Postage stamp paper production involves a multi-step process that ensures the paper meets the required standards for printing and durability.

The paper is made from a mixture of wood pulp and cotton linters, which are added to increase its strength and durability.

The pulp is then refined to create a uniform consistency, allowing for even ink absorption and print quality.

This refinement process involves beating the pulp to break down the fibers, resulting in a smooth and consistent texture.

The pulp is then mixed with water and other chemicals to create a uniform consistency, which is crucial for achieving the desired print quality.

A Fourdrinier machine is used to form the paper, with a wire mesh screen allowing excess water to drain, leaving a thin layer of fibers.

The paper is then pressed to remove any excess water and flatten it out, ensuring it's smooth and even.

The finished paper is then cut into sheets, ready for printing and use as postage stamps.

Paper Quality

Postage stamp paper is made from a specific type of paper that's designed to be durable and long-lasting.

The paper quality of postage stamp paper is crucial because it needs to withstand the rigors of being handled by postal workers and the elements.

It's made from a mixture of wood pulp and cotton linters, which gives it a unique texture and strength.

The cotton linters add a touch of softness and help the paper resist wear and tear.

This blend of materials also makes the paper resistant to moisture and humidity, which is essential for stamps that may be exposed to rain or high humidity.

The paper's weight is typically around 80-100 gsm, which is slightly heavier than regular printing paper.

This heavier weight helps the stamp stay crisp and prevent it from bending or warping over time.

Discover more: Paper Stock Weight

Printing and Security

Security paper is an essential feature of postage stamps, and it's fascinating to see the different techniques used to create it. The Lilac network of Estonia's 1928-35 10s stamp is a great example of this.

Security paper can be identified by its unique features, such as the Lilac network or the Gray network, which are used to prevent counterfeiting. These networks are made up of intricate patterns that make it difficult to replicate the stamp.

Some stamps, like Venezuela's 1932-38 25c stamp, use Blue Winchester security paper, which is a specific type of security paper that's designed to be difficult to counterfeit.

The three main methods of printing postage stamps are lithography, typography, and line-engraving. Each method produces a unique appearance, with lithography resulting in a flat, smooth appearance, as seen in the stamps printed from an absolutely flat surface.

Here's a brief overview of the three methods:

These differences in printing methods and security paper can make a big difference in the authenticity and value of a postage stamp.

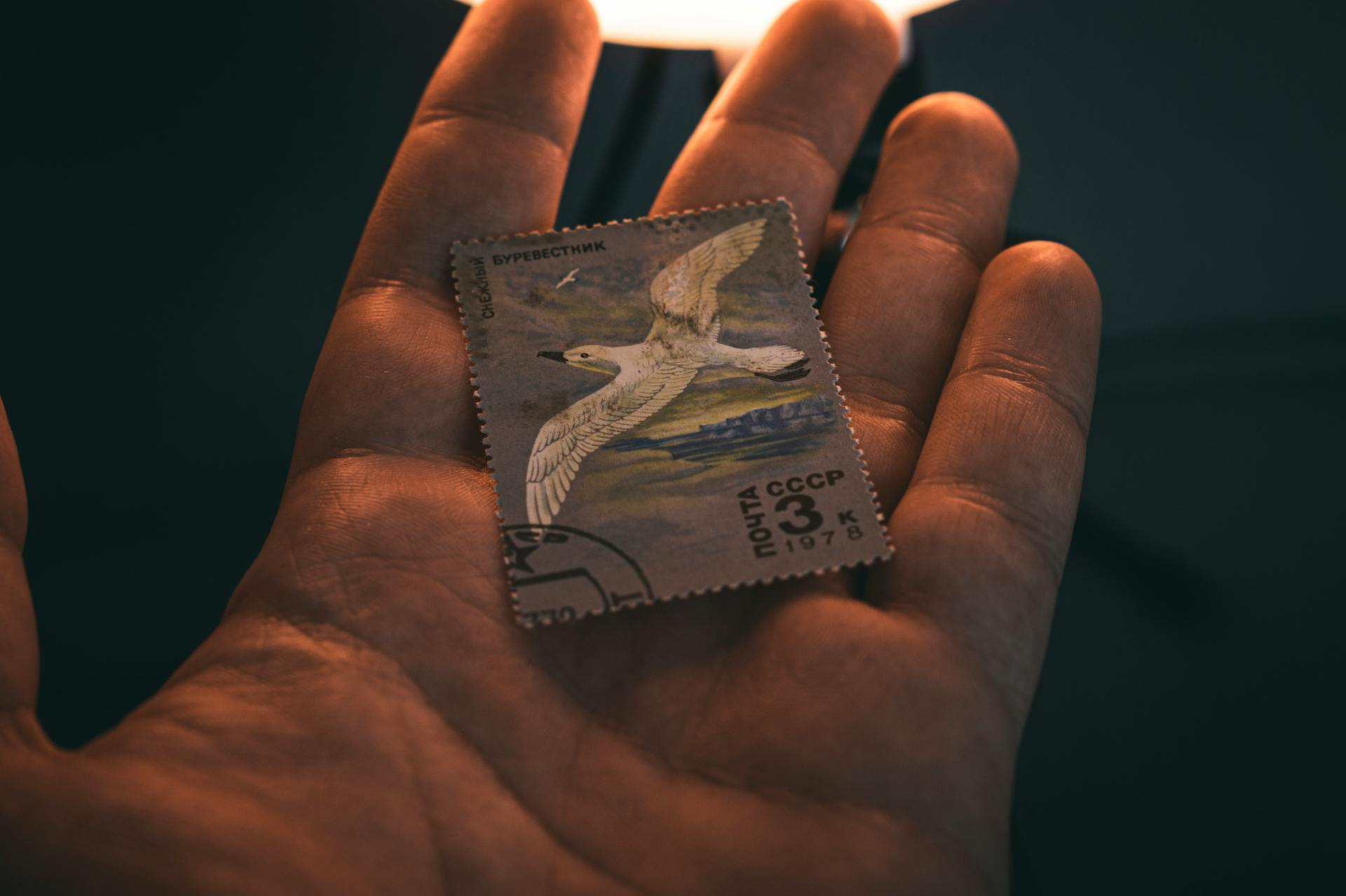

Perforations

Perforations were a game-changer for stamp collectors, making it easy to separate stamps without resorting to scissors.

The first perforating machine produced regular lines of holes between stamps, but the arrangement and spacing of the holes varied, even in stamps of the same issue.

This variation often helped collectors determine the date or period when particular stamps were issued.

The number of holes in a space of two centimeters was used to indicate the perforation of a given side of a stamp, with "Perf. 15" meaning there are 15 holes in any space of two centimeters on that side.

The longer side of a stamp would naturally have more holes than the shorter side.

When the spacing varies on different sides of the same stamp, the perforations are said to be compound.

Opposite sides of a stamp usually have the same spacing, so "Perf. 15x14" means the first figure (15) is the gauge of the top and bottom, while the second (14) is the gauge of the left and right sides.

The figure for top and bottom always comes first.

A perforation gauge makes it easy to measure the correct description of a stamp's perforation.

Readers also liked: Apollo 15 Postal Covers Incident

Three Printing Methods

Lithographed stamps have a flat, smooth appearance because the ink of the design lies smoothly on the surface of the stamp.

Typography stamps or surface printed stamps are printed from the raised portions of the type or printing plate, which receive the ink during its transfer onto paper.

The pressure used during the printing of typography stamps tends to indent the design into the paper.

Line-engraved stamps have a design that is raised on the surface of the stamp, and the lines of ink can often be seen standing up in minute ridges.

The design of line-engraved stamps is cut into the plate, while the ink lies in these cuts, into which the paper is forced during printing.

Security Gallery

Security paper is an essential aspect of postage stamps, and various designs have been used over the years to prevent counterfeiting.

Lilac network security paper was used on Estonia's 1928-35 10s stamp, while a gray network was used on Danzig's 1922 6m stamp.

Security paper with a blue Winchester design was featured on Venezuela's 1932-38 25c stamp, showcasing the country's commitment to secure printing.

Colored dots were also used on El Salvador's 1907 1c stamp to enhance security features.

In addition to these designs, Venezuela's 1952 1b security stamp utilized a unique security paper that further protected against counterfeiting.

Here are some examples of different security paper designs used on postage stamps:

Varieties and Classification

Postage stamp paper comes in various weights, ranging from 50 gsm to 200 gsm, with 80 gsm being the most common.

The weight of the paper affects its durability and ability to hold ink. For example, a heavier weight paper can withstand more wear and tear.

There are two main types of paper fibers used in postage stamp paper: cotton and wood pulp. Cotton fibers are stronger and more durable, while wood pulp fibers are more flexible.

Stamp Varieties

Stamp varieties can be categorized based on their design, size, and material.

Some stamps are printed in sheets, while others are individual pieces.

The Scott catalog lists over 80,000 different stamp varieties, making it a daunting task for collectors to keep track.

Stamp varieties can be identified by their perforations, watermarks, and paper types.

Some stamps have a unique texture or finish, such as the "glossy" finish of the 1901 Pan-American Exposition stamp.

The use of different paper types can affect the overall appearance and value of a stamp.

Comparative Terms

Comparative Terms are an essential part of stamp collecting, allowing us to describe the variations of a stamp's paper.

Thick and thin are relative terms used to describe the paper's variations in a particular issue, with thick being as much as 0.005 inches and thin as little as 0.001 inches.

Paper can be described as opaque, semi-translucent, or semi-transparent, referring to its ability to let light through.

If no light shines through the paper, it's opaque. If some light passes through, the paper is semi-translucent. If the stamp's design can be seen through the back, it's semi-transparent.

Experts have described the snap of the stamp when flicked to determine if it was printed on hard or soft paper. A sharper snap implies hard paper.

Porous paper is used to describe paper as absorbent, often contrasting with less absorbent paper in the same country.

Manufacturing Process

The manufacturing process of postage stamp paper involves several steps to produce high-quality paper that meets the demands of the postal industry.

The raw materials used for postage stamp paper are wood pulp and cotton linters, which are sourced from sustainable forests and cotton farms.

The wood pulp is processed into a pulp, which is then mixed with cotton linters to create a uniform blend.

This blend is then refined and bleached to achieve the desired brightness and texture.

Many Things Go to the Making of a

Many things go into the making of a product, and it's no different for a postage stamp. The paper used for a stamp is just the beginning.

The paper may have a watermark, which is a hidden design or pattern embedded within the paper itself. Watermarks can be a sign of high-quality paper.

The design of a stamp, which includes the pictorial part, is also a crucial aspect of its making. The design can be in various colours, depending on the ink used.

The inscriptions, or lettering and figures of value, are also essential components of a stamp. They need to be clear and readable.

The ink used for printing the design can vary in colour, which affects the overall appearance of the stamp.

Orders Keep Mill Busy

Stowford Mill was kept busy in the mid-twentieth century with orders for postage stamp paper.

The Production Manager at Stowford Paper Mill recognized the hard work of three mill employees who received watches for 35 years of service.

Clyde "Clydo" Pawley recalled working 16 hours a day for four months to make the paper for the Coronation stamps.

The Post Office Supplies Department had new premises located at Hemel Hempstead by the late 1950s.

All procurement of security items for public services, including stamps, postal orders, and national insurance stamps, was coordinated from this location.

Detection and Analysis

Detecting and analyzing postage stamp paper involves several key steps.

The first step is to visually inspect the paper for any visible signs of aging or wear.

Postage stamp paper often develops a yellowish tint over time, which can be a good indicator of its age.

Manufacturers can use various techniques to enhance the paper's durability and resistance to aging.

One such technique is to add a chemical treatment to the paper, which can help to slow down the aging process.

This treatment can be particularly effective when combined with other methods, such as using high-quality wood pulp.

Flaws

Pinholes are a common flaw in very thin paper, typically characterized by a small hole in the substance of the paper. They can be found by holding the stamp up to light.

A rare paper flaw is the Great Britain's Emblems watermark, where a defect was created when the Dandy roll was repaired, resulting in three roses and a shamrock instead of the intended design.

Creases can occur when the paper becomes an overlapped fold, which subsequently is printed upon, making it a printing error as much as a paper flaw. This can also happen as a result of handling, where it's clear that the stamp has been folded.

A tear is a common handling flaw, where the paper is partially ripped, but the stamp is usually complete. Tearing a piece off of the stamp, however, can be evidence that the stamp was postally used.

Soaking a stamp from a water-soluble colored paper can damage it, especially if the paper is red, as the dye can bleed into the stamp's paper, leaving it tinted red.

Watermark Detection

Watermark detection can be a bit tricky, but there are several methods to try. You can start by holding the stamp up to a light or placing it face down on a black surface to see if the watermark is visible.

If that doesn't work, you can try using a special stamp watermark detecting fluid. This fluid can be applied to the stamp lying face down in a black plastic tray, and as it evaporates, the watermark becomes visible. Just be careful not to use it on mint stamps, as it can damage the gum.

Alternatively, you can use a mains or battery-powered device that uses a light to reveal the watermark. These devices are available for purchase and can be a convenient option for detecting watermarks.

Another option is to use the 'Morley Bright' detector, which uses ink to reveal the watermark. This device is easy to use and can be effective in detecting watermarks.

For another approach, see: Black Paper Sheets

If you don't have any specialized equipment, you can also try using color-filtering techniques to make the watermark more visible. Some devices, like the Philatector, electronically employ a set of color filters to detect the watermark.

As a last resort, you can try scanning the stamp and adjusting the color saturation and contrast using graphics software. This can sometimes make the watermark more visible, especially if the stamp is placed on a black background.

Here are some options to consider when trying to detect a watermark:

- Special stamp watermark detecting fluid

- Mains or battery-powered devices

- 'Morley Bright' detector

- Color-filtering techniques (e.g. Philatector)

- Scanning and adjusting color saturation and contrast

Frequently Asked Questions

How do I know if my letter needs two stamps?

Check if your letter weighs over 1 ounce to determine if it needs extra postage. If so, add an extra stamp for each additional ounce

Featured Images: pexels.com