Rail liftgates are designed to handle high-cycle capabilities, with some models able to open and close up to 20 times per minute. This is achieved through a combination of high-performance motors and advanced control systems.

The high-cycle capabilities of rail liftgates make them ideal for use in busy rail yards and terminals, where rapid loading and unloading of cargo is essential. They can also be used in applications where space is limited, as they can be installed in a compact footprint.

Rail liftgates can be designed to meet specific customer needs, with options for different lifting capacities and speeds. This flexibility makes them a popular choice for a wide range of industries, from rail to manufacturing and logistics.

If this caught your attention, see: PATH (rail System)

High-Cycle Models

High-Cycle Models are designed to withstand intensive cycling and come with a steel roller and leaf-chain pulley system to maximize smoothness of motion, endurance, and strength.

These models are ideal for high-cycle applications in any environment and are built with the highest quality components, prioritizing function and safety.

High-Cycle durability is a key feature of these models, ensuring they can handle frequent use without breaking down.

Higher lifting capacities and larger platforms make them perfect for heavy-duty use.

Dock compatibility is also a standard feature, making it easy to integrate with existing infrastructure.

Steel rollers are designed to withstand intensive cycling and are guided vertically within the rail track by dual sealed, maintenance-free ball bearings.

These bearings ensure the rollers are long-lasting and perform consistently in all climate conditions.

Here are the key features of High-Cycle Models:

Safety features such as a safety trip bar, auto open and close, and recessed lights are also standard on High-Cycle Models.

High-Cycle Documents

The High-Cycle Documents section of the rail liftgate manual is a treasure trove of useful information. You can find the owner's manual for the Railgate Series - High-Cycle, which is a whopping 913kb in size.

The manual covers everything you need to know about operating and maintaining your High-Cycle rail liftgate. It's a comprehensive guide that's sure to answer all your questions.

Recommended read: Cross-Harbor Rail Tunnel

You can also download the Flatbed, Stake, & Van - Railgate Series - High-Cycle Parts List, which is a concise 291kb document that lists all the parts you'll need to repair or replace your rail liftgate.

For those who want to delve deeper into the technical aspects, the Auxiliary Battery Box Selection Guide is a 3098kb document that provides detailed information on selecting the right battery box for your High-Cycle rail liftgate.

If you're planning to install a 2500 or 3000lb-capacity railgate, you'll want to download the 4312kb Railgate Installation Instructions document. It's a detailed guide that will walk you through the installation process step-by-step.

Finally, if you need to know the detailed dimensions of your Flatbed/Van - Railgate Series - High-Cycle, you can download the 234kb Flatbed/Van - Railgate Series - High-Cycle Dimensions document.

Here's a summary of the documents available for the High-Cycle rail liftgate:

Railift

The Railift is a heavy-duty liftgate designed to handle demanding distribution requirements. It's a classic design that has been around since the 1970s.

Maxon was the first to bring the Railift to the United States. It's a testament to the company's innovative spirit.

Railift lift gates provide a level ride throughout the lift for maximum load stability. This is especially important for bulk delivery and wheeled cargo.

The Railift Series is ideal for dock and street delivery. Its heavy-duty design can handle a range of lifting capacities.

Rail gates have lifting capacities ranging from 2,000 to 6,000 lbs. That's a significant weight range, making them suitable for various applications.

The DMD design of the Railift features two direct acting cylinders. This reduces the number of moving parts, resulting in lower maintenance needs.

Curious to learn more? Check out: Residential Delivery with Liftgate

Frequently Asked Questions

What is the difference between a liftgate and a tail lift?

In the UK and North America, a tail lift and a liftgate are essentially the same thing: a mechanical device that helps load and unload goods from a vehicle. The terms are used interchangeably, but a liftgate is more commonly used in North America, while tail lift is used in the UK.

What is a rail lift gate?

A Rail Lift Gate is a type of lift gate designed for medium-duty use, offering a stable and smooth ride for maximum load stability. It features a groundbreaking new design that combines high performance with low maintenance needs.

What is the weight limit for a rail gate?

Rail gates have a weight limit of 1600 and 2000 lbs, depending on the model

What are the different types of lift gates?

There are three main types of lift gates: Tuck-Under, Cantilever, and Rail-Lift, each designed to safely and efficiently load and unload heavy items. Understanding the differences between these types can help you choose the right lift gate for your needs.

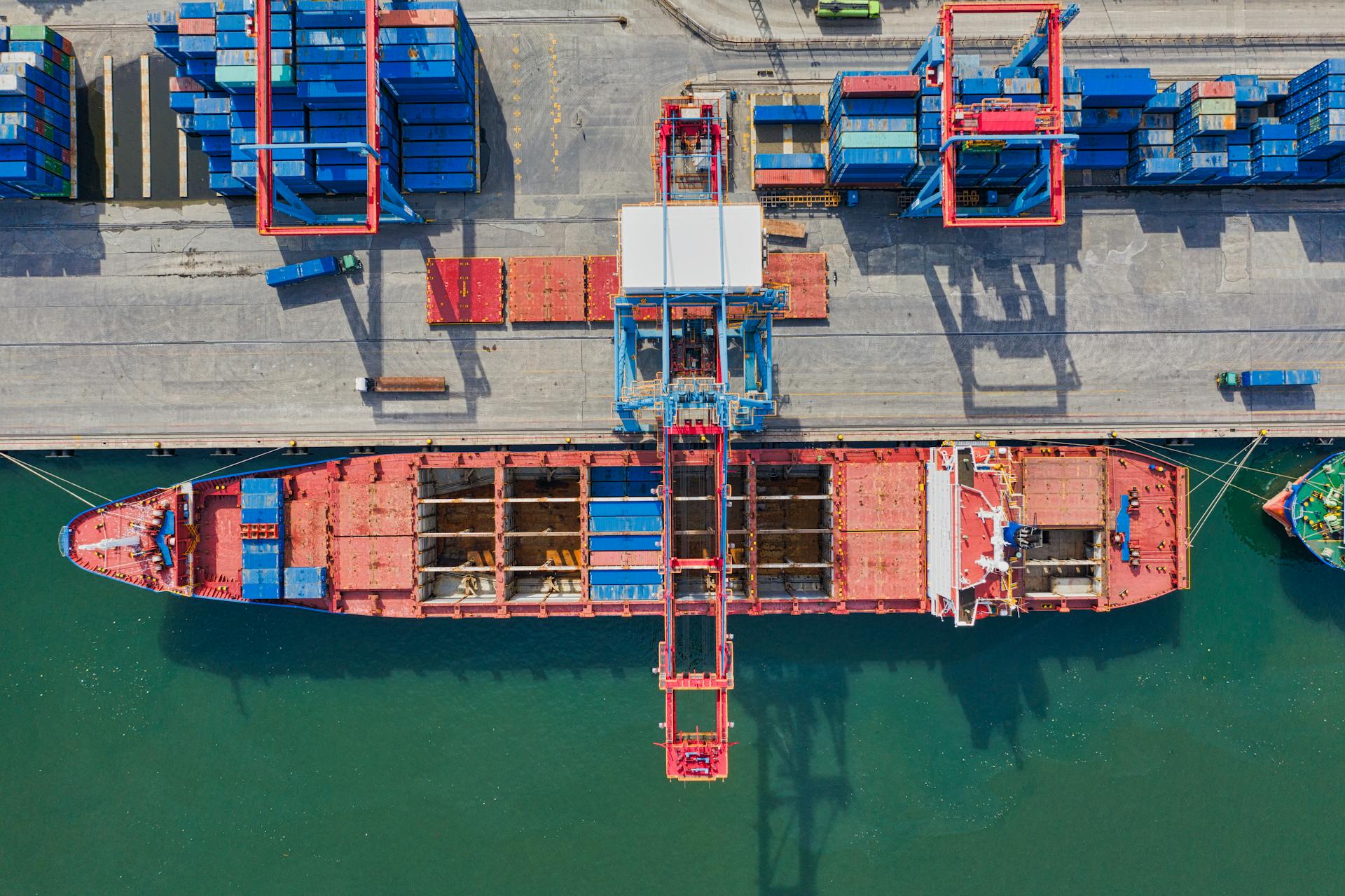

Featured Images: pexels.com