An efficient plastic wrapper machine is a game-changer for packaging. It can wrap up to 100 pieces per minute, making it ideal for high-volume production.

The machine's compact design allows for easy installation in small spaces. This is particularly useful for businesses with limited floor space.

A well-designed plastic wrapper machine can reduce waste by up to 30%. This is achieved through the use of precision-cut film and a smooth wrapping process.

By investing in an efficient plastic wrapper machine, businesses can save time and money in the long run.

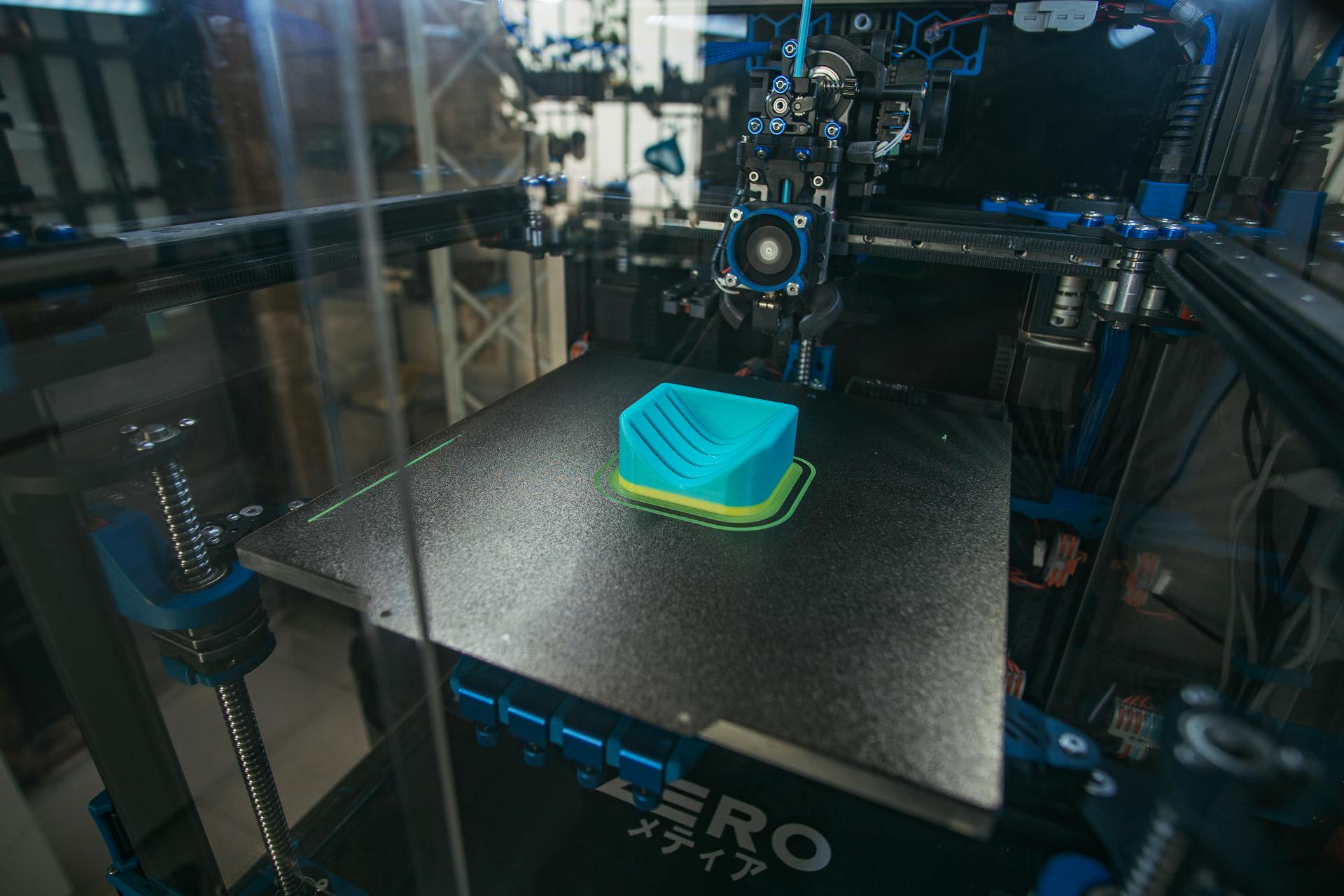

Take a look at this: Plastic Film Wrapper

Industrial Machines

Industrial scale wrapping machines offer precision and time-efficiency, saving you valuable time and effort.

These machines are also cost-effective, making them a smart choice for your packaging needs. With their automated features, you can focus on other important aspects of your business.

The 50-50 Super Deal Packages provide unmatched value for your investment, making industrial scale wrapping machines an attractive option for businesses looking to upgrade their packaging process.

See what others are reading: Industrial Stretch Wrap

Precision Technology

Our plastic wrapper machines are equipped with precision technology that guarantees accurate measurements for every package. This is thanks to state-of-the-art weighing technology that ensures consistent weights and quality standards.

In fact, our machines can even provide built-in weight and height measurements, allowing you to achieve accurate and consistent results with every turn. This is especially useful with our WM-K120 Stretch Wrap, which comes with a label printer feature to save you time and effort.

You can easily integrate our weighing system, the PS-PI, into your existing machinery to enjoy precise measurements with every turn, without the need for extra equipment or intricate setups.

Precision Weighing Technology

In the world of industrial packaging, accuracy is paramount. Our machines are equipped with state-of-the-art weighing technology, guaranteeing accurate measurements for every package.

This technology ensures that you can avoid concerns about inconsistent weights or quality standards. The Universal Shrink Wrap Machine Weighing System, the PS-PI, is a perfect solution for enhancing accuracy and convenience in your packaging process.

You can turn any brand pallet stretch wrapper with scale by integrating this system into your existing machinery. Simply enjoy precise measurements with every turn.

The PS-PI system allows you to avoid the necessity for extra equipment or intricate setups. This makes it a convenient and efficient solution for your packaging needs.

Precision with Every Turn

Precision with Every Turn is a game-changer for packaging. It's all about achieving accurate and consistent results.

The WM-K120 Stretch Wrap is a top choice for precision in packaging. It comes with built-in weight and height measurements, making it easy to get it right every time.

With this innovative product, you can add labels to your packages with the label printer feature, saving you time and effort. This feature is a huge time-saver, especially for high-volume packaging.

The WM-K120 Stretch Wrap is designed to help you achieve precision with every turn. Its built-in measurements ensure accurate results, every time.

By investing in a product like the WM-K120 Stretch Wrap, you can streamline your packaging process and reduce errors. This means more efficient use of your time and resources.

Take a look at this: Label Printer Applicator

Packaging Efficiency

Automated efficiency is the key to streamlining your packaging process. Our auto stretch wrap machines can automate your wrapping process, reducing labor costs and maintaining precision throughout.

Our WM-K120 Pallet Wrapper Ramp is a game-changer for wrapping pallets, making loading and unloading a breeze. It's designed for efficiency, allowing you to wrap pallets effortlessly and save valuable resources.

Every industry has its unique packaging requirements, and our machines offer versatile wrapping solutions to cater to these needs. From logistics to manufacturing and food and beverage industries, find a solution tailored to your business.

Our industrial scale wrapping machines offer versatility in packaging, whether you need added protection or enhanced accuracy. Say goodbye to one-size-fits-all packaging and embrace a customized approach that meets your unique requirements.

The Marksman™ SB machine is designed to apply wrap-style packaging to multipacks of stacked plastic bowls, using patented wrap-locking technology that eliminates the need for glue.

Redefining Packaging Efficiency

Automated efficiency is a game-changer for businesses, allowing them to reduce labor costs and maintain precision throughout the packaging process.

Embracing the future of packaging with auto stretch wrap machines can bring significant efficiency gains. These machines automate the wrapping process, making it easier to wrap pallets and save valuable resources.

The WM-K120 Pallet Wrapper Ramp is a great example of a machine designed for efficiency, allowing you to wrap pallets effortlessly and save time. No more struggling with heavy loads or wasting precious time.

Precision and time-efficiency are just a few reasons why industrial scale wrapping machines are the smart choice for packaging needs. With automated features, these machines save you valuable time and effort, allowing you to focus on other important aspects of your business.

The PS-K200 Fully Automatic Stretch Wrapping Machine is a state-of-the-art solution that provides the complete packaging solution you've been searching for. This machine is designed to deliver tight, secure, and high-quality wraps every time, saving you valuable time and effort.

Versatility in packaging is key, and our industrial scale wrapping machines offer a range of features to meet different industry needs. From top sheet covering to universal shrink wrap device weighing systems, we have the right solution for you.

The Marksman series of wrap-style multipack machines offers a range of solutions for different packaging needs, from low-speed to high-speed machines. These machines are designed to apply wrap-style cartons to cans and bottles, and are ideal for various industries.

Automatic shrink bundling machines are designed to wrap heavy products with thick film, and are ideal for products like firewood, canned goods, and cases of water. These machines use thicker film and higher temperatures to seal and shrink the film, resulting in a finished packaging with two open ends on each side.

The primary purpose of a shrink bundling machine is to wrap heavier products, and they are typically used for products that require extra protection. The machines use a single wound shrink film, which comes off the roll flat, and polyethylene bundling film is the most common material used.

L Bar Sealer

Automatic L bar sealers are fast because of the motion required to make a seal, allowing smaller products to run at 30-40 products per minute.

Companies can wrap tens of thousands of products daily with the right automatic machine.

An L bar sealer should be used with a centerfold shrink film, which is folded lengthways and placed on a roll.

The film should be made from polyolefin and recommended to be irradiated for optimal performance.

Automatic machines do require more than an economy centerfold film to operate smoothly.

A hot knife sealer is the most commonly used item on an automatic L bar sealer, providing increased seal strength and efficiency.

The hot knife sealing blade is a thin piece of metal that is heated to the desired temperature to make seals over and over again, lasting for years with proper cleaning.

A wire sealing blade is not ideal for an automatic L bar sealer, as it will wear out faster and need replacement more often than a hot knife sealing blade.

Operators will be needed to load and unload conveyor belts during operation, but a touchscreen product sizing is ideal for companies wrapping multiple different products per day.

If this caught your attention, see: Case Sealer

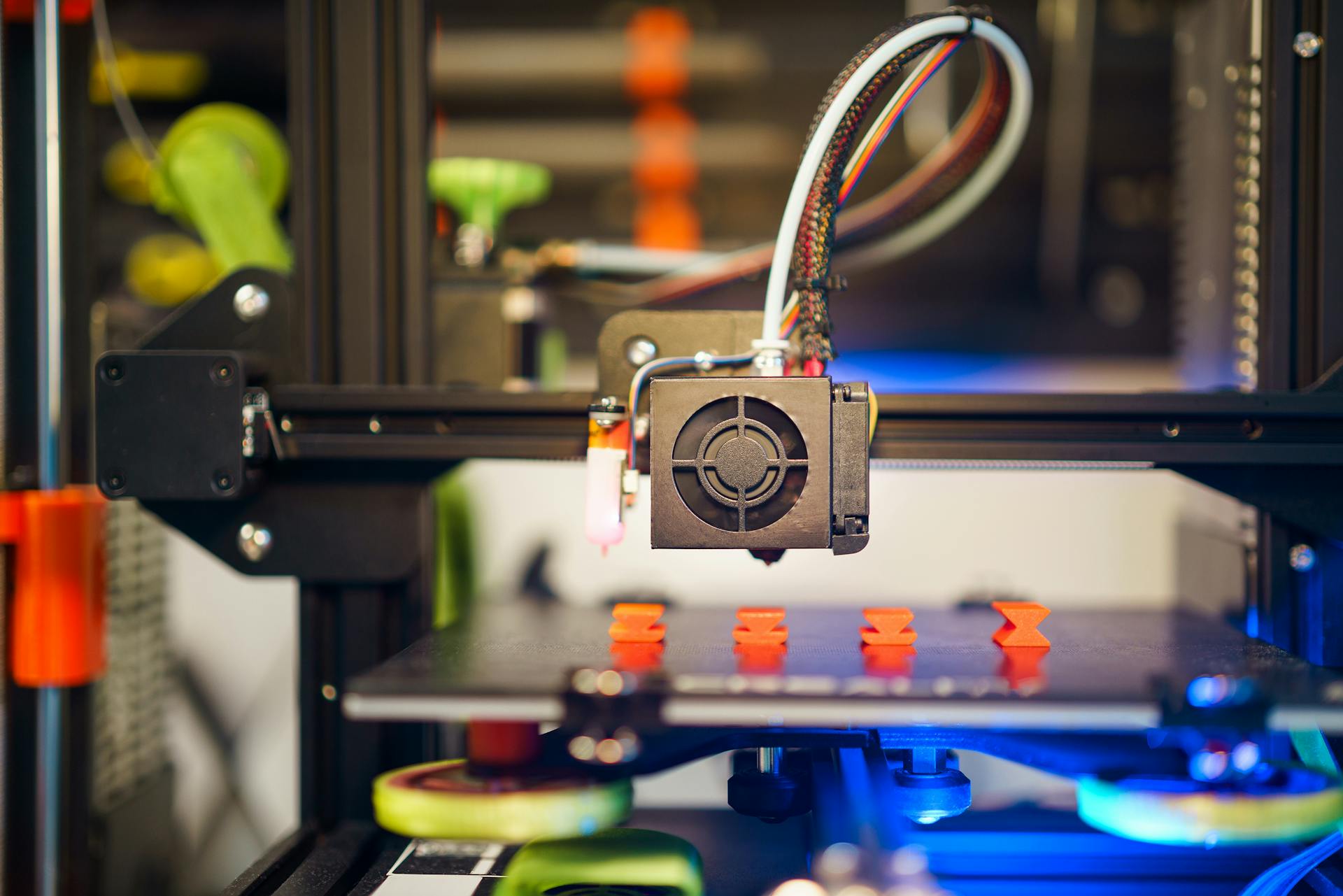

Machine Features

Industrial scale wrapping machines offer precision, time-efficiency, and cost-effectiveness, making them a smart choice for packaging needs.

These machines save valuable time and effort, allowing you to focus on other important aspects of your business. With automated features, you can streamline your packaging process and increase productivity.

Some machines, like the PS-K120FZ, have built-in scales and label printers, allowing you to weigh and label packages all in one go, saving time and effort.

Automatic L bar sealers use a photo eye or laser to detect products as they pass through the conveyor, making the sealing process fast and efficient.

The sealing blade is a critical component of an automatic L bar sealer, and most machines use a hot knife sealer for product seals, which lasts for years with proper cleaning.

Intriguing read: 20 L Plastic Bucket

Industrial Scale Machine Features

Our industrial scale machines come with a range of features that make them incredibly efficient and convenient to use.

The Universal Shrink Wrap Machine Weighing System, the PS-PI, can be integrated into any brand pallet stretch wrapper with scale, eliminating the need for extra equipment or intricate setups.

This system provides precise measurements with every turn, making it a valuable addition to any packaging process.

Some machines, like the WM-K120 Pallet Wrapper Ramp, feature an innovative ramp design that makes loading and unloading pallets a breeze, saving you time and effort.

This machine is designed for efficiency, allowing you to wrap pallets effortlessly and save valuable resources.

The Orion FA- Fully Automatic Stretch Wrapper has a Category 3 Safety Rating, ensuring that it meets the highest safety standards in the industry.

The PS-K120FZ is a fully automatic stretch wrapping machine that comes with a built-in scale and label printer, allowing you to weigh and label your packages all in one go, saving you time and effort.

This machine is designed to make your life easier, with a compact and efficient design that streamlines your packaging process.

If this caught your attention, see: Label Dispenser

MA Rotary Tower

The MA Rotary Tower Automatic Stretch Wrapper is the latest generation of automatic stretch wrap systems. It features top performance and is definitely worth learning more about.

Discover more: Auto Strapping Machine

This system is designed to provide efficiency and precision in wrapping products. With its advanced technology, you can automate your wrapping process and reduce labor costs.

The MA Rotary Tower Automatic Stretch Wrapper is a game-changer for businesses looking to improve their packaging process. By investing in this system, you'll be making a smart investment in your business's success.

This system is perfect for businesses that need to wrap a high volume of products quickly and efficiently. With its advanced features and top performance, you can trust that your products will be wrapped to perfection every time.

Conveyorized Twin Station

The Conveyorized Twin Station Stretch Wrapper, also known as the Orion CTS, is designed to increase your pallet wrapping efficiency.

With its twin station feature, you can wrap two pallets at the same time, significantly reducing production time and increasing your overall output.

This machine is perfect for high-volume operations where speed and efficiency are crucial.

By investing in the Orion CTS, you can say goodbye to manual wrapping and hello to automated convenience.

You can learn more about the Orion CTS and its features by exploring the relevant article sections.

A unique perspective: Orion Stretch Wrap Machine

Machine Types

Industrial scale wrapping machines offer precision, time-efficiency, and cost-effectiveness, making them a smart choice for packaging needs.

With automated features, these machines save you valuable time and effort, allowing you to focus on other important aspects of your business.

You can get unmatched value for your investment with the 50-50 Super Deal Packages, which provide a great balance of features and cost.

These machines are versatile, capable of handling various packaging tasks with ease.

If this caught your attention, see: Franking Machine Cost

Information

Plastic wrapper machines are designed to wrap products in plastic film at high speeds, making them a crucial part of many manufacturing processes.

They can wrap a wide range of products, from food items like sandwiches and pastries to non-food items like electronics and cosmetics.

The machines use a combination of heat and pressure to seal the plastic film around the product, creating a secure and tamper-evident package.

Some plastic wrapper machines can wrap up to 100 products per minute, making them ideal for high-volume production lines.

For your interest: Paper Sack Making Machine

These machines are often used in industries such as food processing, pharmaceuticals, and cosmetics, where product packaging is critical to maintaining product quality and safety.

The plastic film used in these machines is typically made from a type of plastic called polyethylene, which is durable and resistant to tears and punctures.

The machines are also designed to be easy to use and maintain, with features such as automatic film cutting and waste reduction systems.

By using a plastic wrapper machine, businesses can save time and money on packaging materials and labor costs, while also improving product quality and reducing waste.

Additional reading: Product Labeling Machine

Sources

- https://scaledepot.com/industrial-scales/wrapping-machine/

- https://www.orionpackaging.com/videos/orion-fa-fully-automatic-pallet-wrapping-system/

- https://www.graphicpkg.com/solutions/machinery-systems/wrap-style-multipack-machinery/

- https://uspackagingandwrapping.com/automatic-shrink-wrap-machines/

- https://uspackagingandwrapping.com/shrink-wrap-machines/

Featured Images: pexels.com