Flexographic printing machines are incredibly versatile, allowing for a wide range of printing applications, from labels and packaging to corrugated cardboard and even textiles.

One of the key features of flexographic printing machines is their ability to print on a variety of substrates, including paper, foil, and even plastic.

Flexographic printing machines are also known for their high speed and efficiency, with some machines capable of printing up to 500 feet per minute.

The plates used in flexographic printing machines are typically made of rubber or photopolymer, which provides excellent durability and resistance to wear and tear.

Expand your knowledge: Poly Vinyl Chloride Packaging Tape Printing Market

Flexographic Printing Machine Types

Flexographic printing machines come in a variety of types to suit different printing needs.

There are four main categories of flexo printing machines: Wide web flexographic printing machines, narrow web flexo presses, rotogravure printing machines, and in-line and off-line stack flexo presses.

Wide web flexographic printing machines are ideal for printing on larger surfaces and feature central impression drum technology.

Narrow web flexo presses are designed for label and packaging printing on plastic materials.

Rotogravure printing machines provide excellent print consistency.

In-line and off-line stack flexo presses offer greater flexibility in terms of the number of colors used in a single pass and are characterized by vertically stacked print units.

Here are the different types of flexographic printing machines:

- Wide web flexographic printing machine

- Narrow web flexo press

- Rotogravure printing machine

- In-line stack flexo press

- Off-line stack flexo press

Machine Configurations

Flexographic printing machines come in different configurations, which affect their performance and capabilities. The number of colors in a flexo printing press is a key factor in determining its complexity.

The primary categories of flexo printing presses include single, two, three, four, six, eight, or even ten printing colors. This range of options allows for flexibility in printing various materials and designs.

Flexo printing machines can be classified into two main technologies: gearless and geared. Gearless machines use servo motors to directly drive the plate cylinder, while geared machines use gears to drive it. This difference in technology results in varying performance levels.

Here are the key configurations of flexo printing presses:

Custom Built Machines

Custom Built Machines are designed to meet specific needs and requirements. They often feature advanced configurations that enhance production efficiency and quality.

The HRY-450MC model is a great example of a custom built machine. It's a Stack Type machine capable of 2 Colors Printing.

One of the key features of the HRY-450MC is its Corona Treatment System. This system helps to improve the print quality by treating the material before printing.

The machine also comes equipped with an Integrated Die-Cutting System. This system allows for precise cutting of the material, reducing waste and improving efficiency.

In addition to die-cutting, the HRY-450MC also features an Advanced Slitting Mechanism. This mechanism enables the machine to make precise cuts in the material, further improving efficiency.

Dual Rewinding System is another feature of the HRY-450MC. This system allows for faster production and easier handling of the material.

Here are some key features of custom built machines like the HRY-450MC:

- Stack Type

- 2 Colors Printing

- Corona Treatment System

- Integrated Die-Cutting System

- Advanced Slitting Mechanism

- Dual Rewinding System

High-Speed Presses

High-Speed Presses are designed for efficiency and speed. The HRY-320A, for instance, is a high-speed flexo press with a printing speed of up to 60m/min.

These presses are perfect for large-scale label and packaging printing. The HRY-320A is also equipped with a UV dryer, which helps to dry the ink quickly.

You can choose from various printing options, such as label printing, aluminum foil printing, and paper roll printing. The HRY-320A is customizable to meet your specific needs.

For wider format printing, the HRY-850A Roll to Roll Flexo Printing Machine is a great option. It can handle a maximum winding diameter of 1300mm.

If you need to print on a large scale, the HRY-850A is a good choice. It's also customizable to fit your specific needs.

Here's a comparison of the two high-speed presses:

Key Configurations

Flexo printing machines come in different configurations, each with its own set of advantages and characteristics.

The number of colors in a flexo printing press is a key factor in determining the complexity of the machine. Single, two, three, four, six, eight, or even ten printing colors are the primary categories.

The size and positioning of the printed designs are referred to as print repeat. This is an important consideration in flexo printing.

Flexo printing machines can be classified into two main technologies: gearless and geared. Gearless machines use servo motors to directly drive the plate cylinder, while geared machines use gears to drive it.

Here's a breakdown of the different configurations:

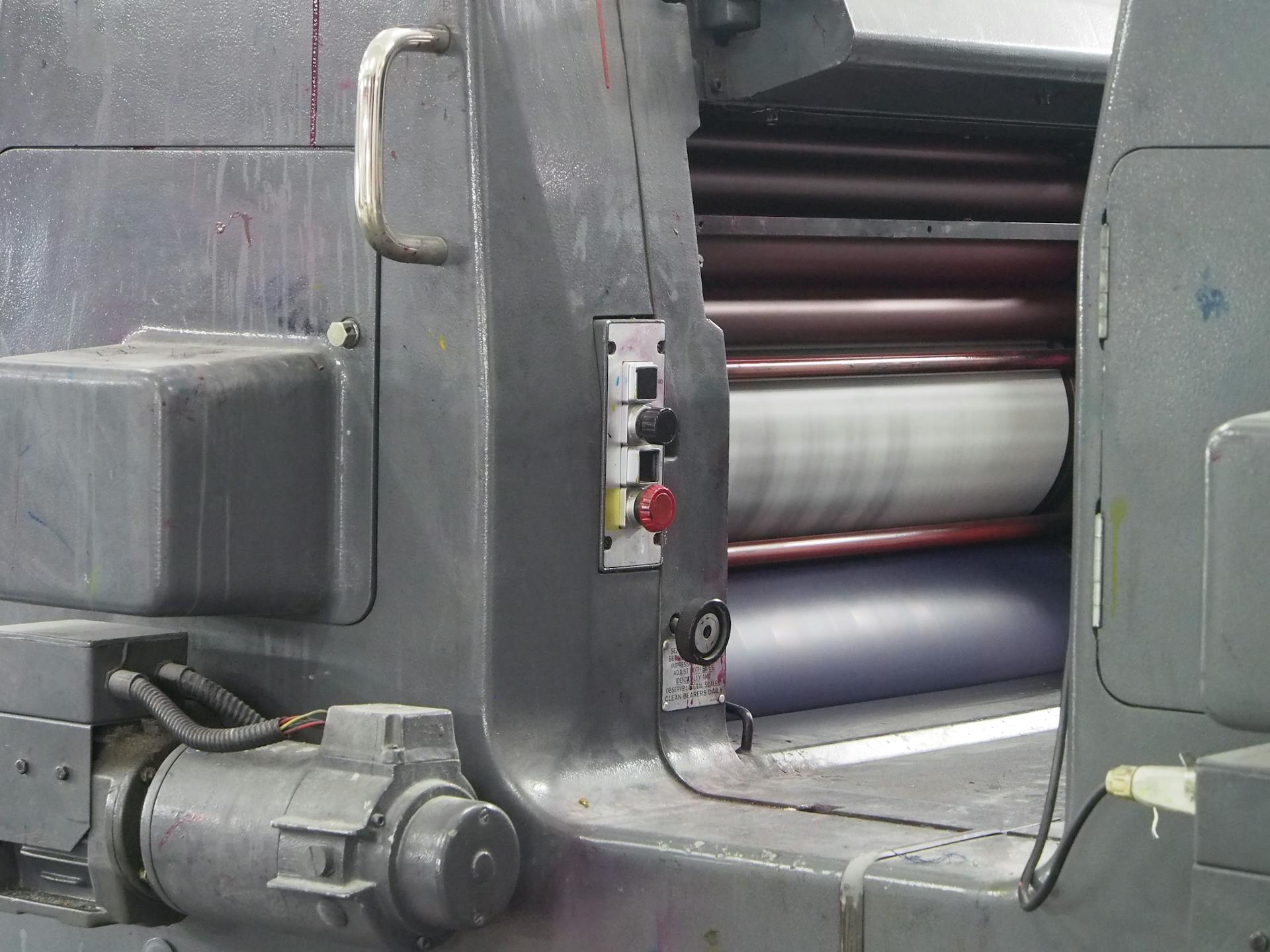

Machine Components

A flexographic printing machine is only as good as its components. High-quality anilox rollers ensure accurate ink transfer and even coating on various substrates.

To achieve consistent print results, robust pressure rollers are critical for accurate alignment and pressure application. They help in maintaining the integrity of the printing process.

Durable doctor blades and gearboxes and motors also play a vital role in the machine's operation. These components work together to ensure optimal performance and minimal waste, while also providing reliable machine operation and consistent performance.

Plates and Sleeves

Plates and Sleeves play a crucial role in maintaining high-quality prints and consistent performance.

Precision-engineered plates and sleeves are available, as mentioned in Example 4. These plates and sleeves are designed to ensure accurate ink transfer and even coating on various substrates.

High-quality anilox rollers are also available, as mentioned in Example 6. These rollers are specifically designed for ensuring accurate ink transfer and even coating on various substrates.

The benefits of using precision-engineered plates and sleeves are numerous. They help to maintain high-quality prints and consistent performance, making them an essential component for any printing machine.

Here are some key features of precision-engineered plates and sleeves:

Paper Cup Machines

Paper Cup Machines are designed to produce cups with specific dimensions, typically between 6-12 ounces in volume. They can produce up to 100 cups per minute.

The machine's die-cutting mechanism cuts out the cup shape from a sheet of paperboard. This process involves a rotating wheel with a series of cutting edges.

The machine's folding mechanism folds the cup in half along a crease line, creating the cup's shape. This is done using a series of rotating rollers with different crease lines.

A coating machine applies a thin layer of wax or varnish to the cup to make it waterproof. This is an important step to prevent the cup from leaking.

The finished cups are then packaged and ready for use. Paper Cup Machines are widely used in the food and beverage industry.

Sheet Cutting Machines

Sheet cutting machines are used in various industries to cut materials such as metal, wood, and plastic into precise shapes and sizes.

These machines are often equipped with rotating blades or saws that move in a linear or circular motion to make clean cuts.

Some sheet cutting machines use a laser cutting technology to cut through materials with high accuracy and precision.

This technology is particularly useful for cutting complex shapes and designs with minimal waste.

Sheet cutting machines can be manual or automatic, depending on the level of precision and speed required.

Manual sheet cutting machines are often used for small-scale cutting operations, while automatic machines are used for large-scale production.

The choice of sheet cutting machine depends on the type of material being cut and the desired level of precision.

For example, a metal sheet cutting machine might use a high-speed saw to make quick cuts, while a wood sheet cutting machine might use a circular saw for more precise cuts.

In some cases, sheet cutting machines are used in conjunction with other machine components, such as conveyors and sorting systems, to streamline the cutting process.

Sheet cutting machines can be powered by electricity or hydraulic systems, depending on the type of machine and the level of power required.

Hydraulic systems are often used in heavy-duty sheet cutting machines that require high levels of torque and power.

Doctor Blades

Doctor blades are a crucial machine component that plays a significant role in the printing process. They are designed to work with different types of inks and substrates, ensuring optimal performance and minimal waste.

Durable doctor blades are a must-have for any printing operation, as they can withstand the rigors of frequent use.

Ink Pumps

Ink pumps are crucial for maintaining print quality, ensuring consistent and efficient ink flow.

Reliable ink pumps minimize downtime, which is a major concern for businesses that rely on printing to meet deadlines.

Inconsistent ink flow can lead to poor print quality, making it essential to choose high-quality ink pumps.

Ink pumps that are prone to failure can result in costly repairs and lost productivity.

Investing in reliable ink pumps can save businesses time and money in the long run.

Pressure Rollers

Pressure rollers play a crucial role in machine components, particularly in print-related machinery. They help in accurate alignment and pressure application, which is critical for consistent print results.

A robust design is essential for pressure rollers to withstand the forces involved in printing processes. This is evident in the mention of "robust pressure rollers" in the article section.

In practice, pressure rollers help to ensure that the print is applied evenly and consistently, which is vital for high-quality output.

Conveyor Belts

Conveyor belts are a crucial part of the printing and die-cutting processes, providing smooth and reliable transportation of materials.

High-performance conveyor belts are designed to handle the demands of these processes, ensuring that materials are transported efficiently and effectively.

In fact, conveyor belts are often the backbone of these processes, allowing for continuous production and minimizing downtime.

Their smooth operation is critical, as it affects the overall quality of the final product.

Sensors and Electronics

Sensors and electronics play a crucial role in machine components, allowing for accurate monitoring and control of machine functions.

Advanced sensors can detect even the slightest changes in temperature, pressure, or vibrations, enabling machines to respond quickly and efficiently.

These sensors are often paired with electronic components that process and analyze the data, making informed decisions to adjust machine performance.

For example, a temperature sensor might trigger a cooling system to kick in when the machine's temperature reaches a certain threshold.

In addition to monitoring, sensors and electronics also enable precise control over machine functions, ensuring that each component operates within optimal parameters.

This level of control is essential for maintaining machine efficiency, reducing wear and tear, and preventing costly repairs.

Gearboxes and Motors

Gearboxes and motors are crucial machine components that ensure reliable operation and consistent performance. Durable gearboxes can withstand heavy use and harsh environments, making them a key factor in machine longevity.

A well-designed gearbox can significantly reduce wear and tear on motors, extending their lifespan. In fact, a gearbox's design can impact motor performance by up to 20%.

Motors play a vital role in machine operation, converting electrical energy into mechanical energy. The right motor selection is essential to achieve optimal machine performance.

Gearboxes and motors often work together to achieve precise control and smooth operation. A mismatch between the two can lead to reduced efficiency and increased wear.

SIAT

The SIAT lTC 6/50 Flexo printing machine is a versatile piece of equipment. It has a printing width of 500 mm, which is a standard size for many printing applications.

The machine has two speed settings, with the first one reaching 200 m/min. This speed is ideal for high-volume printing tasks.

The SIAT lTC 6/50 Flexo printing machine can print with up to 8 colours, making it suitable for a wide range of applications.

Technical Training

Technical training is essential to get the most out of your machine components. Our seasoned professionals will provide you with comprehensive technical training to ensure you and your team are fully equipped to operate and maintain your new equipment.

We offer hands-on training sessions to give you practical experience with your machinery. This type of training is invaluable in helping you troubleshoot any issues that may arise.

Detailed manuals are also provided, covering every aspect of machine operation, troubleshooting, and maintenance. These manuals will become your go-to resource for any questions or concerns you may have.

Our goal is to empower you with the knowledge needed to maximize the efficiency and longevity of your machinery.

Spare Parts and Accessories

At Wenzhou Henghao Machinery Co., Ltd., we offer a comprehensive spare parts supply service for our flexographic printing machines. This ensures that your equipment stays reliable and running smoothly.

Our extensive inventory includes all essential components needed to keep your machines in top condition. This includes spare parts for flexo printing and die-cutting machines.

We provide a detailed list of spare parts, but some of the most common ones include those for the printing units, die-cutting units, and conveyor systems.

Spare Parts Supply

Having a reliable spare parts supply is crucial for keeping your equipment running smoothly. At Wenzhou Henghao Machinery Co., Ltd., they offer a comprehensive spare parts supply service that includes all essential components.

Their extensive inventory covers everything needed to keep flexo printing and die-cutting machines running smoothly.

Their service ensures that you have access to the parts you need, when you need them.

Wenzhou Henghao Machinery Co., Ltd. prioritizes the reliability and longevity of your equipment by offering a comprehensive spare parts supply service.

Their inventory includes all essential components needed to keep your flexo printing and die-cutting machines running smoothly.

Solutions for Your Needs

Schiavi's SG1200 printing press is a great example of a machine that can handle demanding print jobs. It's available in 9 colors.

W&H, a company with a rich history of innovation, has been building printing presses since 1880. Their experience and expertise have led to the development of powerful flexographic and gravure printing presses.

The SG1200 has a material width of 1250 mm and a printing width of 1200 mm. This makes it suitable for a variety of print applications.

W&H's focus on sustainability and energy efficiency is reflected in their modern printing presses. Their solutions are designed to minimize downtime and maximize productivity.

Here's a comparison of the SG1200's dimensions:

W&H's commitment to innovation and customer needs has made them a leader in the printing industry.

Leading Manufacturers

Mark Andy is a leading name in the label and package printing industry, offering a range of Flexo presses designed for high-quality printing and efficient production.

Nilpeter, a global company with a century-long history, produces high-quality Flexo presses primarily catering to the label printing industry.

Bobst, known for die-cutting and folding-gluing equipment, also offers a range of Flexo post-print machines suitable for corrugated board printing.

Heidelberg, a titan in the printing industry, offers a range of printing solutions, including Flexo machines for specific applications.

Comexi specializes in solutions for the flexible packaging printing and converting sector, offering Flexo presses known for their efficiency and innovation.

Uteco, an Italian manufacturer, is known for its Flexo presses catering to a range of printing applications, including packaging and labels.

Nilpeter

Nilpeter is a global company with a century-long history, producing high-quality Flexo presses primarily catering to the label printing industry.

Nilpeter offers a range of Flexo presses, including the FA-3 and FA-4 Line models. The FA-3 has a printing width of 330 mm and can print with 7 colors. The FA-4 Line has a printing width of 410 mm and a material width of 420 mm.

Nilpeter's Flexo presses are known for their quality and efficiency. If you're looking for a reliable Flexo press for your label printing needs, Nilpeter is definitely a manufacturer worth considering.

Here's a brief overview of Nilpeter's Flexo presses:

Nilpeter's Flexo presses are designed to meet the specific needs of the label printing industry, making them a popular choice among label printers.

Uteco

Uteco is a well-established Italian manufacturer of Flexo printing machines. They cater to a range of printing applications, including packaging and labels.

One of their notable models is the UTECO Cristal CI Flexo printer, which features 10 colors and a material width of 1020mm. This is a significant detail to consider when evaluating their machines.

Uteco's Cristal CI printer also boasts a gearless servo motor, indicating a high level of precision and efficiency. This is a key factor to consider when choosing a Flexo machine.

The Uteco GOLD 612 RR Flexo printing machine has a printing width of 800 mm, making it suitable for a variety of applications. This is a crucial detail to consider when selecting a machine for your specific needs.

Uteco's machines are known for their advanced technology and quality, making them a popular choice in the industry. This is evident in their commitment to innovation and customer satisfaction.

Here are some key specs of Uteco's Flexo machines:

Overall, Uteco's Flexo machines are designed to deliver high-quality prints and efficient production.

Windmöller Hölscher

Windmöller Hölscher is a prominent manufacturer in the industry, known for their high-quality printing machines.

Their Astra Flex Flexo printing machine is a notable example, with a printing width of 1570 mm, making it suitable for a wide range of applications.

This machine also features an unwinder diameter of 1000 mm, which is a key component in the printing process.

Here's a quick rundown of some key specs for the Astra Flex Flexo printing machine:

TIFMAK

TIFMAK is a leading manufacturer of high-quality machinery components. They specialize in producing precision-engineered parts for various industries.

TIFMAK's expertise lies in creating complex components with tight tolerances, which is a testament to their advanced manufacturing capabilities. Their commitment to precision has earned them a reputation for delivering reliable and durable products.

One of TIFMAK's notable achievements is their ability to produce components with a high level of surface finish, which is critical for applications where smooth operation is essential. This is a result of their investment in state-of-the-art manufacturing equipment and processes.

TIFMAK's dedication to quality has led to a significant reduction in defects and rework, resulting in cost savings for their customers. By minimizing errors, they can focus on producing high-quality products that meet or exceed customer expectations.

Officine Padane

Officine Padane is a leading manufacturer of high-quality machinery and equipment. Their expertise lies in the production of precision tools and machines that cater to various industries.

They have a long history of innovation, dating back to the early 20th century. Officine Padane's commitment to quality and customer satisfaction has earned them a reputation as one of the most trusted manufacturers in the industry.

One of their notable products is the PDM 350, a precision lathe machine that has been widely used in various sectors. This machine is known for its high precision and durability.

Used and Available Machines

Euro Machinery offers a wide range of used flexographic printing presses, including CI flexographic presses, in-line and off-line stack flexo presses, narrow web flexo presses, and rotogravure presses. These machines are valuable assets for businesses seeking economical and adaptable printing solutions.

Their selection of available machinery consists of well-known brands such as UTECO, COMEXI, W&H, Flexotecnica, FISHER & KRECKE, and Bobst, each with unique specifications.

Flexo printing presses available for sale by Euro Machinery fall into four categories: wide web flexographic printing machines, narrow web flexo presses, rotogravure printing machines, and in-line and off-line stack flexo presses.

Here are the different types of flexo printing machines available:

- Wide web flexo press: ideal for printing on larger surfaces, featuring central impression drum technology.

- Narrow web flexo press: ideal for label and packaging printing on plastic materials.

- Rotogravure printing machine: provides excellent print consistency.

- In-line stack flexo press and off-line stack flexo press: offer greater flexibility in terms of number of colours used in a single pass, and are characterized by vertically stacked print units.

Machine Features and Advantages

Flexo printing machines are incredibly versatile, able to print on a wide variety of substrates including paper, plastic, cellophane, metallic films, and even non-absorbent materials.

They're also designed for high-speed production, ensuring rapid turnaround times that make them an excellent choice for large-scale printing operations.

Flexo machines use durable photopolymer plates that can withstand long print runs without needing frequent changes.

Consistent quality is a hallmark of flexo printing, producing sharp images and vibrant colors throughout the run.

One of the most significant advantages of flexo printing is its cost-effectiveness for long print runs, thanks to the efficiency and speed of the process.

Main Advantages

Flexo printing machines offer a wide range of advantages that make them a popular choice in the printing industry. They can print on a variety of substrates, including paper, plastic, cellophane, metallic films, and non-absorbent materials.

One of the standout features of flexo printing is its ability to produce high-quality prints at a rapid pace. Flexo machines are designed for high-speed production, ensuring rapid turnaround times.

Flexo printing machines use durable photopolymer plates that can withstand long print runs without the need for frequent plate changes. This saves time and resources.

Consistent quality is another benefit of flexo printing machines. Once set up, they can produce high-quality prints throughout the run, with sharp images and vibrant colors.

Flexo printing is particularly cost-effective for long print runs due to its efficiency and speed. This makes it an excellent choice for large-scale printing operations.

Flexo printing machines also offer an environmentally friendly alternative, using water-based inks that are low in VOCs (Volatile Organic Compounds). This reduces the environmental impact of the printing process.

While the initial setup can be intricate, flexo machines can have relatively short setup times once mastered. This saves time and increases productivity.

Flexo printing machines can often be integrated with other processes, such as die cutting, laminating, or varnishing, within the same production line. This streamlines the production process and saves both time and money.

Recent advancements in flexo printing technology have led to reduced wastage, both in terms of materials and inks. This not only leads to cost savings but also aligns with sustainable and environmentally responsible printing practices.

Area of Use

Flexo printing machines are primarily employed in the packaging industry, where they produce high-quality prints on various materials, including flexible plastics, corrugated cardboard, and labels.

Their ability to print on a wide array of materials makes them ideal for label production, where vibrant, sharp, and durable prints are crucial.

One of the most prominent sectors that rely on flexo printing is the packaging industry, particularly for food packaging, pharmaceuticals, and consumer goods.

Flexo printing machines are also heavily utilised in label production due to their ability to produce vibrant, sharp, and durable prints.

They're particularly useful for product labels, where both aesthetics and durability are crucial.

Shopping bags, made from paper or reusable fabric, are another area where flexo printing machines excel, catering to the growing demand for eco-friendly materials.

The intricate designs and patterns found on wallpapers are often the result of flexo printing, which can handle large runs and produce consistent quality.

Newspapers and publications still rely on flexo for its speed and efficiency, especially for large-scale print runs.

Flexography is a choice method for printing bulk envelopes, particularly those with coloured designs or branding.

Some industries, like agriculture or construction, require printed bulk bags, which flexo printing offers as a durable and efficient solution.

Tickets for events, transport, or lotteries often use flexography due to its ability to handle different substrates and produce secure, high-quality prints.

Items like notebooks or business stationery that require bulk printing with consistent quality might be produced using flexo machines.

Disposable items, especially those made of paper or thin plastics like cups, trays, and cutlery sleeves, are often printed with flexography for vibrant and lasting designs.

Frequently Asked Questions

Is flexography cheap?

Yes, flexography is a cost-efficient printing process that uses low-cost materials, making it a cheaper option compared to other printing methods.

What are the disadvantages of flexographic printing?

Flexographic printing has a high initial cost for plates and can be time-consuming to set up for complex jobs.

What is the future of flexographic printing to 2027?

Flexographic printing is expected to grow at 2.1% annually from 2022 to 2027, reaching a total market value of $205 billion by 2027. Global output is projected to reach 449.7 billion square meters in 2022 alone.

What is a flexographic printing press?

A flexographic printing press is a high-speed machine used for printing large volumes of labels and flexible packaging materials. It operates at incredible speeds, up to 2000 linear feet per minute, making it ideal for mass production.

What does a flexo press operator do?

A flexo press operator is responsible for setting up, operating, and maintaining a flexographic printing press, ensuring high-quality production and timely repairs. They install and adjust press components, including Anilox rollers, plates, inks, and dies, to meet production demands.

Sources

Featured Images: pexels.com