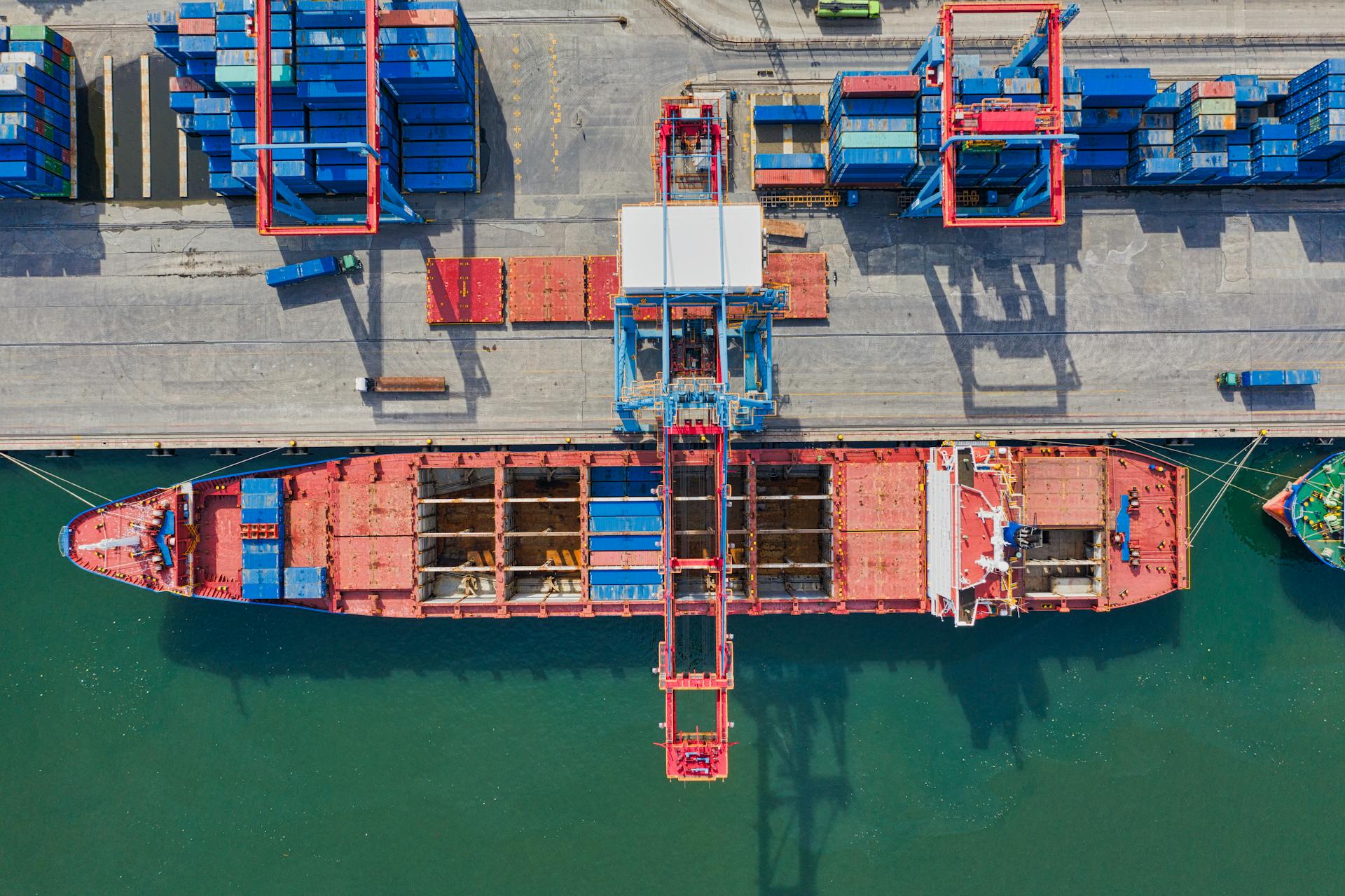

Shipping container weight is a crucial aspect to consider when transporting goods, as it affects the cost, safety, and efficiency of the shipment. The maximum gross weight of a shipping container is typically 40,000 pounds (18,144 kilograms).

To ensure compliance with regulations, shippers must accurately calculate the total weight of the container and its contents. This includes the weight of the container itself, as well as any additional cargo, fuel, and accessories.

The International Organization for Standardization (ISO) sets standards for shipping container dimensions and weight capacities. The most common shipping container sizes are 20-foot and 40-foot containers, with the 40-foot container being the largest and most widely used.

The tare weight of a shipping container is the weight of the container itself, which can range from 2,400 to 4,800 pounds (1,089 to 2,177 kilograms) depending on the size and type of container.

Why Weighing Matters

Weighing shipping containers is crucial for safety and compliance reasons. Overloaded or unbalanced containers can pose a significant risk to container ships, road safety, and cargo.

Explore further: Double Door Shipping Containers

The International Maritime Organization (IMO) requires shippers to provide a Verified Gross Mass (VGM) of the containers before loading them onto a ship for export. This ensures safety by minimizing accidents caused by overweight containers.

Accurate weight measurements are essential to avoid penalties and fines. Shipping organizations must comply with the Safety Of Life At Sea (SOLAS) VGM requirements, which means accurately weighing containers and optimizing loads.

An empty 20ft shipping container typically weighs under 5,000lbs, mostly between 3,970lbs and 4,850lbs, or between 1.8 and 2.2 metric tonnes.

Check this out: How Do Shipping Containers Lock Together

Why Is Weighing Important?

Weighing a shipping container is crucial for safety purposes. Overloaded or unbalanced containers can pose a great risk for container ships, general road safety, and the cargo itself.

The International Maritime Organization (IMO) requires shippers to provide a Verified Gross Mass (VGM) of the containers before being loaded onto a ship for export. This is to ensure safety by minimizing accidents caused by overweight containers.

Shipping organizations need to comply with the Safety Of Life At Sea (SOLAS) VGM requirements, which means they must accurately weigh the shipping containers and optimize the loads to avoid penalties and fines.

For road transport, check state truck size and weight limit laws, issued by the Federal Highway Administration under the US DoT. These vary from state to state and the gross vehicle weight differs for regular and special operations.

Accurate weight measurements can help determine if you are complying with regulatory guidelines and government transport regulations. Weight limits matter in both export compliance and inland movement of containerized cargo units.

An empty 20ft shipping container will typically weigh under 5,000lbs or mostly hover between 3,970lbs and 4,850lbs or between 1.8 and 2.2 metric tonnes.

Weighing Options

Weighing a shipping container is crucial for optimizing payload, ensuring regulatory compliance, and maintaining road safety. The International Maritime Organization (IMO) requires a Verified Gross Mass (VGM) for export, while the Safety Of Life At Sea (SOLAS) regulations need to be followed.

There are different methods to weigh shipping containers, and accuracy matters. Trailer suspension weighing systems can be fitted to a truck's suspension, but they're only accurate to within 3-5%. Weighbridges, on the other hand, are large platform scales that can accurately weigh large vehicles and their payload, with an accuracy of 0.2% to 0.5%.

Axle weigh pads are a popular option for weighing shipping containers, as they're lightweight and economical. They can measure the weight of both stationary vehicles and vehicles in motion.

Here are the three main methods of weighing shipping containers on a chassis:

- Trailer Suspension Weighing System: This method is not highly efficient, with an accuracy of 3% - 5%.

- Weighbridge: This method has an accuracy of 0.2% to 0.5%, but it may be expensive and take up a lot of space.

- Axle Weigh Pads: These devices are lightweight and economical, with an accuracy that's hard to beat.

Crane or hoist weighing is another method, where the container is lifted off the ground and measured. Lever arm weighing is a manual method that uses a lever arm, fulcrum, and counterweight to measure the container's weight.

Shipping containers are typically weighed dry, as weighing a loaded container can be quite challenging. The tare weight of a dry 20ft container is around 5,000lbs, its maximum gross weight is just over 55,000lbs, and its maximum payload weight is around 50,000lbs.

Understanding Container Weights

So, how much does a shipping container weigh? You have three sets of weights to be aware of: the Tare Weight, the Gross Weight, and the Payload.

The Tare Weight is the weight of the empty container itself, which can vary depending on the size and type of container. For example, an empty 20ft shipping container typically weighs under 5,000lbs or between 3,970lbs and 4,850lbs.

Knowing the weight of a shipping container is super-important for safety purposes. Overloaded or unbalanced shipping containers are a disaster waiting to happen, putting both container ships and shippers at risk.

In 2016, a rule was established by the IMO (International Maritime Organisation) requiring shippers to provide the VGM (Verified Gross Mass) of a shipping container before it can be loaded for export. This rule was established as a direct response to the accidents which kept occurring because of overweight containers.

A 10 ft. shipping container has a tare weight of approximately 2645 lbs, and has a payload capacity of about 19,753 lbs, making the gross or laden weight about 22,398 lbs.

Related reading: Why Gross Weight Is Needed for Shipping

Container Sizes and Capacities

A 20-foot shipping container can carry around 30,480 kilograms of cargo, including its own weight of 2,300 kilograms.

The weight capacity of a 40-foot container is similar to a 20-foot one, but it can carry slightly less cargo, approximately 26,680 kilograms.

The maximum load for a 20-foot container is 2.5 tons or 2 tonnes, which you should also consider in relation to the shipping line's regulations and the specific cargo.

A 40-foot container has a heavier tare weight, but it provides greater payload capacity, making it a better choice for larger or heavier loads, like machinery weighing 26,000 kilograms.

See what others are reading: Cargo Ship Container Capacity

10ft

A 10ft shipping container is a great size for many uses, and knowing its weight capacity can be really helpful.

A 10ft container weighs around 1.5 tons, which is a significant amount of weight.

You can load a 10ft container with up to 11 tons of payload, which is a substantial amount of cargo.

The gross weight of a 10ft container is 12.5 tons, so it's essential to consider this when planning your shipping needs.

Here's a quick summary of the weight capacity of a 10ft container:

- Weight: 1.5 tons

- Payload: up to 11 tons

- Gross weight: 12.5 tons

20ft Capacity

A 20ft shipping container is a standard size that can carry up to 30,480 kilograms (67,200 pounds) of cargo, including the weight of the container itself.

The empty container weighs about 2,300 kg (5,070 lbs), so the cargo weight should be around 28,180 kilograms (62,130 lbs) or less. This makes it a great option for lighter, bulkier items.

A 20ft container can hold about half the number of pallets as the next size up, which is a 40ft container. Here's a rough guide to help you plan:

The maximum payload capacity of a 20ft container is around 2.5 tons (2 tonnes), and the gross weight is approximately 33.5 tons (30.5 tonnes).

Related reading: 5 Yard Container

Weight Measurement and Regulations

The International Maritime Organization (IMO) requires shippers to provide a Verified Gross Mass (VGM) of the containers before being loaded onto a ship for export. This is to ensure safety by minimizing accidents caused by overweight containers.

To calculate the VGM, you can weigh the container once it is packed or weigh the cargo and contents separately and then add the container's empty weight. There are two approved methods to determine the VGM.

Shipping organizations need to comply with the Safety Of Life At Sea (SOLAS) VGM requirements, meaning they need to accurately weigh the shipping containers and optimize the loads to avoid penalties and fines. This includes checking state truck size and weight limit laws, issued by the Federal Highway Administration under the US DoT.

Here are the three methods of weighing shipping containers on a chassis:

- Trailer Suspension Weighing System: Not a highly efficient method as the accuracy is around 3% - 5%.

- Weighbridge: A large platform scale that is mounted onto a concrete foundation and can weigh large vehicles and their payload with an accuracy of about 0.2% to 0.5%.

- Axle Weigh Pads: Portable weighing scales that can measure the weight of both stationary vehicles and vehicles in motion with a high level of accuracy.

Ocean Transport Regulations

Ocean Transport Regulations require shippers to accurately declare the total weight of each packed container before it's loaded onto a vessel.

The Verified Gross Mass (VGM) of packed shipping containers is a critical requirement mandated by the International Maritime Organization (IMO) in 2016.

To calculate the VGM, you have two approved methods: weigh the container once it's packed or weigh the cargo and contents separately and then add the container's empty weight.

Shippers must calculate the VGM and communicate it to the ocean carrier and port terminal in time for the ship's planning process.

Different container types and sizes have varying maximum gross weights, which must be considered to comply with safety standards.

For example, a 40ft Open Side High Cube container has a maximum gross weight of 28,000 kgs or 61,729 lbs.

To ensure compliance with regulations, it's essential to accurately measure the weight of the container and its contents.

The SOLAS VGM regulations aim to minimize accidents caused by overweight containers and ensure the safety of the crew, cargo, and environment.

Here's a summary of the VGM calculation methods:

By following these regulations and accurately measuring the weight of shipping containers, shippers can ensure compliance with safety standards and avoid penalties and fines.

Trailer Suspension Weighing System

The trailer suspension weighing system is a method used to estimate the weight of a container based on how much it affects the truck's suspension. This system is fitted to the truck's suspension and can be used if the container is already loaded onto a truck chassis.

It's not the most accurate method, though - it's only accurate to within 3-5%. This means that the weight estimated by the system might not be entirely reliable.

Axle Weigh Pads

Axle weigh pads are a popular option for measuring the weight of shipping containers on a truck. They're lightweight and cheaper to use.

These pads are directly attached to the vehicle carrying the container, similar to the trailer suspension system. However, axle weigh pads are more accurate than the trailer suspension system, with a higher accuracy rate.

Axle weigh pads are portable weighing scales that can measure the weight of both stationary vehicles and vehicles in motion. They transmit this data to a central indicator.

Here are the key features of axle weigh pads:

Shipping and Ocean Transport

Shipping by sea requires careful attention to weight regulations to ensure the safety of the crew, cargo, and environment.

Complying with weight regulations is vital when shipping by sea, as it impacts the economics and ensures the safety of the crew, cargo, and environment. The International Maritime Organization (IMO) updated the Safety of Life at Sea (SOLAS) convention in 2016 to include the Verified Gross Mass (VGM) requirement.

Expand your knowledge: Sea Container Lock

To calculate the VGM, you have to consider the weight of all the cargo, including pallets and packing materials, and add the empty container's weight to it. There are two approved methods to determine the VGM: weighing the container once it is packed, or weighing the cargo and contents separately and then adding the container's empty weight. The shipper is required to calculate the VGM and communicate it to the ocean carrier and port terminal in time for the ship's planning process.

Handling

Handling overweight containers can pose significant risks to the vessel, cargo, and handling equipment.

Overweight containers can result in additional charges or penalties.

It's essential to follow regulations for containers on road transport to avoid these risks.

Overweight containers can cause damage to the vessel, cargo, and handling equipment, leading to costly repairs and downtime.

Additional charges or penalties can be incurred for handling overweight containers.

To minimize risks, it's crucial to ensure containers are properly loaded and weighed before transport.

Proper Distribution

Proper Distribution is crucial for a smooth shipping process. Distributing the weight inside the container evenly is important to avoid stability issues during loading, transport, and stacking.

This is particularly important because uneven weight distribution can cause the container to tip or become unstable, leading to accidents or damage during transit. Proper weight distribution also helps prevent containers from shifting or falling during transportation.

To achieve proper weight distribution, it's essential to consider the container's dimensions and the weight of the cargo. This will ensure that the weight is evenly balanced and the container remains stable.

By following these guidelines, shippers can minimize the risk of accidents and ensure a safe and efficient shipping process.

Shipping Weight

Shipping weight is a crucial factor to consider when shipping goods by sea. It's essential to understand the different types of weights associated with shipping containers.

A shipping container has three sets of weights: Tare Weight, Gross Weight, and Payload.

The Tare Weight is the weight of the empty container itself, which varies depending on the size and type of container. For example, a 40 ft. high cube container has a Tare Weight of approximately 8,747 lbs.

The Gross Weight is the total weight of the container, including its contents and any additional weight from accessories like pallets or tie-downs. A 20 ft. container has a maximum Gross Weight of 52,813 lbs.

The Payload is the maximum weight of goods that can be carried in a container. A 40 ft. standard shipping container has a maximum Payload capacity of about 59,039 lbs.

Understanding these weights is crucial to avoid overweight containers, which can pose significant risks to the vessel, cargo, and handling equipment. Overweight containers can also result in additional charges or penalties.

Here's a summary of the weights for different types of shipping containers:

By understanding the weights of shipping containers, you can ensure that your cargo is properly loaded and transported safely and efficiently.

Factors to Consider

When considering the weight of a shipping container, there are several factors to keep in mind.

Height matters, as high cube containers are a foot taller than standard containers, which means they weigh more.

The age and condition of a shipping container also play a role, with older containers weighing less and being less reliable.

A shipping container's weight can also be affected by whether it's been altered in any way, such as being cut down or made bespoke.

Here are some key factors to consider:

- Height: High cube containers are a foot taller than standard containers.

- Age and Condition: Older containers weigh less and are less reliable.

- Alterations: Cut-down or bespoke containers have been altered from the standard.

Frequently Asked Questions

How much does a 40ft container weight?

A 40ft shipping container weighs approximately 3,750 kg (8,265 lbs) when empty. Its maximum cargo capacity is 26,730 kg (58,935 lbs).

How much does a 20 ft shipping container weigh?

A 20 ft shipping container typically weighs between 3,970 and 4,850 pounds when empty, varying by type, age, and construction. For a more accurate weight, consider the specific container's details.

How do you move a 20 foot shipping container?

To move a 20-foot shipping container, consider using a forklift, crane, or specialized trucking services, depending on the distance and location. For long-distance moves, hiring a professional trucking service is often the most efficient and secure option.

How much does a 30 foot conex weigh?

A 30 foot conex typically weighs around 7,000 pounds (3,200 kg). This weight can vary depending on the container's specifications and contents.

Sources

- https://www.mobilemodularcontainers.com/blog/how-much-does-a-shipping-containers-weigh

- https://dedola.com/2023/08/guide-to-weight-regulations-for-shipping-containers-navigating-the-ocean-and-road-rules/

- https://www.container-xchange.com/blog/shipping-container-weight/

- https://cargostore.com/how-much-does-a-shipping-container-weigh/

- https://universal-containers.com/news/how-much-does-a-shipping-container-weigh/

Featured Images: pexels.com