When designing a concrete loading dock, it's essential to consider the type of loading equipment that will be used. A forklift, for example, requires a dock leveler that can handle its weight and size.

The International Building Code (IBC) requires that dock levelers be designed to support a minimum of 5,000 pounds per square foot. This is crucial for ensuring the safety of employees and equipment.

A well-designed concrete loading dock can significantly improve efficiency and productivity in a warehouse or manufacturing facility. By incorporating features such as a slip-resistant surface and adequate lighting, dock workers can operate more safely and effectively.

The American National Standards Institute (ANSI) recommends that loading docks be designed with a minimum of 12 inches of clearance between the dock and the vehicle. This allows for safe and easy loading and unloading of goods.

Consider reading: Concrete Pallets

Design Principles

Design Principles are crucial for a successful concrete loading dock.

Signing off on the most suitable design activates the second stage of the process.

The following list should be set in stone when it comes to constructing your chosen concrete loading dock.

A well-designed concrete loading dock requires at least 8 steps to be successful.

Constructing your chosen design involves setting these steps in stone, literally.

For another approach, see: Packaging Design Corporation

Dock Types

There are a few different styles of loading bays, and understanding the type of dock you'll build is crucial for a successful concrete loading dock design.

A Type 1 dock, for example, is a simple and straightforward design that's perfect for small operations. It's a great option for businesses with limited space.

A Type 2 dock, on the other hand, is a bit more complex and offers more flexibility. It's a good choice for businesses that need to handle a variety of cargo sizes and types.

It's also worth noting that there are different styles of loading bays, which can affect the overall design of your concrete loading dock.

You might like: Cosmetic Packaging Design Companies

Flush

A flush dock is a space-saving design that simplifies loading and delivery. It's a common design where the outside building wall sits flush with the loading dock's concrete face, also called the foundation.

This design can save space, making it ideal for facilities with limited room for expansion.

Curious to learn more? Check out: Packaging Design Trends 2024

Type of Docking

There are a few different styles of loading bays.

One of the main styles is the Type of Dock, which is also known as a "Type of Docking" system.

A Type of Dock is important to know when building a dock, as it determines the design and functionality of the loading bay.

There are a few different types of docks, including those with different designs of loading bays.

The design of the loading bay will impact the size and shape of the dock, as well as its overall functionality.

It's also worth noting that the Type of Dock is closely related to the type/design of dock you will build.

Design Considerations

As you start designing your concrete loading dock, it's essential to consider the size and complexity of the project. A larger number of bays will amplify the scale of the project, driving the cost upwards.

The size of the dock, including both depth and width, plays a significant role in determining the construction cost. A larger footprint escalates the need for additional materials and labor.

Think carefully about the average length of the trucks that will be using the dock, as drivers need sufficient room to position their vehicle in front of the bay. The apron area should be designed with a maneuverability distance of at least 5 to 10 feet, more than twice the size of the trailer.

Prioritize Location

When designing a warehouse, it's crucial to prioritize the location of loading docks. This involves situating them to optimize safety and ease of access for freight traffic.

Loading docks should be positioned away from areas of unrelated traffic, such as where non-loading-dock personnel operate. This helps prevent congestion and reduces the risk of accidents.

The dock should also be far from entry and exit points for staff or visitor vehicles. This minimizes the potential for conflicts between freight traffic and other vehicles.

By taking these factors into consideration, you can create a more efficient and safer loading dock area.

Obey Construction Codes

Obeying construction codes is a must when designing a loading dock. Compliance with building codes and regulations is crucial.

Poorly constructed docks can jeopardize staff and the surrounding ecosystem through improper drainage/runoff provisions. This is a critical consideration that can't be ignored.

Sawtooth

Sawtooth designs are a great option when space is limited, but they do require above average indoor dimensions. This type of design is often used by large-scale commercial operations.

You'll need to consider the dock apron space, the area required to maneuver and position trailers into place, when deciding on a sawtooth design.

Cantilever

Cantilever designs are a great way to add some extra functionality to a structure without taking up too much space. This design projects outward from the main wall, creating an extended docking space for vehicles.

Accidental vehicle impacts can cause significant damage to the main structure, but cantilever designs can help mitigate this risk by providing a dedicated space for vehicles to dock.

Cantilever docks are an effective way to reduce damage to the main structure, as mentioned in the article section on cantilever docks.

Protect Against Elements

Protecting your dock against the elements is crucial for its longevity and functionality. Seals and shelters can provide a dock design with several benefits, including preventing heat and AC loss from the edges of a dock.

Adding seals and shelters can save you money in the long run by blocking problems such as rain and snow, airborne debris, and pests like insects and rodents. This is a smart investment for any business, as it can prevent costly repairs and maintenance down the line.

Covered docks become a strategic choice for businesses requiring weather-resistant loading and unloading operations. They offer protection against the elements, but also come with an associated price tag.

The installation of roofing systems and enclosures elevates the project’s intricacy, demanding additional materials, labor, and design considerations. This means you'll need to carefully weigh the benefits of shelter against the financial implications.

Recommended read: Loading Dock Door Seals

Ventilate Your Space

Ventilate Your Space is crucial to ensure a safe and healthy environment. Enclosed docks, like any other space, require an effective ventilation system to remove exhaust fumes.

Proper ventilation is a must-have, especially in areas where trucks and forklifts are present, as they often produce fumes from diesel, gas, and propane.

All docking spaces, regardless of type, need to be ventilated regularly to prevent the buildup of hazardous fumes. This is especially true for enclosed docks where vehicles are parked inside.

Hire Experts

Dedicated professionals bring more than tried-and-tested expertise in concrete loading dock design and execution. They will also be fully certified and insured, and able to create a strong and durable loading dock that’s perfectly designed to fit a client’s individual needs.

Hiring experts can make a huge difference in the outcome of your loading dock project.

Number of Bays

The number of bays in your loading dock is a crucial consideration. It directly impacts the overall cost of the project.

A typical loading bay has a door width between 7.5 and 10 feet wide, depending on the size of the trailer. This is a standard measurement that you should keep in mind.

The minimum distance between each dock is 12 feet, which is essential for safe and efficient operations. This space requirement is a key factor in determining the number of bays your dock can accommodate.

The more bays you need, the larger the project becomes, and the higher the construction cost will be. This is because each additional bay requires more concrete, excavation, and labor resources.

The size of the dock, including its depth and width, also plays a significant role in the overall cost. Larger dimensions mean a more extensive footprint and increased material and labor needs.

Apron Area

The apron area is a crucial consideration in dock design. It's the space where drivers position their trucks in front of the bay, and it needs to be designed with the average length of trucks in mind.

For optimal maneuverability, the apron area should be at least 5 to 10 feet longer than the trailer. This extra space allows drivers to position their trucks safely and efficiently.

Take a look at this: Portable Loading Ramps for Semi Trucks

Approach Angle

The approach angle is a crucial design consideration for your loading dock. This refers to the angle at which trucks approach your dock, whether they're traveling downward, upward, or on level ground.

Trucks traveling downward or upward can have a huge impact on your dock's design, so proper bumpers need to be installed to factor in this angle.

A well-designed dock can prevent damage to your building and make loading and unloading easier for drivers.

Indicators of Poor Design

Indicators of Poor Design can be identified in several ways. A poorly designed loading dock can lead to vehicular and structural damage.

Heavy vehicles don't always park on-center, resulting in repeated impacts on the loading dock opening. This can compromise the facility's structure over time.

Bad design can also result in a loading dock that's too short, too narrow, or incorrectly sloped. This can lead to a lack of maneuverability for vehicles and an increase in potential accidents.

Ignoring local and state building codes can result in a Notice of Violation, a Stop Work Order, or both. These can cost businesses and violators dearly in time and money.

Here are some common indicators of poor design:

- Loading docks with insufficient concrete reinforcement

- Loading docks that are too short, too narrow, or incorrectly sloped

- Loading docks that fail to comply with local and state building codes

- Loading docks without the right permits and permissions

These pitfalls can be avoided when dedicated professionals handle the job.

Design Process

The design process is a crucial step in creating a successful concrete loading dock. It involves signing off on the most suitable design, which activates the second stage of the process.

To ensure a solid design, consider the following essential elements. The second stage of the process should be set in stone, literally, as it involves constructing the chosen concrete loading dock.

Cost and Budget

Estimating the cost of a concrete loading dock isn't a straightforward calculation. Several factors play a crucial role in determining the final figure, making each dock as unique as the needs it serves.

Soil conditions, such as soft or uneven ground, can significantly impact construction costs. This is because they demand additional efforts, like soil stabilization, to ensure a stable foundation.

Effective drainage and waterproofing systems are not just elements of convenience; they are vital components that influence material choices and installation costs. The ability to navigate the flow of water efficiently ensures the longevity and structural integrity of the dock.

The construction cost of a loading dock is contingent on various factors, such as the dock's size, complexity, materials utilized, location, and labor expenses. A straightforward loading dock project might have a construction cost as low as $5,000, while a more intricate one could incur expenses exceeding $50,000.

Get a Quote

To get a quote for your project, consider the size and number of trucks you expect to use the loading dock. This will help determine the necessary dimensions and design for safe and effective operations.

Designing a loading dock requires careful planning, taking into account the typical loading dock dimensions to ensure accurate alignment for incoming vehicles.

You'll need to think about the protection against drivers' mistakes, which is a vital feature for running businesses like shopping centers and manufacturing plants.

Silver Spur Concrete's team of skilled professionals can help you develop a strategic plan to build concrete docks on your property, ensuring a smooth flow of goods and materials.

Breaking Down the Budget

The construction cost of a loading dock is contingent on various factors, such as the dock's size, complexity, materials utilized, location, and labor expenses. A straightforward loading dock project might have a construction cost as low as $5,000, while a more intricate one could incur expenses exceeding $50,000.

The average cost per square foot for a loading dock falls within the range of $20 to $50, with an average of $35 per square foot. This means that the larger the dock, the higher the cost will be.

For a concrete loading dock, costs typically range from $5,000 to $10,000, with variations based on the dock's size and location. This is because the materials and labor required for a concrete dock are more extensive than those for a simpler dock.

The size and complexity of the project emerge as pivotal determinants influencing the overall cost, with an increase in the number of bays amplifying the scale of the project and driving the cost upwards. Larger dimensions not only result in a more extensive footprint but also escalate the need for additional materials and labor.

Effective drainage and waterproofing systems also impact material choices and installation costs, with robust drainage systems and waterproofing adding another dimension to the project's intricacies and associated expenses.

Design Features

Optimizing the design of your concrete loading dock is crucial to managing costs and maximizing efficiency. Carefully evaluate the size requirements of the loading dock based on your business's current and future demands.

Avoid overdesigning, as an excessively large or complex loading dock can significantly inflate construction costs without providing tangible benefits. Engage with professionals to conduct a thorough analysis of your workflow, ensuring that the design maximizes efficiency and functionality.

Adequate lighting is essential for safe and efficient operations. It helps drivers fix their entry point when docking in low-light conditions, thus avoiding damage to the dock or injury to its staff.

Illuminate Your

Adequate lighting is essential to perform key functions, such as fixing the entry point when docking in low-light conditions to avoid damage to the dock or injury to staff.

Good illumination can also be a great theft deterrent.

Well-lit docks allow for safer loading and unloading after the truck has stopped.

Adequate lighting helps drivers fix their entry point when docking in low-light conditions.

Proper lighting can make a big difference in the overall functionality and safety of your space.

Explore further: Weston Point Docks

Levelers and Bumpers: Enhancing Functionality

Dock levelers and bumpers can be a valuable addition to a loading dock, enhancing operational efficiency and safety.

Their design allows for the seamless transfer of goods between the dock and the transport vehicle, making it easier to load and unload cargo.

These components contribute to the project's overall complexity and financial requirements, introducing an additional layer of cost.

However, the long-term benefits of dock levelers and bumpers often justify the upfront investment, providing a balancing act between enhanced capabilities and associated costs.

In fact, the added cost of dock levelers and bumpers may be seen as a worthwhile expense, considering their potential to increase operational ease and safety.

Maintenance and Upkeep

When designing a concrete loading dock, maintenance and upkeep are crucial factors to consider. Open docks require less maintenance than enclosed docks, especially when it comes to structural elements.

Cleaning and weatherproofing open docks is essential to prevent damage from the elements. Regular checks on dock levelers and bumpers are also necessary for flush docks.

Enclosed docks, on the other hand, require the most maintenance due to their integration into the building. They need routine inspections, as well as management of the internal environment for temperature and humidity.

Maintenance & Upkeep

Loading docks can be relatively low-maintenance, but it's essential to consider the time and money you're willing to invest in upkeep.

Open docks generally require less maintenance than enclosed docks because they have fewer structural elements.

Regular cleaning and weatherproofing are crucial for open docks to prevent damage from the elements.

Flush docks, which are close to the building, need regular checks on dock levelers and bumpers to ensure they're functioning properly.

In saw-tooth designs, the alignment and condition of the dock angles need regular checks to prevent undue strain on vehicles or equipment.

Enclosed docks, being fully integrated into the building, require routine inspections and management of the internal environment for temperature and humidity.

By understanding the specific needs of your dock style, you can develop a maintenance plan that suits your resources and keeps your loading dock running smoothly.

What to Know About Replacement

Replacing a loading dock is a big job, but it's essential to do it right. The first step is removing the broken concrete or asphalt currently in place.

Before you can start fresh, the exposed dirt, also known as the subgrade, needs to be inspected to make sure it's suitable for the new concrete. Professionals will install and compact base rock to create a solid foundation for the new concrete.

You'll need to drill the remaining pavement to accept steel pins that will support the new concrete. This is a crucial step to ensure the new dock is safe and sturdy.

Faster-setting concrete might be tempting, but it may not be as durable as slower-setting concrete. It's essential to choose the right type of concrete for the job to ensure it lasts.

The experts at Lanham Construction can help you pick the best concrete for your specifications, so you can be confident in the quality of the work.

Boosting Efficiency

Optimizing the design of your concrete loading dock is crucial to its efficiency. Prioritize size and features based on your actual needs to avoid overdesigning and inflate construction costs.

A thorough analysis of your workflow with professionals is essential to maximize efficiency and functionality. This will help you tailor the size and features to meet specific operational requirements.

Carefully evaluate the size requirements of the loading dock based on your business's current and future demands. Avoid an excessively large or complex loading dock that can significantly inflate construction costs.

Building a concrete loading dock is an investment in your business's future. It should facilitate smooth operations, enhance safety, and stand strong for years to come.

Delve into the details and arm yourself with knowledge to build a concrete loading dock that serves your business with unwavering strength and efficiency.

Quality and Safety

Quality and Safety is a top priority in concrete loading dock design. Ignoring this can compromise a company's productivity and safety.

Vehicular and structural damage are just a few of the risks associated with poorly designed loading docks. These risks can be mitigated by hiring seasoned construction experts who can steer you clear of common pitfalls.

Badly designed loading docks can be too short, too narrow, or incorrectly sloped, resulting in a lack of maneuverability for vehicles and an increase in potential accidents. This can lead to fines, imprisonment, and a Notice of Violation or Stop Work Order.

Here are some common pitfalls to watch out for:

- Loading docks handling heavy vehicles that don’t always park on-center.

- Loading docks that are too short, too narrow, or incorrectly sloped.

- Failing to comply with local and state building codes.

- Poorly prepared building teams failing to secure the right permits and permissions.

Must-Haves of High-Quality

When building a high-quality concrete loading dock, there are some must-haves to consider.

Durability is key, and a strong concrete mix with a low water ratio to cement and high-quality aggregate can withstand heavyweight machinery.

A versatile design is also essential, and stamped concrete can ensure that your loading dock matches the aesthetic of your entire business.

Expert knowledge is crucial, and understanding local zoning laws will give you peace of mind knowing your loading dock complies with the law.

Here are some must-haves to consider when building a high-quality concrete loading dock:

- Durability: A strong concrete mix with a low water ratio to cement and high-quality aggregate

- Versatile Designs: Stamped concrete to match the aesthetic of your entire business

- Expert Knowledge: Understanding local zoning laws

Contact Limitless Paving for Safe Designs

For safe and reliable loading docks, it's crucial to have dependable designs that function strongly without getting in the way. Limitless Paving & Concrete experts can walk you through their concrete loading dock design and construction process from start to finish.

Their team can handle all your concrete paving, repair, and maintenance needs.

Benefits of a

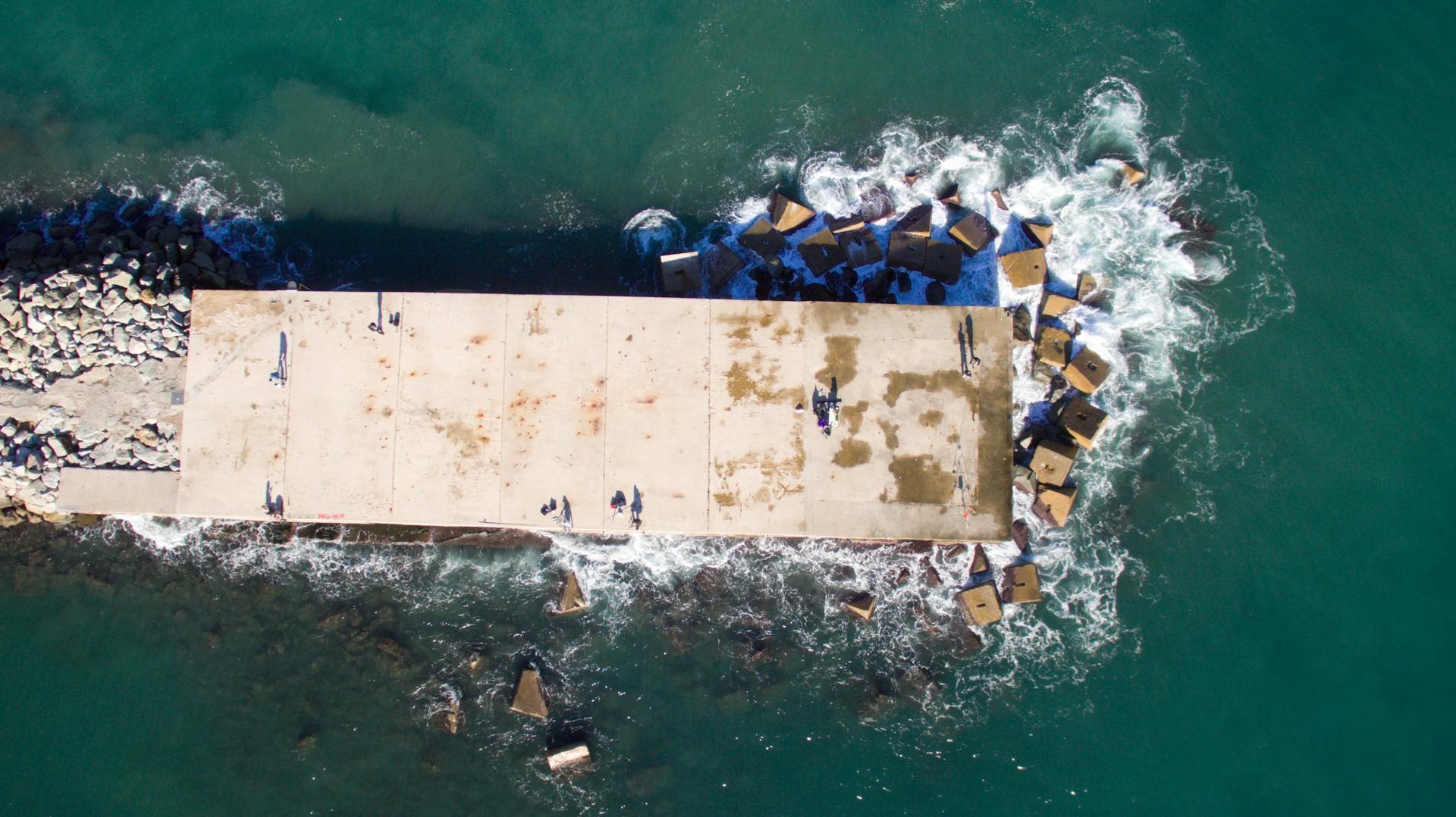

A well-designed concrete loading dock can make all the difference in the efficiency and safety of your business operations. Concrete docks are highly durable and can withstand heavy loads, making them a long-lasting option for marine structures.

The customization options for concrete docks are vast, allowing you to tailor the design to meet the specific needs of your project. This flexibility is a major advantage, especially when working with unique spaces or requirements.

A smooth and even surface is crucial for safe and efficient loading and unloading of goods. The surface of the loading dock should be designed to prevent accidents or damage to vehicles.

Safety features such as handrails, bumpers, and dock levelers should be included to protect both workers and vehicles. Adequate lighting is also essential for safety and to ensure that workers can see what they are doing.

Here are some key benefits of a concrete loading dock:

- Durability: Concrete docks can withstand heavy loads and are long-lasting.

- Low maintenance: Concrete docks require minimal maintenance, making them a convenient and cost-effective choice.

- Environmentally friendly: Concrete docks are a sustainable building material, as concrete can be recycled and reused.

- Aesthetically pleasing: Concrete docks can be finished with a variety of textures and colors, enhancing the overall appearance of the waterfront.

Frequently Asked Questions

How thick should concrete be for loading docks?

For loading docks, concrete thickness should be at least 10 inches, with 12 inches recommended for heavy loads. The ideal thickness depends on the size and weight of the loads it will bear.

What is the typical loading dock layout?

The typical loading dock layout features a flush wall with doors spaced 12 feet apart, accommodating most trucks with side mirrors. However, door spacing may vary depending on trailer size and facility constraints.

How much does it cost to build a concrete loading dock?

The cost of building a concrete loading dock can range from $40,000 to $60,000, depending on the project's size and complexity. Get a more accurate estimate by considering factors like location, design, and labor costs.

What are the OSHA requirements for a loading dock?

OSHA requires a standard railing or equivalent to guard open-sided dock areas 4 feet or more above adjacent floor or ground level to prevent employee falls

Sources

- https://limitlesspavingandconcrete.com/guide-to-concrete-loading-dock-design/

- https://silverspurconcrete.com/concrete-dock/

- https://estimatorflorida.com/how-much-does-it-concrete-loading-dock-construction-cost/

- https://www.gandgconcrete.com/building-a-loading-dock/

- https://www.lanhamconstruction.com/blog/what-you-should-know-about-concrete-loading-docks/

Featured Images: pexels.com