The old corrugated cardboard industry is a fascinating space, and there are some interesting trends and statistics worth noting. In the US alone, over 90% of corrugated containers are recovered for recycling.

One of the most significant statistics is that the average American generates about 4.4 pounds of corrugated cardboard waste per day. This adds up quickly, with the US generating over 100 million tons of corrugated cardboard waste each year.

The demand for corrugated cardboard is also on the rise, with the global market expected to reach 170 million tons by 2025. This growth is driven in part by the increasing use of e-commerce and online shopping.

You might like: Wine Gift Box Cardboard

What Is OCC?

Old corrugated cardboard, or OCC, is a type of recyclable material.

OCC is made from old corrugated cardboard boxes, which are collected and sorted from households, businesses, and other sources.

The cardboard is then processed into a bale, which can be sold to paper mills or other manufacturers.

These bales are typically 40 inches long and weigh around 1,000 pounds.

OCC is used to make new paper products, such as cardboard boxes, paperboard, and even tissue products.

It's also used as a fuel source in some facilities, providing a renewable energy option.

See what others are reading: Old Chicago Main Post Office

Characteristics and Standards

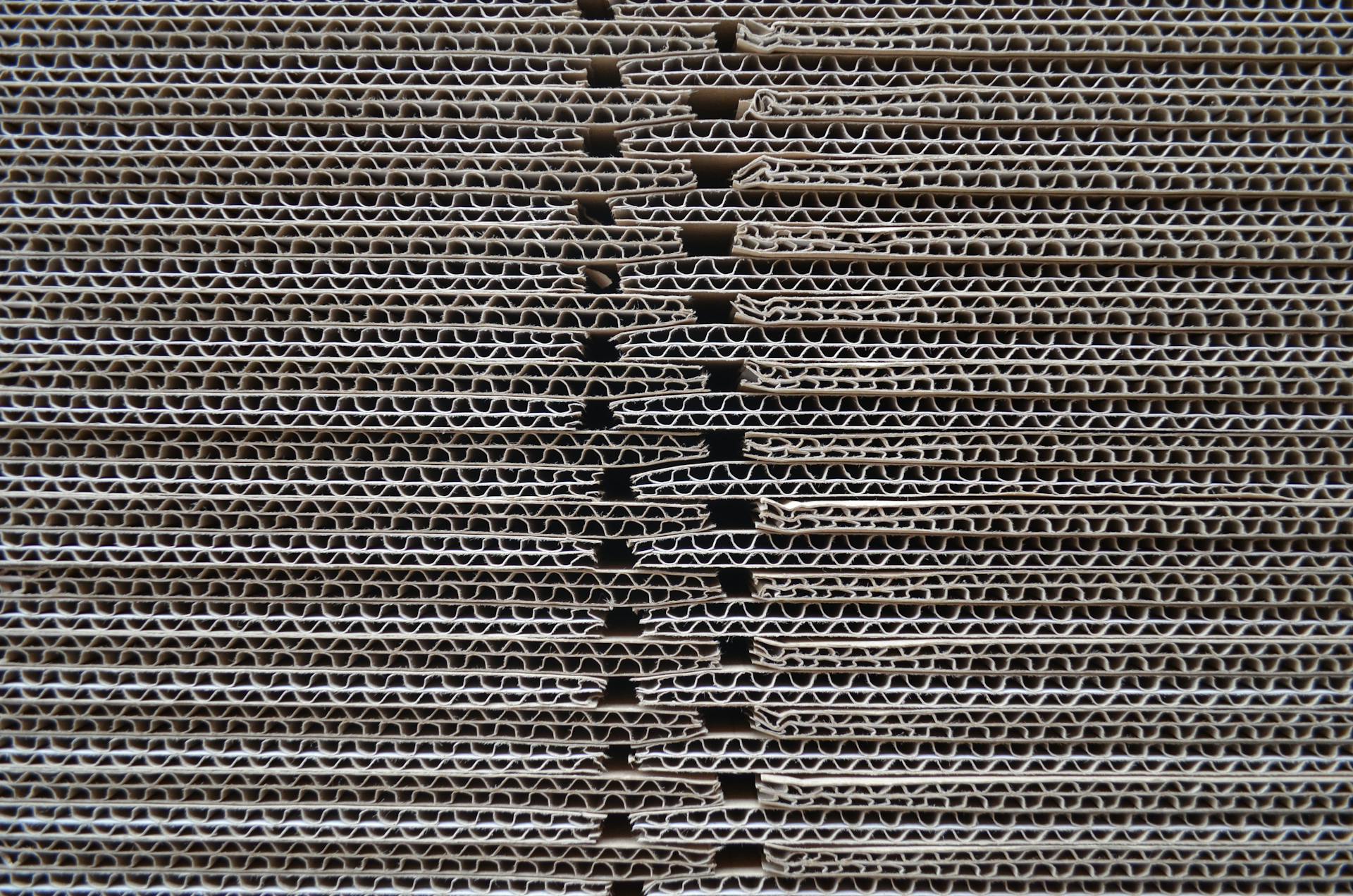

Old Corrugated Cardboard has a distinctive wavy inner layer, also known as fluting, which provides structural strength and rigidity.

This corrugated design allows boxes to hold their shape under weight and resist crushing, making OCC useful for shipping temperature-sensitive items.

The recycling industry adheres to specific guidelines to ensure the quality and purity of recycled OCC, including parameters such as the percentage of Prohibitive Materials and Outthrows.

The #11 grade is a well-known standard for Old Corrugated Cardboard recycling, indicating the quality and purity of the material.

Related reading: Old Town Main Post Office

Standards

The standards for recycling Old Corrugated Cardboard (OCC) are crucial for ensuring its quality and purity. The recycling industry adheres to specific guidelines to achieve this.

These guidelines typically include parameters such as the percentage of Prohibitive Materials. The presence of these materials can greatly impact the recyclability of OCC.

Outthrows are also an important consideration in OCC recycling. They refer to materials that are not recyclable and must be removed from the process.

The #11 grade is a well-known standard for OCC. It represents a high-quality grade of recycled cardboard.

Characteristics

OCC is easily recognizable by its characteristic wavy inner layer, also known as fluting, which provides structural strength and rigidity. This design allows boxes to hold their shape under weight and resist crushing.

The corrugated design of OCC also provides some level of insulation, making it useful for shipping temperature-sensitive items.

Its unique fluting pattern gives OCC a distinct look and feel, making it easy to identify in a stack of boxes.

Worth a look: Wine Storage Boxes Cardboard

Environmental Impact

Old corrugated cardboard has a significant impact on the environment, and it's largely positive. One of the key aspects of OCC is its recyclability, making it one of the most recycled materials globally.

Properly managed OCC recycling can significantly reduce the demand for virgin paper pulp, thereby reducing deforestation and conserving natural resources. This is because OCC is made from wood pulp fiber, which can be reprocessed into new forms.

Old corrugated containers can be crushed and used as a packing or cushioning material, or they can be recycled into new paper, fiber, and packaging materials. The packaging industry size is estimated to grow from USD 1.20 trillion in 2022 to reach an estimated USD 1.58 trillion by 2032.

In fact, the technique of recycling OCC is quite straightforward as long as it is clean, dry, and devoid of pollutants like food, oil, wax coatings, and strong adhesives. This makes it easy for companies to gather and sell OCC to recycling facilities, generating extra revenue.

Here are some ways companies are saving money on packing and shipping by using OCC:

- Manufacturers, retailers, and logistics service providers save money on packing and shipping.

- Offices and companies can generate extra revenue by gathering and selling OCC to recycling facilities.

- Old Corrugated Container can be crushed and used as a packing or cushioning material, or it can be recycled into new paper, fiber, and packaging materials.

Upcycling and Reuse

Ocean Ridge Group, a global leader in forest product commodities, has been a prominent North American trader since 2018.

Established in Toronto, Canada, they specialize in a diverse range of products, including containerboard, market pulp, and recycled fibers.

Beyond traditional recycling processes, old corrugated cardboard can be repurposed through upcycling and creative reuse.

Artists, designers, and innovators have embraced the potential of cardboard to create unique and functional products, such as furniture and home décor.

Upcycling cardboard extends the lifespan of the material and reduces the demand for new resources.

The versatility of OCC allows for endless possibilities, from artistic installations to practical items.

By giving old cardboard a new life, we can reduce waste and contribute to a circular economy.

Established in 2018, Ocean Ridge Group is a distinguished global leader that has been promoting sustainable reuse of OCC.

Market and Industry

The old corrugated cardboard market is a significant industry, with Asia Pacific leading the market in 2023. This region holds the largest share, making it a key player in the global market.

The market is also growing rapidly in North America, which is expected to be the fastest growing region over the forecast period. This growth is driven by emerging markets and trends, as well as increasing regulatory support.

In terms of grades, OCC 12 segment dominated the market with the largest share in 2023. This segment is a crucial part of the old corrugated cardboard market, and its growth is expected to continue in the future.

Here are some key statistics about the old corrugated cardboard market:

- Asia Pacific led the market with the largest share in 2023.

- North America is expected to be the fastest growing region over the forecast period.

- OCC 12 segment dominated the market with the largest share in 2023.

- Retail segment is expected to grow at a significant rate during the forecast period.

- Food & beverage segment dominated the old corrugated container market in 2023.

Market Size

The market size for the industry is projected to reach $1.2 trillion by 2025, driven by increasing demand for innovative solutions.

This growth is fueled by the rising adoption of digital technologies, which is expected to reach 90% of the global population by 2023.

The industry's large market size is also due to its vast reach, with over 500 million users worldwide in 2022.

The increasing demand for sustainable and eco-friendly products is also driving growth in the industry, with 70% of consumers preferring environmentally responsible brands.

Market Segments

The old corrugated container market is divided into several segments, each with its own unique characteristics and growth prospects. The Asia Pacific region led the market with the largest share in 2023.

The market is also segmented by grade, with OCC 12 dominating the market with the largest share in 2023. This segment is expected to continue its dominance in the coming years.

By source, the retail segment is expected to grow at a significant rate during the forecast period. This is due to the increasing popularity of e-commerce and the need for durable and protective packaging.

The food & beverage segment dominated the old corrugated container market in 2023, with a significant share of the market. This segment is expected to continue its growth in the coming years.

In terms of geography, Europe is estimated to grow notably in the upcoming period, driven by the adoption of sustainable practices and the use of old corrugated containers as a branding tool by retailers.

Here's a breakdown of the market segments:

Impact of China's E-commerce

The growth of e-commerce has led to a significant increase in home deliveries, resulting in more corrugated containers being used and ultimately, more OCC generation in city recycling programs.

This has posed new challenges for recycling, as the traditional collection systems are not equipped to handle the surge in OCC generation.

The continued growth of e-commerce has resulted in more home deliveries, creating a ripple effect on the recycling industry.

OCC generation in city recycling programs has increased due to the rise of e-commerce, making it essential for recycling programs to adapt to this new reality.

The increased demand for corrugated containers has led to a higher volume of OCC being generated, which poses a challenge for recycling programs to manage efficiently.

Production and Quality

The production and quality of old corrugated cardboard can be a challenge due to fluctuation in the prices of recycled paper and raw materials. This can affect the stability and attractiveness of the market.

Contaminants and low-quality old corrugated containers can complicate the recycling process, reducing efficiency and profitability. This is a major concern for key players in the market.

Economic slowdowns can reduce demand for packaging materials and recycling services, impacting the overall old corrugated cardboard market.

Difference Between Grade 11 and 12

The difference between OCC Grade 11 and 12 is quite significant. OCC Grade 11 mainly includes corrugated containers used for paper recycling, with kraft, jute, or test liners.

In contrast, OCC Grade 12, also known as DS OCC or Double Sorted Corrugated, consists of double corrugated containers generated from supermarkets, commercial, and industrial facilities. These double corrugated containers have liners of jute, test liner, and/or kraft.

The materials in OCC Grade 12 are specially sorted to ensure they are free of boxboard and off-shore corrugated materials, wax, and plastic. The total out-throws for OCC Grade 12 do not exceed 2%.

Here are some key differences between OCC Grade 11 and 12:

- Grade 11 mainly includes corrugated containers, while Grade 12 consists of double corrugated containers.

- Grade 12 has stricter sorting requirements to ensure purity.

- Grade 12 has a higher standard for purity, with prohibitive materials not exceeding 2%.

The prohibitive materials for OCC Grade 12 may not exceed 2%, and the out-throws plus prohibitive's may not exceed 4%. Other acceptable papers may not exceed 30%.

Methods of Handling

To handle OCC, it's essential to open and flatten corrugated boxes before placing them in storage containers, and remove any harmful contaminants to ensure a clean and ready material for recycling.

Flattening boxes allows for better space utilization, making it easier to transport and process the material. This simple step can make a big difference in the overall efficiency of the recycling process.

Before deciding whether to bale or not, consider the amount of OCC your business generates. Small businesses with a small amount of OCC can manually bundle it, store it in a suitable container, and have it collected by a hauler.

In contrast, businesses with a large amount of OCC should use large storage containers and compact or bale it using an industrial baler for efficient transportation to recycling centers. This helps reduce transportation costs and increases the density of the material.

Production Statistics

In 2016, a record 67.2% of paper and paperboard was recovered for domestic and export use.

Paper and paperboard recovery rates have improved significantly over the years, with a notable jump from 72% in 2006 to 89.5% in 2014.

On average, a corrugated box contains roughly 50% recycled fiber.

Around 51% of OCC is used to make new corrugated board, with 11.5% used for boxboard materials, such as cereal boxes.

Recycling OCC has contributed to a reduction in greenhouse gas emissions, with the corrugated industry reducing its emissions by 35% between 2006 and 2014.

A small convenience store can generate between 700-1000 lbs of OCC per month, while a grocery supermarket can generate between 8-30 tons during that time span.

Quality Issues

Quality issues are a significant problem in the old corrugated container market. Contaminants and low-quality old corrugated containers can complicate the recycling process, reducing efficiency and profitability.

The fluctuation in prices of recycled paper and raw materials can affect the stability and attractiveness of the market. This can make it difficult for companies to operate profitably.

Inadequate or outdated recycling facilities and technologies can hinder the effective processing and utilization of old corrugated containers. This can lead to a decrease in the quality of the final product.

Economic slowdowns can reduce demand for packaging materials and recycling services, impacting the overall market. This can have a ripple effect throughout the industry.

Benefits of

Recycling old corrugated cardboard (OCC) has numerous benefits. It reduces energy and water usage while cutting the production of greenhouse gas and certain air pollutants like total reduced sulfur (TRS), volatile organic chemicals (VOCs), and hazardous air pollutants (HAP).

Recycling OCC also reduces the demand for virgin timber. It takes approximately three tons of trees to manufacture just one ton of virgin cardboard.

The recycling of one ton of cardboard saves more than nine cubic yards of landfill space. This is a significant reduction in waste that can help keep our communities cleaner.

Recycling OCC helps reduce waste tipping fees as well. This means that municipalities can save money on waste disposal, which can be redirected to other community programs.

By recycling OCC, we can conserve natural resources and reduce our environmental footprint.

Industry and Innovation

DS Smith plc is a multinational packaging company that has been at the forefront of innovation in the old corrugated cardboard industry. They designed and developed a stackable system display for Pepsi in January 2024, which minimized supply chain costs and utilized old corrugated container.

The company revealed that over 6,000 recyclable corrugated packaging solutions have been added to their product portfolio and are being sold to customers, including e-commerce and retail platforms. This is a significant milestone in the industry, demonstrating the potential of old corrugated cardboard as a sustainable packaging solution.

DS Smith's collaboration with Coca-Cola HBC Austria GmbH in September 2023 is another example of innovation in the industry. They replaced plastic shrink wrap for 1.5 litre PET soft drink multi-packs with old corrugated cardboard based outer packaging, saving over 200 tonnes of plastic annually.

Industry Advancements

DS Smith plc has been at the forefront of innovation in the old corrugated container industry. In 2023, the company collaborated with Coca-Cola HBC Austria GmbH to replace plastic shrink wrap with old corrugated cardboard based outer packaging, reducing plastic usage by over 200 tonnes annually.

The Shop.able Carriers, introduced by DS Smith in March 2024, offer consumers a convenient and sustainable packaging solution for everyday grocery shopping. This innovative box is made from old corrugated container and provides a practical alternative to traditional packaging.

Kite Packaging Ltd. has also made significant advancements in the industry, unveiling the old corrugated advanced custom-size box in March 2024. This new product showcases the versatility of old corrugated containers and their potential for various applications.

The key players in the market are adopting inorganic growth strategies, such as collaboration and partnerships, to develop new product applications from old corrugated containers. This approach is estimated to create lucrative opportunities for the growth of the old corrugated container market.

Here are some recent developments in the industry:

- DS Smith's collaboration with Coca-Cola HBC Austria GmbH

- DS Smith's introduction of the Shop.able Carriers

- Kite Packaging Ltd.'s introduction of the old corrugated advanced custom-size box

DS Smith's Packaging Innovation

DS Smith plc, a multinational packaging company, has made a significant impact with its innovative use of old corrugated container packaging. In January 2024, they designed a stackable system display for Pepsi to introduce a new flavor and minimize supply chain costs.

This display is made from old corrugated container and is both sturdy and tough in nature. Over 6,000 recyclable corrugated packaging solutions have been added to their product portfolio and are being sold to customers, including e-commerce and retail platforms.

AI Improves Industry

AI is revolutionizing the old corrugated container industry by increasing efficiency and sustainability. This is done through AI systems that can differentiate between different types of paper and pollutants, expediting processing and improving the quality of the recycled material.

AI can also forecast maintenance requirements and equipment breakdowns, cutting downtime and increasing overall operational effectiveness. This is a game-changer for businesses, allowing them to stay ahead of potential issues and maintain productivity.

Machine learning algorithms can evaluate data to estimate demand, manage inventories, and optimize transportation, improving old corrugated container collection and distribution. This leads to reduced waste and higher standards of quality.

AI-powered automation has the potential to save labor expenses and expedite the recycling process. This is a significant advantage for businesses, allowing them to reduce costs and increase efficiency.

DS Smith plc, a multinational packaging company, is already leveraging AI to innovate in the industry. They designed a stackable system display made from old corrugated container for Pepsi, minimizing supply chain costs. This is just one example of how AI is being used to drive innovation and efficiency in the industry.

Here are some examples of AI-powered innovations in the old corrugated container industry:

- DS Smith's stackable system display for Pepsi

- Shop.able Carriers, a boxes manufactured out of old corrugated container for everyday grocery shopping

- Old corrugated advanced custom-size box by Kite Packaging Ltd.

Prohibitive Materials and Regulations

The industry standard for recycling old corrugated cardboard (OCC) is strict when it comes to Prohibitive Materials, which should not exceed 1% of the total material.

This 1% threshold is crucial to maintain the quality of the recycled cardboard, ensuring it can be effectively reused.

Prohibitive Materials include contaminants like plastics, metals, and other materials that can interfere with the recycling process.

These contaminants can be a major problem if not properly removed, causing the entire batch of OCC to be rejected.

The 1% limit is a clear guideline that recyclers and manufacturers must follow to ensure the integrity of the recycling process.

Frequently Asked Questions

What is the difference between cardboard and corrugated cardboard?

Cardboard is a single-layered material, while corrugated cardboard has multiple layers, including a wavy inner layer that provides added strength and durability. This key difference makes corrugated cardboard a more versatile and widely used material in packaging and shipping.

Where can I get corrugated cardboard for free?

You can often get free corrugated cardboard from warehouse clubs like Costco, BJ's, or Sam's Club, either as a member or by asking the manager. Some stores may also offer free cardboard if you ask.

What are old corrugated containers?

Old Corrugated Containers (OCC) are made from corrugated paperboard and are a robust, versatile material used for packaging and shipping. They are commonly recognized as cardboard.

Is corrugated cardboard 100% recyclable?

Corrugated cardboard is 100% recyclable, but some treatments like wet strength or petroleum-based wax can make it non-recyclable

Sources

- https://www.ocridge.com/old-corrugated-cardboard/

- https://tradexglobalusa.com/service/old-corrugated-cardboard-occ

- https://www.iwrecycling.com/glossary/occ-old-corrugated-cardboard/

- https://www.towardspackaging.com/insights/old-corrugated-container-market-sizing

- https://www.liveabout.com/old-corrugated-cardboard-recycling-2877885

Featured Images: pexels.com