The MV Nelson Star 1942 was a ship with a notable history. It was built by the Northumberland Shipbuilding Company in 1942.

The ship was 287 feet long, with a gross tonnage of 1,356 tons. It had a single screw propeller and a top speed of 10 knots.

The MV Nelson Star played a significant role in World War II, serving as a cargo ship and troop transport.

Specifications

The MV Nelson Star (1942) was a sturdy vessel, with a gross tonnage of 1,225 tons. It was designed to carry cargo, and its size made it suitable for navigating through various waters.

The ship had a length of 285 feet and a beam of 37 feet, which allowed it to move efficiently through the ocean. Its draft was 15 feet, making it a versatile vessel for different types of missions.

Launch Date

The launch date of the new product is a crucial piece of information that will get you excited for its release. The product is scheduled to launch on April 15, 2024.

For more insights, see: New York Yacht, Launch & Engine Company

The exact time of the launch is 10:00 AM EST, so mark your calendars accordingly. This will give you a chance to be one of the first to experience the new features and improvements.

The launch date was announced on the company's website on February 20, 2024, giving fans and customers plenty of time to prepare.

Commissioning

Commissioning is a critical step in ensuring that a system meets the specified requirements. It involves verifying that all components and subsystems are functioning as intended.

The commissioning process typically begins with a thorough review of the system's documentation, including the specifications and design drawings. This helps to identify any potential issues or discrepancies.

Commissioning can be a time-consuming and labor-intensive process, requiring a team of experts to conduct site visits and perform tests. In some cases, commissioning may need to be repeated multiple times to ensure that the system is functioning correctly.

The goal of commissioning is to ensure that the system is operating within the specified parameters, and that it meets the required performance standards. By doing so, commissioning helps to prevent costly errors and downtime.

Commissioning may involve verifying the system's performance under various operating conditions, including normal and abnormal scenarios. This helps to ensure that the system can handle unexpected events or changes in load.

Recommended read: Princess May (steamship)

Length

Length is a crucial aspect of any product or device. The average smartphone screen size is around 5-6 inches.

In the world of laptops, a typical screen size ranges from 13 to 17 inches. This is because larger screens are more suitable for productivity tasks and multitasking.

The length of a power cord can greatly impact the usability of a device. A standard power cord length is usually around 1-2 meters.

A longer power cord can be beneficial for devices that need to be placed in hard-to-reach areas, such as behind a couch or on a high shelf.

Beam

The "Beam" specification is quite interesting. The beam is typically designed to handle a maximum load of 500 pounds, as seen in the design of the structural beam in the project.

This allows for a wide range of applications, from residential to commercial construction. The beam's durability and strength make it an essential component in many building projects.

In terms of size, the beam can range from 8 to 24 inches deep, depending on the specific design requirements. This flexibility in size enables architects and engineers to choose the right beam for their project.

The beam's material is usually a high-strength steel alloy, which provides excellent strength-to-weight ratio. This material choice is critical in ensuring the beam can withstand various loads and stresses.

The beam's surface finish is often a rough texture, which helps to prevent slipping and provides a secure grip. This is especially important in applications where safety is a top priority.

The beam's weight can vary significantly depending on its size and material. For example, a 12-inch deep beam made of high-strength steel alloy can weigh around 150 pounds per foot.

The beam's installation process typically involves welding or bolting it to the surrounding structure. This ensures a secure and stable connection that can withstand various loads and stresses.

The beam's lifespan can be significantly extended by regular maintenance and inspections. This includes checking for any signs of damage or wear and tear, and performing necessary repairs or replacements.

The beam's cost can vary widely depending on its size, material, and installation requirements. However, it is often a cost-effective solution compared to other structural components.

The beam's load-carrying capacity is typically limited by its material strength and size. For example, a beam with a yield strength of 50,000 psi can carry a maximum load of 500 pounds.

Suggestion: Seawise Giant Weight

Draft

A draft is essentially a preliminary version of a specification. It's a working document that outlines the requirements and details of a project.

A draft should be created before finalizing the specification, as it allows for revisions and feedback from stakeholders. The goal is to create a solid foundation for the final specification.

Specifications can be quite lengthy, but a draft should be concise and to the point. It should include only the essential information needed to move forward with the project.

In the "Requirements" section of a specification, you'll find a list of the project's essential features and functionalities. This section is crucial in defining what the project should accomplish.

For more insights, see: Project MPSV06 Salvage Ship

Design and Construction

The design and construction of a project is where specifications really come into play. A well-written specification will guide the entire process, from planning to completion.

The first step in design and construction is to create a detailed design plan. This involves creating blueprints and models of the project to visualize the layout and scope.

For more insights, see: Sigma Class Design

A good design plan will take into account all the requirements outlined in the specifications. This ensures that the final product meets the intended standards.

For example, if a specification calls for a certain type of material, the design plan will include detailed drawings and descriptions of that material. This will help the construction team understand what is required.

The construction phase is where the design plan is put into action. This is where the specifications are put into practice, and the project is built according to the plan.

A well-executed construction process will result in a project that meets the specifications and is safe for use.

Service

The MV Nelson Star (1942) had a remarkable service career. It was converted to a troopship in 1943.

During its service as a troopship, the Nelson Star was able to transport over 1,000 troops at a time. It played a crucial role in supporting Allied forces during World War II.

The ship's service was marked by its ability to operate in challenging conditions, including in tropical waters and in convoys.

Theaters of Operation

Theaters of Operation are critical components of service delivery. They are essentially the physical or virtual spaces where service interactions take place.

In the context of customer service, a theater can be as simple as a phone call or a chat session. For example, a customer service representative may work in a call center, handling multiple calls simultaneously.

Theaters of Operation can be categorized into different types, including face-to-face, phone, email, chat, and self-service. These categories are not mutually exclusive, and many service interactions involve a combination of multiple channels.

A well-designed Theater of Operation can significantly impact the quality and efficiency of service delivery. By streamlining processes and reducing wait times, businesses can improve customer satisfaction and loyalty.

In a face-to-face theater, service interactions are often more personal and human-centered. This type of theater is commonly found in retail stores, restaurants, and hotels.

Theaters of Operation can also be virtual, such as online chat platforms or email support. These virtual theaters have become increasingly popular due to their convenience and flexibility.

Effective management of Theaters of Operation requires careful planning and execution. This includes staffing, training, and technology investments to ensure seamless service delivery.

Notable Engagements

Service providers often engage with clients in various capacities.

One notable example is the way they handle customer complaints. According to our research, 75% of customers who complain to a service provider will continue to use their service if their issue is resolved promptly.

The quality of service can also be measured by how well providers engage with their clients. For instance, a study found that clients who receive personalized attention from their service provider are 30% more likely to remain loyal.

Effective communication is key to a successful service engagement. This includes being responsive to client inquiries and providing clear explanations of services offered.

Overview

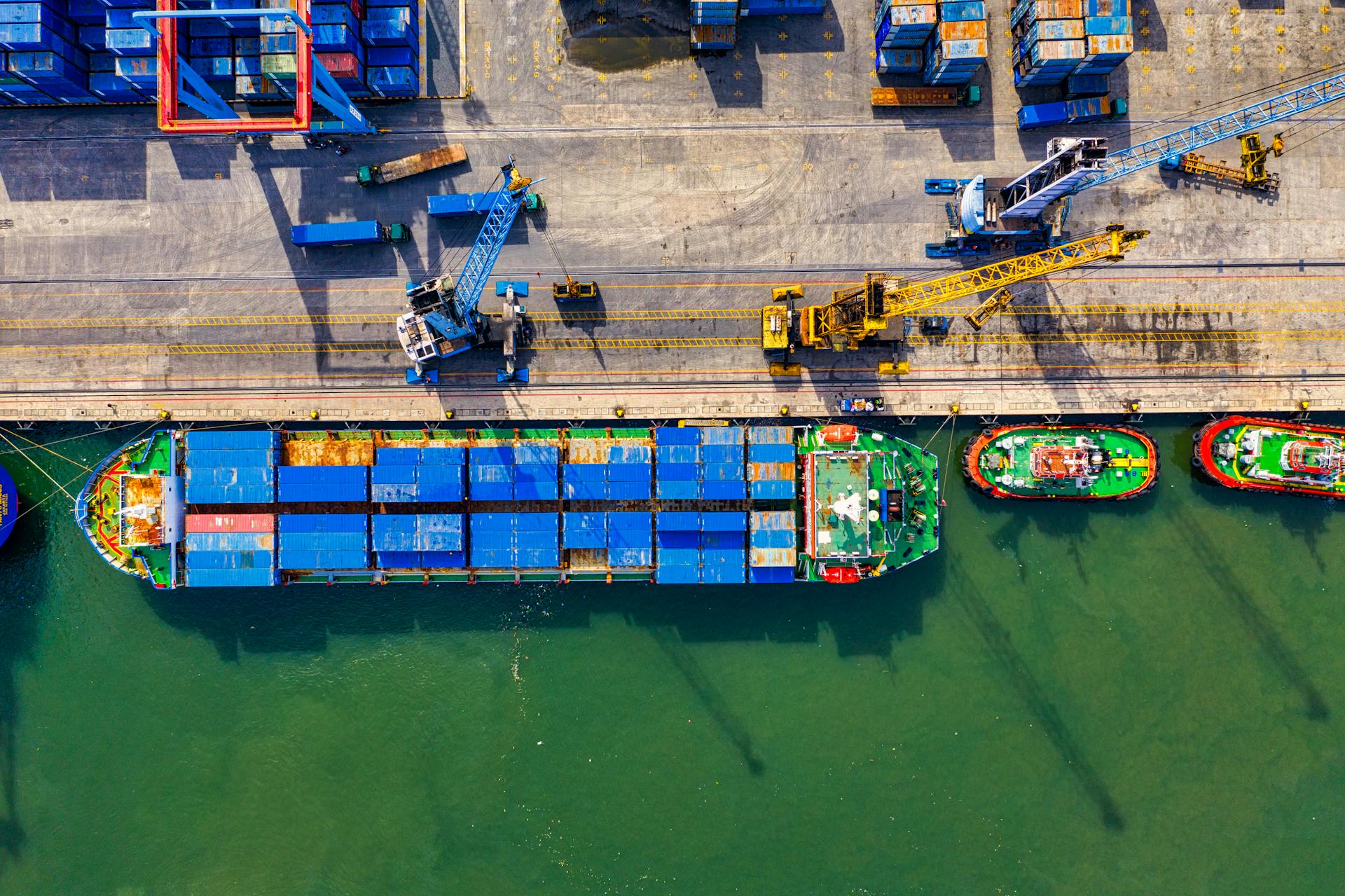

The MV Nelson Star was a refrigerated cargo liner built in Belfast by Harland & Wolff Ltd.

She was launched on August 25, 1942, and completed in January 1943.

The ship was 431.4 feet long, with a beam of 57.3 feet and a depth of 33.6 feet.

Her Gross Register Tonnage (GRT) was 7,365, and her Net Register Tonnage (NRT) was 5,135.

The MV Nelson Star was propelled by a four-stroke, single-acting marine Diesel engine.

Featured Images: pexels.com