Inland PETG is a type of plastic that's gaining popularity among makers and DIY enthusiasts. It's known for its excellent chemical resistance and durability.

Inland PETG is available in a range of types, including clear and opaque options. These types have different properties that make them suitable for specific applications.

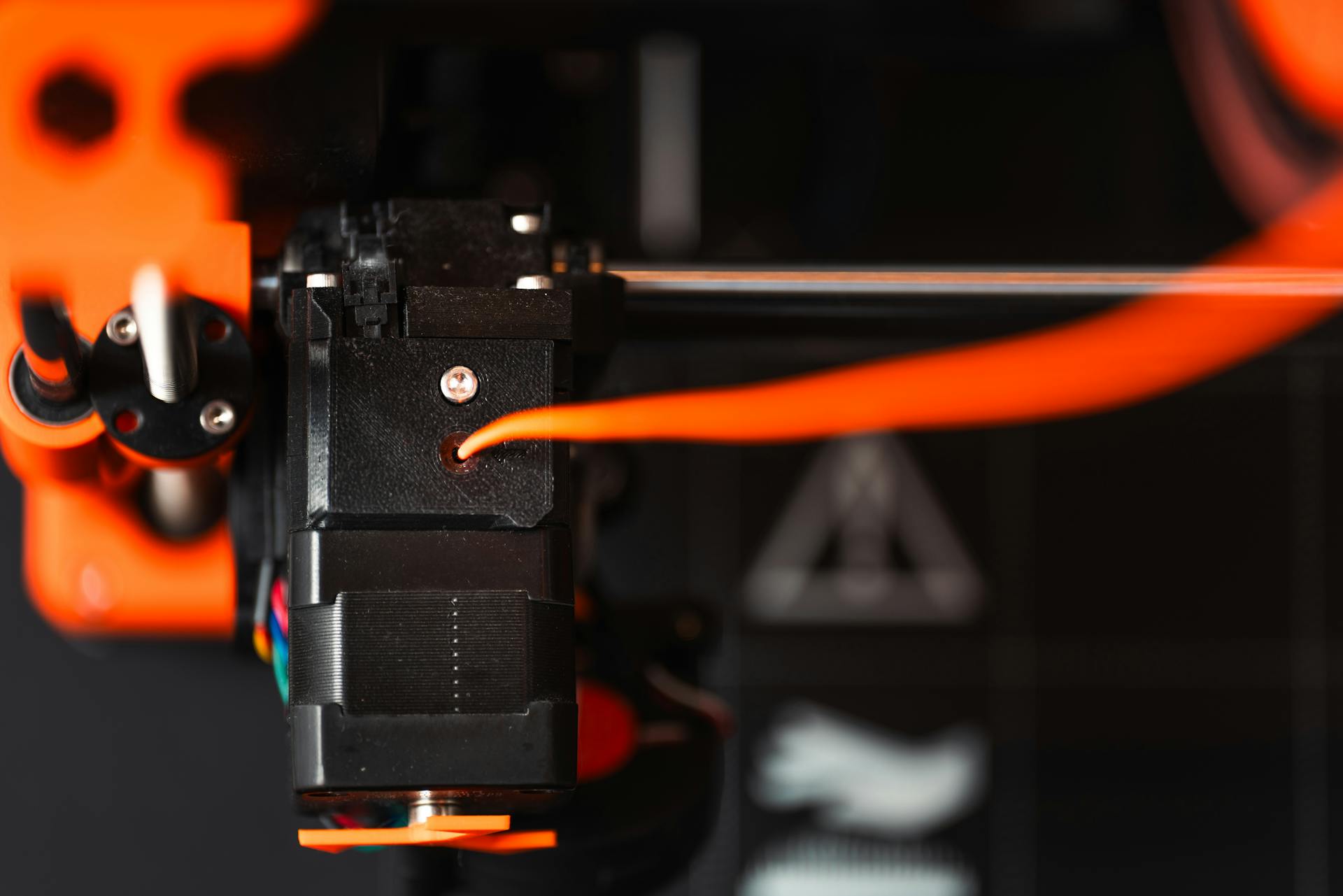

For example, the Inland PETG 3D printing filament is a popular choice for creating functional parts and prototypes. It's strong, yet flexible, making it perfect for applications where impact resistance is crucial.

Inland PETG can be used for a variety of applications, from making phone cases to creating art pieces. Its versatility and ease of use make it a favorite among makers and artists.

What is Inland Petg

Inland Petg is a type of bioplastic that's gaining popularity due to its eco-friendly properties.

Inland Petg is made from a combination of polyethylene and polypropylene, which are two of the most widely used plastics in the world.

This unique blend gives Inland Petg its strength and flexibility, making it suitable for a wide range of applications, from packaging to medical devices.

Inland Petg is also biodegradable, meaning it can easily decompose and return to nature without harming the environment.

Definition

Inland Petg is a type of polyethylene terephthalate (PET) film that is specifically designed for use in the interior of buildings.

It's made from a thin, flexible sheet of PET that can be molded into various shapes and sizes.

Inland Petg is often used as a substitute for traditional glass or metal partitions in interior design.

This is because it's lightweight, easy to install, and can be easily cleaned and maintained.

Inland Petg is also resistant to scratches, cracks, and fading, making it a durable option for interior design.

Types

Inland Petg comes in two main types: Type I and Type II.

Type I is typically used for packaging food and beverages, while Type II is used for non-food items.

Type II is further divided into two subtypes: Type II A and Type II B.

Type II A has a higher oxygen barrier than Type II B.

Type I is also available in a variety of thicknesses, ranging from 20 microns to 200 microns.

This allows for flexibility in packaging design and weight reduction.

Specifications

Inland Petg is a versatile material that's worth getting to know.

The color of Inland Petg is black, making it a sleek and modern choice for 3D printing projects.

In terms of weight, Inland Petg is a solid 2.20 lbs (1.00 kg), which is relatively standard for most 3D printing materials.

The diameter of Inland Petg is 1.75mm, with a tolerance of 0.05mm, which ensures a precise and consistent printing experience.

To extrude Inland Petg, you'll need to heat it up to a temperature range of 230°C - 250°C, which is a bit higher than some other materials.

Inland Petg combines the advantages of both PLA and ABS, making it a great all-around choice for 3D printing enthusiasts.

Here's a quick rundown of the key specifications:

- Color: Black

- Material: PETG

- Weight: 2.20 lbs (1.00 kg)

- Diameter: 1.75mm

- Tolerance: 0.05mm

- Extrusion Temperature: 230°C - 250°C

Inland Petg is compatible with the majority of 3D printers on the market, making it a great choice for beginners and experienced users alike.

Printing Inland Petg

Printing Inland PETG is a unique process that requires attention to detail.

Inland PETG has a high crystallization rate, which can lead to a more brittle finish if not properly managed. This is because the material has a high tendency to form crystals, which can cause it to become more prone to cracking.

Printing at a slower speed can help to mitigate this issue, as it gives the material more time to crystallize and become more stable.

Inland PETG also has a relatively low warping tendency, making it easier to print without the need for extensive post-processing. This is due to its low thermal expansion coefficient, which helps to minimize shrinkage and warping during the printing process.

Printing at a temperature range of 220-240°C can help to achieve optimal results with Inland PETG. This temperature range allows for a good balance between print speed and material quality.

Frequently Asked Questions

Is Inland PETG food safe?

Yes, Inland PETG is food safe, having been cleared by the FDA for use in food and beverage products.

Why do people use PETG instead of PET?

People prefer PETG for 3D printing due to its higher impact resistance and flexibility. It's a more practical choice for most applications, offering a good balance of properties.

Sources

- https://www.microcenter.com/product/503745/inland-175mm-petg-3d-printer-filament-1kg-carboard-spool-(22-lbs)-black

- https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-how-do-i-print-this-printing-help/problems-printing-with-inland-petg/

- https://3dprinting.stackexchange.com/questions/18413/what-oem-is-inland-petg

- https://community.microcenter.com/discussion/7133/differences-in-new-inland-filaments

- https://www.ic3dprinters.com/shop/petg-filaments/

Featured Images: pexels.com