Petg shrinkage can be a real nuisance in 3D printing, causing prints to come out smaller than expected. This is often due to the thermal contraction of the petg material as it cools.

One major contributor to petg shrinkage is the cooling rate of the print. If the print cools too quickly, the petg material can contract rapidly, leading to shrinkage. This can result in prints that are smaller than the intended size.

In addition to cooling rate, the layer adhesion of petg also plays a significant role in shrinkage. Poor layer adhesion can cause the layers to separate, leading to uneven shrinkage and a distorted print.

Causes and Effects of PETG Shrinkage

PETG shrinkage can occur due to high temperatures, exceeding 80°C (176°F), which causes the material to contract and lose its shape. This temperature range is critical because it's the point at which PETG's molecular structure begins to break down.

Moisture exposure is another significant contributor to PETG shrinkage, as it can cause the material to absorb water and expand, leading to uneven contraction and warping.

The rate of cooling also plays a crucial role, as rapid cooling can cause the material to contract too quickly, resulting in shrinkage.

Causes of 3D Printing

Shrinkage in 3D printing is a real phenomenon, and it's essential to understand what causes it.

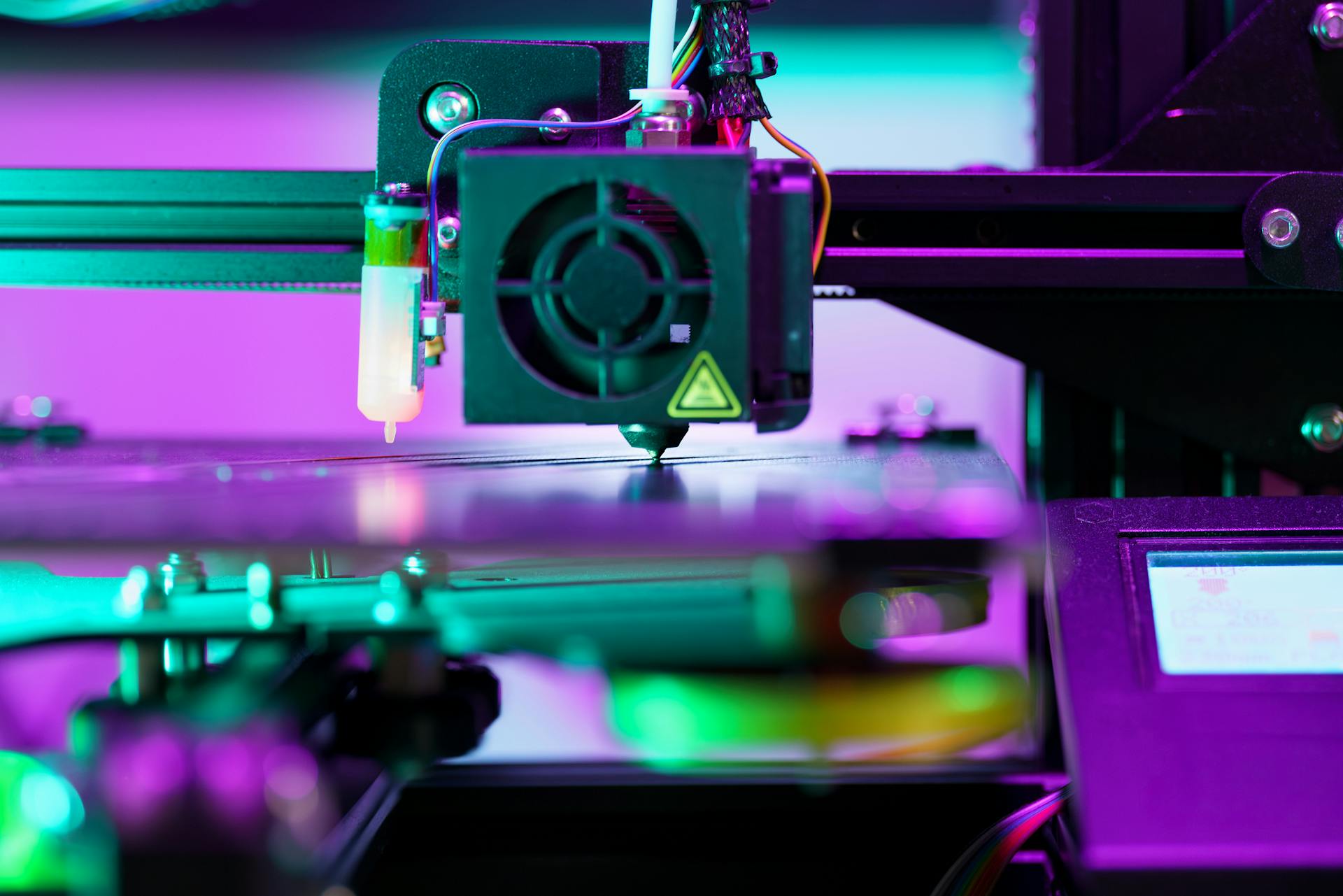

Printing temperature is a significant factor in shrinkage. Printing at the wrong temperature can lead to uneven cooling and shrinkage.

Cooling speed also plays a crucial role in shrinkage. Faster cooling speeds can cause the material to contract and shrink.

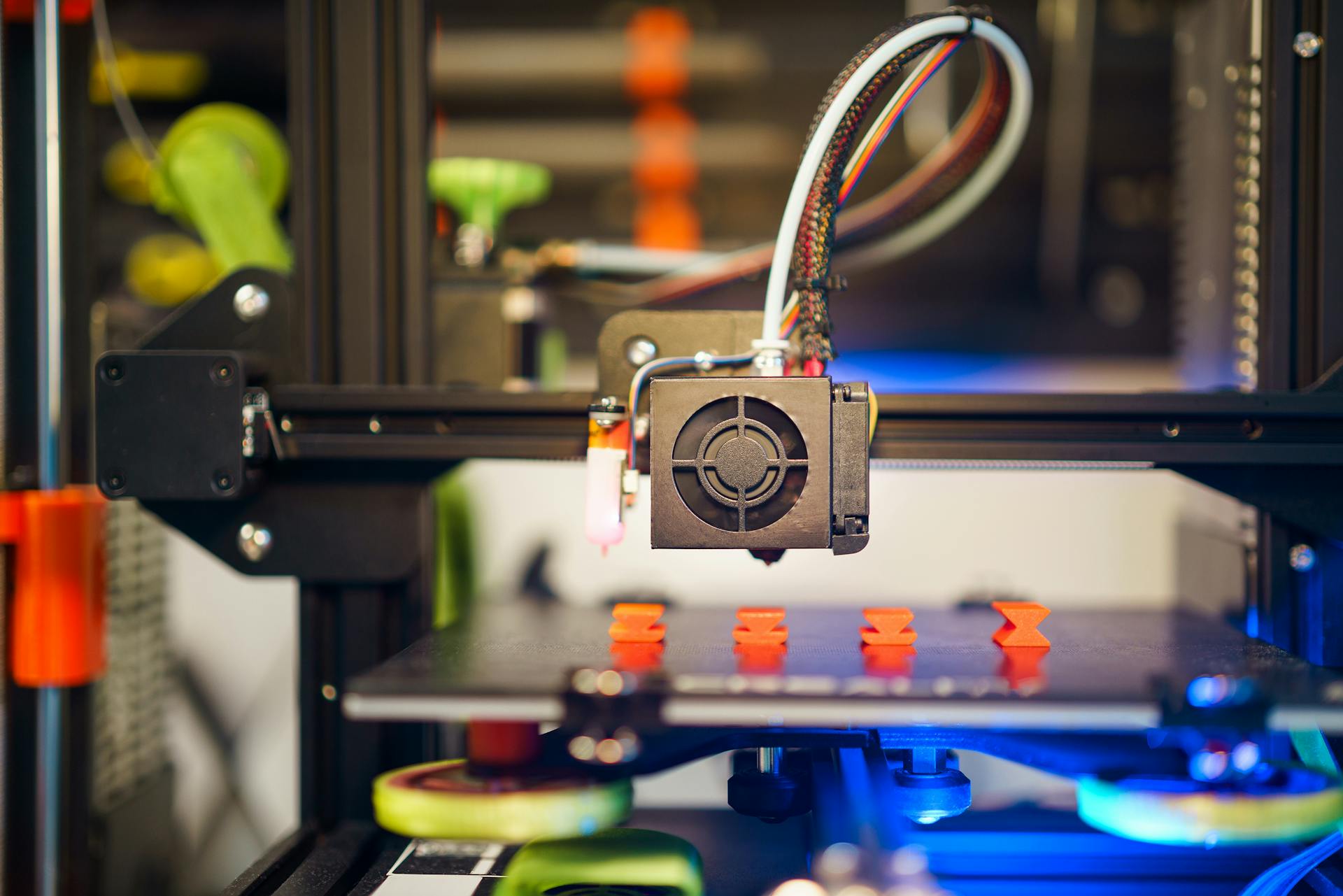

The printing technology used can also contribute to shrinkage. Different technologies have varying levels of control over temperature and cooling speed.

The material used for printing is another critical factor in shrinkage. Some materials are more prone to shrinkage than others.

Here's a summary of the main causes of 3D printing shrinkage:

- Printing temperature

- Cooling speed

- Printing technology

- The material used for printing

Definition

The shrinkage factor is a crucial concept in understanding PETG shrinkage. It refers to the percentage by which the PETG shrink film reduces in size when heat is applied during the shrink-wrapping process.

The shrinkage factor is critical in determining how tightly the film conforms to the shape of the product being packaged. This is especially important in industries where precise packaging is required.

A high shrinkage rate is typical of PETG shrink films, often between 70% to 80% in one direction, usually the transverse direction. This rate can vary depending on the specific formulation and thickness of the film.

Print Distortion:

Print Distortion is a common issue that arises from PETG shrinkage. Shrinkage causes the graphics or text printed on the PETG film to distort if not properly accounted for during design.

The shrinkage factor must be considered when creating the artwork, especially if the shrinkage is not uniform across the film.

To compensate for this, designers often pre-distort the print, ensuring that once the film shrinks, the final appearance is correct.

Here are some key factors to consider when designing for PETG shrinkage:

- Shrinkage factor

- Uniformity of shrinkage

- Pre-distortion of print

By taking these factors into account, you can minimize the risk of print distortion and ensure that your final product looks as intended.

PETG Shrinkage and 3D Printing

PETG shrinkage is caused by thermal expansion and thermal contraction, which affect the dimensions of your 3D printed model.

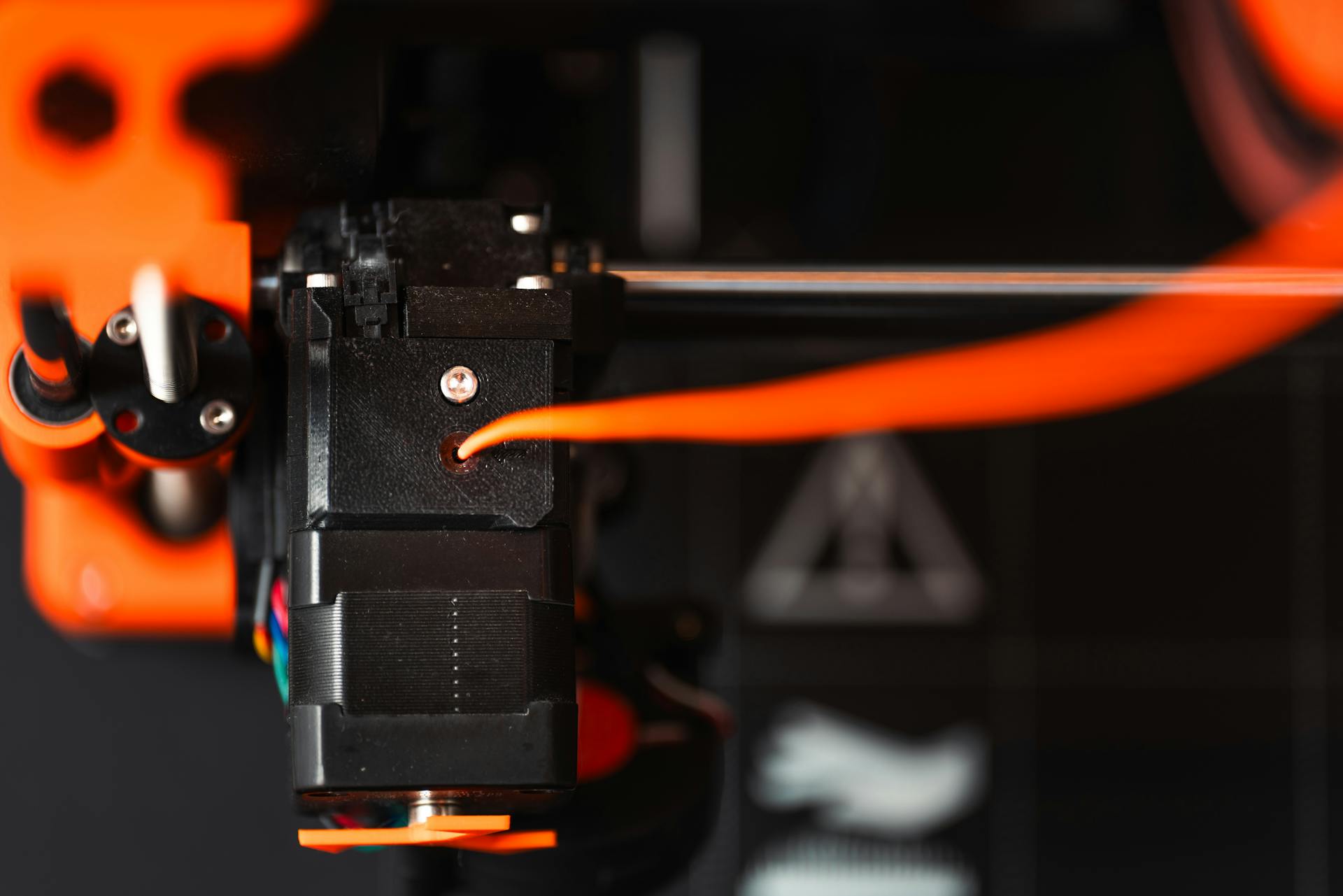

The plastic thermally expands due to the extreme temperatures of the nozzle, making it larger than it should be while it's in its melted state.

This expansion is followed by rapid cooling, causing the plastic to contract and become dimensionally smaller than it was in its melted state, which we call shrinking.

The temperature of the nozzle, the cooling speed, and the material used for printing all contribute to PETG shrinkage.

Thermal contraction occurs when the plastic rapidly cools down due to the ambient temperature and the build plate temperature, which are much lower than the nozzle temperature.

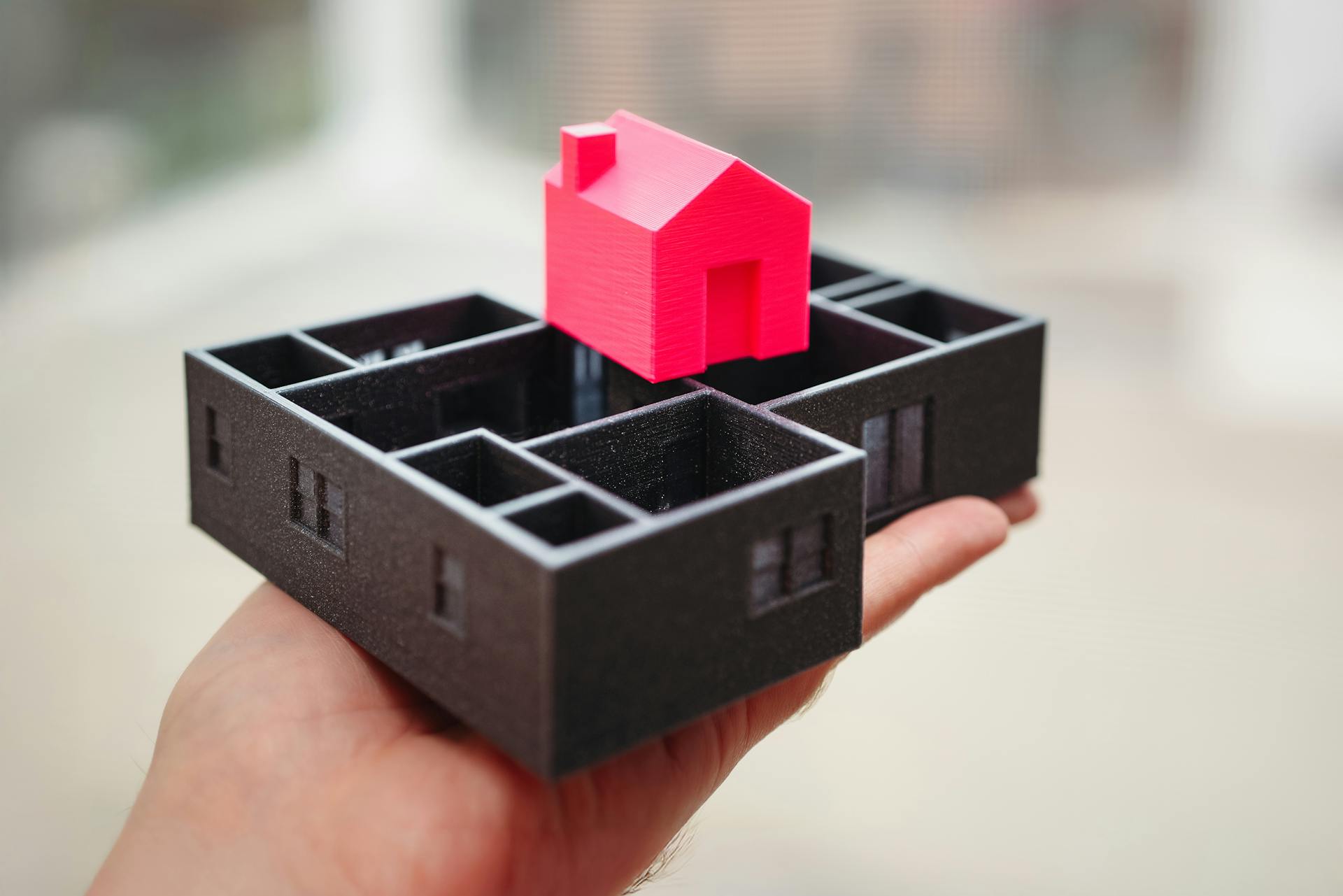

PETG shrinkage can result in a reduction in the dimensions of your 3D printed model, making it slightly smaller than the original dimensions you input into the slicer.

The following factors contribute to PETG shrinkage:

- Printing temperature

- Cooling speed

- Printing technology

- The material used for printing

These factors can be managed to minimize PETG shrinkage and achieve more accurate prints.

PETG Shrinkage and Print Quality

Print distortion can be a major issue with PETG film, causing graphics or text to distort during the shrink process if not properly accounted for during design.

The shrinkage factor must be considered when creating the artwork, especially if the shrinkage is not uniform across the film.

Designers often compensate for print distortion by pre-distorting the print, ensuring that once the film shrinks, the final appearance is correct.

PETG's Impact on 3D Printing

PETG shrinkage affects the 3D printing process, causing your 3D printed model to become slightly smaller than the original dimensions you input into the slicer.

Thermal expansion is one of the two things that contribute to shrinkage, where the plastic becomes larger than it should be while it's in its melted state due to extreme temperatures of the nozzle.

The plastic rapidly cools down when it makes its way out of the nozzle and onto the build plate, causing thermal contraction and making the plastic dimensionally smaller than it was in its melted state.

Cooling speed plays a significant role in shrinkage, with freshly printed objects experiencing more shrinkage when they cool down quickly.

The ambient temperature can also impact geometrical accuracy, with objects cooling down too quickly in an open environment experiencing more shrinkage than those cooling down in an enclosure.

Conformity to Product Shape

A higher shrinkage factor allows the film to conform closely to irregularly shaped products, resulting in a smooth, tight wrap that enhances the visual appeal of the packaging. This is particularly useful for products with complex geometries.

A higher shrinkage factor means the film will cling tightly to the product, reducing wrinkles and loose sections in the packaging. This can be especially important for products that need to be displayed in a retail setting.

A lower shrinkage factor might not conform as tightly, which could result in wrinkles or loose sections in the packaging, reducing the overall appearance and protection. This can be a problem if the product is sensitive to damage.

The tight wrap provided by a higher shrinkage factor can also help to prevent product movement during shipping, which can reduce the risk of damage. This is especially important for fragile products.

Clarity and Gloss

The clarity and gloss of PETG film can be affected by the shrinkage process.

A uniform shrinkage ensures that the film remains clear and glossy, maintaining a high-quality appearance.

Uneven shrinkage can lead to areas of distortion, reducing clarity. This distortion can be a major issue, especially if you're working with large prints or complex designs.

A uniform shrinkage process is crucial to maintaining the film's clarity and gloss.

Material Waste:

Material waste is a real concern when working with PETG film, and one factor that can greatly impact it is the shrinkage factor. A higher shrinkage factor can reduce material waste by allowing more of the film to be utilized in wrapping irregular shapes.

However, if not properly managed, it can also lead to excess shrinkage, where the film pulls too tightly, potentially damaging the product or the packaging. This is why it's essential to consider the shrinkage factor when cutting the film to size before application.

Miscalculations can result in insufficient coverage or excessive waste, which can be costly and time-consuming to rectify.

Packaging Integrity

The right shrinkage factor in PETG film is crucial for packaging integrity. It ensures a secure, tamper-evident seal that protects the product from environmental factors like moisture and contaminants.

Properly shrunk PETG film enhances the durability of the packaging, making it withstand handling, transportation, and shelf life.

PETG Shrinkage and Filament Selection

PETG is one of the least susceptible filaments to shrinking, with an average shrinkage rate of only 0.6%. This makes it ideal for making detailed models with accurate dimensions.

However, it's worth noting that the actual concentration of PETG between different filaments can show a high degree of variance, which can affect the shrinkage rate. Low-end brands may use less pure PETG and more filler material, leading to varying shrinkage rates.

PETG's thermal properties, such as thermal expansion and contraction, also play a significant role in determining its shrinkage rate. This is why running your own experimentations to find the real shrinkage rate can yield the best results.

In some cases, different brands of the same filament can have different shrinkage rates, adding to the variation in shrinkage percentages.

Printing Filament

When choosing a filament for 3D printing, the type of filament you select can significantly impact the level of shrinkage in your prints.

Filaments behave differently when cooling, with shrinkage happening once the temperature drops below the glass transition temperature.

The glass transition temperature varies across filaments, meaning one filament might shrink more than another. In some cases, different brands of the same filament will have different shrinkage rates.

ABS is a popular filament for making rigid, long-lasting objects and toys, but it's notoriously sensitive to temperature changes during the printing process. It cools much slower than PLA, requiring steady temperatures to prevent deformities.

Cooling speed is another factor that affects shrinkage, with filaments cooling faster resulting in less shrinkage.

Here's a brief comparison of some common filaments:

Filaments with a high glass transition temperature are more prone to shrinkage, so it's essential to choose a filament that suits your printing needs.

Core Considerations for Film Selection

Selecting the right film for your PETG project is crucial to achieving the desired result. Consider the product's geometry and how the film needs to conform to it.

High shrinkage may be necessary for complex shapes. This is because the film needs to tightly wrap around the product without wrinkles or creases.

Factor in the need for precise print alignment after shrinkage. Adjusting artwork as necessary to compensate for the expected shrinkage is essential to avoid misaligned prints.

Ensure that the shrink tunnels or heat application devices are calibrated to the correct temperature for the desired shrinkage factor. This will prevent overheating or underheating, which can affect the final product's quality.

Bonpet 1U

Bonpet 1U is a clear PETG film that combines the same shrinkage characteristics of B10 with an optical brightener additive for tamper-evident performance.

This film can be detected using UV light for fast and reliable security checks. The detection of a secure closure is ensured with this feature.

Bonpet 1U can also be successfully printed by any print method if desired.

Bonpet 8a

Bonpet 8A is a clear PETG film that exhibits a unique combination of high ultimate transverse direction (TD) shrink and machine direction (MD) growth.

This high ultimate TD shrink makes Bonpet 8A ideal for packages with complex geometries that require a high degree of shrink to conform fully and avoid "flowering".

The MD growth is a beneficial feature that can permit film savings in applications where the sleeve height is often over-sized to compensate for the inherent MD shrink of traditional PETG films.

A water-based antistatic coating is applied to one side of the film, which is wound to be the outside surface of the finished roll.

The inside surface of the film is the preferred print side for Bonpet 8A.

PETG Shrinkage and Comparison

PETG has an average shrinkage rate of 0.6%, making it ideal for making detailed models with accurate dimensions.

This rate is slightly higher than PLA, which has a shrinkage rate of around 0.2% to 0.3%.

The difference in shrinkage between PETG and PLA is minor, making it easy to compensate for shrinkage while printing with either material.

Bonpet 7X

Bonpet 7X is a matte white PETG film designed to have high ultimate transverse direction (TD) shrink coupled with machine direction (MD) growth. This unique property makes it an excellent choice for applications where shrinkage is a concern.

The B7X film offers high opacity, which provides enhanced light protection for package contents. This is especially useful for products that are sensitive to light.

A matte finish and opacity are achieved by micro-voiding the film, which reduces its specific gravity. This results in a high-yield film compared to clear PETG films.

Flexographic, offset, or digital printing are the preferred print methods for B7X. This is because these methods can effectively take advantage of the film's unique properties.

A water-based antistatic coating is applied to one side of the film, which is wound to be the outside surface of the finished roll.

How Much Do ABS and PLA Prints Shrink?

ABS prints suffer from significant shrinkage, with rates ranging from 1% to 5%. This is due to the high printing temperature required for ABS, which can cause the material to contract more than other plastics.

PLA, on the other hand, experiences little shrinkage, with rates of between 0.2% and 3%. This is because PLA has a lower printing temperature than ABS, which reduces the amount of contraction.

One way to reduce shrinkage in PLA is to print in an enclosed environment, which helps to maintain a consistent temperature and reduce physical stress on the model. This can be achieved by using a 3D printing enclosure, such as the Creality Fireproof & Dustproof Enclosure from Amazon.

The printing temperature is a key factor in determining the amount of shrinkage in a 3D print. ABS requires a higher temperature than PLA, which can lead to more significant contraction.

Here's a comparison of the shrinkage rates for ABS and PLA:

It's worth noting that the color of the filament can also affect the amount of shrinkage, with darker colors tend to shrink more than lighter colors. However, this is an extreme case and can be reduced with the right setup.

Pla Shrink Comparison

PLA has a shrinkage rate of around 0.2% to 0.3%.

This is slightly less than PETG's shrinkage rate on average.

The difference in shrinkage between PLA and PETG is minor, making it easy to compensate for the shrinkage while printing with either filament.

PETG Shrinkage Compensation and Calculation

PETG shrinkage compensation is crucial to ensure your model retains its original dimensions. To compensate for PETG shrinkage, scale your model up in the slicer software by the shrinkage rate of PETG, which is typically between 0.3% to 0.6%.

You can find the real shrinkage rate value by running a test print with the original dimensions of your model. Measure the dimensions of the finished model, note them down, and compare them to the original values you inputted into the slicer software.

To calculate the shrinkage rate, divide the measurements you took by the original dimension values, multiply the result by 100, and then subtract it from 100. For example, if your model has actual dimensions of 39.8×39.8×39.8, and you were planning to print a 40x40x40 cube, the shrinkage rate would be 0.5%.

Here's a step-by-step guide to calculate the shrinkage rate:

- Divide the measurements you took by the original dimension values.

- Multiply the result by 100.

- Subtract the result from 100.

How to Get Proper Compensation in 3D Printing

Compensating for PETG shrinkage is crucial to ensure your 3D printed model has the dimensions you intended. The good news is that PETG is one of the least susceptible filaments to shrinking, with an average shrinkage rate of only 0.6%.

To compensate for PETG shrinkage, you can scale up your model in the slicer software by the shrinkage rate of PETG. This will print a model that is slightly larger than its original dimensions, negating the effects of shrinkage and retaining the actual dimensions.

The shrinkage rate of PETG varies between 0.3% to 0.6%, depending on the exact PETG filament you use. Running your own experimentations to find the real shrinkage rate will yield the best results.

You can calculate the shrinkage rate by measuring your model, noting the dimensions down, and comparing these dimensions to the original values you inputted into the slicer software. To do this, divide the measurements you took by the original dimension values, multiply the value you found with 100, and then subtract the value you found from 100.

Here's a simple formula to calculate the shrinkage rate:

1. Divide the measurements you took by the original dimension values.

2. Multiply the value you found with 100.

3. Subtract the value you found from 100.

For example, let's say you were planning to print a 40x40x40 cube, and the measurements you took showed that the actual object has dimensions of 39.8×39.8×39.8. By following the formula, you'll find that the shrinkage rate is 0.5%.

You can also use a setting called Horizontal Expansion in your slicer software to adjust the size of your 3D prints in the X/Y dimension, compensating for changes in size as the model cools and shrinks. This can be a more accurate way to compensate for shrinkage, especially if you're printing with PETG.

Compensating for shrinkage is not a one-off attempt; you'll need to test out a couple of prints before figuring out the correct values to use to offset shrinkage changes. However, it's an excellent way to get pinpoint accuracy on your 3D prints without spending a fortune on high-end printers.

Bonpet Renew C66

The Bonpet Renew C66 is a clear crystallizable PETG heat-shrink film designed for shrink labels that can be reclaimed with PET bottle flake in the PET mechanical recycling process.

It provides high ultimate transverse direction (TD) shrink coupled with low machine direction (MD) growth to conform to a range of container designs.

A water-based antistatic coating is applied to one side of the film, specifically the outside surface of the finished roll.

The inside surface of the film is the preferred print side, making it suitable for various print methods.

Bonpet Renew C66 can be successfully printed by any print method, making it a versatile option for label production.

PETG's Impact on 3D Printing

PETG shrinkage is a real issue in 3D printing, causing your model to become slightly smaller than the original dimensions you input into the slicer.

Thermal expansion is one of the main contributors to shrinkage, where the plastic expands due to the extreme temperatures of the nozzle, making it larger than it should be in its melted state.

The plastic rapidly cools down when it hits the build plate, causing thermal contraction and making it dimensionally smaller than it was in its melted state, which we call shrinking.

This means your 3D printed model will be smaller than you expected, and it's essential to understand this process to take the necessary steps for compensation.

The extreme temperatures of the nozzle are what cause the plastic to thermally expand, making it larger than it should be in its melted state.

Frequently Asked Questions

Which shrinks more, PLA or PETG?

PLA shrinks very little, while PETG has noticeable shrinkage, but less than ABS. If you're concerned about shrinkage, PLA is a good choice for minimal distortion.

Sources

- https://www.3dsourced.com/guides/3d-print-shrinkage-pla-abs-petg/

- https://www.hyfpack.com/news/effects-of-petg-shrink-film-shrinkage-factor.html

- https://www.bonset.com/heat-shrinkable-film-products/petg-heat-shrink-film/

- https://3dprinterly.com/pla-abs-petg-shrinkage-compensation-in-3d-printing/

- https://www.3dprintbeast.com/petg-shrinkage/

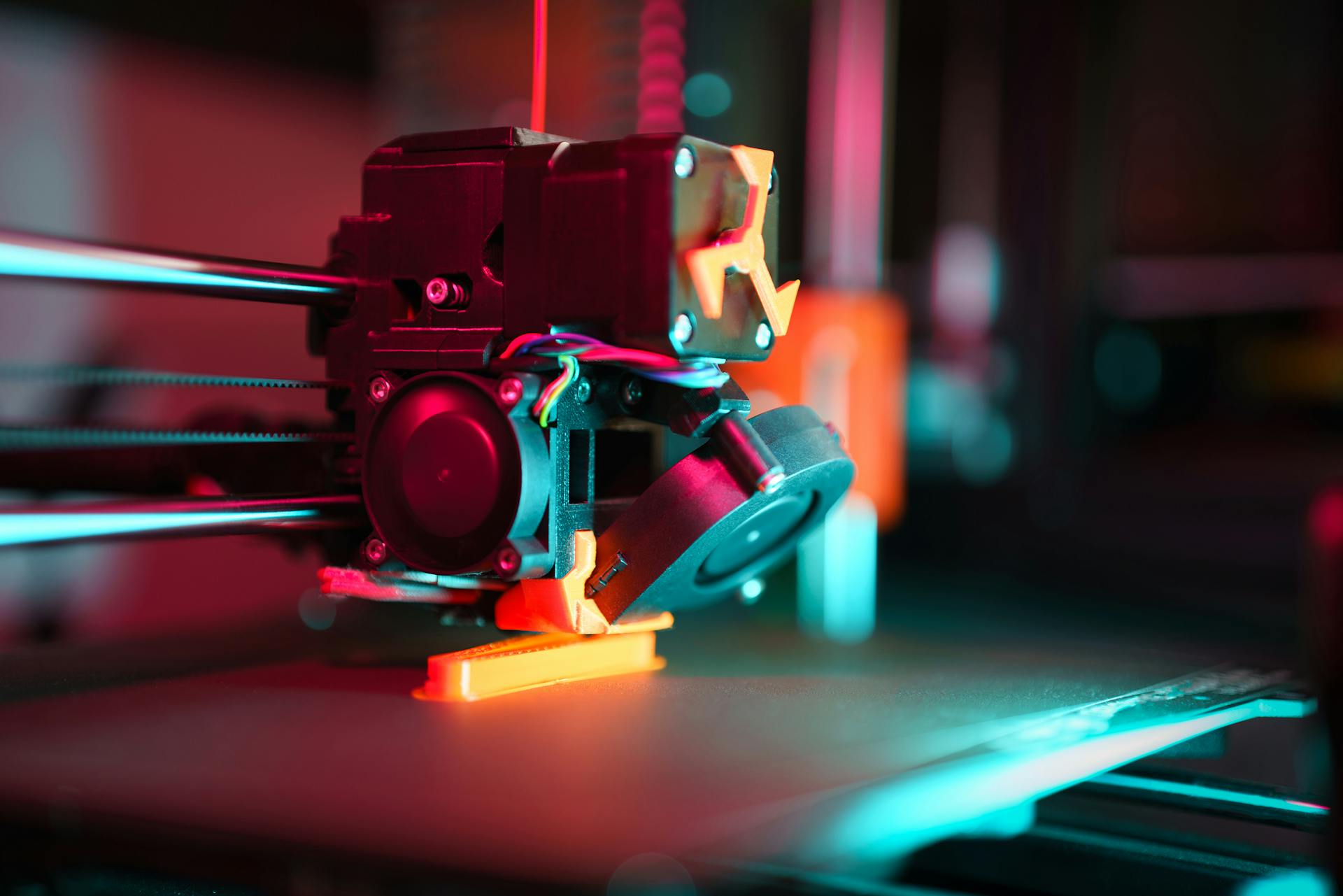

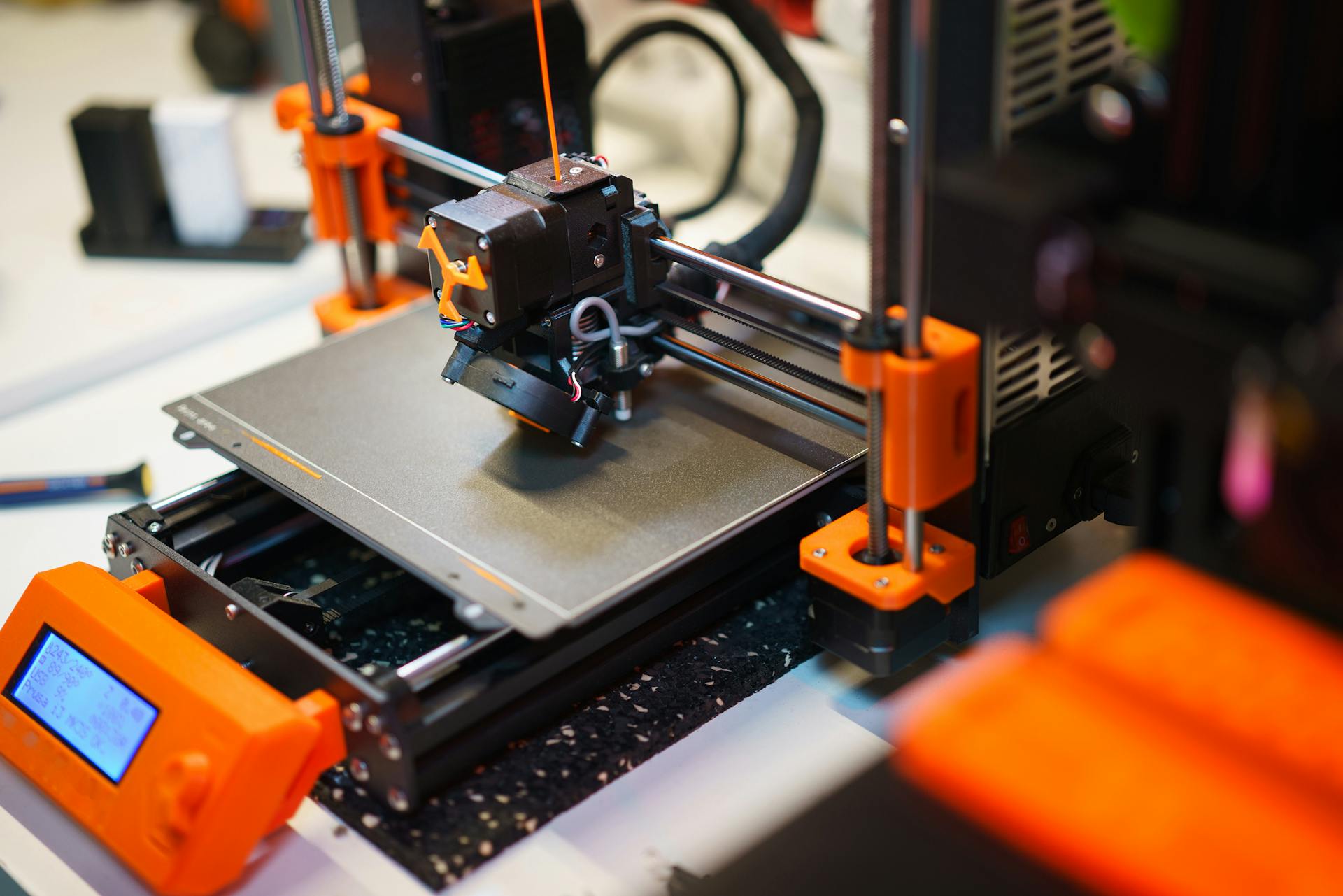

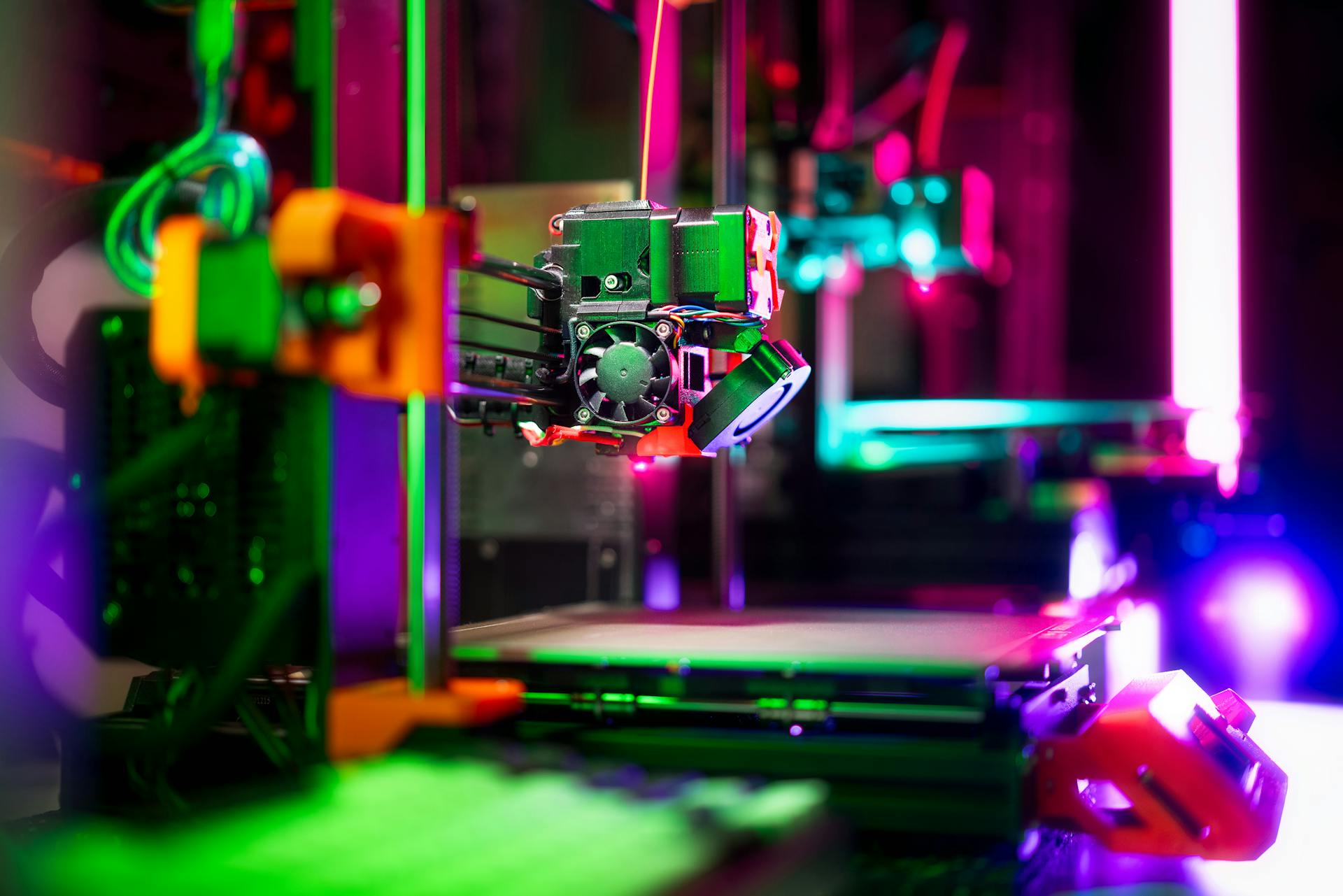

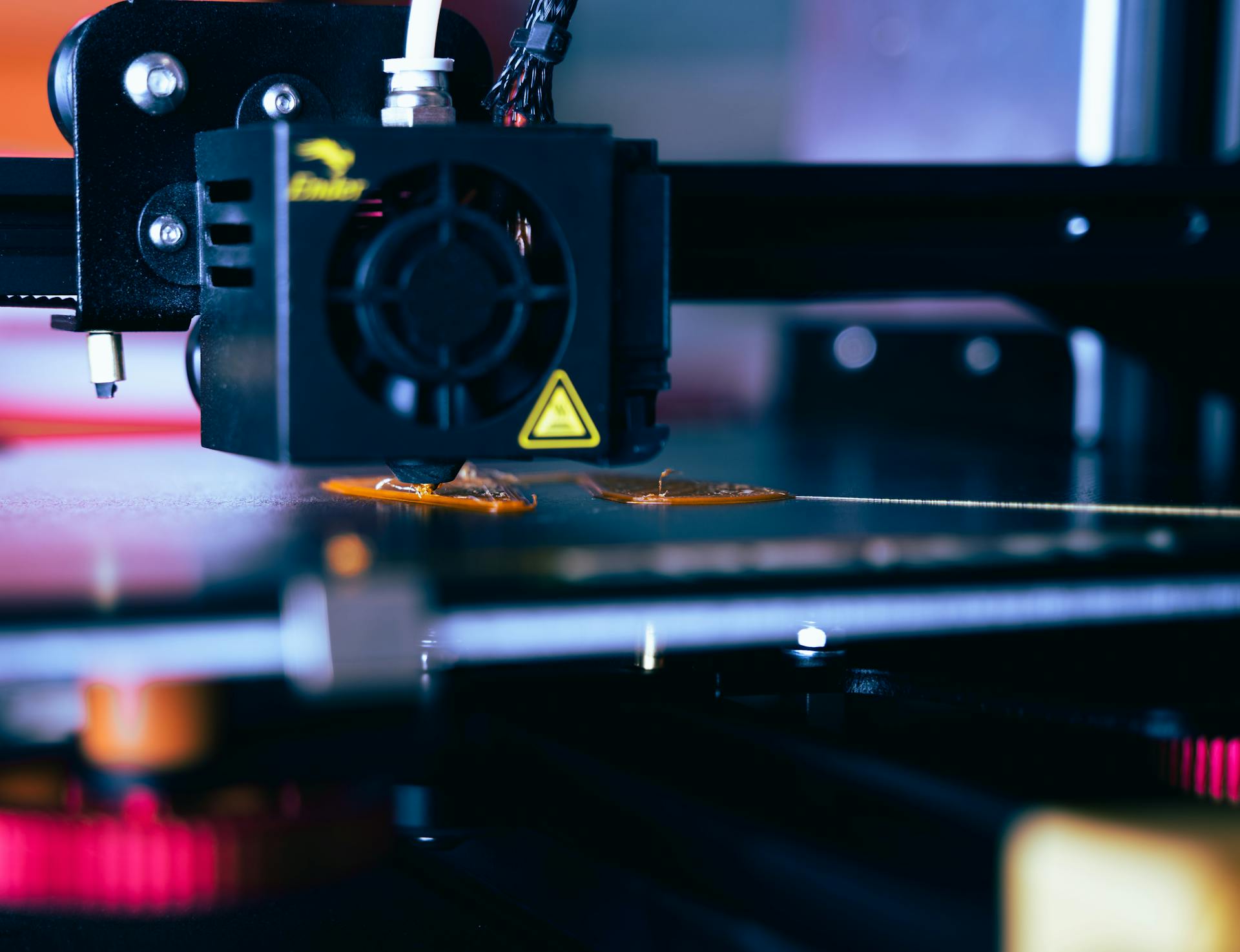

Featured Images: pexels.com