The cost of plastic pallets can be a significant expense for businesses, especially those in the shipping and logistics industry. The average cost of a plastic pallet can range from $20 to $100, depending on the size and quality of the pallet.

The cost of plastic pallets can vary depending on the material used, with HDPE pallets being the most expensive option, costing around $60 to $80 per pallet. On the other hand, PP pallets are a more affordable option, costing around $20 to $40 per pallet.

Plastic pallets are often more expensive than their wood or metal counterparts, but they offer several advantages, including durability, resistance to moisture and pests, and ease of cleaning. However, the initial cost of a plastic pallet can be a barrier for some businesses.

Cost of Plastic Pallets

A cheap plastic pallet can quickly lose its low-cost title if it's not the right pallet for your load. This is because price alone doesn't determine your pallet cost.

Plastic pallets have a higher purchase price than wooden pallets, but their durability and longevity of up to 10 years, or 250 trips, exponentially increase their value. This makes them a cost-effective option in the long run.

Buying a new pallet for every load can add up quickly, but using plastic pallets for more than one-way shipping applications can help reduce costs. With a lifespan of up to 10 years, you can reuse them for other shipping and storage needs.

Here's a breakdown of the cost benefits of plastic pallets:

Used plastic pallets are another affordable option, with prices ranging from $5 to $50 per unit. Buying used pallets can significantly reduce costs without compromising quality.

Storage

Storage is a breeze with plastic pallets, which require minimal maintenance compared to their wood counterparts. They can be stored in clean, organized areas.

Plastic pallets can be stored away from extreme heat sources or prolonged direct sunlight that might affect their material properties over time. This is because they are made from materials like HDPE or PP that can be damaged by heat and sunlight.

A fresh viewpoint: Are Chep Pallets Heat Treated

It's a good idea to store empty pallets in a dry, cool place. Avoid storing them in areas where they might get wet or exposed to chemicals.

Plastic pallets are highly impact-resistant, but it's still a good idea to avoid unnecessary dropping or dragging that could potentially damage their structural elements over time.

Curious to learn more? Check out: Good Pallets

Material

Plastic pallets are made from a variety of materials, but one common type is HDPE/PP, which is used in the example of a New Plastic Pallet.

These pallets are durable and can withstand heavy loads, with a static load capacity of up to 3,500 pounds and a dynamic load capacity of 2,200 pounds.

New and Recycled

New and Recycled plastic pallets are available for various applications, with prices ranging from $10 to $80 per unit, depending on the quantity and quality.

Plastic pallets can be purchased in bulk or as common models, making them extremely affordable, with prices estimated at reasonable rates.

You can select from multiple pallet types when buying used plastic pallets, with prices spanning between $5 and $50 per unit.

Buying used plastic pallets is an excellent way to reduce overall pallet costs without compromising quality.

Up-1210-N-Plast Pana Lip

The Up-1210-N-Plast Pana Lip plastic pallet is a sturdy option for your shipping needs. It's made of high-density polyethylene (HDPE) and measures 48x40 inches.

This pallet is relatively lightweight, weighing in at 16.5 pounds. You can expect a static load of 4,400 pounds and a dynamic load of 2,200 pounds.

One of the benefits of this pallet is its open deck design, which allows for easy loading and unloading of products. It also has a 9 feet base, providing a stable foundation for your items.

This pallet is designed for multi-trip use, making it a cost-effective option in the long run. It's also suitable for export, so you can use it for shipping internationally.

Here are the key specifications of the Up-1210-N-Plast Pana Lip pallet:

- Pallet type: Used Plastic Pallet (HDPE)

- Dimensions: 48x40 inches

- Weight: 16.5 pounds

- Static load: 4,400 pounds

- DYNAMIC load: 2,200 pounds

- Deck design: Open Deck

- Base: 9 feet

- Use: Multi-Trip, Export

Up-1210-N-Qpcd18lbs

The UP-1210-N-QPCD18lbs plastic pallet is a great example of a cost-effective option. It's made of used plastic and has a weight capacity of 5,500 lb static load.

This pallet measures 48x40 inches and has a base size of 9 feet. Its closed deck design provides stability and support for heavy loads.

The UP-1210-N-QPCD18lbs pallet is also nestable, making it easy to store and transport. This feature is especially useful in warehouses and distribution centers.

Here are some key features of the UP-1210-N-QPCD18lbs pallet:

- Used plastic construction

- 48x40 inch size

- 18 lbs weight

- Closed deck design

- 9 feet base

- Nestable design

One of the benefits of this pallet is its low cost. It's a great option for businesses looking to save money on their plastic pallet needs.

Up-1280-N-Polypal830

The UP-1280-N-Polypal830 is a used plastic pallet made from high-density polyethylene (HDPE). It measures 48x32 inches and weighs 17.5 pounds.

This pallet has a 9-foot base and an open deck design, making it suitable for a variety of applications. Its static load capacity is 4,400 pounds, while its dynamic load capacity is 2,200 pounds.

The UP-1280-N-Polypal830 is designed for multi-trip use, making it a cost-effective option for businesses that need to transport goods frequently. It's also suitable for export and in-house use.

Here are some key features of the UP-1280-N-Polypal830:

- Used plastic pallet made from HDPE

- 48x32 inches in size

- 17.5 pounds in weight

- Open deck design with 9-foot base

- 4,400 lb static load capacity

- 2,200 lb dynamic load capacity

- Nestable and one-way design

- Suitable for multi-trip use, export, and in-house use

Types of Plastic Pallets

You have multiple options to select from when it comes to plastic pallet types, each available at various material price points.

There are different types of plastic pallets, including standard plastic pallets, heavy-duty plastic pallets, and export plastic pallets.

Standard plastic pallets are a cost-effective option, often priced lower than other types of plastic pallets.

Heavy-duty plastic pallets, on the other hand, are designed for heavier loads and may be more expensive due to their increased durability.

Export plastic pallets are designed for international shipping and may have additional features such as reinforced corners and a smooth surface to prevent cargo damage.

High-Density Polyethylene (HDPE)

HDPE pallets are manufactured from durable HDPE resin, making them a great option for general applications.

These pallets offer an excellent balance between strength, weight, and cost-effectiveness, making them a reliable choice for various material handling scenarios.

Their resilient composition resists impact damage while maintaining dimensional stability under varied environmental conditions.

HDPE pallets also provide natural resistance to moisture, acids, and many chemicals commonly encountered in industrial environments.

This makes them a widely-used pallet type that offers excellent value and operational flexibility in general material handling scenarios.

If this caught your attention, see: Hdpe Pallets

Polypropylene (PP)

Polypropylene (PP) pallets are a type of plastic pallet that excels in environments with exposure to aggressive substances or temperature extremes.

Their advanced composition maintains structural integrity in both high and low-temperature applications, with a functional range typically spanning -20°F to 220°F. This makes them particularly valuable in chemical processing and laboratory environments.

These specialized pallets prove superior to alternative materials in resisting acids, caustics, and solvents that would rapidly degrade them. They're a great choice for applications requiring resistance to challenging environmental conditions.

Here are some key characteristics of polypropylene (PP) pallets:

Exceptional Durability

Plastic pallets are built to last and can withstand the rigors of frequent use. They can be reused for multiple shipments and storage needs, making them a cost-effective option in the long run.

A key benefit of plastic pallets is their durability, which can last up to 10 years or 250 trips. This extended lifespan is a significant advantage over wooden pallets, which may require frequent replacement.

The material used to make plastic pallets, High-Density Polyethylene (HDPE) resin, is a key factor in their exceptional durability. HDPE pallets offer excellent balance between strength, weight, and cost-effectiveness.

Plastic pallets also provide unmatched service life, with an extended lifespan averaging 10+ years in standard applications. They can withstand impact damage from forklift handling and maintain dimensional stability without warping.

Here are some key features of plastic pallets that contribute to their exceptional durability:

- Extended lifespan averaging 10+ years in standard applications.

- Impact resistance that prevents damage from forklift handling.

- Dimensional stability that maintains performance without warping.

- Weather resistance for indoor/outdoor applications without degradation.

Stackable

Stackable plastic pallets are a great option for shipping and storage due to their light-weight and budget-friendly nature. They can cost as low as $17.99 per unit, making them a reliable and affordable choice.

Economical stackable pallets are typically nestable with 3-6 runners added to create a stackable and possibly rackable pallet. This design allows for efficient storage and transportation.

Their low cost also makes them ideal for purchasing in small quantities before transitioning to a more permanent plastic pallet solution. This can help reduce upfront costs and make the switch to plastic pallets more manageable.

Good quality and reasonably priced rackable pallets are also available, and they don't require snap-on runners. This is a great option for those who need a durable and reliable pallet without the added cost of runners.

Consider reading: Storage Pallets

Nestable

Nestable pallets are a game-changer for logistics operations, especially those with limited warehouse space. They can reduce storage space requirements by up to 70% compared to non-nestable alternatives.

Their space-saving design makes them particularly valuable for operations that require efficient return transport of empty pallets. By allowing pallets to nest within each other, nestable pallets minimize storage needs and reduce clutter.

On average, nestable pallets lower transport costs and decrease storage fees up to 75%. This is because they take up only one-quarter of the space when nested together.

Nestable pallets are favorites for use in warehouses, distribution centers, and for transportation from factories to warehouses or retail centers. However, the most common application for nestable pallets is one-time shipping.

Some popular types of nestable pallets include the UP-1210-N-Lip12lbs and the CPP200/PE. These pallets offer a range of benefits, including low cost, open deck designs, and high load capacities.

Here are some key features of nestable pallets:

Up-1210-N-Peblue

The UP-1210-N-PEBLUE plastic pallet is a reliable choice for many applications. It's made from a combination of HDPE and PP materials, which provides excellent durability.

This pallet measures 48x40 inches, making it a standard size for many industries. Its open deck design allows for easy loading and unloading of products.

The UP-1210-N-PEBLUE pallet weighs 16 pounds, which is relatively lightweight compared to other types of pallets. This makes it easy to handle and maneuver.

This pallet has a 9-foot base, which provides stability and prevents it from tipping over. It's also nestable, which means it can be stacked on top of other pallets to save space.

Here are some key features of the UP-1210-N-PEBLUE pallet at a glance:

- Used

- 48x40

- Plastic

- 16 lbs

- Low Cost

- Open Deck

- 9 Feet Base

- Nestable

- One-Way

- Multi-Trip

- Export

The UP-1210-N-PEBLUE pallet has a static load capacity of 5,000 pounds and a dynamic load capacity of 2,200 pounds. This means it can handle heavy loads, but it's still relatively lightweight and easy to handle.

Choosing the Right Pallet

Choosing the right pallet for your business is crucial, and it's not just about the initial cost. The cost of wooden pallets versus plastic pallets is a crucial factor to consider, with wooden pallets offering significant advantages in cost, availability, and environmental sustainability.

In Australia, the choice between wooden and plastic pallets is influenced by factors such as climate, regulatory requirements, and industry standards. Wooden pallets available in Australia are designed to meet the specific needs of various industries, providing a versatile and cost-effective solution.

You should consider the specific needs of your business, including the type of goods you are shipping, the conditions they will be exposed to, and your sustainability goals. For those in industries requiring robust, long-lasting pallets, wooden pallets can be a reliable and cost-effective choice.

Here are some key factors to consider when choosing between wooden and plastic pallets:

Ultimately, both types of pallets have their place in the logistics and shipping industry. By understanding the costs and benefits of each, businesses can make informed decisions that align with their operational needs and sustainability goals.

Custom

Customizing plastic pallets can be a pricey option, but it's valid if your industry requires specific measurements or features.

The estimated cost of custom plastic pallets depends on materials used, pallet design, the quantity, and the quality of the product.

Request a quote from a trusted manufacturer or consult with a pallet expert for a more accurate cost estimate.

Custom pallets can offer long-term benefits, such as increased durability and a longer lifespan, which can offset the initial higher cost.

A plastic pallet's lifespan is over ten years, compared to one to two years for a wooden pallet, making them a better option for long-term use.

Plastic pallets are also more structurally sound, with stronger connections on blocks and runners, reducing the risk of damage and breakage.

Recommended read: How Long Are Pallets

Initial: Wood vs

The initial cost of wooden pallets is generally lower than that of plastic pallets, with a standard wooden pallet costing between $10 and $25. However, the cost of plastic pallets can range from $50 to $100 or more, depending on the type and specifications.

One of the main factors affecting the initial cost of wooden pallets is the type of lumber used, which can impact the price. In contrast, the manufacturing process for plastic pallets is more complex and requires specialized tooling and moulding machinery, making them more expensive to produce.

The price of wood has been rising over the years, with the price index of imported sawn or planed wood growing from 132 in 2020 to 195.6 in 2022. This increase in wood prices has narrowed the price differential between wooden and plastic pallets.

Here's a comparison of the initial costs of wooden and plastic pallets:

It's worth noting that the initial cost of a pallet is just one factor to consider, and the overall cost of ownership can be affected by many other factors, including the lifespan and durability of the pallet.

Benefits and Features

Buying plastic pallets can seem like a big upfront cost, but they offer a range of benefits that can save you money in the long run.

Reusable plastic pallets can be used for multiple shipping and storage needs, making them a cost-effective option compared to buying new pallets for every load.

Their durability and longevity of up to 10 years or 250 trips exponentially increase their value, offsetting the higher initial price point.

Quality plastic pallets deliver multiple advantages that impact operational efficiency, product protection, and long-term economics.

Here are some key features that make plastic pallets a great choice:

- Consistent dimensions that optimize automated handling systems.

- Lighter weight that reduces shipping costs and worker strain.

- Four-way entry that facilitates handling from any direction.

- Nestable designs that minimize storage space for empty pallets.

Purchasing and Maintenance

Maintenance costs for plastic pallets are significantly lower than those for wooden pallets, thanks to their resistance to moisture, chemicals, and pests. This means you'll save money on treatments and repairs.

Proper handling of plastic pallets can maximize their lifespan. Store them in clean, organized areas away from extreme heat sources or prolonged direct sunlight. Avoid unnecessary dropping or dragging, as this can damage structural elements over time.

Plastic pallets require minimal maintenance, with no need for nail inspection, board replacement, or splinter removal. They can be easily cleaned with standard pressure washing and conventional detergents.

Maintenance

Maintenance is a crucial aspect of owning pallets, and the type of pallet you choose will greatly impact the effort and cost involved.

Wooden pallets require regular inspections and occasional repairs to ensure they remain safe and functional. This includes treatments for pests and moisture, which add to their maintenance costs.

Proper handling is key to maximizing the lifespan of plastic pallets. Store empty pallets in clean, organized areas away from extreme heat sources or prolonged direct sunlight that might affect material properties over time.

Plastic pallets are highly impact-resistant, but avoid unnecessary dropping or dragging that could potentially damage structural elements over time. For cleaning, most models permit standard pressure washing with conventional detergents without special precautions beyond typical equipment safety procedures.

Here are some key differences in maintenance requirements between wooden and plastic pallets:

By choosing the right type of pallet, you can minimize maintenance costs and effort, and focus on other aspects of your business.

Wholesale Purchasing: Advantages and Considerations

Wholesale purchasing of plastic pallets can significantly reduce per-unit costs compared to individual pallet purchases, delivering 20-30% savings over small-quantity procurement.

This substantial cost savings enhances the already favorable economics of plastic pallet systems, improving ROI calculations and accelerating payback periods on plastic pallet investments.

Bulk purchasing also facilitates comprehensive implementation across your entire operation, eliminating inconsistencies and inefficiencies of mixed pallet systems.

Standardizing your pallet system with wholesale quantities simplifies training, handling protocols, and storage configurations, while maximizing the benefits of transitioning to plastic pallet systems.

Pallets sourced from the same production batch ensure uniform performance, dimensions, and appearance, critical factors for automated systems and consistent operations.

This manufacturing consistency prevents variations that might occur when sourcing pallets from multiple suppliers or production runs, creating predictable handling characteristics and load stability.

Single delivery of wholesale quantities reduces receiving complexity and administrative overhead compared to multiple smaller deliveries.

Consolidated procurement minimizes transportation costs and environmental impact, while simplifying inventory management and tracking processes.

Establishing a relationship with a wholesale supplier helps ensure consistent access to compatible replacement pallets as needed over time, preventing future compatibility issues or operational disruptions.

Here are some key benefits of wholesale purchasing of plastic pallets:

- Substantial cost savings (20-30% savings)

- System-wide implementation

- Consistent quality

- Streamlined logistics

- Long-term availability

Comparison and Analysis

When evaluating pallet systems, it's essential to go beyond simple price comparison. A comprehensive value analysis framework considers the entire cost structure, including initial purchase, expected lifespan, replacement frequency, damage rates, operational efficiency, workplace safety, and disposal/recycling considerations.

Plastic pallets often demonstrate compelling economic advantages, particularly in applications involving regulated products, automated handling, long-distance shipping, or high-value goods.

In these specialized applications, plastic pallets can deliver maximum value, even if traditional alternatives are more suitable for general or low-frequency usage.

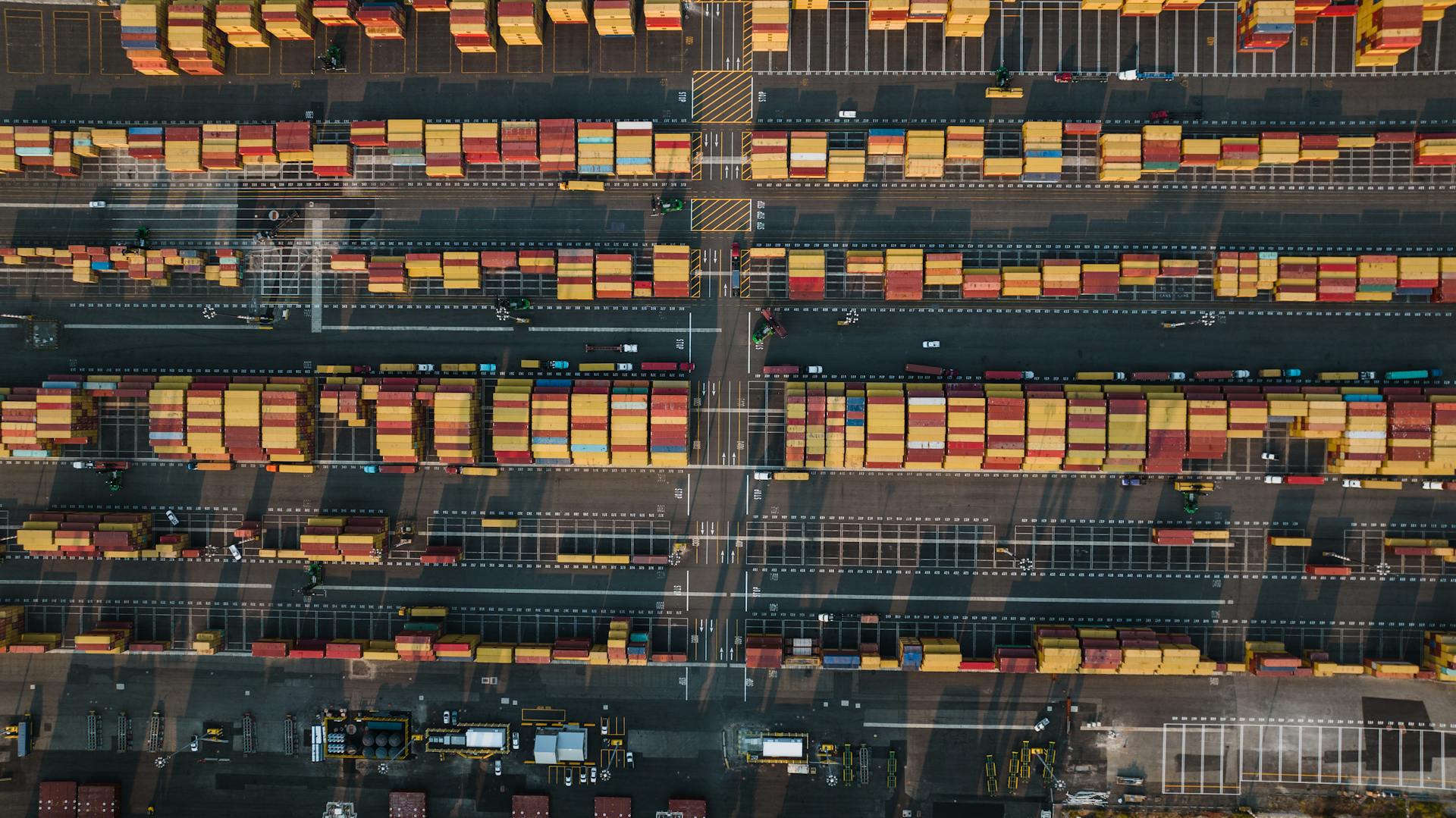

International Shipping and Trade

International shipping can be a complex and costly process, but plastic pallets offer a solution to simplify this process. Plastic pallets are exempt from ISPM-15 regulations that require fumigation and treatment certification for wood packaging materials crossing international borders.

This exemption eliminates treatment costs, documentation requirements, and potential customs delays associated with wood alternatives. By choosing plastic pallets, you can avoid these unnecessary expenses and streamline your export process.

Curious to learn more? Check out: Wooden Pallet Treatment

Their lighter weight reduces shipping costs in weight-based freight calculations, making them an attractive option for international shippers. Plastic pallets' consistent dimensions also optimize container loading efficiency, allowing for more efficient use of space.

Nestable designs facilitate economical return shipping when closed-loop systems operate across international boundaries. This feature is particularly beneficial for export-focused operations that need to ship goods back and forth across borders.

Plastic pallets meet global transportation regulations while optimizing shipping economics, making them a reliable choice for international shipping.

Intriguing read: Shipping by Pallet

Pallet Options and Considerations

A cheap plastic pallet can quickly lose its low-cost title if it's not the right pallet for your load. Dig even deeper, see why price alone doesn't determine your pallet cost.

Plastic pallets have a higher purchase price than wooden pallets, but their durability and longevity of up to 10 years, or 250 trips, exponentially increase their value. This makes them a cost-effective option in the long run.

Buying a new pallet for every load quickly adds up after continually restocking your supply. However, reusable plastic pallets can be used for more than one-way shipping applications, making them a great option for businesses with frequent shipping needs.

Reusable plastic pallets are durable and easy to clean, reducing the risk of injury and contamination due to nails or broken wood. This makes them a safer and more hygienic option for shipping and storage.

Plastic pallets eliminate several significant challenges associated with international shipping, including treatment costs, documentation requirements, and potential customs delays. This makes them a great option for export-focused operations.

Here's an interesting read: Plastic Shipping Pallets

Cost and Value

The cost of plastic pallets can be a bit misleading at first glance, but let's dig in and explore the facts. Plastic pallets are often perceived as a premium option, but they can actually deliver 30-50% lower total cost over their lifecycle.

One key factor is the lifespan of plastic pallets, which can withstand repeated use without significant wear and tear. This means they can be used for many more trips than wooden pallets, saving on transportation costs in the long run. After five years, the operational cost of plastic pallets can be £75,000 less than wooden pallets, and the savings only grow after ten years.

To get a clear picture of the cost and value of plastic pallets, consider evaluating them through a comprehensive value analysis framework, which accounts for the entire cost structure, including initial purchase, expected lifespan, replacement frequency, and more. This approach can help you see the compelling economic advantages of plastic pallets, especially in applications involving regulated products, automated handling, or long-distance shipping.

Here's a rough breakdown of the cost comparison between plastic and wooden pallets:

This table illustrates how the higher initial cost of plastic pallets can be offset by their longer lifespan and reduced replacement costs, making them a more cost-effective option in the long term.

Environmental Impact

The environmental impact of pallets is a crucial aspect to consider. Wooden pallets are made from renewable resources, making them a more sustainable choice.

Wooden pallets can be sourced from sustainably managed forests, which reduces their environmental footprint. This is a key factor in making wooden pallets a more eco-friendly option.

The durability of plastic pallets may reduce the need for frequent replacements, but their initial production cost is higher. This is a significant consideration when weighing the environmental impact of pallets.

Wooden pallets can be recycled and repurposed at the end of their life cycle, avoiding landfills altogether. This reduces waste and minimizes the environmental harm caused by pallet disposal.

Our Lowest

Plastic pallets are often seen as a premium option, but they can actually be more cost-effective in the long term. Despite being twice as expensive as wooden pallets, plastic pallets can save £75,000 in operational costs after five years.

The key is to consider the total cost of ownership, not just the initial procurement costs. This includes extended service life, reduced repair costs, and improved workplace safety. In fact, plastic pallets can deliver 30-50% lower total cost when evaluated over an appropriate time horizon.

When evaluating pallet systems, it's essential to consider the entire cost structure, including initial purchase, expected lifespan, and replacement frequency. This comprehensive approach can help you make a more informed decision.

Recommended read: When Were Pallets Invented

Here are some key factors to consider when choosing between plastic and wooden pallets:

- Initial investment: Plastic pallets typically require 3-5 times higher initial investment than wood alternatives.

- Sanitation & cleaning: Plastic pallets are easier to clean and sanitize, making them more suitable for industries where hygiene is vital.

- Weight considerations: Plastic pallets typically weigh 30-50% less than comparable wood alternatives, reducing shipping costs and fuel consumption.

- Regulatory compliance: Plastic pallets eliminate the need for fumigation and treatment documentation, streamlining export operations.

- Product protection: Plastic pallets eliminate the risk of damage to packaging and products, reducing product damage rates and improving customer satisfaction.

By considering these factors, you can make a more informed decision about which type of pallet is best for your business.

Our lowest cost plastic pallets are designed to provide maximum value at a lower price point. Here are some key features:

- New 48x40 plastic pallets, weighing 11.0 lbs, available for a low cost.

- Used 48x40 plastic pallets, weighing 22 lbs, also available for a low cost.

- Both options are open deck, nestable, and suitable for one-way or multi-trip use.

These pallets are designed to provide a cost-effective solution for businesses that need a reliable and durable pallet option.

UP-1210-FP-150mm22lbs

The UP-1210-FP-150mm22lbs used plastic pallet is a great example of a cost-effective option. It's made of HDPE, a durable plastic material.

This pallet measures 48x40 and weighs 15 lbs, making it easy to handle and maneuver. Its open deck design allows for easy loading and unloading of goods.

The static load capacity of 6,600 lb and dynamic load capacity of 2,200 lb ensure that it can hold a significant amount of weight. This makes it suitable for heavy-duty applications.

Here are some key features of the UP-1210-FP-150mm22lbs pallet:

- Used: This pallet has been previously used, which can help reduce costs.

- Low Cost: The low cost of this pallet makes it an attractive option for those on a budget.

- Nestable: The pallet's nestable design allows for efficient storage and transportation.

- Multi-Trip: This pallet is designed for multiple trips, making it a cost-effective option for frequent use.

Pallet Types and Specifications

You have multiple options to select from when it comes to plastic pallet types, each available at various material price points.

The base cost of purchasing a pallet depends on the type you choose. Plastic pallets are made from different materials, such as HDPE, PP, and PE.

HDPE pallets are more durable and resistant to chemicals, but also more expensive. They're a great option if you need a pallet that can withstand harsh environments.

PP pallets are lighter and more versatile, making them ideal for shipping and storage. They're also more affordable than HDPE pallets.

PE pallets are the most affordable option, but may not be as durable as HDPE or PP pallets. They're a good choice if you're on a tight budget.

Each type of pallet has its own specifications, such as size and weight capacity. It's essential to assess your needs before making a purchase.

Frequently Asked Questions

How much does a 48x40 plastic pallet weigh?

Our 48x40 plastic pallet weighs approximately 14 pounds, making it a lightweight and convenient option for shipping and storage.

What is a good price for a pallet?

A good price for a pallet can range from $20 to $100 or more, depending on the type and quality. For more specific pricing, consider checking with local suppliers or manufacturers for bulk purchases or custom quotes.

Featured Images: pexels.com