmental impact.

Services and Solutions

Cross docking services can help you overcome the complexities of supply chain management by breaking down incoming shipments at the dock and matching them with pending orders. This streamlined process eliminates storage and labor costs associated with conventional warehousing.

Our cross docking services offer numerous benefits, including reduced warehouse and distribution costs, quick and reliable delivery times, and increased productivity and order fill rates. By using our services, you can also reduce costs related to operating, handling, and inventory storage.

Some of the key services we offer include loading and unloading, pallet breaking and repacking, export consolidation, and import deconsolidation and distribution of product. Our team can also provide origin masking, climate-controlled environments, and tracking ability to see end-to-end cross dock movement.

If this caught your attention, see: Cross Docking Services East Coast

Here are some of the benefits of our cross docking services:

- Reduction in warehouse and distribution costs

- Quick, reliable delivery times

- Reduction in costs related to operating, handling and inventory storage

- Increase in productivity and order fill rates

- Reduction in delivery lead times

Our team can also help you manage all inventory and order fulfillment within a single portal, and work live in customer ERP/MRP systems through any WMS.

Post-Distribution

Post-Distribution is a flexible approach to cross-docking that's perfect for businesses with unpredictable demand. This method allows you to delay sorting until customer orders are received, giving you the flexibility to react to changing demands.

By postponing sorting, you can reduce the amount of time merchandise spends at a cross-dock warehouse, which can be a cost-effective solution. Merchandise spends less time at a cross-dock warehouse.

One of the key benefits of Post-Distribution Cross Docking is its ability to provide fast distribution. Handling and processing time is fairly minimal at the cross-dock facility, speeding up the distribution process.

To take full advantage of Post-Distribution Cross Docking, you'll need to choose cross-dock facilities based on demand and location. This adaptability is crucial for businesses that need to respond quickly to changing market conditions.

Here are some key benefits of Post-Distribution Cross Docking at a glance:

Services at Their Best

Cross docking services can be a game-changer for businesses looking to streamline their supply chain management.

With cross docking, materials are unloaded from inbound shipments and combined with other materials or re-processed for final delivery, all with little or no storage in between.

This process eliminates storage and labor costs associated with conventional warehousing.

Omni offers numerous services to streamline your cross dock processes, including loading and unloading, pallet breaking and repacking, export consolidation, and more.

Here are some of the key benefits of using cross docking services:

- Reduction in warehouse and distribution costs

- Quick, reliable delivery times

- Reduction in costs related to operating, handling and inventory storage

- Increase in productivity and order fill rates

- Reduction in delivery lead times

Omni's cross docking services also offer a range of features, including the ability to work live in customer ERP/MRP systems, create product labeling and documentation, and provide worldwide availability.

Modern Warehouse Facility

Our modern warehouse facility is designed to meet the demands of cross docking, with a 70,000 square foot space that includes both ambient and temperature-controlled areas to ensure the integrity of your products.

A state-of-the-art security system, complete with 24/7 surveillance, keeps your inventory monitored at all times. This gives you peace of mind knowing your goods are secure.

Our dedicated team oversees operations and maintains strict quality control to guarantee your goods are not only stored securely but handled with the highest care.

Specialized Solutions

At Barclay Brand Ferdon, we've found that specialized solutions can make all the difference in a cross dock warehouse. Our team has worked with Yale's rugged trucks that can handle any load capacity.

These trucks are designed with safety in mind, featuring the highest standards for safety. Yale's proprietary iSi (Integrated Smart Interface) ensures consistent functionality between trucks.

The iSi system is customizable, allowing it to match the truck's performance to the operator's skill level. This optimized system ensures safe, efficient, and productive use in your facility.

Suggestion: Warehouse and Transportation Management System

The Future of Logistics

Cross-docking is set to dominate the industry due to its efficiency in meeting customer expectations. The rapid expansion of online shopping requires logistics models like cross-docking to keep up with demand.

E-commerce growth is a key driver of the cross-docking trend, with same-day and next-day delivery becoming the norm. This is because cross-docking supports these timelines by reducing transit times and simplifying customs processes.

Cross-docking eliminates costly storage and manual order-picking functions, reducing inventory costs and minimizing the risk of damage. This is achieved by utilizing business systems and technology to create an integrated cross-docking network system.

The benefits of cross-docking are clear: fast, affordable, and on-time delivery. By adopting cross-docking, businesses can gain a significant competitive advantage and improve the quality of service.

Here are some key benefits of cross-docking:

- Reduces inventory costs

- Shortens transit times

- Minimizes the risk of damage

- Improves the quality of service

Frequently Asked Questions

What are examples of cross-docking companies?

Large retailers like Walmart, Target, and Home Depot use cross-docking to replenish their stores with fast-moving products. Cross-docking is also used by other companies in various industries, including manufacturing and logistics

Sources

- https://ware2go.co/articles/cross-dock-warehouse/

- https://omnilogistics.com/our-solutions/warehousing-distribution/cross-dock-logistics/

- https://phasev.com/services/florida-cross-dock-warehouse/

- https://www.bbfyale.com/warehouse-solutions/dock-to-rack-cross-dock-solutions/

- https://phasev.com/the-future-of-cross-dock-warehouses/

Featured Images: pexels.com