Shipping pallets can be a daunting task, but with the right preparation and knowledge, it can be a breeze. First, make sure you've properly secured your pallet with sturdy straps or twine, as loose pallets can be a hazard on the road.

To ensure your pallet is properly secured, you'll need to use a minimum of 3 straps or 1 inch of twine, depending on the size of the pallet. This will prevent shifting and damage during transit.

Next, carefully load your pallet with the items you want to ship, making sure to distribute the weight evenly to prevent the pallet from tipping over. The maximum weight capacity for a standard pallet is 2,200 pounds.

A well-packed pallet is essential for safe shipping, so take the time to arrange your items thoughtfully and cover them with a layer of bubble wrap or packing paper to protect them from damage.

What Is Shipping?

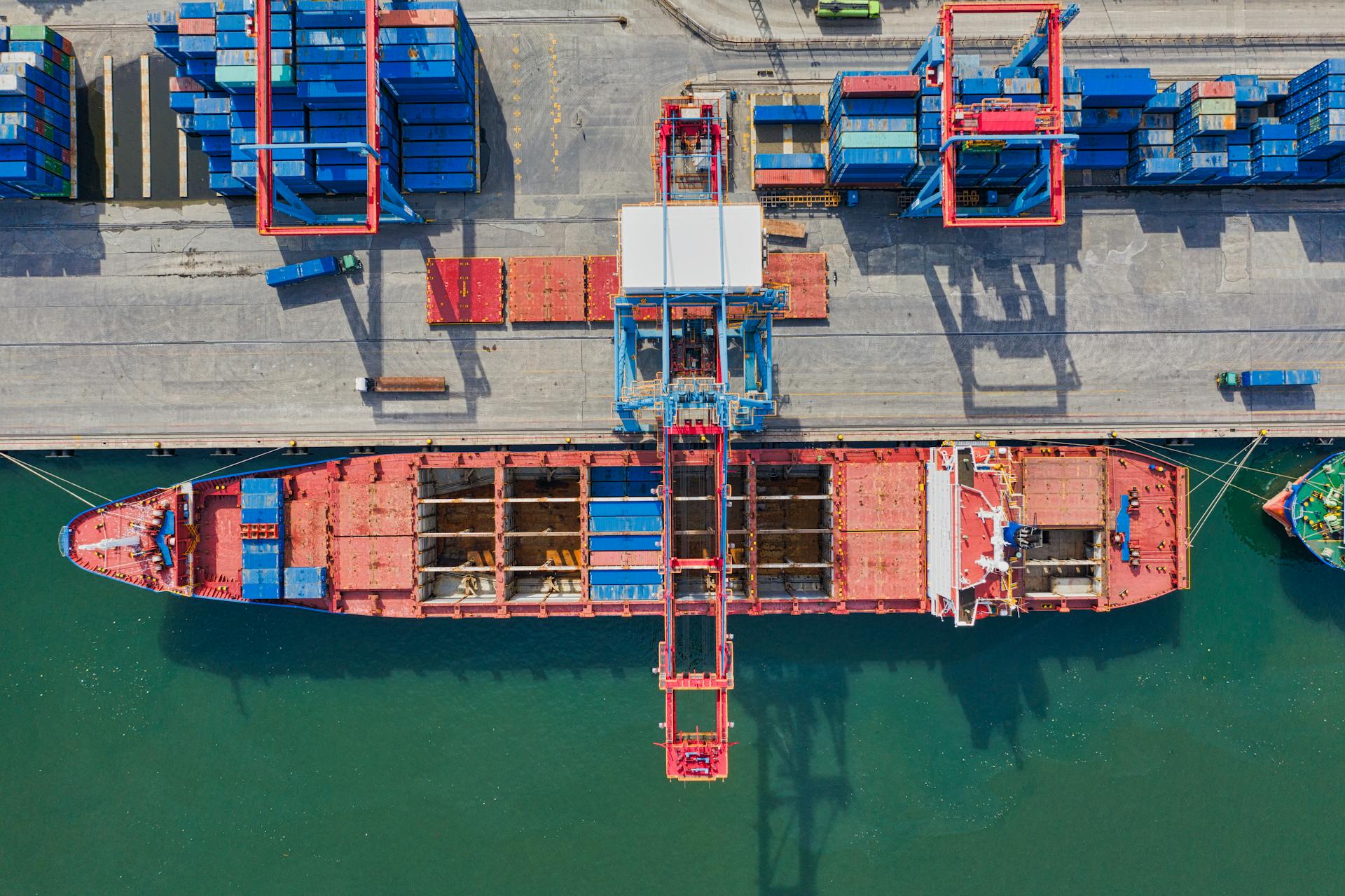

Shipping is a common solution for transporting multiple items or large items, often using pallets, skids, or crates for easy movement and loading.

Pallets are the most commonly used method of packing in freight transport.

They allow for easy movement, loading, and unloading of items.

Shipping pallets can be a great solution for transporting items, especially when compared to traditional shipping methods.

On Shiply, there are hundreds of pallet shipping companies ready to send you a custom quote for your job.

This can often be up to 75% cheaper than usual.

Shipping pallets can be a cost-effective option, making it a popular choice for many businesses and individuals.

Preparing Shipment

Preparing shipment is a crucial step in the pallet shipping process. It's essential to have all necessary documents ready, including a bill of sale or customs documents, depending on the item's destination.

First, make sure to clean the items being shipped to check their condition before pickup. This will help identify any potential damages during transit. Take time-stamped high-quality photographs of the items as well.

To pack your items securely, discuss the details with your chosen pallet shipping company. Ensure all items are tightly secured to the pallet and wrapped in a protective material like cling film and bubble wrap.

For typical LTL and FTL shipping purposes, recommended pallets should have the following characteristics:

Make sure to clearly label your pallet shipment by removing previous labels and markings, and placing the shipping label on the side of the pallet. This ensures the sender and receiver information is clearly visible.

Choosing the Right Pallet

Choosing the right pallet is crucial for safe and secure shipping. A standard industry size pallet is at least 48” x 40” box-style.

You'll want to choose a pallet that's suitable for a forklift, hand truck, or pallet jack. Make sure it's strong and free of damage.

For most freight shipping needs, there are two main pallet types: stringer pallets and block pallets. Stringer pallets, also called 2-way pallets, have three parallel pieces of wood supporting the boards.

Block pallets, on the other hand, are 4-way pallets that can be picked up from all sides. They're reinforced with wooden blocks at the middle of each edge and on the sides.

The most common pallet sizes used in the food industry are CBA (Consumer Brands Association) sized pallets with dimensions of 48″ x 48″.

Here are the most common pallet sizes:

For typical LTL and FTL shipping purposes, recommended pallets should have four-way entry capabilities. They should also be relatively new and undamaged.

A standard wood pallet measuring 40″ x 48″ is ideal for LTL and FTL shipping. It should be sturdy enough to withstand heavy or light loads and support the full weight of the packaged products.

Using pallets that are in good condition and made of sturdy materials will help ensure that your shipments are safe and secure during transportation.

Securing and Loading

Securing and loading your pallets is a crucial step in shipping goods safely and efficiently. Transport providers will usually tie up your items securely in the transport vehicle to prevent damage. Confirm safety precautions and packing needs with your transport provider before accepting a quote.

To load your pallet correctly, start by placing the heaviest items at the bottom of the stack. This will ensure that the load is evenly distributed and prevent shifting or tipping during transportation. You should also ensure that all containers fill the base of the pallet completely with no overhang.

Here are some key loading tips to keep in mind:

- Place the heavier boxes at the bottom of the stack

- Carefully stack the containers evenly and avoid space between them

- Make sure all containers fill the base of the pallet completely with no overhang

- Ensure your shipment falls within the maximum size and weight limitations

Seal Each Container

Use a good quality shipping tape that's at least 3” (7.6cm) wide to ensure your containers are securely sealed.

Sealing all seams and flaps is crucial to prevent any potential damage or tampering during transit.

You should always confirm with transport providers what type of shipping tape they recommend using for your specific needs.

A good quality shipping tape is essential to keep your goods safe and secure during the shipping process.

Make sure to seal all seams and flaps as much as possible to prevent any air leaks or moisture from entering the container.

Here's a quick rundown of the essentials to keep in mind when sealing each container:

- Use a good quality shipping tape that’s at least 3” (7.6cm) wide

- Seal all seams and flaps if possible

Load Your

Loading a pallet is a crucial step in securing and shipping your goods safely. You should place the heavier boxes at the bottom to prevent the pallet from toppling over.

Using a pallet jack or forklift can greatly reduce the risk of injury or accidents when handling heavy or awkward loads. These tools can make the process of moving pallets around your warehouse or shipping facility much easier.

To ensure the stability and safety of the goods on the pallet, follow proper stacking guidelines. This includes placing the heaviest items at the bottom of the stack and ensuring that the load is evenly distributed.

To prevent accidents and injuries while handling the load, use a pallet jack or forklift if possible. This will help you avoid straining your back or losing control of the pallet.

To avoid injury when handling pallets, use your legs to lift, rather than your back, and keep your load close to your body to maintain proper balance. This will help you maintain control and prevent accidents.

For more insights, see: Electric Pallet Jack Canada

Before loading, make sure your shipment falls within the maximum size and weight limitations. Check the Manufacturer’s Certification Stamp to ensure the weight of the contents should not exceed 50% of the gross weight limit.

Here is a summary of the key tips to keep in mind:

- Place heavier boxes at the bottom

- Use a pallet jack or forklift to move the pallet

- Follow proper stacking guidelines

- Use proper lifting techniques

- Check the weight and size limitations before loading

Securing a Load

Securing a load is a crucial step in the shipping process. To prevent shifting or tipping during transportation, distribute the weight of your items evenly across the pallet and secure them firmly in place. Use straps, shrink wrap, or other suitable materials to keep the goods stable.

It's essential to secure the goods on the pallet properly. Not doing so can lead to damage or accidents during transport. To prevent this, use straps, shrink wrap, or other suitable materials to keep the goods in place.

To ensure the pallet is stable during shipping, properly secure it to the shipping vehicle. Use straps, ropes, or other suitable materials to prevent the pallet from shifting or falling.

Worth a look: Saran Wrap for Pallets

Here are some steps to follow when securing a load:

- Use high-quality 70 gauge or similar shrink wrap to wrap the pallet

- Start by wrapping around the bottom, encircling the lowest containers at least three times

- Continue wrapping upwards, overlapping previous layers by half on each pass

- Wrap the top tier of containers three times and leave a 3” (8cm) overlap over the top corners

- Finally, bring the wrap back down to the bottom containers and secure the load firmly to the pallet by encircling it 3 times

Before transporting your goods, make sure to check if the transport provider will tie up the item in the transport vehicle. It's also a good idea to confirm safety precautions and packing needs with the transport provider before accepting a quote.

To prevent damage to your goods, ensure that the items on your pallet are evenly distributed and secured. Fill any gaps between the items with wooden dunnage, foam sheets, or other materials to keep the load stable.

Corner Boards

Corner boards are a simple yet effective way to reinforce the edges of a pallet and protect the items on it from damage. They can be made of wood or plastic and come in various sizes to fit different types of pallets.

By using corner boards, you can prevent items from getting scratched or crushed during transportation or storage. Corner boards act as a barrier between the pallet and the items, absorbing any shocks or impacts.

To get the most out of corner boards, make sure to install them securely to the pallet. You can use nails, screws, or adhesive to attach them.

Labeling and Documentation

Labeling and documentation are crucial steps in shipping pallets. A clear and legible label will help ensure that your shipment is properly routed and delivered to the correct destination.

First, remove any labels and markings from previous shipments to avoid confusion. Then, place the shipping label on the side of the pallet, making sure it's clearly visible with the sender and receiver information.

You should also label each box within the pallet with the same information, in case of separation during transit. This will help prevent accidents and ensure proper handling.

To label your pallet correctly, include the recipient's name, address, and contact information, as well as any necessary shipping instructions or handling requirements. You can also use labels to indicate the top and bottom of the pallet, as well as the contents of the load or destination.

Here's a checklist of essential information to include on your labels:

Don't forget to prepare your bill of lading, which is a critical document that includes information on the type, quantity, and destination of goods. It acts as both a contract and a receipt between you and the carrier, and should be properly signed by an authorized representative from all parties.

Shipping Options and Services

Shipping options and services can vary depending on what you're shipping, where your shipment is coming from and where it's going to, how much it weighs, and so much more. This makes it a complex process to navigate.

Different carriers have their own specialties, strengths, and weaknesses, so understanding these can lead to a more informed decision when shipping a pallet. At RS Group, we specialize in finding the right carrier and the best rates that fit your needs.

Pallet costs will vary depending on the material they're made of, quality of construction, and size, so it's essential to choose the right pallet for your product and logistical needs.

What's the Cost?

The cost of shipping a pallet can be a bit tricky to pin down, but we've got some factors to consider. Distance plays a big role, with international shipments costing more due to customs and extra travel.

If you need a pallet delivered by a certain time, be prepared for a higher cost, as the shipping company may need to send a vehicle exclusively for your shipment. Timings can add up quickly.

The size of the items on the pallet also affects the cost, with larger items taking up more space and increasing the price. A standard pallet is 48’ x 40", but custom sizes are available.

Urban and densely populated areas are often easier to pick up from and cost less than remote areas that require extra travel. Locations of pickup and delivery can make a big difference in the cost.

Here are some key factors that affect the cost of shipping a pallet:

- Cost of the pallet itself

- Weight of the shipment

- Route/destination

- Correctly classing your freight

- Minimum billable weights

- And more

To get the best pricing, consider consolidating your pallets together into one larger shipment when possible. This can help you save money and get better service.

Shipping Options and Services

Optimizing pallet shipping is key to a seamless supply chain. Pallets are integral components that streamline logistics, safeguard cargo, and boost the bottom line.

Pallet shipping efficacy hinges on knowledge and strategy. Knowing the industry jargon is crucial for informed choices.

The type of pallet used can significantly impact shipping efficiency. A thorough grasp of pallet types is a strategic advantage.

Pallet shipping involves more than just shipping a pallet; it's about doing so with unmatched efficiency. This underpins enhanced productivity and profitability.

Shipping options and services are vast, but understanding the industry vocabulary is essential. Decoding pallet shipping terminology is a must for making informed decisions.

Partial Truckload (PTL)

Partial Truckload (PTL) shipping is most efficient when your shipment doesn't require an entire truck but is too large for LTL.

PTL shipping can offer flexibility in size and weight, making it a great option for oversized or heavy items. This flexibility can also help bypass distribution centers, potentially reducing shipping times and the risk of damage.

PTL shipping is ideal for shipments that are too big for Less-than-Truckload (LTL) but not large enough to fill an entire truck. By choosing PTL, you can save on costs and ensure your items arrive safely and on time.

Here are some of the key benefits of PTL shipping:

- Flexibility in size and weight

- Potential to bypass distribution centers

- Reduced shipping times

- Lower risk of damage

Full Truckload

Full Truckload shipping is best suited for large shipments that can fill an entire truck.

This shipping method is ideal for shipments that need to be delivered quickly.

Full truckload shipping can often provide faster delivery times since the shipment remains on the same vehicle throughout transit.

It's a cost-effective option for large shipments that can fill a truck, allowing you to save money on shipping costs.

On a similar theme: Pallet Truck En Español

Freight Services

Freight services play a crucial role in getting your goods from one place to another. There are several types of freight services to choose from, each with its own unique benefits.

LTL (Less Than Truckload) shipping is a great option for smaller shipments, while PTL (Partial Truckload) shipping is better suited for larger shipments that don't quite fill a full truck.

Full Truckload Shipping is ideal for large shipments that can fill an entire truck, and Ground Expedited shipping is perfect for time-sensitive shipments that need to arrive quickly.

Readers also liked: Semi Electric Pallet Truck

Drayage is a service that involves the movement of cargo from a ship or train to a warehouse or other facility. Refrigerated shipping is also available for perishable goods that require a specific temperature to stay fresh.

Here's a breakdown of some common freight services:

Compare Rates and Carriers

Choosing the right shipping carrier is crucial, and it's not just about finding the cheapest option. Different carriers have their specialties, strengths, and weaknesses.

Not all shipping carriers are created equal, and freight rates can fluctuate based on factors like time of year, market demand, fuel costs, and even geopolitical events.

To make an informed decision, consider the delivery time, cost, and handling requirements of your goods. This will help you choose the right shipping service for your needs.

Comparing shipping rates and carriers can be overwhelming, but it's essential to find the best fit for your business. At RS Group, we specialize in finding the right carrier and the best rates that fit your needs.

Pallet costs will vary depending on what they're made of, quality of the construction, and their size. If you need help determining a pallet that's a good fit for your product, business, and logistical needs, contact our customer support team.

Shipping a pallet of freight can be complex, depending on what you're shipping, where it's coming from, where it's going, and how much it weighs.

Pallet Types and Materials

Pallets come in a variety of types and materials, each with its own unique characteristics and benefits.

Standard wood pallets, measuring 40″ x 48″, are the most common type and are widely used in various industries. They can be made from hardwoods or softwoods and can be either new or used.

Plastic pallets are another popular option, known for their durability and resistance to moisture and pests. They are often used in food, pharmaceutical, and chemical industries due to their ease of cleaning and sanitizing.

There are also metal pallets made from steel or aluminum, which are used in heavy-duty applications requiring high load-bearing capacity and durability.

Recommended Pallet Types for LTL Shipping

For LTL shipping, you'll want to use pallets that can withstand the rigors of handling and transportation. Standard wood pallets measuring 40″ x 48″ are a good choice.

These pallets should have four-way entry capabilities, allowing for easy loading and unloading from all sides. A relatively new and undamaged pallet is essential to ensure it can support the weight of your packaged products.

The pallet should be sturdy enough to withstand both heavy and light loads, and be able to support the full weight of the packaged products. It's also important to choose a pallet with minimal top board spacing to avoid forklift blade impact.

Here's a summary of the recommended pallet characteristics:

Types to Avoid in LTL

When shipping goods via Less Than Truckload (LTL) or Truckload (TL), it's essential to choose the right pallet type to ensure safe and efficient transportation.

Corrugated fiberboard pallets are not recommended due to their lack of sturdiness.

Damaged or repaired pallets should be avoided as they can compromise the integrity of the goods being shipped.

Pallets made from flimsy materials or rotten wood are also not suitable for LTL and TL shipping.

Pressed block-style pallets are another type to avoid, as they often lack the stiffness and strength of standard wood pallets.

Molded pulp pallets are not recommended because they can be prone to moisture damage.

Here are some pallet types to avoid in LTL and TL shipping:

- Corrugated fiberboard pallets

- Damaged or repaired pallets

- Rotten or flimsy pallets

- Pressed block-style pallets

- Molded pulp pallets

Common Pallet Sizes and Dimensions

The most common pallet sizes are a crucial aspect of shipping and logistics. In North America, the standard pallet dimensions are 48″ x 40″, also known as CBA (Consumer Brands Association) sized pallets.

These pallets are widely used due to their versatility and ability to accommodate a variety of products. The next most common pallet sizes are 42″ x 42″ and 48″ x 48″.

The weight of a shipment also plays a significant role in choosing the right pallet size. A heavier shipment may require a more durable pallet material, and the average 48″ x 40″ pallet typically weighs between 33-48 pounds.

Here are some common pallet dimensions used in different regions:

What Is a Pallet

A pallet is a flat structure made of wood, plastic, or metal that is used to support and transport goods.

Pallets are typically used in conjunction with a forklift, pallet jack, or other mechanical handling equipment to move goods around a warehouse, distribution center, or other storage facility.

They are standardized in size and shape to allow for efficient handling and storage.

Pallets are also often used to stack and secure goods for shipping or storage in a trailer or container.

Benefits of Wooden Pallets

Wooden pallets are a great choice for businesses due to their sturdy and durable nature, making them strong enough to withstand heavy loads.

One of the most significant advantages of wooden pallets is their cost-effectiveness, as they are generally less expensive than other types of pallets.

Wooden pallets can be used for a wide range of applications, including storage, transportation, and material handling, making them a versatile option.

They can be used for a long time with proper maintenance, extending their useful life and reducing the need for frequent replacements.

Wooden pallets can be recycled or repurposed after their useful life is over, making them a more sustainable option than disposable plastic pallets.

Benefits of Plastic

Plastic pallets are more durable than wooden pallets and can withstand harsh handling and harsh environments.

They're also resistant to moisture, pests, and other contaminants, making them ideal for use in food and pharmaceutical industries.

Plastic pallets are typically lighter than wooden pallets, which makes them easier to handle and reduces shipping costs.

Plastic pallets are easier to clean and sanitize than wooden pallets, which is a must-have in industries that require high levels of hygiene.

They're made from recycled materials, making them more environmentally friendly than wooden pallets.

Plastic pallets can be recycled at the end of their lifespan, further reducing their environmental impact.

Their longer lifespan means they can be more cost-effective in the long run, and they don't require the same level of maintenance as wooden pallets.

Plastic pallets can be customized to meet specific needs, such as specific weight capacities or dimensions.

Dunnage: Core Meaning

Dunnage is a crucial component in maintaining the stability of a pallet load. It's used to fill gaps between items on a pallet.

You can use wooden dunnage, foam sheets, or other materials to achieve this. These materials help keep the load stable and prevent items from shifting during transportation.

Using the right dunnage can make a big difference in the overall safety and security of the pallet load. It's not just about filling gaps, but also about ensuring the load is properly secured.

Wooden dunnage is a popular choice due to its durability and effectiveness in keeping the load stable. Foam sheets are also a good option, especially for lighter loads.

Proper use of dunnage can help prevent damage to the pallet and its contents during transit. It's an essential step in ensuring the load arrives at its destination safely and securely.

For more insights, see: Slip Sheets vs Pallets

Safety and Best Practices

Shipping pallets requires attention to safety and best practices to ensure a smooth and successful delivery. Distribute the weight of your items evenly across the pallet to prevent shifting or tipping.

Proper loading techniques are crucial to prevent accidents and damage. This includes securing your items firmly in place to prevent them from shifting during shipping.

A well-balanced and stable pallet is essential for safe transportation. By following these simple steps, you can help prevent costly delays and ensure your pallets arrive at their destination in good condition.

Safety and Best Practices

Uniformity is key to load safety and stability, and never letting the loaded products overhang the vertical limits of the pallet can prevent punctures, package tears, and product damage. This can also reduce compression strength by as much as 32 percent.

Pyramid stacking doesn't have a level top load surface, which limits the ability to maximize space and save shipping costs through stacking additional pallets. It also increases the risk of additional damage through handling.

Distribute the weight of your items evenly across the pallet, and secure them firmly in place to prevent shifting or tipping. This will help ensure that your pallets are balanced and stable during shipping.

By following these simple guidelines, you can significantly reduce the risk of damage and ensure a smooth shipping process.

Proper Lifting Techniques

Proper lifting techniques are crucial to avoid injury when handling pallets.

Use your legs to lift, rather than your back, to maintain proper lifting posture.

Keeping your load close to your body is essential to maintain balance and prevent accidents.

This simple technique can make a huge difference in preventing back strain and other injuries.

Intriguing read: Which End of Pallet Industry Standard for Lifting Pallets

Equipment and Supplies

To prevent your pallet from falling apart, choose packing supplies that are sturdy enough to contain your goods, particularly for fragile, bulky, or unusually shaped items.

Using the right materials upfront can save you a lot in damage costs later. Secure each box with wide, high shear strength adhesive tape to prevent them from opening or tearing.

Strong straps or bands made of rayon, polyester, polypropylene, or steel hold your pallet together best. Linear, low-density polyethylene stretch film keeps everything securely contained and protected from the elements.

Automating the handling of pallets with tools such as pallet conveyors can help streamline your shipping process and reduce the risk of accidents or damage.

Sources

Featured Images: pexels.com