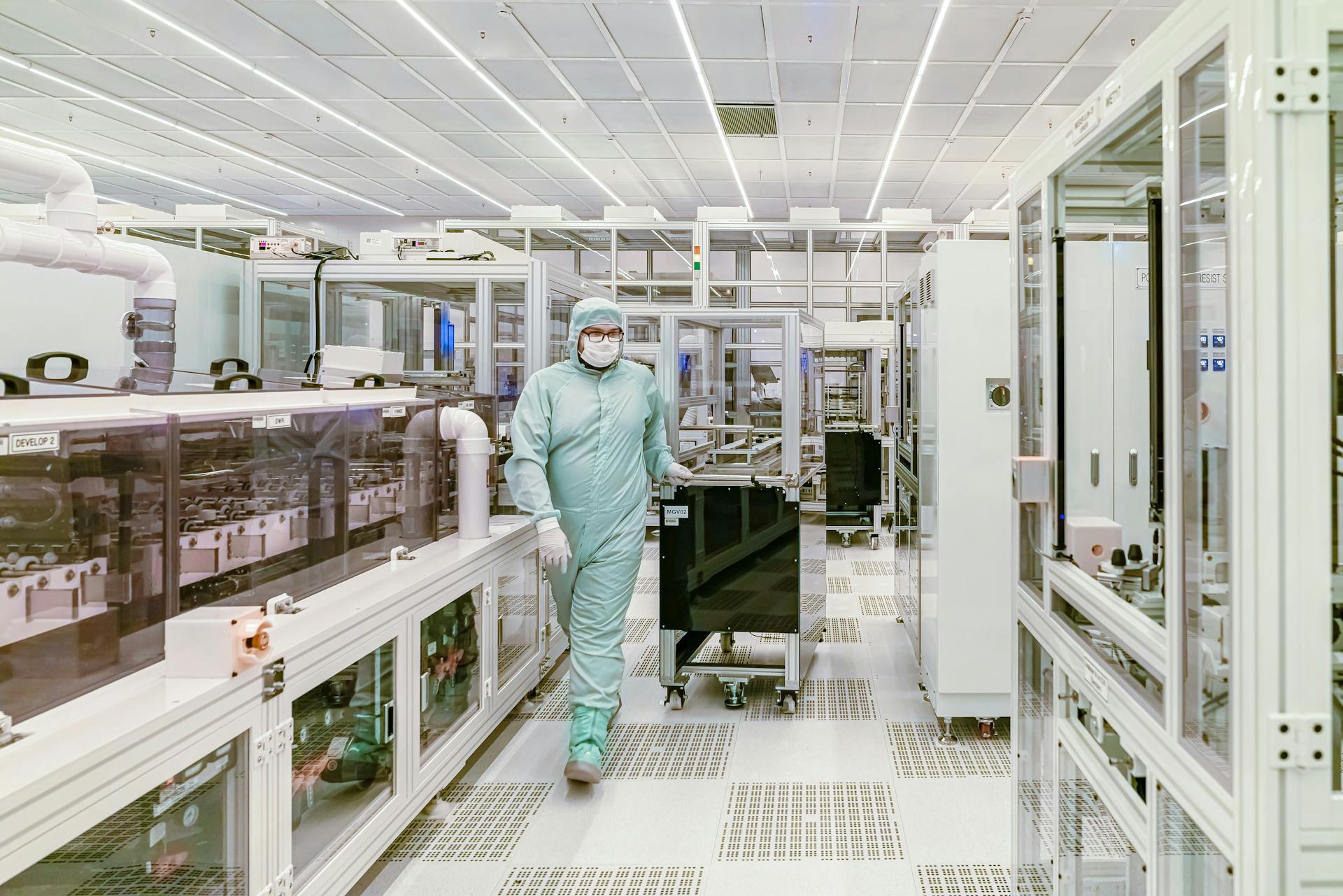

Cleanroom pallets are a crucial component in maintaining a sterile environment, especially in industries like pharmaceuticals and biotechnology. They are designed to prevent contamination and keep sensitive equipment and materials clean.

These pallets are typically made of materials like stainless steel or polypropylene, which are easy to clean and resistant to corrosion. The smooth surface of cleanroom pallets also makes it easy to disinfect and maintain a high level of cleanliness.

Cleanroom pallets are used to transport and store sensitive equipment, materials, and products in controlled environments. They help to prevent cross-contamination and maintain the integrity of the products being handled.

What's Special About Cleanroom Pallets

Cleanroom pallets are designed with a simplified design and smooth surfaces to prevent dirt and liquids from accumulating, making them perfect for transporting sensitive products like dairy products, raw meat, or pharmaceutical/chemical substances.

Their sturdy build allows them to handle heavy weights, with a dynamic load capacity of up to 1,250 kg.

These pallets are made of materials that resist temperature variations between -20°C and +50°C, making them suitable for use in cold storage.

This means you can rely on cleanroom pallets to safely transport your products in a variety of conditions.

Types of Cleanroom Pallets

There are several types of cleanroom pallets designed to meet the specific needs of various environments. AUER Packaging's cleanroom pallet is ideal for storage and transportation of hygienic goods due to its smooth, solid storage surface that's easy to clean thoroughly.

A hygienic 5-runner industrial pallet, like the polyethylene pallet CLEAN 1210-C5, is suitable for environments requiring maximum hygiene with maximum rack load performance. It's completely plain and closed, facilitating cleaning after each reuse.

The type of plastic pallet you choose for your cleanroom depends on its classification. The iGPS plastic pallet is a perfect fit for most cleanroom environments, offering a durable and easy-to-clean design.

Aluminum 45 Series

The Aluminum 45 Series is a top-notch choice for cleanroom applications. It features a frame and crossmembers made of sealed, heavy-duty, corrosion-resistant aluminum.

This makes it perfect for handling heavy loads in sensitive environments. Its durable design ensures it can withstand the rigors of roller conveyors.

The Aluminum 45 Series is also suitable for use on roller conveyors. This adds to its versatility and makes it a great option for a variety of cleanroom applications.

Its corrosion-resistant properties are especially important in cleanroom settings where moisture and humidity can be a concern.

Clean Room Series 12

The Clean Room Series 12 is a popular choice for industries that require maximum hygiene and cleanliness.

This series is designed for heavy loads in cleanroom applications, making it perfect for environments where cleanliness is paramount.

Aluminium pallets with skids are suitable for use on roller conveyors, ensuring smooth and efficient transportation of goods.

The Clean Room Series 12 is also ideal for storing and transporting hygienic goods, thanks to its smooth, solid storage surface that facilitates thorough cleaning.

The AUER Packaging's cleanroom pallet in this series is easy to clean thoroughly, making it an ideal solution for industries that require maximum hygiene.

This series is designed to withstand heavy loads, with some pallets capable of withstanding a load of up to 1,500 kg in high-bay racking.

Using Igps Pooled Plastic

Using iGPS Pooled Plastic pallets in your cleanroom is a smart choice. The iGPS plastic pallet is a perfect fit for most cleanroom environments, offering a durable and easy-to-clean solution.

It's made from a single piece of plastic, eliminating the risk of individual boards coming loose. This design also means it doesn't create sawdust, splinters, or nails.

Since plastic pallets are nonabsorbent, they can be washed and dried thoroughly using a power washer or automated pallet washing machine. This ensures they're safe for use within the cleanroom and outside of it.

iGPS plastic pallets can be sanitized to kill over 96 percent of microbes, making them an ideal choice for cleanroom environments. This process can be contracted with a third-party sanitization service.

The iGPS pallet complies with standard Consumer Brands Association (formerly GMA) pallet specifications, allowing it to be stacked, racked in a warehouse, and shipped to end retailers. This eliminates the need for transferring products from cleanroom pallets to shipping pallets, reducing the Total Cost of Business (TCOB).

Description and Dimensions

Cleanroom pallets come in standard sizes that are widely used in the industry. The most common sizes are 120 x 80 cm and 120 x 100 cm.

These sizes can vary depending on the intended use and requirements, but they are the most common dimensions. Cleanroom pallets are designed to be versatile and can be used in a variety of settings.

Here are some specific dimensions and options:

Polyethylene Clean 1208-C3

The Polyethylene Clean 1208-C3 is a European standard hygienic pallet with 3 runners.

It's ideal for environments requiring maximum hygiene with maximum rack load performance.

This pallet is completely plain and closed, which facilitates cleaning after each reuse.

It's designed to withstand ISO tests with a standard load, uniformly distributed, compact, and stable, for a specified time at room temperature (20ºC [68ºF]).

A unique perspective: Which End of Pallet Industry Standard for Lifting Pallets Forklifts

The General Dimensions

The general dimensions of cleanroom pallets can be a bit tricky to figure out, but don't worry, I've got you covered. The most common sizes are 120 x 80 cm and 120 x 100 cm.

These dimensions are widely used in the industry and are a great starting point for most cleanroom pallets. You'll often see them made from plastic or stainless steel, which makes them easy to clean and sanitize.

If you're looking for a specific size, here are some common options:

Keep in mind that these dimensions are just a starting point, and you may need to consider other factors like the type of products you're storing or transporting. But as a general rule, 120 x 80 cm and 120 x 100 cm are great options to consider.

Hygiene and Materials

Cleanroom pallets are designed to meet the highest hygiene standards, and for good reason. Wood pallets, on the other hand, are a logistical nightmare in a cleanroom environment.

Wood pallets absorb moisture, including chemicals and other contaminants, and create a friendly environment for bacteria, mold, and mildew. Other materials, such as metal, are occasionally used to make cleanroom pallets but tend to be appropriate only for specific niche applications.

Plastic pallets are the clear choice for cleanroom use. They offer a nonabsorbent surface that's easy to clean and sanitize.

Expand your knowledge: Wood Shipping Pallet

Here are the key advantages of plastic pallets:

• Non-absorbent surface

• Non-conductive material

• Lightweight for easy handling

• Available in a variety of sizes and designs

• Gentle on floors and other surfaces

• Doesn't conduct electricity

The type of plastic pallet you choose will depend on your cleanroom's classification. Some cleanrooms require a plastic pallet with an entirely solid deck, but most just need a durable plastic pallet that's easy to clean.

The iGPS plastic pallet is a perfect fit for this type of cleanroom, offering a fused whole with no individual boards that can pull free and no sawdust, splinters, or nails.

Advantages and General Information

A cleanroom pallet is a game-changer for transporting food, as it can protect goods from contamination.

The closed deck of a cleanroom pallet makes it particularly hygienic, shielding products from dirty floors and other environmental influences.

Cleanroom pallets are made from food-safe, virgin material that's approved for food transport, which is essential in the food industry.

These pallets are also extremely resistant to heat and cold, yet they're still very robust and easy to transport.

A cleanroom pallet with a closed deck can withstand static loads of up to 4,500 kg, thanks to the tubular steel reinforcement inside.

They can even handle a load of up to 1,500 kg in high-bay racking, making them perfect for storing goods on high shelves.

Sources

- https://logisticpackaging.com/products/standard-assortment/plastic-pallets/hygienic-pallets/

- https://igps.net/resources/cleanroom-pallets-choosing-a-hygienic-plastic-pallet-for-cleanroom-applications/

- https://www.directindustry.com/industrial-manufacturer/clean-room-pallet-186802.html

- https://www.baust.de/en/types-of-pallets/clean-room-pallet/

- https://fintabo.de/en/plastic-pallets-2.html

- https://interbrush.gr/en/proionta/cleanroom-pallets-made-from-reclaimed-material/

Featured Images: pexels.com