The Damen Group is a global leader in shipbuilding and repair, with a presence in over 35 countries.

Their innovative approach to ship design and construction has resulted in significant efficiency gains, with vessels being built up to 50% faster than traditional methods.

Damen's commitment to sustainability is evident in their use of eco-friendly materials and processes.

Their focus on quality and safety has led to a remarkable 99% delivery rate of vessels on time or ahead of schedule.

Damen Group News

Damen Shipyards Gorinchem recently showcased a new class of fish farm vessels, specifically the UV 4312. This vessel is a result of a contract signed in December 2016 by Damen Shipyards Group and Norway-based VOLT Service.

The UV 4312 is a significant innovation in fish farm management, offering the ability to service more farms across larger areas and in more open waters. It's fitted with the latest chemical-free delousing installation.

The vessel was handed over to the client in the Netherlands after the open day and sailed to Norway, where it is currently being fitted with modular delousing equipment. This equipment will play a crucial role in the vessel's operation.

The UV 4312 will be formally christened VOLT Processor at the end of May, marking a significant milestone in its development.

Recommended read: Diamond S Shipping Group Inc.

Shipbuilding and Vessels

Damen Group is a family-owned business that has been building ships since 1927, with 35 shipyards and 12,000 employees globally.

The company is committed to becoming the most sustainable maritime solution provider, with a goal to deliver vessels as part of a tailored services package to optimize their management throughout their lifecycle.

Damen has embarked on a digital transformation journey, consolidating its IT applications and bringing its engineering offices, shipbuilding sites, and stakeholders into a centralized digital environment – the 3DEXPERIENCE platform.

The company aims to become a data-driven organization, allowing it to handle complex vessel configurations and design changes in an agile manner, plan manufacturing, assembly, and maintenance early in the design phase, and collaborate effectively with suppliers and customers.

Damen is also investing in virtual twin capabilities to extend the lifespan of fleets, monitor vessels' systems and components to optimize operational performance, and carry out smart, predictive maintenance.

If this caught your attention, see: Tianjin Port (Group) Company

RV OceanXplorer Rebuild Complete

The RV OceanXplorer Rebuild Complete is a remarkable achievement in shipbuilding. Damen Shipyards Group has completed the rebuild of this research vessel at Damen Shiprepair Rotterdam.

OceanXplorer is equipped with a series of submersibles, sonar arrays, manned submarines, an ROV, and AUV, giving it full capability to explore and map the depths of the oceans. This state-of-the-art equipment will undoubtedly aid in groundbreaking discoveries.

The vessel's research facilities are paired with Hollywood-quality filming and media studios, developed in partnership with renowned filmmaker James Cameron. This unique combination allows for the live-streaming of findings to audiences worldwide at the exact moment of discovery.

Shipbuilding: New Diving Bell Ship

Damen Shipyards Group has a long history of building unique vessels that serve specific purposes. They recently signed a contract with WSA Koblenz to build a new diving bell ship.

The new vessel will operate in the River Rhine and its tributaries, replacing an existing vessel that has been in operation since 1963. This new ship will be an upgrade from the old one, offering more advanced capabilities.

WSA Koblenz's President, Prof. Dr.-Ing. Hans-Heinrich Witte, emphasized the importance of this special vessel in searching for and recovering lost cargo or wreckage in the region.

Damen Shipyards Group has a proven track record of delivering high-quality vessels that meet the needs of their clients.

Shipbuilding: Digital Shipbuilding to Unlock Efficiencies

Shipbuilding is an industry ripe for digital transformation, driven by growing demand for customized, sustainable, and cost-competitive vessels. This shift is being led by companies like Damen Group, which has been building ships since 1927 and now has 35 shipyards and 12,000 employees globally.

Damen's ambition is to become the most sustainable maritime solution provider, and it's using digitalization to achieve this goal. The company is moving from a product-centric to a service-centric business model, where vessels are delivered as part of a tailored services package.

The 3DEXPERIENCE platform is at the heart of Damen's digital transformation, enabling a continuous data flow across its value chain. This platform will support Damen to deliver higher quality, cost-competitive, and configurable products to market faster than anyone else.

Becoming a data-driven organization will allow Damen to handle complex vessel configurations and design changes in an agile manner, plan manufacturing, assembly, and maintenance early in the design phase, and collaborate effectively with suppliers and customers. This will help keep projects on time and within budget.

Damen's use of the 3DEXPERIENCE platform will also enable it to monitor the full environmental impact of its vessels and make its business operations even more compelling.

Mining

Damen Shipyards has built a 177 meter diamond mining vessel for De Beers Marine Namibia, which was completed in 2022 and named Benguela Gem.

This massive vessel is used for subsea diamond extraction from depths of between 90 and 150 meters off the coast of Namibia.

The Benguela Gem is the largest diamond mining vessel of its kind, costing $468 million to build.

The diamonds extracted by the Benguela Gem are then processed using the vessel's onboard equipment.

Digital Transformation

Damen Group's digital transformation journey is a remarkable example of how a company can leverage technology to drive innovation and efficiency. The company has been building ships since 1927 and has 35 shipyards and 12,000 employees globally.

To achieve its ambition of becoming the most sustainable maritime solution provider, Damen has embarked on a journey to consolidate its IT applications and bring its engineering offices, shipbuilding sites, and other stakeholders into a centralized digital environment - the 3DEXPERIENCE platform. This platform will support Damen to deliver higher quality, cost-competitive, and configurable products to market faster than anybody else.

The 3DEXPERIENCE platform has already shown its benefits in Damen's Naval division, where it has replaced over 200 spreadsheet-based applications with a single data management environment. This has enabled Damen to work from one data model from requirements to manufacturing, reducing the complexity and increasing efficiency.

MO4 Pact to Digitalize Offshore Wind Ops

Damen Shipyards Group has teamed up with MO4 to digitalize offshore wind farm operations. This strategic alliance aims to make vessel operation more effective and increase safety levels.

Damen Triton, a remote monitoring and operational insight tool, will be paired with MO4's motion forecasting knowledge. Damen Triton is a connected, collaborative IoT platform that collects data from multiple sensors.

The partnership will offer data analytic-based services, leveraging MO4's expertise in offshore motion prediction. This will enable more informed decision-making and improved efficiency in offshore wind farm operations.

From Silos to 3dExperience Platform

Damen Group's journey to the 3DEXPERIENCE platform is a great example of digital transformation in action. They've already seen significant benefits in their Naval division, where they've moved from using over 200 spreadsheet-based applications to a single data management environment on the 3DEXPERIENCE platform.

This transformation required Damen to change their entire workflow, which took time and discipline. They chose Dassault Systèmes as their partner due to their comprehensive suite of applications and industry know-how.

The 3DEXPERIENCE platform has enabled Damen to work from a single data model, from requirements to manufacturing, which is a game-changer for their engineering process. By standardizing and reusing data, they can improve efficiency and reduce errors.

Joost Mathot, Director of Products in the Workboats division, believes that the 3DEXPERIENCE platform will help them make better products by reducing mistakes and making it easier to translate customer feedback into product improvements. He's a big believer in the platform and its potential to improve their business.

Damen's experience shows that digital transformation requires a significant commitment, but the payoff can be huge. By investing in the 3DEXPERIENCE platform, they're setting themselves up for future success and staying ahead of the curve in the maritime industry.

Shipyards and Industry

Damen Shipyards Group is a family company that prioritizes securing tomorrow for the next generation.

Damen stands for fellowship, craftsmanship, entrepreneurship, and stewardship.

The company is committed to caring for our oceans, seas, lakes, and rivers, and enables humanity to responsibly harness the opportunities our waters present.

Damen introduced standardized shipbuilding in series in the previous century.

Its aim is to combine its heritage with innovation to become the world's most sustainable shipbuilder.

Statistics and History

Damen Group has a significant presence worldwide, with 32 yards globally, including 14 in the Netherlands and 18 abroad.

The group employs a total of 9,000 people worldwide, with 3,000 based in the Netherlands and 6,000 internationally.

Here's a breakdown of the group's annual deliveries in 2015: Tugs / Workboats: 82Offshore Vessels: 8High Speed Craft & Ferries: 62Pontoons & Barges: 10Dredging & Specials: 15Naval & Yachts: 5Stock hulls: >200

The company's annual turnover in 2015 was 2.1 billion Euro, with Damen Shiprepair & Conversion operating 15 yards in 6 countries and employing 1,500 people.

History

In 1969, Kommer Damen took over the company from his father Jan Damen.

This marked a significant turning point in the company's history, as Kommer Damen brought new leadership and direction.

Statistics

The Damen Shipyards Group has a massive presence worldwide, with 32 yards across the globe. Of these, 14 are located in the Netherlands and 18 are abroad.

Their annual turnover in 2015 was a staggering 2.1 billion Euro. This is a significant figure, considering the company's focus on shipbuilding and repair.

Damen Shiprepair & Conversion has 15 yards in 6 countries, making it a major player in the industry.

The company has a total of 9,000 employees worldwide, with 3,000 based in the Netherlands and 6,000 working internationally.

In 2015, Damen delivered 180 vessels, including 82 tugs and workboats, 8 offshore vessels, and 62 high-speed craft and ferries.

Here's a breakdown of the types of vessels delivered in 2015:

Damen Shiprepair & Conversion also delivered over 1,500 repair, maintenance, refit, and conversion projects in 2015.

Freighters and Fisheries

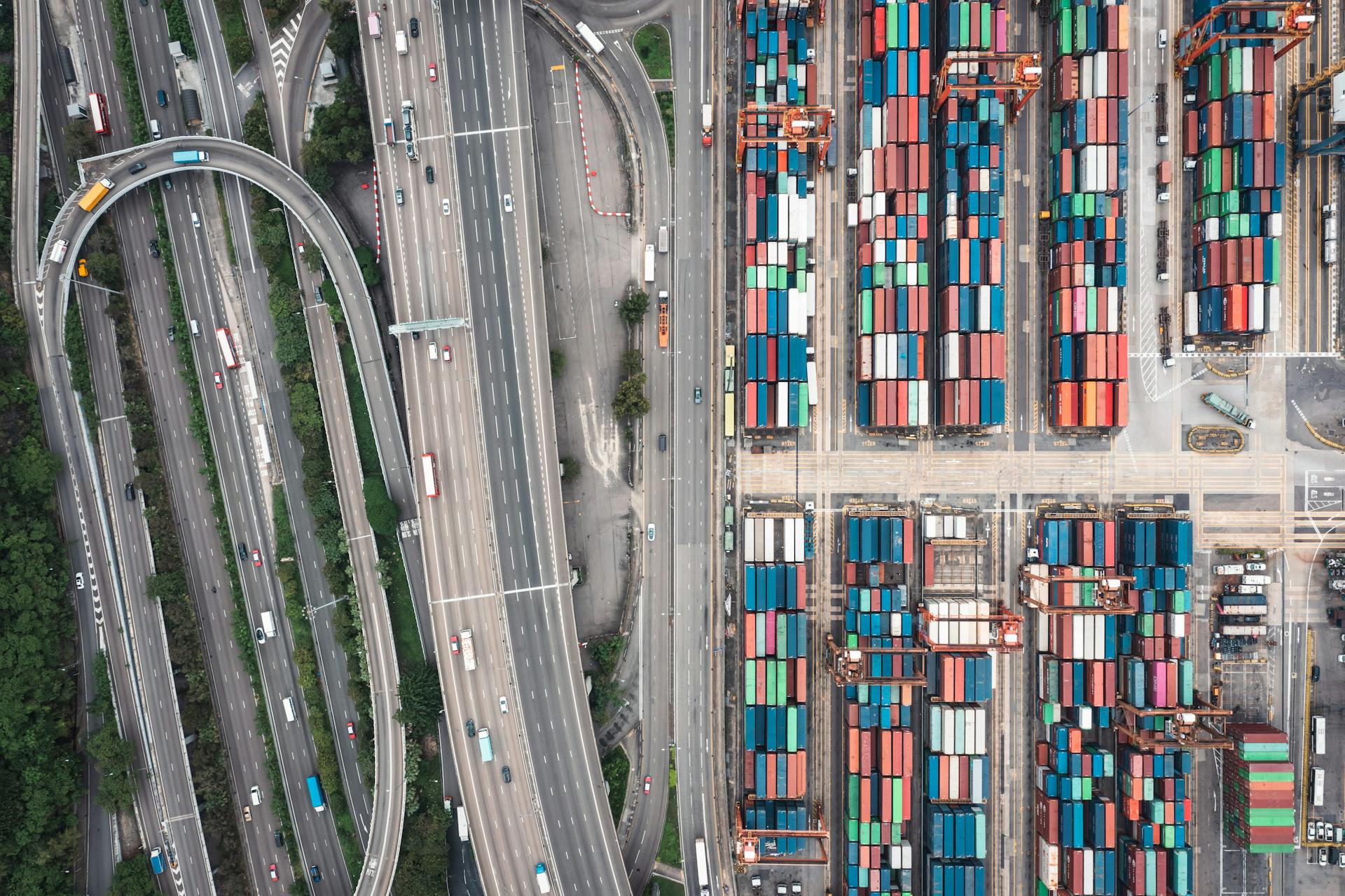

Damen Group has a variety of freighters that cater to different needs, including container ships, tankers, heavy-lift ships, and cargo ships.

Damen's container ships, such as the Damen Container Feeder, are designed to efficiently transport containers. Their tankers, like the Damen Tanker, are built for transporting liquids.

The Damen HLV (Heavy-Lift Ship) is another type of freighter in their fleet, capable of handling heavy and oversized cargo. The Damen Combi Freighter and Combi Coaster are also part of their cargo ship offerings, providing flexibility in cargo transportation.

Damen's fleet also includes catamarans, which are ideal for certain types of transportation.

New Fish Farm Vessels

Damen Shipyards Group has recently delivered a new class of fish farm vessels, the first of which is the UV 4312. This vessel is equipped with a chemical-free delousing installation.

The UV 4312 is designed to service more fish farms across larger areas and in more open waters. It was handed over to the client in the Netherlands and is currently being fitted with modular delousing equipment in Norway.

The vessel will be formally christened VOLT Processor at the end of May. It's a significant development in the field of fish farming, offering a more efficient and environmentally friendly way to manage fish farms.

Damen Shipyards Group has also signed a contract with the German Federal Office for Agriculture and Food to build a new fisheries research vessel, the Walther Herwig. The vessel will measure 85 x 17,40 meters.

The Walther Herwig will support Germany's fisheries and oceanographic research programs, enabling scientists to better understand and manage marine ecosystems.

Freighters

Freighters are the backbone of international trade, transporting goods across the globe. They come in different shapes and sizes, each designed to carry specific types of cargo.

The Damen Container Feeder is a type of container ship used for transporting large volumes of containers. Tankers, on the other hand, are designed to carry liquids such as oil and chemicals.

Heavy-lift ships like the Damen HLV are used for transporting oversized and heavy cargo. Cargo ships, including the Damen Combi Freighter and Combi Coaster, are versatile vessels that can carry a variety of goods.

Some freighters, like the MV Veteran and MV Legionnaire, have been designed to carry both cargo and passengers.

Frequently Asked Questions

Who owns Damen Group?

The Damen Group is owned by the Damen family, who have a long history of expertise in the shipbuilding industry. This family ownership allows for a personal and dedicated approach to serving clients.

How many shipyards does Damen have?

Damen operates 36 shipbuilding and repair yards worldwide. This extensive network employs 12,000 people globally.

Featured Images: pexels.com