Freight train container transport and logistics is a complex process that requires careful planning and execution.

Standard containers are typically 20 or 40 feet long and can hold up to 53,000 pounds of cargo.

The type of cargo being transported plays a significant role in determining the size and type of container needed.

Intermodal containers can be easily transferred between ships, trains, and trucks, making them a convenient option for international trade.

Broaden your view: Hamburg Express-class Container Ship

History of Freight Train Containers

The history of freight train containers is a fascinating story that spans decades. The first notable use of freight containers was on the London, Midland and Scottish Railway (LMS) in 1928.

Freight containers have come a long way since then. In the 1970s, many containers still featured riveted aluminum sheet-and-post wall construction, instead of the more modern welded, corrugated steel.

The U.S. Army also used a type of steel container called a CONEX box during the Vietnam era, which is still used today.

Additional reading: Freight Forwarding Companies to Canada

Intermodal's Long History

Intermodal's long history has been a game-changer for the freight rail industry, transforming it from a traditional bulk hauler into a key player in global commerce.

In 1980, regulatory reforms enabled railroads to invest heavily in intermodal infrastructure, technology, and services. This shift allowed railroads to seamlessly integrate with trucking and maritime industries.

The success of intermodal transportation has led to the widespread adoption of double-stacked containers, making freight transport more efficient and cost-effective.

Railroads have also leveraged advanced logistics and streamlined operations to create a more flexible and resilient supply chain.

See what others are reading: Freight Forwarding to Alaska

Domestic Growth & Tech Enhancements

In the late 1980s, a major breakthrough in domestic freight transport occurred when Johnnie B. Hunt partnered with Santa Fe Railway to move truck trailers on flatcars.

This innovative solution paved the way for rail to become a competitive alternative to trucking, even for short-haul shipments, due to rising fuel costs, driver shortages, and highway congestion.

Rising fuel costs have indeed made rail a more attractive option, as it offers a cleaner and more efficient way to transport goods.

Investments in zero-emission electric cranes have significantly improved container transfers, making the process faster and cleaner.

Optical scanners and automated gates have also been implemented to reduce truck idling and enhance security at terminals, making the entire process more efficient and secure.

Types of Freight Train Containers

There are several types of freight train containers, each designed for specific purposes.

Dry containers are used for transporting general cargo, such as machinery, vehicles, and household goods.

Refrigerated containers, also known as reefers, are equipped with cooling systems to keep perishable goods at the right temperature.

Tank containers are used for transporting liquids, gases, and other hazardous materials.

20ft and 40ft

The 20ft and 40ft containers are the most popular choices for dry cargo transportation. These standard containers are perfect for moving a wide range of goods, from paper and grains to clothing and electronics.

You can buy a cargo-worthy 20ft container in the US on Container xChange for $1,325, and a 40ft for $1,605. This is a great option if you're looking for a reliable and efficient way to transport your goods.

On Container xChange, you can negotiate directly with suppliers to get the best deal. This means you can settle on a price you're 100% happy with, which is a big plus.

Flat Rack

Flat racks are designed to move oddly shaped, extra large or tall cargo. They have lashing rings to secure goods tightly during transport, preventing them from shifting or getting damaged.

You can buy a used 40ft flat rack on xChange for around US $6,600. This is a great option for out-of-gauge cargo.

Flat racks are the answer to oddly shaped or extra-large cargo woes.

European Pallet Wide

European Pallet Wide containers are a type of container that's specifically designed to accommodate European Euro-pallets with greater efficiency and capacity. They're minimally wider than standard containers, with a typical internal width of 96+1⁄8 in (2.44 m), which allows for a usable internal floor width of 94+1⁄2 in (2.40 m).

This extra width enables users to load two Euro-pallets end on end across their width, or three of them side by side, without overspill. In contrast, standard ISO containers have a strip of internal floor-width of about 13 inches (33 cm) that can't be used by Euro-pallets.

Here's a comparison of the pallet capacity of European Pallet Wide containers and standard ISO containers:

Some European Pallet Wide containers are manufactured with the same ISO-standard floor structure, but with the side-panels welded in, making them just 96+7⁄8 in (2.462 m) wide. Others can be 98+3⁄8 in (2.50 m) wide.

International Standards and Regulations

International standards and regulations play a crucial role in the freight train container industry. The Bureau International des Containers et du Transport Intermodal established the first international standard for containers in 1933, which was primarily for transport between European countries.

In the United States, American containers were not standardized at this time, and early containers were not stackable. The Pennsylvania Rail Road Company opened the first container terminal in the world in Enola, Pennsylvania in November 1932.

ASTM D5728-00 sets standard practices for securement of cargo in intermodal and unimodal surface transport. This is just one of many international standards that ensure the safe and efficient transportation of freight containers.

International Organization for Standardization (ISO) has developed numerous standards for freight containers, including ISO 668:2013, which classifies, dimensions, and rates freight containers. ISO 830:1999 provides a vocabulary for freight containers, while ISO 1161:1984 specifies corner fittings for freight containers.

Here are some key ISO standards for freight containers:

- ISO 668:2013 Series 1 freight containers – Classification, dimensions and ratings

- ISO 830:1999 Freight containers – Vocabulary

- ISO 1161:1984 Series 1 freight containers – Corner fittings – Specification

- ISO 1496 – Series 1 freight containers – Specification and testing

- ISO 2308:1972 Hooks for lifting freight containers of up to 30 tonnes capacity – Basic requirements

- ISO 3874:1997 Series 1 freight containers – Handling and securing

- ISO 6346:1995 Freight containers – Coding, identification and marking

- ISO 9897:1997 Freight containers – Container equipment data exchange (CEDEX) – General communication codes

- ISO/TS 10891:2009 Freight containers – Radio frequency identification (RFID) – Licence plate tag

- ISO 14829:2002 Freight containers – Straddle carriers for freight container handling – Calculation of stability

- ISO 17363:2007 Supply chain applications of RFID – Freight containers

- ISO/PAS 17712:2006 Freight containers – Mechanical seals

- ISO 18185-2:2007 Freight containers – Electronic seals

The International Convention for Safe Containers, signed in Geneva on December 2, 1972, further emphasizes the importance of international standards and regulations in the freight train container industry.

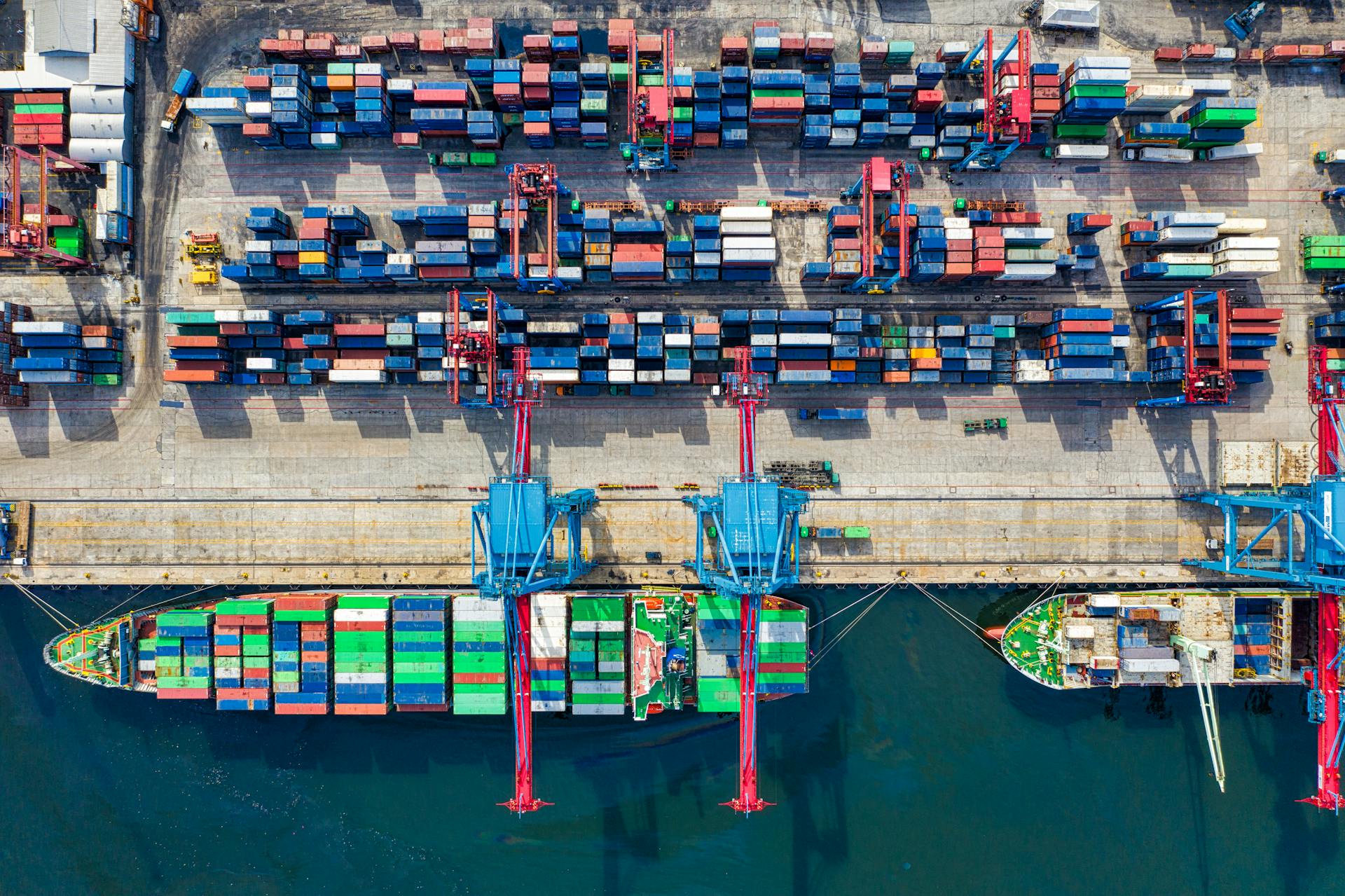

Freight Train Container Transport

Freight train container transport is a crucial part of global trade, with over 70% of international cargo transported by containerized freight trains.

The standard size of a freight train container is 20 or 40 feet long, which allows for efficient loading and unloading at ports and terminals.

Explore further: Train Horns for Semi Trucks

Most freight train containers are made of steel and are designed to be stackable, which maximizes storage space and reduces transportation costs.

Container weights range from 2,000 to 3,000 pounds, depending on the size and materials used.

A typical freight train can carry up to 70 containers, with some trains carrying over 100 containers in peak seasons.

The average speed of a freight train is around 40-50 miles per hour, with some trains reaching speeds of up to 60 miles per hour on certain routes.

Freight train containers are often sealed and locked to prevent theft and damage during transit, and are equipped with tracking devices to monitor their location and status.

Intermodal Service and Terminals

The modern intermodal system was born with the invention of the shipping container in 1956, when Malcom McLean's Sea-Land standardized container transport across ships, railroads, and trucks.

Rail terminals have been around since the 19th century, but they were converted into intermodal facilities by 1960 with the rise of container shipping. This shift enabled freight transfers between modes at strategically located terminals.

With over 180 intermodal terminals in the U.S., rail has become a competitive option for domestic freight, reducing road congestion and improving shipping times. Railroads have invested billions in expanding these facilities, adding advanced equipment like GPS-enabled cranes for quick transfers.

Double-Stack Transport Options

Double-stacking is a convenient method of intermodal transportation that allows twice the amount of cargo to be transported in one shipment.

Special rail cars called 'well cars' are used for double-stack transport in the US, designed to reduce damage and protect containers during intermodal transportation.

Two 20ft containers can be stacked at the bottom with one 40ft container on top, a pattern allowed in India, China, and the US.

One 40ft container can be stacked at the bottom with another 40ft container on top, a pattern allowed in India and the US.

Here are the specific double-stack transport options:

Intermodal Terminals

Intermodal terminals have a long history, dating back to the 19th century when they were used as rail terminals. They were converted into intermodal facilities by 1960 with the rise of container shipping.

Railroads have invested billions in expanding these facilities, adding advanced equipment like GPS-enabled cranes for quick transfers. This has enabled faster and more efficient transfers between modes of transportation.

Strategically located terminals are crucial for modern intermodal, allowing freight to be transferred between modes of transportation. There are over 180 intermodal terminals in the U.S., making rail a competitive option for domestic freight.

By reducing road congestion and improving shipping times, intermodal terminals have become a vital part of the intermodal system. They play a key role in the efficient transportation of goods across the country.

Buying and Selling Freight Train Containers

Before buying freight train containers, it's essential to consider the cost of shipping container, which can vary depending on the supplier and quality.

New containers are ideal for long-term use and can last up to 25 years if properly maintained. They also come with no maintenance required before use, but at a higher price.

Used containers, on the other hand, are perfect for a tighter budget and can be used for storage when not needed for shipping. They may have a few dents and scratches, but are a great option for those who don't mind.

Types of Sale and Prices

When buying or selling freight train containers, it's essential to consider the type of cargo you'll be transporting and the quantity involved. This will help determine which container type and size you'll need for shipping.

The type of cargo you'll be transporting, as well as the quantity, will determine which container type and size you'll need for shipping. The price of the container will also depend on these factors.

Standard containers are commonly used for railroads and come in various sizes, including 20-foot and 40-foot containers. These containers are suitable for general cargo and are often the most affordable option.

Special containers, such as refrigerated containers, are designed for specific types of cargo that require temperature control. These containers can be more expensive than standard containers but are essential for transporting perishable goods.

The price of a container can range from a few thousand to tens of thousands of dollars, depending on the type and size. It's essential to research and compare prices to find the best deal for your needs.

Things to Consider Before Buying

Before buying freight train containers, it's essential to consider a few key factors. The cost of shipping containers can vary significantly, so it's crucial to have a budget in mind.

You'll need to decide whether to opt for a new or used container. New containers are ideal for long-term use and can last up to 25 years if properly maintained.

If your budget is tighter, used containers are a great option. They may have a few dents and scratches, but they're a cost-effective choice.

To make an informed decision, you'll want to define your criteria. Here are the key things to consider:

- Container type and size

- Container condition

- The price you're willing to shell out

- The location you want to buy shipping containers in

Having these factors in mind will help you make a decision that's right for you.

How to Buy Shipping in 4 Steps

Buying a shipping container for rail transport can seem daunting, but it's actually quite straightforward. On the right platform, you can find the perfect container for your needs in just four easy steps.

First, identify your container requirements. This includes understanding the size, type, and condition of the container you need. Don't worry, on the right platform, you can filter options to find the right fit for your needs.

Next, browse through available containers on the platform. With a large inventory to choose from, you're sure to find a container that meets your requirements. On our platform, you can find containers for all types of rail transport needs.

Now, select the container that best suits your needs. Consider factors such as the container's age, condition, and any additional features you may require. Once you've made your selection, you can proceed to the next step.

Finally, complete the purchase and arrange for delivery. This will ensure that your container is delivered to you quickly and efficiently. On our platform, you can even track the container's progress and stay up-to-date on its delivery status.

Affordable Removals

Buying and selling freight train containers can be a cost-effective option for individuals and businesses alike. Moving Containers offers affordable rates for removals or commercial freight, making it a great choice for those on a budget.

Their connections enable them to provide affordable freight train container solutions for both individual clients and commercial clients. This includes regular container transport routes for businesses with ongoing shipping needs.

With a focus on understanding each client's requirements, Moving Containers can give you a quote that suits both your budget and any deadlines for the container to arrive by. This personalized approach helps ensure a smooth and stress-free experience for all clients.

Specialized Freight Train Containers

There are many types of specialized freight train containers, including tank cars for transporting liquids and gases.

Intermodal containers are another type, designed to carry a wide range of goods, from cars to electronics.

Tank cars are equipped with specialized valves and piping to safely transport hazardous materials.

Open-Top

Open-top containers are perfect for transporting tall or oddly-shaped cargo that won't fit in a standard unit with a fixed roof.

They come with a detachable tarpaulin sheet to keep cargo protected from sun damage, storms, and other extreme weather.

You can expect open-top containers to come at a higher price than standard dry units, with a 40ft open top in the US costing around US $5,416 on some platforms.

Three- and Five-Pack Well Cars

Three- and five-pack well cars are designed to carry freight containers between their trucks, which are referred to as wells.

These wells can hold containers of varying lengths, including 20, 40, or 53 feet.

Double-stacking containers on well cars allows for an impressive capacity, with up to 10 containers carried on one railcar.

The 20 and 40-foot containers are typically used for international traffic and are referred to as steamship containers.

ABC Bulk

ABC Bulk containers are a type of specialized freight train container. They're designed for hauling dense materials and are typically 20 ft long and 5 ft high.

Their smaller size reduces the tare weight compared to using a half-full standard height container. This makes them more efficient for transporting heavy loads.

The smaller size also allows for more containers to be carried on specialized railroad flatcars. In fact, 6 ABC containers can be carried in the space of 4 standard containers.

These containers are often used by the U.S. Navy for transporting Quadcon containers and other specialized equipment. They can even be loaded onto transport aircraft like the Lockheed C-5 Galaxy.

Environmental and Economic Benefits

Using freight train containers is an excellent way to reduce your carbon footprint. According to the International Energy Agency, using a train with containers means about 90% less energy is required than by using trucks per unit of freight.

This makes rail freight services a more environmentally friendly option, perfect for those looking to go green. It's also a cost-effective way to transport goods, especially for long-distance hauls.

By choosing rail freight, you can significantly reduce your logistics costs and contribute to a more sustainable future. Whether you're moving your belongings across the country or sending regular shipments to a client, rail freight services will get the job done with the lowest carbon footprint possible.

Global Freight Train Container Routes

The Silk Road route between China and Europe is a significant one, spanning from Dzungarian Gate in Kazakhstan to Duisburg, Germany, passing through Russia, Belarus, and Poland along the way.

Goods transported from Chongqing, China to Duisburg, Germany in a 40ft dry container can incur a pick-up charge of around US $1,355 on Container xChange.

The journey can take around 60 freedays, with per diem charges of US $5 added to the overall cost.

53ft ISO Shipping

53ft ISO shipping containers are the largest units on the market, built for extra large shipments of dry goods, as well as bulky cargo like vehicles and machinery.

A new 53ft high cube container in the US will cost you around US $9,853 on our platform.

You can find 53ft high cubes in over 2,500 locations around the world, making it easy to find the right container for your rail freight needs.

These massive containers are perfect for transporting oversized cargo that can't fit in standard containers.

China-Europe Silk Road Route

The China-Europe Silk Road Route is a significant freight train route that connects China to Europe. It spans from Chongqing, China to Duisburg, Germany.

This route is facilitated by the Chongqing–Xinjiang–Europe railway, which passes through Kazakhstan, Russia, Belarus, and Poland before reaching Germany.

The journey is quite long, taking an average of 60 free days to complete. You'll also need to factor in daily charges of around $5 per diem.

To give you an idea of the costs involved, transporting a 40ft dry container from Chongqing to Duisburg can set you back around $1,355 in pick-up charges.

Explore further: Train from Munich to Hamburg Germany

Specifications and Description

A freight train container is a standard unit of shipping that measures 53 feet in length, 8.5 feet in width, and 9.5 feet in height. These dimensions allow for efficient stacking and transportation.

The typical weight of a freight train container is around 3,000 pounds, which is relatively light compared to its cargo capacity. This makes it easier to transport and maneuver on the rail network.

Freight train containers are made of durable materials, such as steel or aluminum, to withstand the rigors of transportation and harsh weather conditions.

Canadian 60-Foot

Canadian 60-Foot containers are a game-changer for shipping goods, and here's why: they're transportable on the road using specially configured trucks and telescoping trailers.

These containers can also be used on the railway, taking up the top positions of double-stack container cars. The deployment of these containers was announced in April 2017 by Canadian Tire and Canadian Pacific Railway.

They claimed to be the first 60-foot intermodal containers in North America, which is a significant achievement. Canadian Tire believed that these larger containers would allow them to increase the volume of goods shipped per container by 13%.

For now, these larger containers seem to be exclusive to Canada, due to stricter truck size regulations in the United States.

Japan: 12-Foot

In Japan, a unique standard pallet size is used, which is a key factor in determining the length of containers used in domestic freight rail transport. Most containers are 12 ft long.

This length allows for efficient use of space and easy loading and unloading of goods.

Description

The device has a sleek and compact design, measuring 12 inches in width and 8 inches in height. Its lightweight construction makes it easy to carry around.

The device's screen is a high-resolution display with a 10-point multi-touch interface, allowing for smooth and precise navigation. It's perfect for watching videos or browsing the web.

The device is powered by a long-lasting battery that can last up to 12 hours on a single charge. This means you can use it all day without worrying about running out of power.

The device comes with 16GB of internal storage, which can be expanded up to 128GB with a microSD card. This provides ample space for storing your favorite apps, music, and movies.

Specifications

The specifications of a product or system are crucial to understanding its capabilities and limitations.

The article highlights that a product's specifications can include details such as its dimensions, weight, and materials used.

The dimensions of a product, for instance, can affect its portability and storage space requirements.

A product's weight can also impact its shipping and handling costs.

The materials used in a product's construction can influence its durability and maintenance needs.

The article also notes that a product's specifications can include technical details such as its voltage, frequency, and power consumption.

A product's voltage requirements, for example, can determine whether it can be safely used in different countries or regions.

The frequency of a product can affect its performance and compatibility with other devices.

A product's power consumption can impact its energy efficiency and operating costs.

Rail and Transport

Rail transport is a safe and efficient option for freight transportation, especially for large volumes of containers. It's much quicker than road transport, with some services able to transport containers from Melbourne to Perth in just three days.

The Australian rail freight network is extensive, consisting of more than seven different companies that manage both the rail infrastructure and trains. This can be a headache to navigate, but Moving Containers can help coordinate between the different rail companies on your behalf.

Containers can be transported by container ship, truck, and freight trains as part of a single journey without unpacking, making it a convenient option for businesses. They can be secured in transit using "twistlock" points located at each corner of the container.

National Transport Organization

Australia's rail freight network is quite complex, with over seven different companies managing both the rail infrastructure and trains.

Each rail company operates independently, making it difficult to navigate the system.

Rail container transport from Perth to Cairns, for example, involves working with three different rail companies across different states.

The Pilbara region and Tasmania have their own separate freight rail networks, adding to the complexity.

This can be overwhelming, especially for those who are new to rail transport.

Moving Containers can help simplify the process by co-ordinating between the different rail companies on your behalf.

This ensures that your containers are delivered to the right train going in the right direction.

By using Moving Containers, you can still take full advantage of all rail freight services in Australia without the hassle.

It saves you a huge amount of time and effort, and ultimately guarantees your containers end up where they need to.

Australian Race

Australian RACE containers are a great example of optimized shipping solutions. They are slightly wider to accommodate Australia Standard Pallets.

In fact, some Australian RACE containers are 41 ft long and 8 ft 2 in wide, which allows them to fit up to 40 pallets. This is a significant increase in storage capacity, making them ideal for bulk shipments.

Rail

Rail transport is a safe and efficient option for moving large volumes of containers across the country, with Moving Containers able to transport shipping containers by rail from Melbourne to Perth door to door in just three days.

The Australian rail freight network consists of more than seven different companies that manage both the rail infrastructure and trains, making it complex to navigate on your own.

Containers can be transported by rail on a spine car, flatcar, or well cars, with the latter being specially designed for container transport and able to accommodate double-stacked containers.

The loading gauge of a rail system may restrict the modes and types of container shipment, with smaller gauges only accommodating single-stacked containers.

About 90% of non-bulk cargo worldwide is transported by container, making rail a convenient option for many businesses.

Containers can be secured in transit using "twistlock" points located at each corner of the container, ensuring they remain stable during transport.

Frequently Asked Questions

How much does a train container cost?

Train container prices range from $1,750 to $7,900, depending on condition and availability

Featured Images: pexels.com