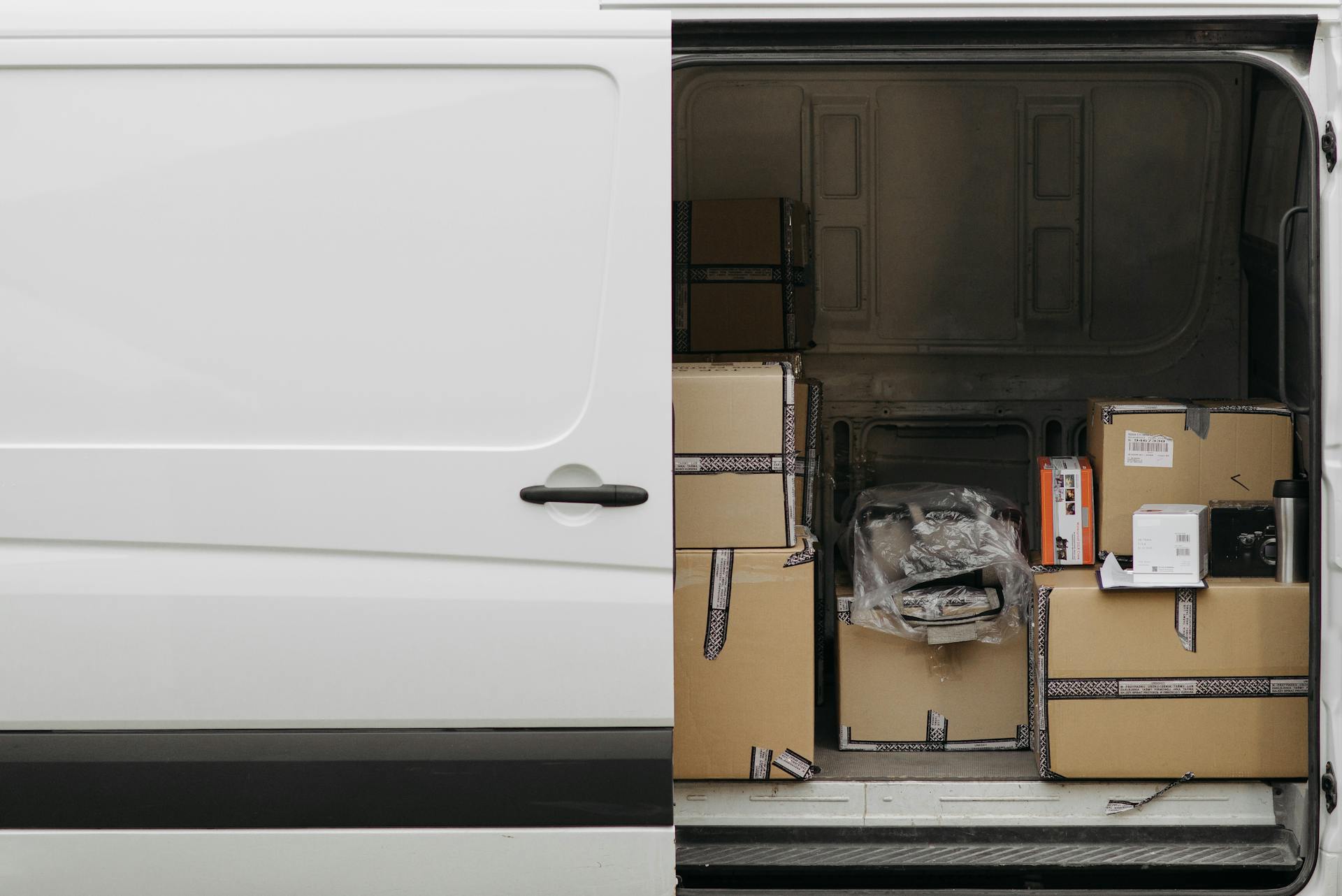

Box truck liftgate repair is a complex process that requires careful attention to detail. A faulty liftgate can cause significant downtime and lost productivity.

Common issues with box truck liftgates include worn-out rollers, misaligned chains, and faulty sensors. These problems can be caused by heavy use, poor maintenance, or even a manufacturing defect.

A damaged or worn-out chain can cause the liftgate to malfunction, leading to costly repairs. According to the article, a broken chain can cost up to $1,500 to replace.

Regular maintenance is key to preventing these issues. This includes lubricating the rollers, checking the chain alignment, and testing the sensors.

A fresh viewpoint: Power Liftgate Truck

Repair Services

If you're dealing with a malfunctioning liftgate, it's essential to address the issue promptly to avoid further damage and ensure your truck remains operational.

Fast, dependable repairs are crucial for businesses that rely heavily on their liftgates. At Linthicum-Ferndale Truck Repair, they understand the importance of getting your liftgate back in action as soon as possible.

Related reading: Electric Liftgate

The common problems that can occur with commercial truck lift gates include a liftgate not opening at all, not closing completely, or not locking properly. These issues can be caused by worn-out components, broken springs, or faulty locking mechanisms.

To diagnose and repair liftgate malfunctions, it's essential to inspect the hydraulic system, electrical components, and mechanical parts. Regular lubrication and alignment adjustments can also prevent wear and tear on the mechanical components.

Here are some common liftgate repair services:

- Liftgate cylinder repairs

- Liftgate pump repairs

- Liftgate motor repairs

- Liftgate switch repairs

- Liftgate deck repairs and adjustments

- Liftgate spring replacements

- Custom liftgate fabrication

At IP Truck, they offer an extensive line-up of different liftgates and can handle all types of liftgate service needs, including installations, repairs, and general service and maintenance.

If you're experiencing issues with your liftgate, it's best to consult a professional for proper diagnosis and repair. They can help you identify the root cause of the problem and provide a reliable solution to get your truck back on the road.

Intriguing read: Hands Free Power Liftgate

Common Issues

Hydraulic leaks can cause a liftgate to malfunction, so it's essential to have a technician inspect and repair the hydraulic system promptly if you notice slow operation or leaking fluid.

Electrical problems, such as a malfunctioning motor or faulty wiring, can also cause a liftgate to stop working altogether, requiring a trained technician to diagnose and fix the issue.

Mechanical failures, like wear and tear on hinges, lifting arms, or the platform itself, can lead to operational issues, and these parts need to be repaired or replaced to restore the liftgate's functionality.

Some common problems with commercial truck lift gates include a liftgate not opening at all, which can be caused by a broken spring or other component within the liftgate assembly.

A liftgate not closing completely can be caused by worn out components, such as hinges, springs, or cables, which our expert technicians will make sure are working properly before leaving your property.

Pneumatic lift gates can encounter issues like air leaks or malfunctioning valves, which require identifying and sealing air leaks, repairing or replacing valves, and ensuring proper air pressure and flow.

Here are some common liftgate issues and their causes:

Pump Failures:

Pump failures can be a real headache, but understanding the common issues that cause them can help you prevent or fix the problem.

Repairs for pump failures may entail motor replacement.

In some cases, overheating issues can lead to pump failures.

Repairing or replacing damaged valves is often necessary to get the pump up and running again.

Pneumatic Issues:

Pneumatic issues can be a real pain to deal with. Pneumatic lift gates use air pressure for operation and can encounter issues like air leaks or malfunctioning valves.

Repairing pneumatic lift gate issues involves identifying and sealing air leaks. This is often a straightforward process that can be done with the right tools and some basic knowledge of how the system works.

Malfunctioning valves can be a bit more tricky to fix, but it's usually just a matter of replacing the faulty valve with a new one. Proper air pressure and flow are also crucial to ensure the lift gate operates smoothly.

Air leaks can be caused by worn-out seals or damaged hoses, so inspecting these areas is essential when troubleshooting pneumatic lift gate issues. By taking the time to properly repair or replace these components, you can get your pneumatic lift gate up and running in no time.

You might enjoy: Tractor Trailer Tire Psi

Less Common Problems

Less Common Problems can be a challenge to diagnose and repair, but they're not impossible to fix. Less frequent failures can occur, demanding specialized attention and expertise.

Some less common lift gate failures include problems that require specialized attention and expertise. These issues can be just as frustrating as common problems, but they often have more complex solutions.

These less common issues can be caused by a variety of factors, including worn-out or damaged parts. In some cases, the problem may be related to the lift gate's electrical system, which can be a bit more complicated to diagnose and repair.

Less Common Failures and Fixes

Less common lift gate failures can be just as frustrating as common ones, but they often require specialized attention and expertise.

While the above problems represent common lift gate issues, less frequent failures can also occur, demanding specialized attention and expertise.

One such less common failure is a faulty hydraulic system, which can be caused by a variety of factors, including worn-out seals or incorrect fluid levels.

A faulty hydraulic system can lead to a loss of lift gate functionality, requiring a professional repair or replacement.

Some lift gates may experience issues with their electrical systems, including faulty sensors or wiring problems, which can be difficult to diagnose and repair.

In some cases, a lift gate may experience a mechanical failure, such as a broken chain or gear, which can be costly to repair or replace.

Less common failures can be just as costly as common ones, so it's essential to address them promptly to avoid further damage and downtime.

Structural Damage

Structural damage to a lift gate can be a serious issue, and it's not as common as some other problems, but it's still something to watch out for.

Structural damage can include bent or cracked frames or platforms, which can impact safety and performance.

Repairing structural damage may involve welding, reinforcing, or replacing damaged components to restore the lift gate's integrity.

Worn/Damaged Edges

Worn/Damaged Edges can be a real safety hazard, especially during cargo handling. The edges of the lift gate platform can wear out or become damaged, compromising safety.

This can happen due to regular use and may not be noticeable at first, but it's essential to address the issue before it causes an accident. Repairing worn or damaged lift gate edges may necessitate replacing the platform's edge material, ensuring a smooth and safe surface for loading and unloading.

Service and Support

Regular liftgate maintenance is crucial to prevent malfunctions and ensure smooth operation. This includes hydraulic system checks to prevent degradation or leaks.

Faulty wiring or connections can cause liftgate malfunctions, so regular electrical components inspections are essential. This helps prevent unexpected failures and keeps your truck running efficiently.

Liftgates have many moving parts that need regular lubrication to prevent wear and tear. This reduces the need for expensive repairs and keeps your truck in good working condition.

Safety features like limit switches and overload sensors should be functioning correctly at all times. These features prevent the liftgate from operating beyond its capacity, protecting both the truck and the operator.

If you need liftgate repair service, consider calling a reputable company like Red Rover Service. They specialize in servicing commercial trucks, including Ford, Chevy, Dodge, Freightliner Cascadia, Kenworth T680, and others.

Their team of ASE-certified liftgate repair technicians can repair and service any type of liftgate, from manual to electric. They also offer live dispatch and no call-outs, making it convenient to get the help you need.

Here are some common liftgate repair services offered by companies like Red Rover Service:

- Hydraulic system checks and repairs

- Electrical components inspections and repairs

- Lubrication and mechanical parts maintenance

- Safety feature inspections and repairs

IP Truck Sales and Service

IP Truck is a full-service provider of commercial truck liftgates, specializing in sales, installation, and service. Our team of experts can help you find the perfect liftgate for your specific needs.

We offer a wide range of liftgates from top brands like Waltco, Anthony, and Palfinger. Whether you need a new or used liftgate, we can provide it.

Our body shop is fully equipped to handle all types of liftgate service needs, from repairs to installations. We service the DFW and surrounding areas, and can even come to you if you can't move your truck.

Our team is authorized to service many popular liftgate brands, including Maxon, Leyman, Thieman, Eaglelift, Tommy Gate, and Interlift.

Here are some of the services we offer:

- New & used liftgate sales

- New & used liftgate installation

- Liftgate cylinder repairs

- Liftgate pump repairs

- Liftgate motor repairs

- Liftgate switch repairs

- Liftgate deck repairs and adjustments

- Liftgate spring replacements

- Custom liftgate fabrication

We understand that your liftgate is crucial to your business efficiency, and we're here to help you keep it running smoothly.

Frequently Asked Questions

How do I know if my liftgate solenoid is bad?

If you hear a clicking noise when the switch is activated, it's likely a bad solenoid. Try bypassing the solenoid with a jumper cable to see if the motor runs directly.

What is the lift on the back of a box truck called?

The lift on the back of a box truck is called a lift gate. It's a crucial component that ensures safe and efficient cargo loading and unloading.

Featured Images: pexels.com